Line-breakage sensor of knitting machine

A sensor and knitting machine technology, applied in the field of sensors, can solve the problems of low parking sensitivity, affecting the quality of weaving, and easy damage, etc., and achieve the effect of high parking sensitivity, good weaving effect and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

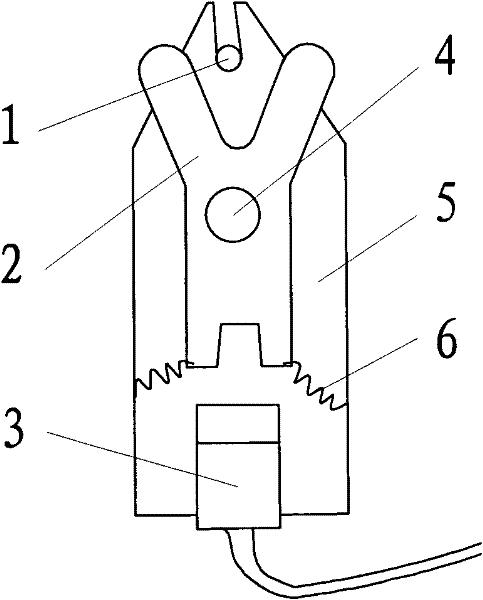

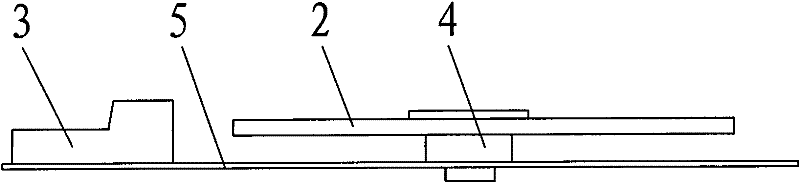

[0017] Embodiment 1: The sensor includes a bracket and a switch, and the switch is installed on the bracket. The support includes a claw 2, a switch 3, a claw shaft 4, and a return spring 6. The claw is connected to the disc of the knitting machine through the claw shaft, and the switch is connected to the disc of the knitting machine and is located behind the claw. end; a return spring is connected between the rear end of the claw and the disc of the knitting machine.

[0018] There is a connection hole in the middle of the claw, the front end of the claw is a "herringbone" fork, and there is a groove at the rear end, and a return spring is respectively connected to the two sides of the rear end of the claw, and the switch is located in the groove.

[0019] The switch is a proximity switch.

Embodiment 2

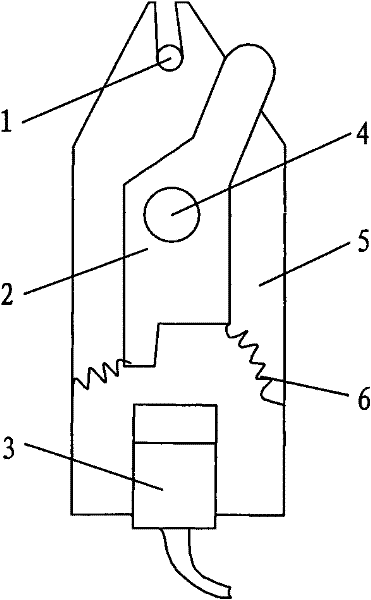

[0020] Embodiment 2: The front end of the finger is an oblique protrusion, the rear end has a protrusion, and the two protrusions are arranged diagonally. The switch is a micro switch. Others are the same as in Example 1.

Embodiment 3

[0021] Embodiment 3: The two protrusions at the front end and the rear end are arranged on the same side of the finger. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com