Preparation method of inorganic powder cataplasm

A powder paste, inorganic powder technology, applied in mixing methods, chemical instruments and methods, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as inability to obtain dispersion effect, large shear force, and difficulty in obtaining , to achieve the effect of excellent dispersibility, good dispersibility and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] best practice

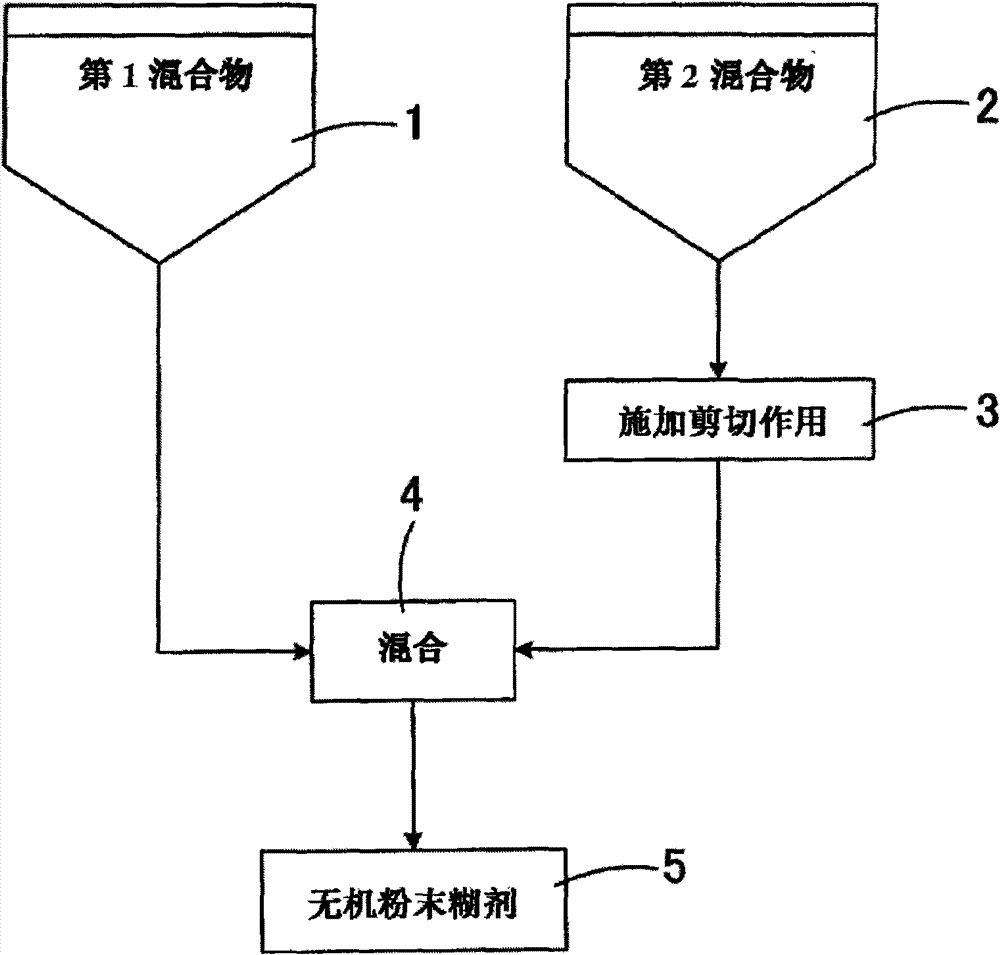

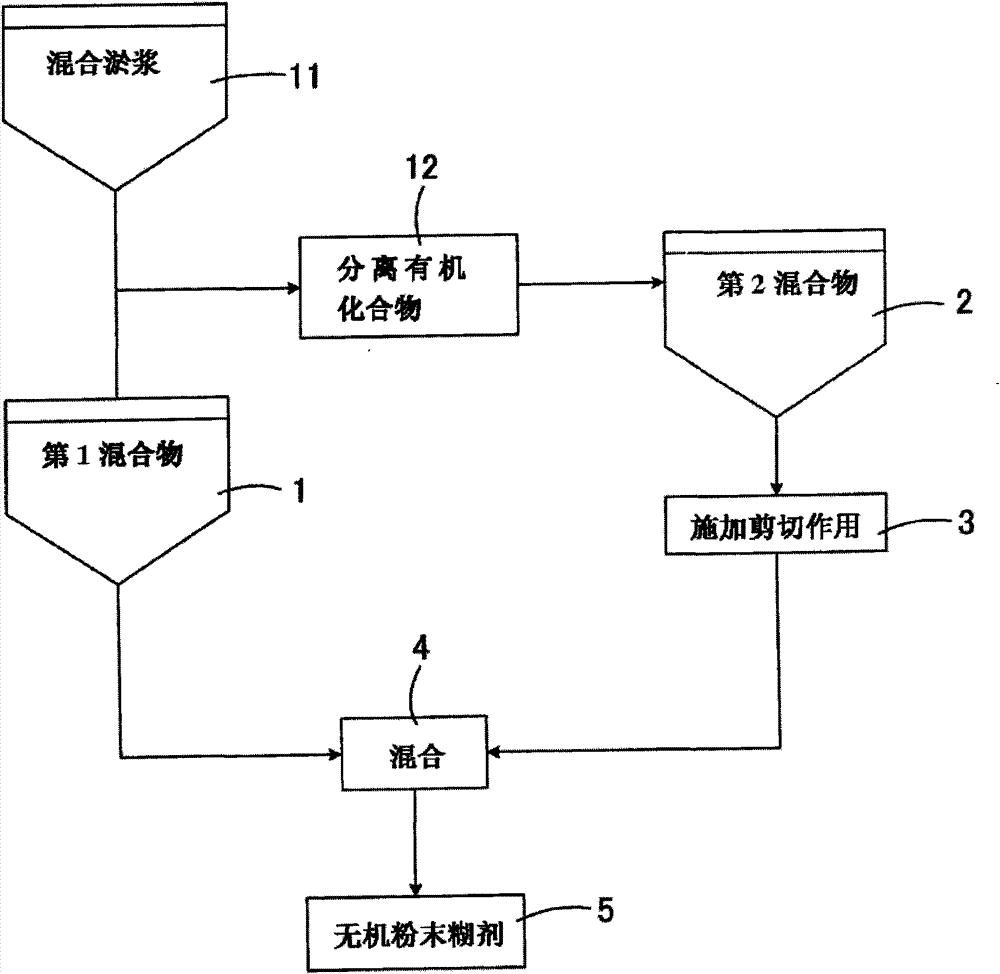

[0034] figure 1 It is a process drawing which shows the manufacturing method of the inorganic powder paste of 1st Embodiment of this invention. The inorganic powder paste to be obtained contains an inorganic powder component and an organic compound capable of improving the dispersibility of the inorganic powder component by being adsorbed on the inorganic powder component in a solvent.

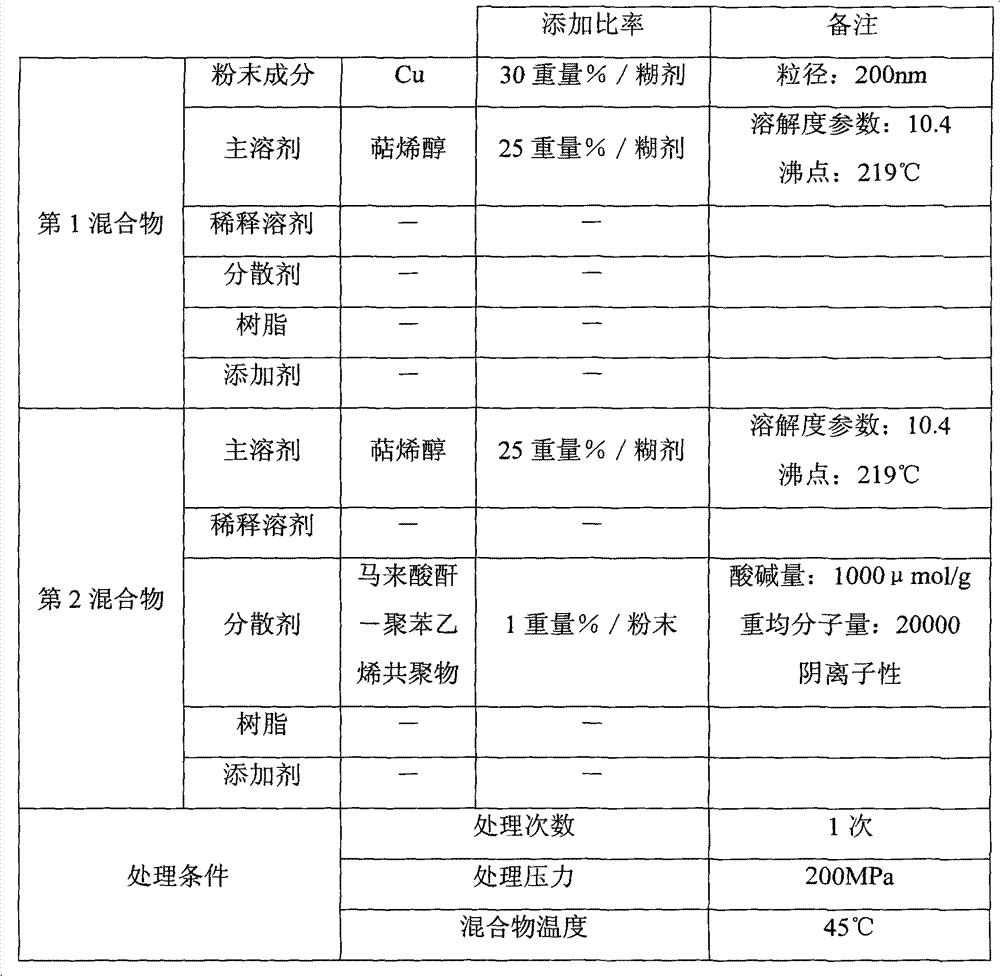

[0035] To prepare the inorganic powder component, a step of obtaining a first mixture 1 containing at least an inorganic powder component and a step of obtaining a second mixture 2 containing at least a solvent and an organic compound but not containing an inorganic powder component can be performed.

[0036] Then, a shearing action application step 3 of applying a shearing force to the second mixture 2 is performed, and then a mixing step 4 of mixing the first mixture 1 and the second mixture 2 is performed to obtain an inorganic powder paste 5 . In order to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com