Air drilling double-wall drill rod

A double-walled drill pipe and air technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of high manufacturing cost, high construction cost, short service life, etc., and achieve low manufacturing cost, low construction cost, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

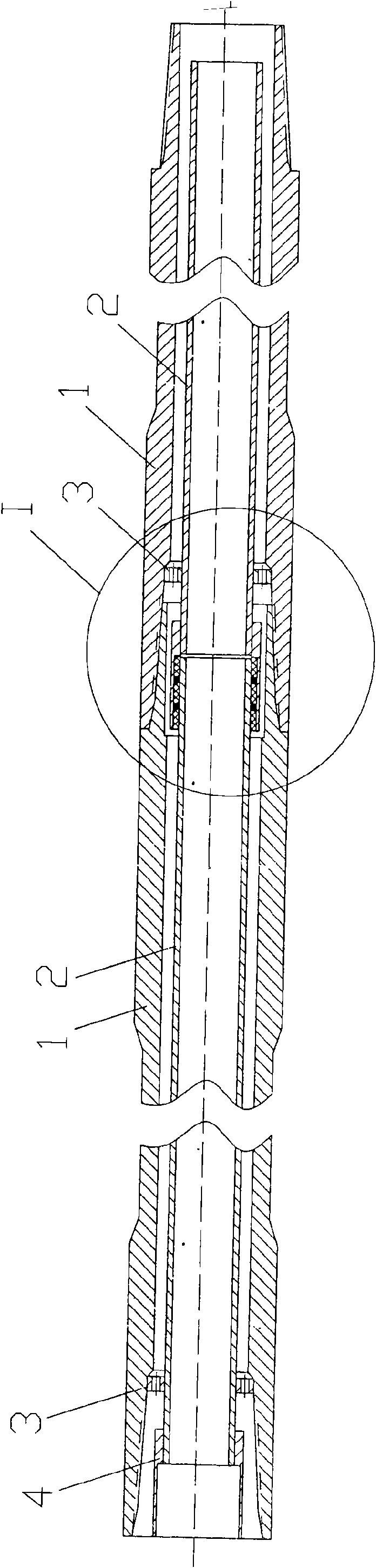

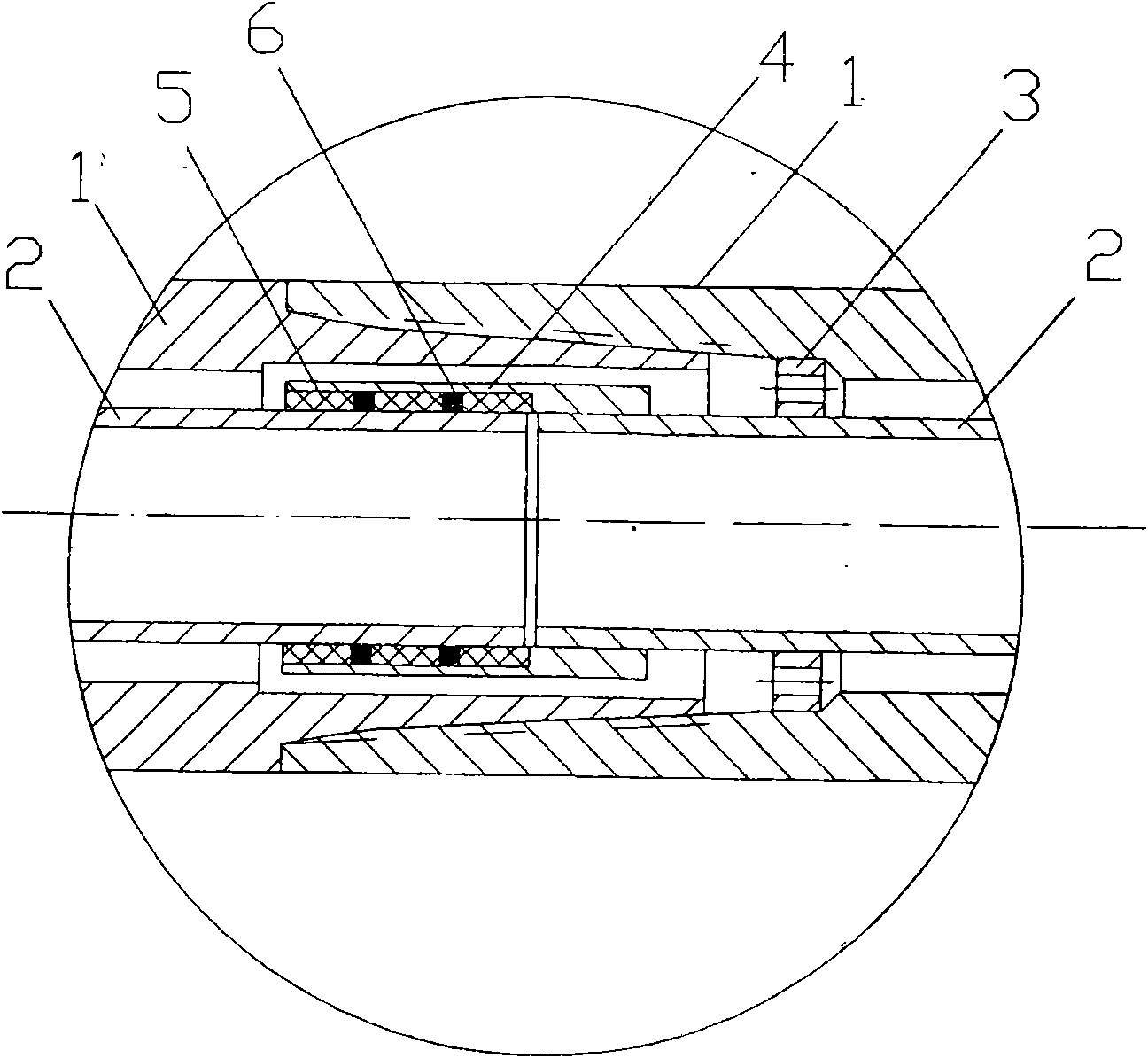

[0014] As shown in the figure, an air-drilling double-walled drill pipe is composed of an outer pipe body 1 and an inner pipe body 2. It is processed with an external thread with the same nominal diameter, tooth shape and pitch as the internal thread at the upper end, and the same thread length. The upper end of the inner pipe body 2 is fixed with a sleeve-type inner pipe joint 4, and the lower part of the inner pipe joint 4 A breathable disk 3 matching the inner diameter of the inner clamping platform of the outer pipe body 1 is fixed on the pipe body. The outer diameter of the inner pipe joint 4 is smaller than the inner diameter of the outer pipe body 1. Inside the body 1, the upper end surface of the inner pipe joint 4 is flush with the upper end surface of the outer pipe body 1, and the lower end surface of the inner pipe body 2 is when the external thread at the lower end of the outer pipe body 1 is screwed into the internal thread of another outer pipe body 1 Enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com