Hoisting and lowering driving engagement multi-row chain

An elevating drive and meshing technology, applied in the field of meshing multi-row chains for elevating drive, can solve the problems of driving noise, chain durability decline, load balance deterioration, etc., and achieve the effect of suppressing bending and improving meshing balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

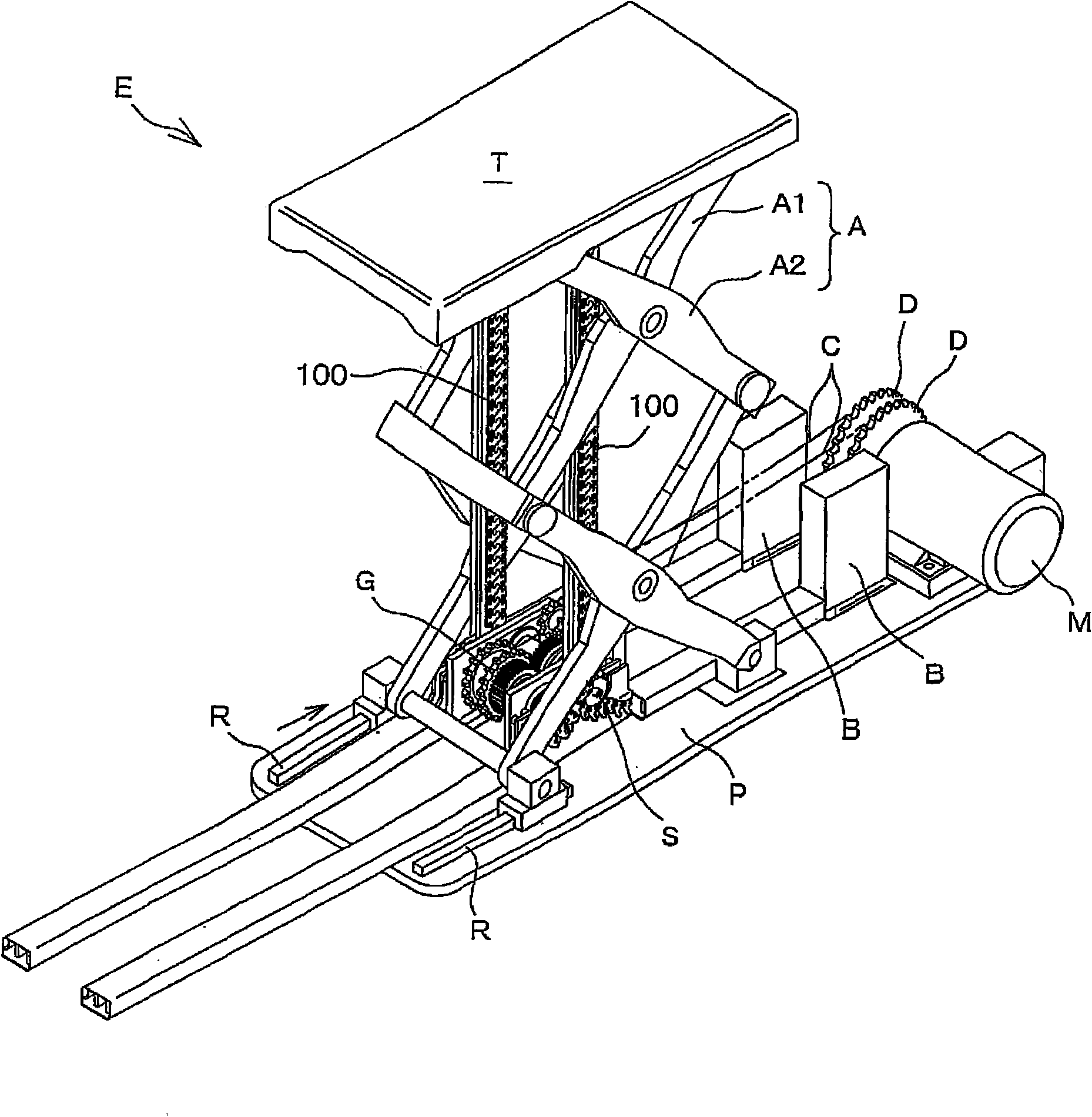

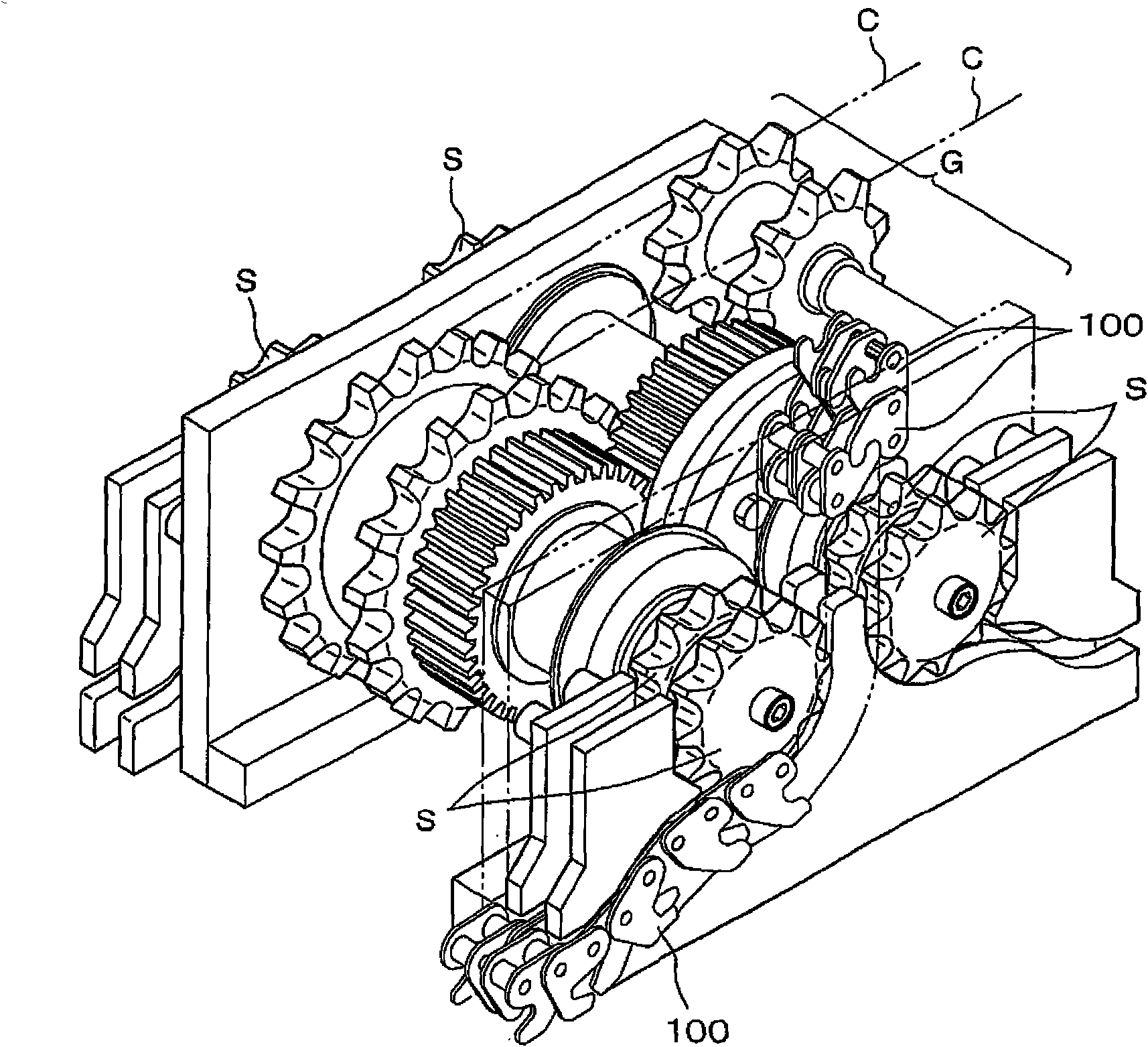

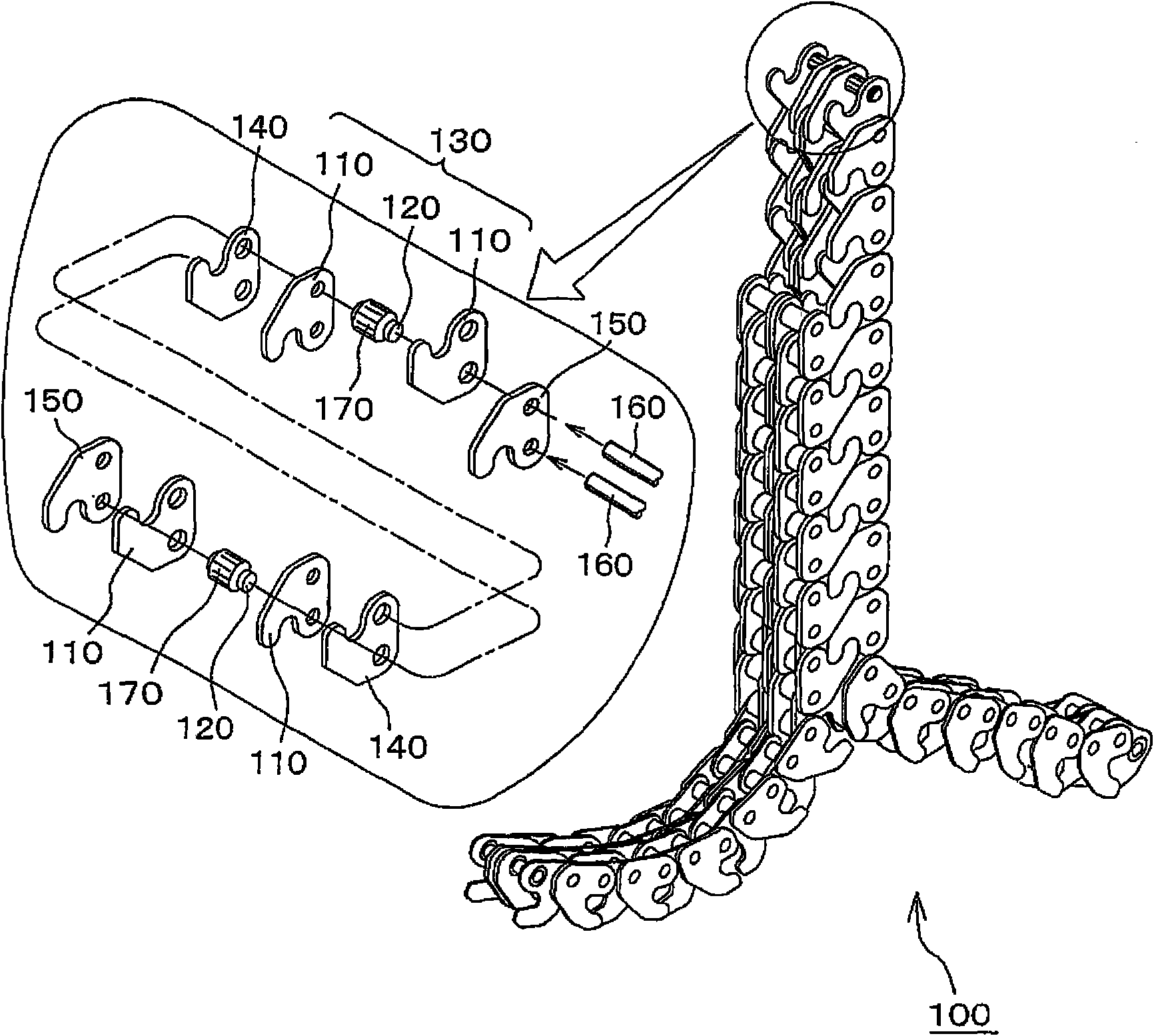

[0034] In the meshing multi-row chain for lifting and lowering drive of the present invention, a pair of front and rear bushings are press-fitted into a pair of left and right inner tooth pieces that are arranged separately and have hooks to form an inner chain link unit. A pair of front and rear connecting pins are press-fitted into a pair of front and rear pin holes of an outer tooth piece with a hook arranged on the outermost side in the chain width direction and are arranged side by side with the middle tooth piece having a hook portion interposed therebetween in the direction. A plurality of inner chain link units are connected along the length direction of the chain, and the inner tooth pieces are respectively arranged on a pair of lifting sprockets engaged with the bushing and facing each other while deflecting from the horizontal direction to the vertical direction. Each other, the outer gears and the middle gears mesh with each other and rise in an independent state as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com