Deep-well centrifugal pump with two thrust bearing pairs on each impeller

A thrust bearing and centrifugal pump technology, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of reduced pump efficiency, damage, limited ability to withstand axial forces, etc. The effect of long service life, simple solution and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

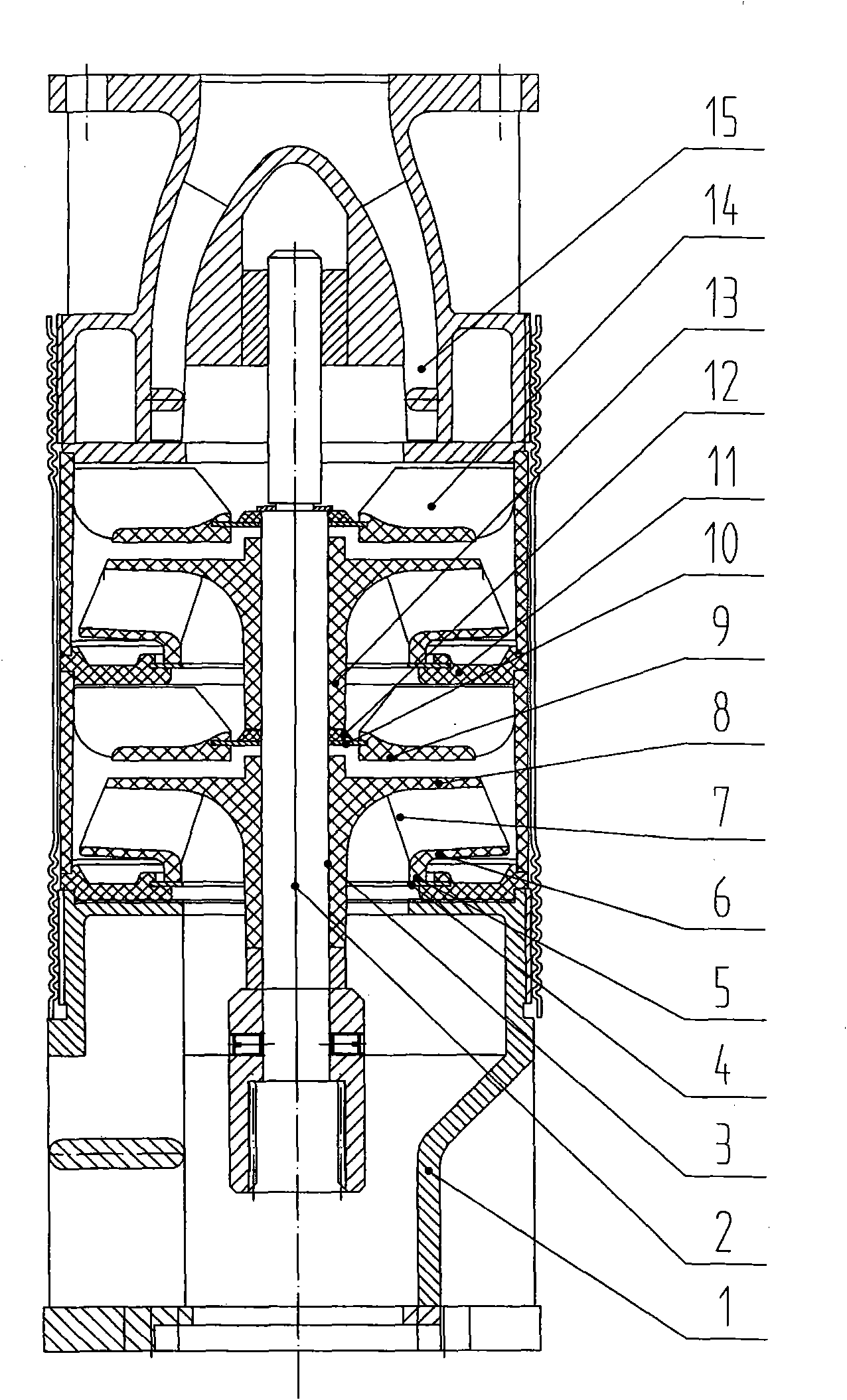

[0014] figure 1 The shown embodiment is a well submersible pump that an impeller 7 and a flow guide casing 14 are all made of engineering plastics, and it is also a deep well centrifugal pump, which consists of a two-stage impeller 7 and a flow flow casing 14 together with a water inlet section 1 and A water outlet section 15 is formed in series. The impeller 7 is a closed impeller with an impeller front cover 6 and an impeller rear cover 8. The diameter of the impeller rear cover 8 is smaller than that of the impeller front cover 6, and its axial force is higher than that of a conventional impeller. The impeller is lowered. The impeller inlet adopts end face seal, and the impeller inlet end face seal pair composed of the moving ring 5 of the impeller inlet end face seal and the static ring 4 of the impeller inlet end face seal is made of stainless steel plate and engineering plastic, which is also a thrust capable of bearing axial force The bearing pair, the impeller shaft h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com