Capillary type encapsulation method of bare F-P optical fiber transducer

A technology of optical fiber sensor and packaging method, which is applied in the direction of adopting optical devices, instruments, measuring devices, etc., can solve the problems of complex structure, bubbles in packaging materials, high packaging cost, etc., and achieve simple process, good neutrality and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

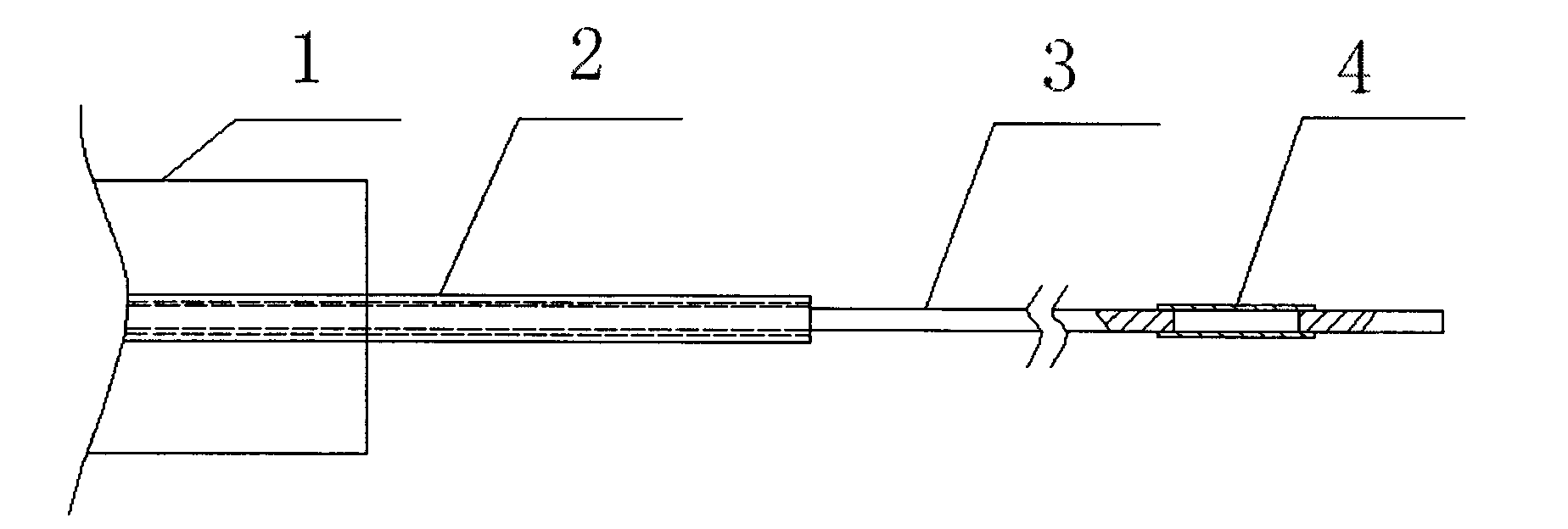

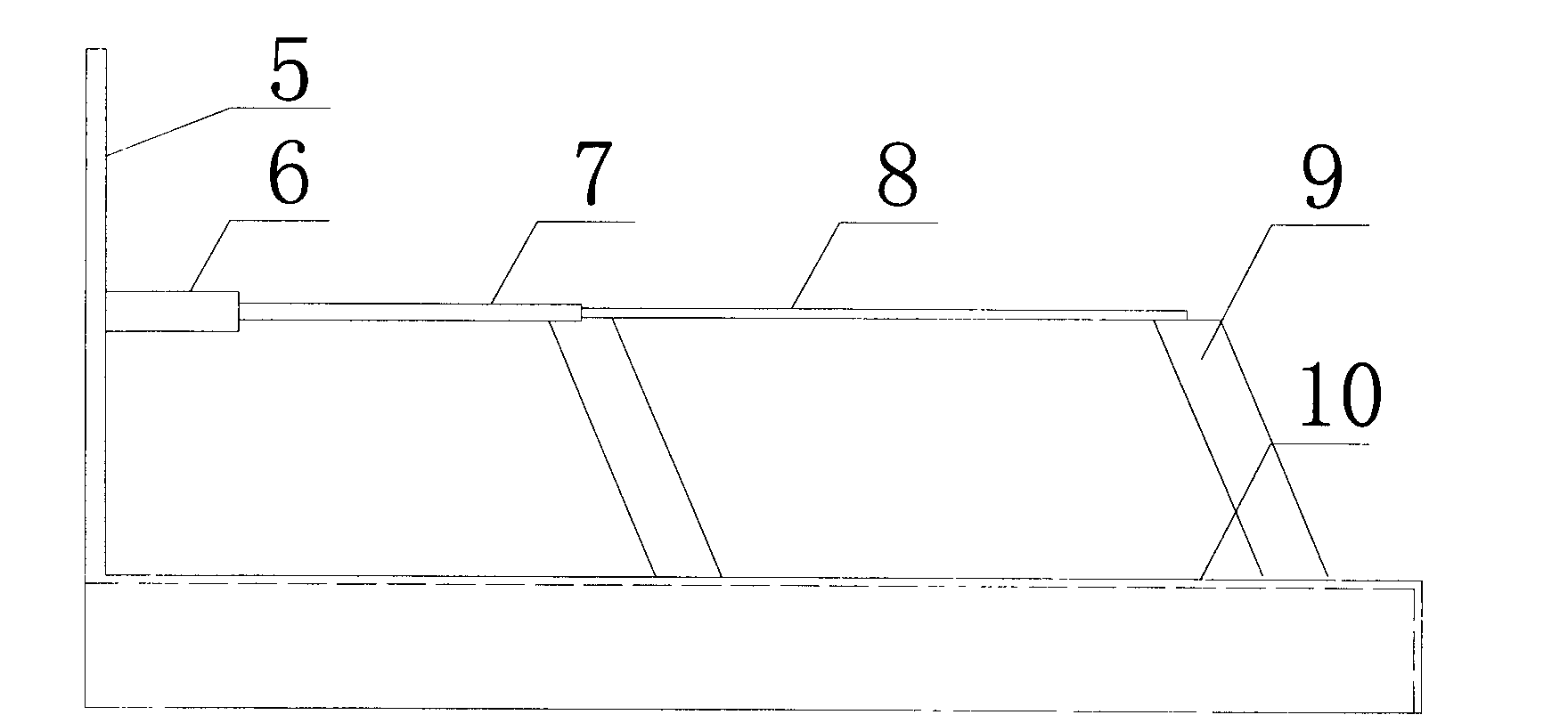

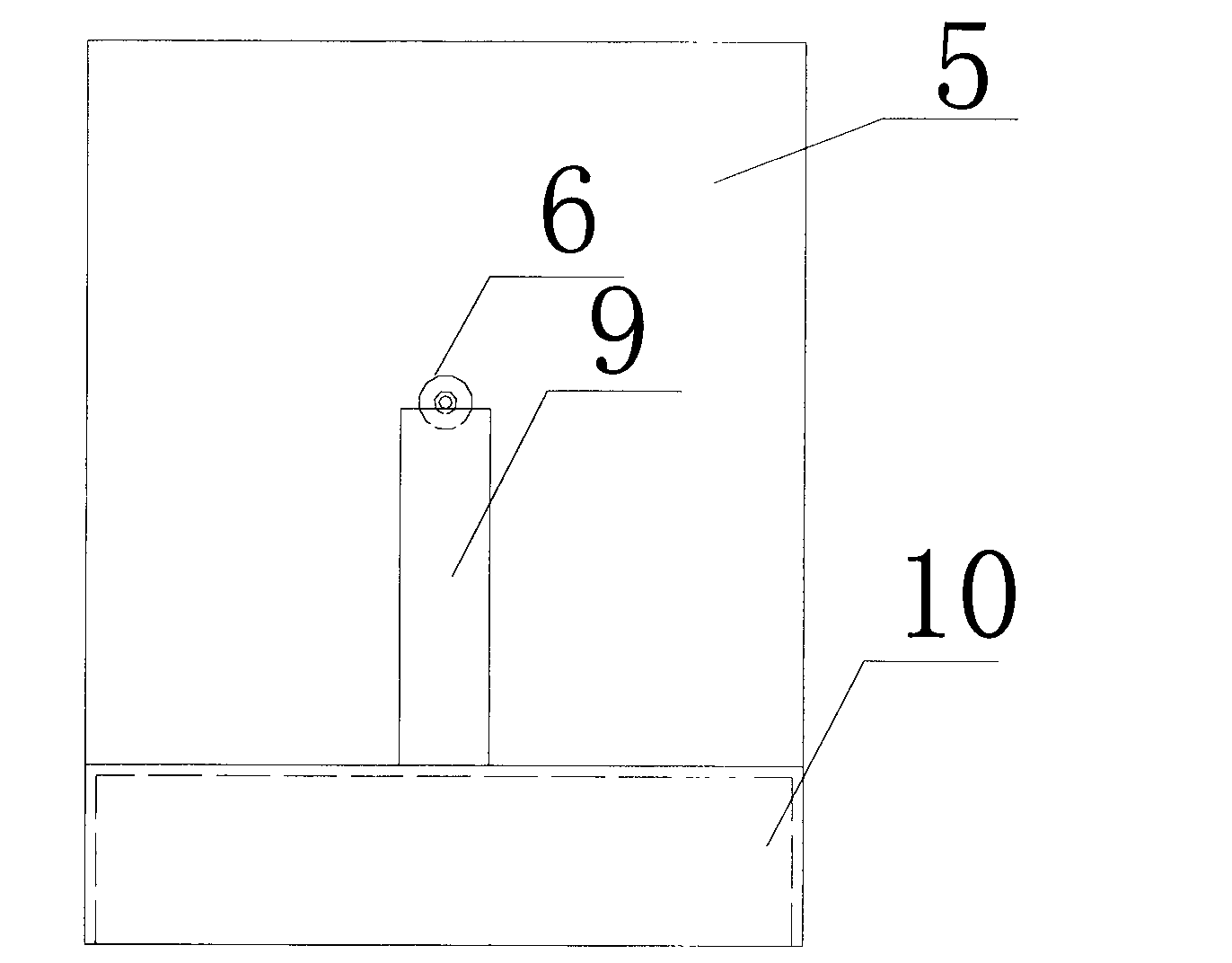

[0022] see figure 1 , 2 , 3, 4, a kind of bare F-P optical fiber sensor capillary type packaging method, according to the following steps:

[0023] (1) Preparing the resin model: the first protective sleeve 1, the first capillary 17 and the second capillary 19 are sequentially connected into a rod with a large radius at one end and a small radius at the other end, and input the size parameters of the rod into the computer. The virtual rod is made in the computer according to the size parameters of the rod; a virtual lower base plate is set under the virtual rod, a virtual runner is set between the virtual rod and the virtual lower base, and the end of the virtual rod with a larger radius is fixed on the virtual side wall Above, the virtual side wall is vertically connected with the virtual lower bottom plate; the virtual bar, the virtual side wall, the virtual runner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com