Intelligent positioning method of tobacco bundles

A technology of intelligent positioning and cigarette handles, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve problems such as uneven material flow, frequent shutdowns due to failures, and material blocking, so as to improve labor productivity, reduce the burden of swinging handles, and overcome blockages Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The cigarette handle intelligent positioning method includes the following steps:

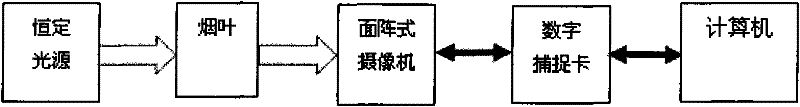

[0030] (1) if figure 1 . Set up a static tobacco leaf sample measurement system, including a detection cabinet. A constant light source and an area array camera are arranged above the bottom plate of the detection cabinet. The constant light source adopts a light source combined with a ballast and a fluorescent tube, and the area array camera adopts DH-SV1300FC A digital color camera, the area array camera is electrically connected to a matching digital capture card, and a computer is also provided. The computer adopts Advantech TPC6000-158 true color LCD industrial computer, and the computer is electrically connected to the digital capture card ; The tobacco leaf sample is reflected and captured by the area array camera under the illumination of the light source, converted into a digital image signal by a digital capture card, and written into the computer memory. The digital capture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com