Scraper planeness detection system

A detection system, flatness technology, used in measuring devices, instruments, optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

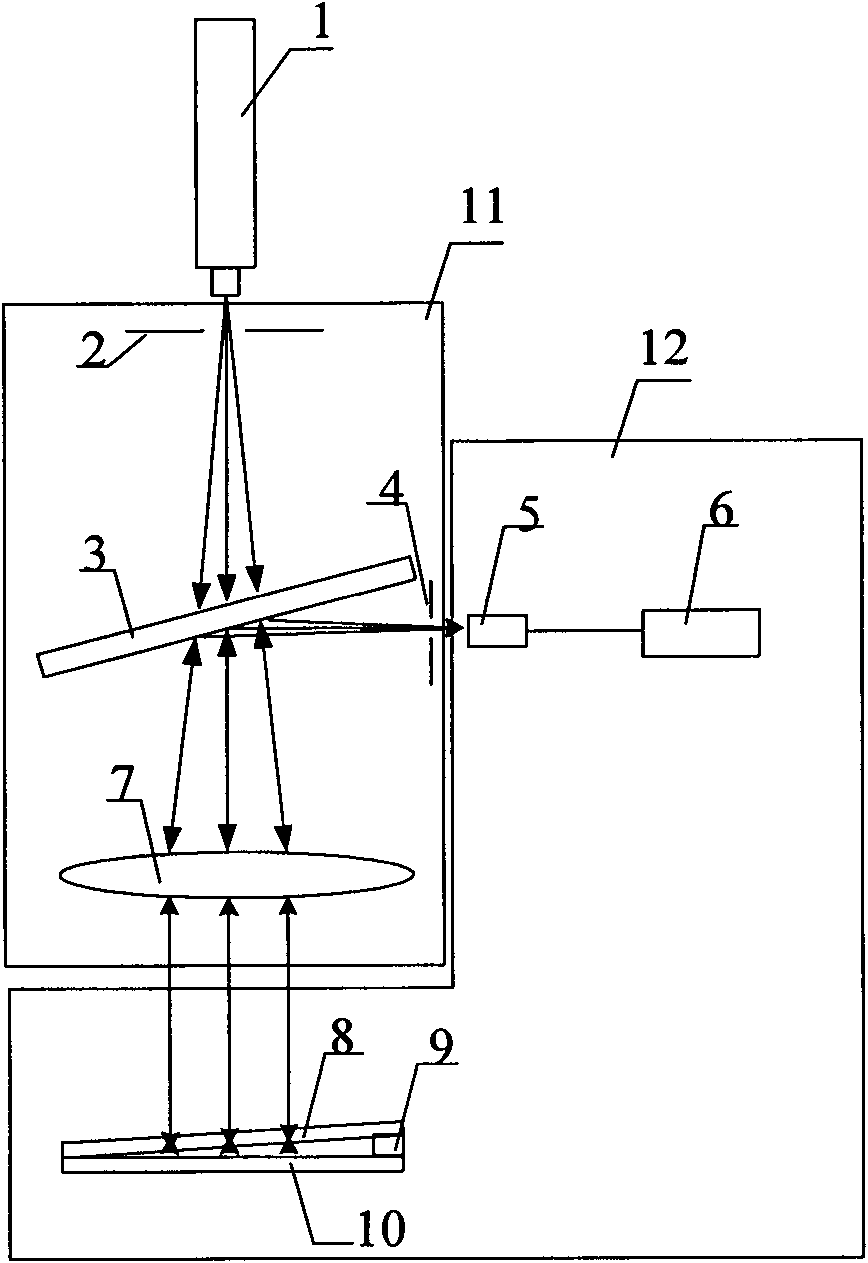

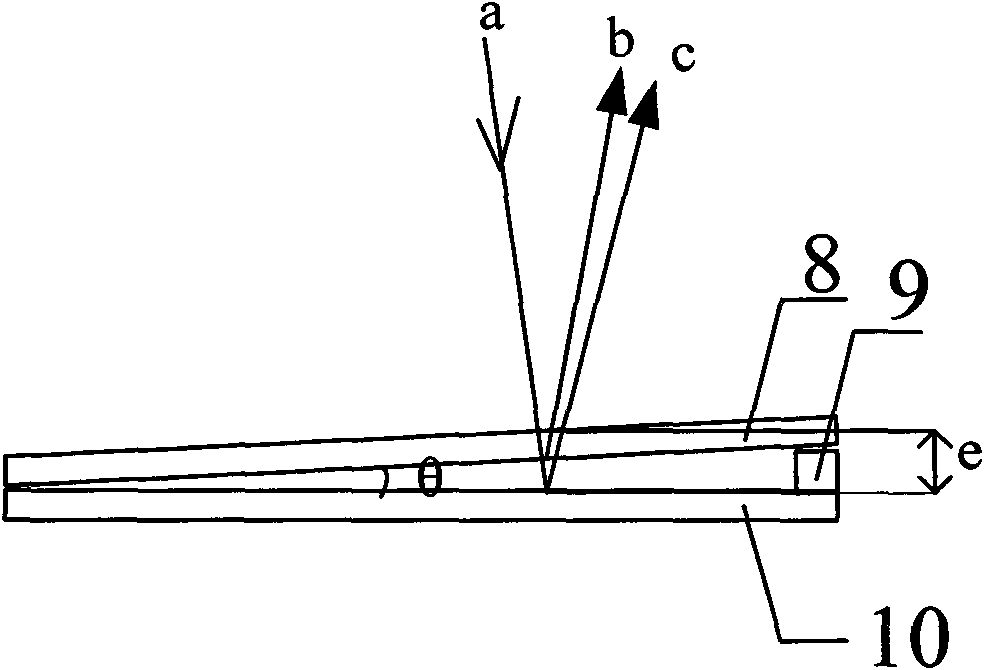

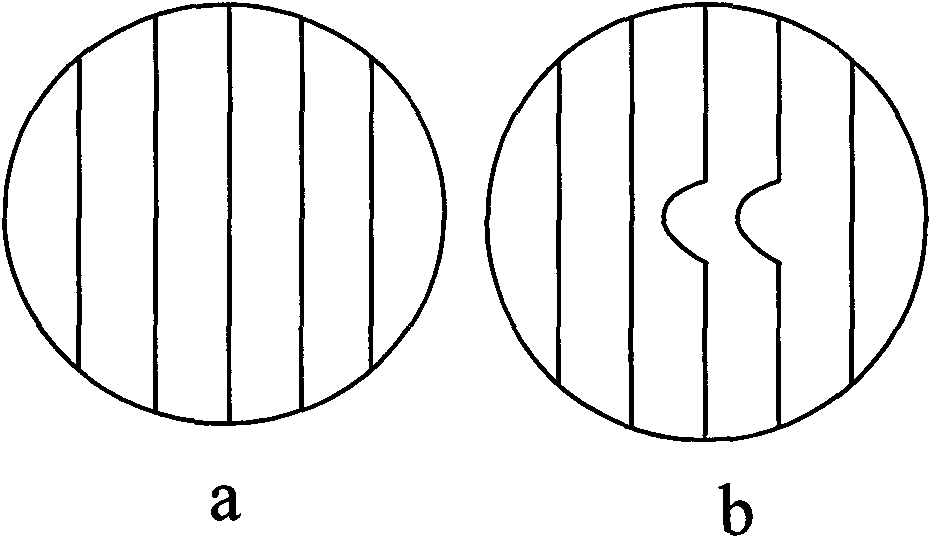

[0020] When observing the flatness of the measured workpiece, install the measured workpiece 10 on the horizontal device, place the standard sample 8 on the top of the measured workpiece, and separate it with a thin paper sheet 9 so that there is an appropriate air angle between the two. ; Turn on the laser light source system 1 to make it emit a laser beam. The laser beam is shaped into collimated parallel light through the diaphragm and the convex lens, and the adjustment device makes the beam shaping reach the best state; The light reflected from the upper and lower surfaces of the air wedge formed by the measured workpiece and the standard workpiece forms interference fringes; the interference fringes are reflected by the semi-mirror and irradiated on the CCD; the sensing system is turned on, and the change of the interference light intensity is collected by the CCD, and then passed through the computer. displayed, so that the flatness of the measured workpiece can be visua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com