Method and apparatus for producing a three-dimensionally shaped object, and three dimesionally shaped object

A three-dimensional shape and article technology, which is applied in the field of a device for manufacturing the article, a three-dimensional shaped article, and a device for manufacturing a three-dimensional shaped article, to achieve the effect of maintaining basic uniformity and improving maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0046] (Selective Laser Sintering or Melting)

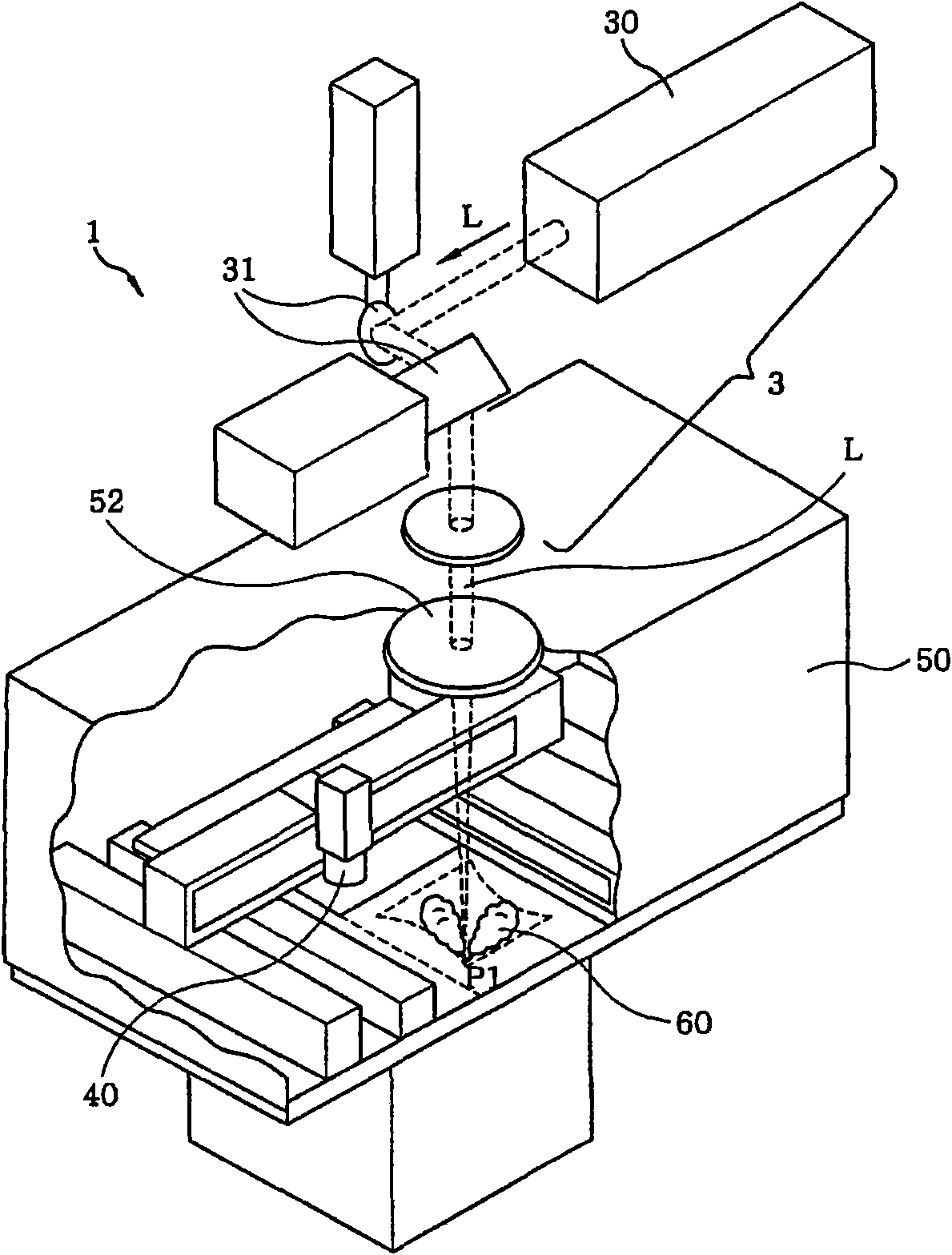

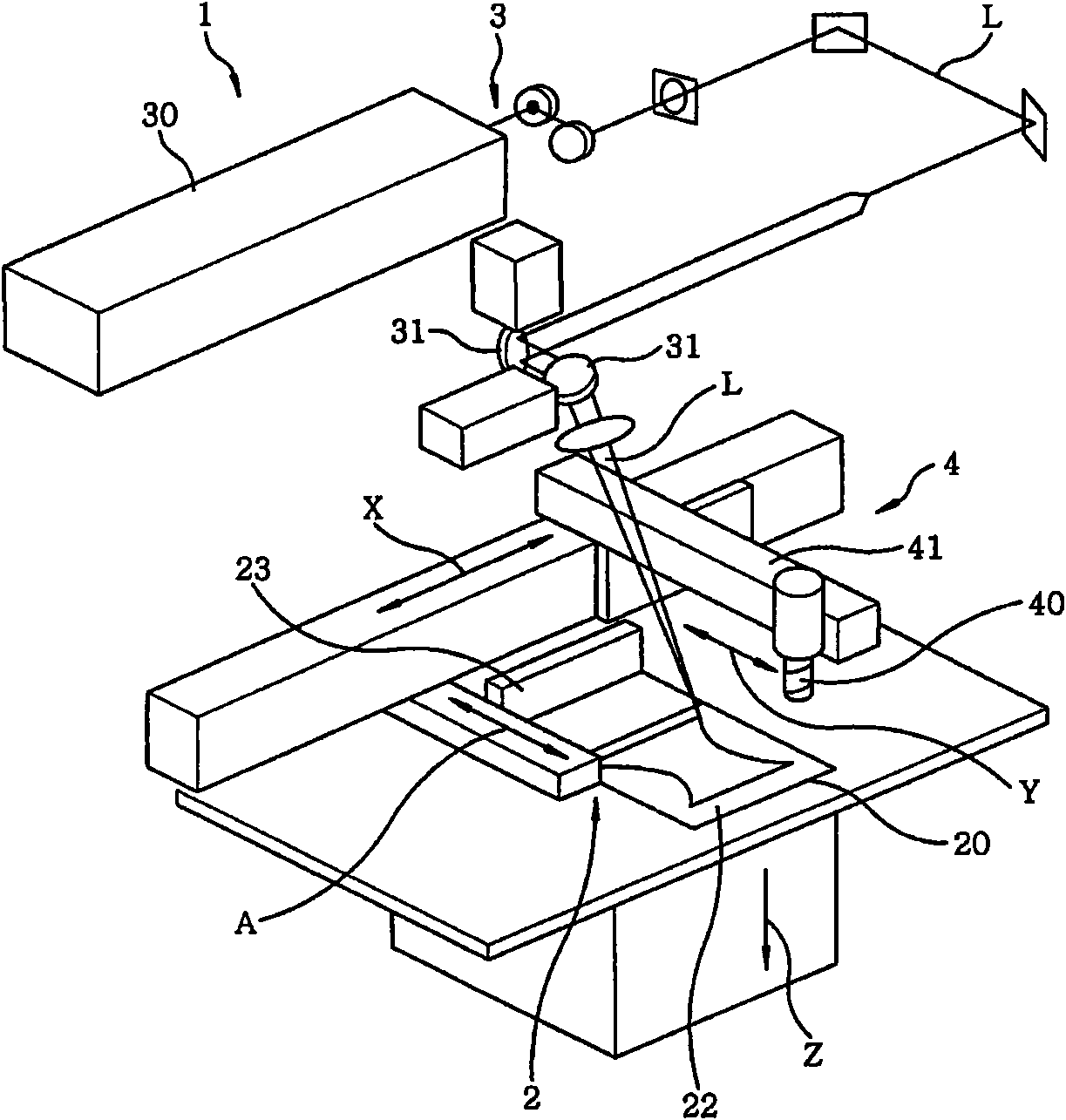

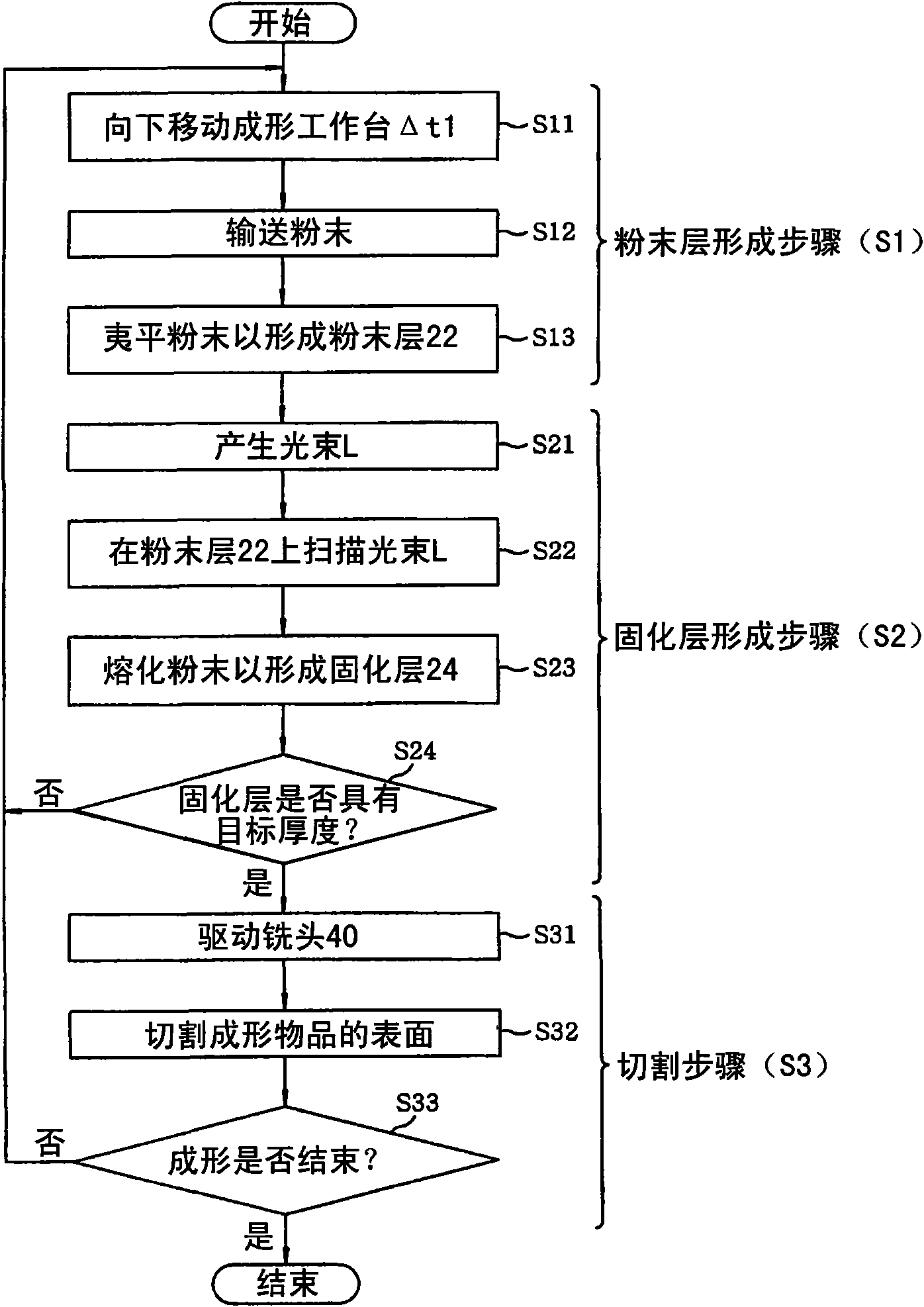

[0047] First, selective laser sintering or melting, which is the basis of the manufacturing method of the present invention, will be described. figure 2 The structure of the compound optical shaping machine 1 for performing selective laser sintering or melting is shown. The composite optical forming machine 1 mainly includes a powder layer forming unit 2 and a forming workbench 20 (see Figure 4A and 4B ), a beam irradiation unit 3 and a cutting unit 4, wherein the powder layer forming unit 2 is used to form a powder layer by spreading powder such as metal powder or resin powder to a certain thickness, and the forming table 20 is operated by the cylinder in the forming box 29 Vertically movable, the periphery of the cylinder is surrounded by a wall 27, the beam irradiation unit 3 is used to ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com