Surface defect form and depth on-line lossless detection method of high-temperature continuous casting blank

A defect form, non-destructive testing technology, applied in the field of metallurgy, can solve problems such as large influence, poor accuracy, and inability to detect depth information, and achieve the effect of improving the level of automation, improving the quality of casting billets, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

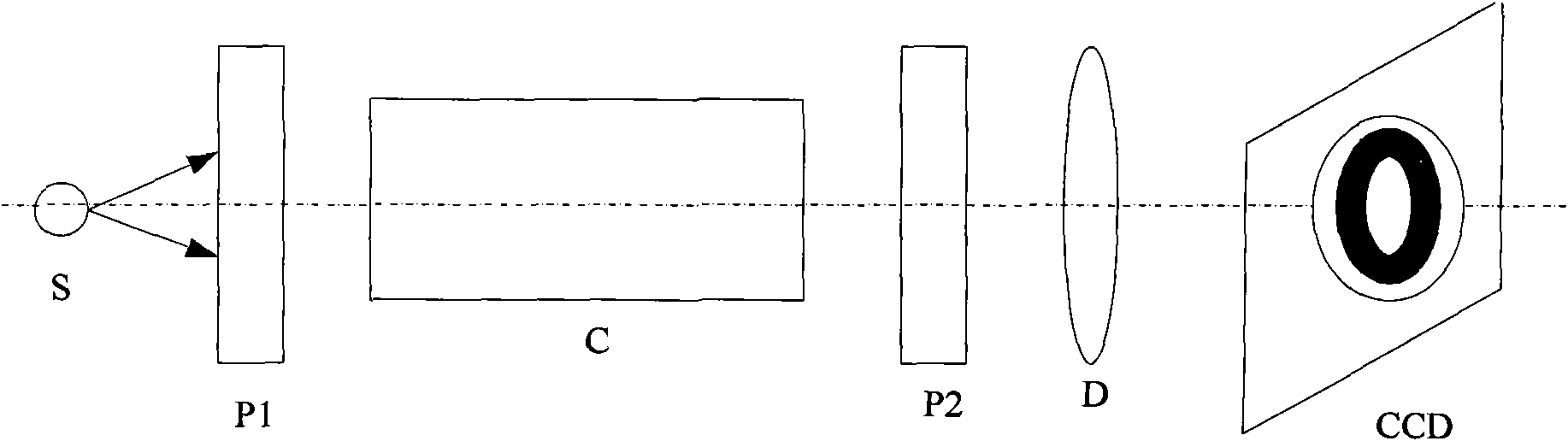

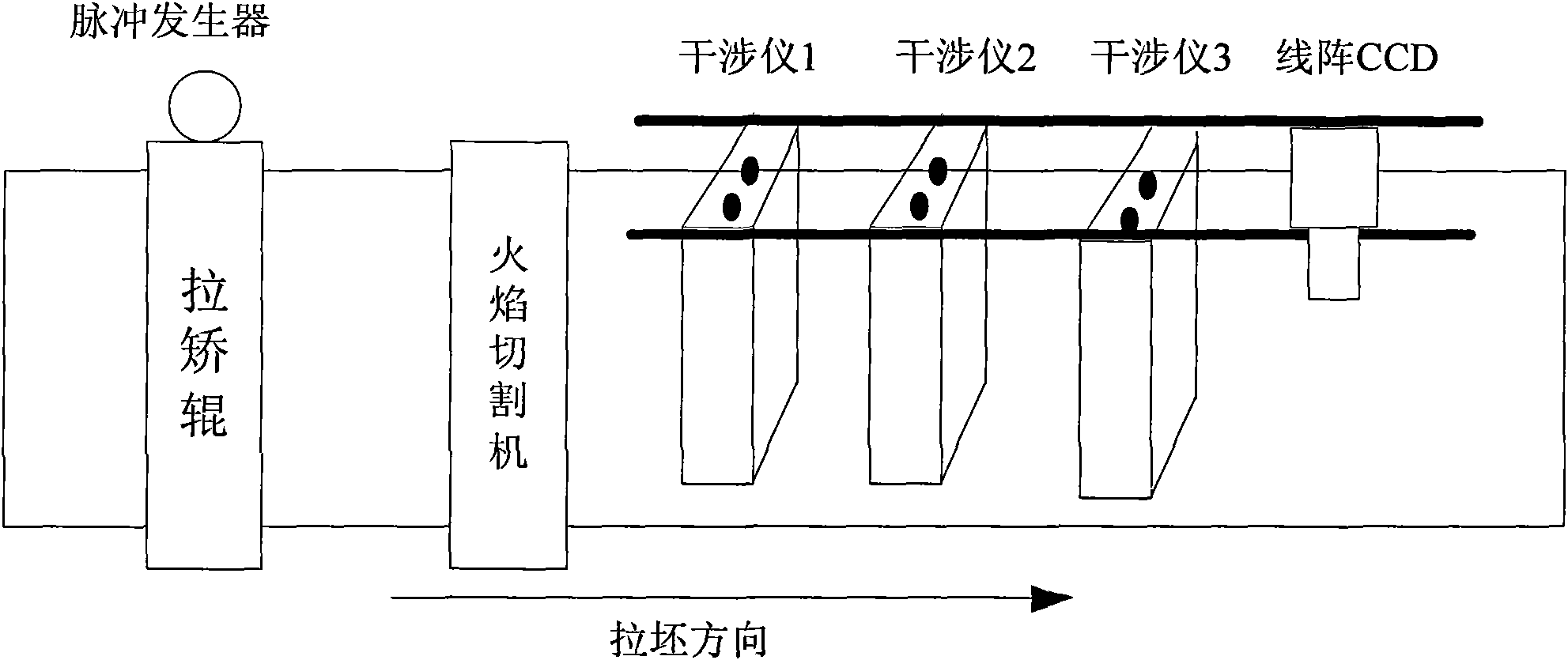

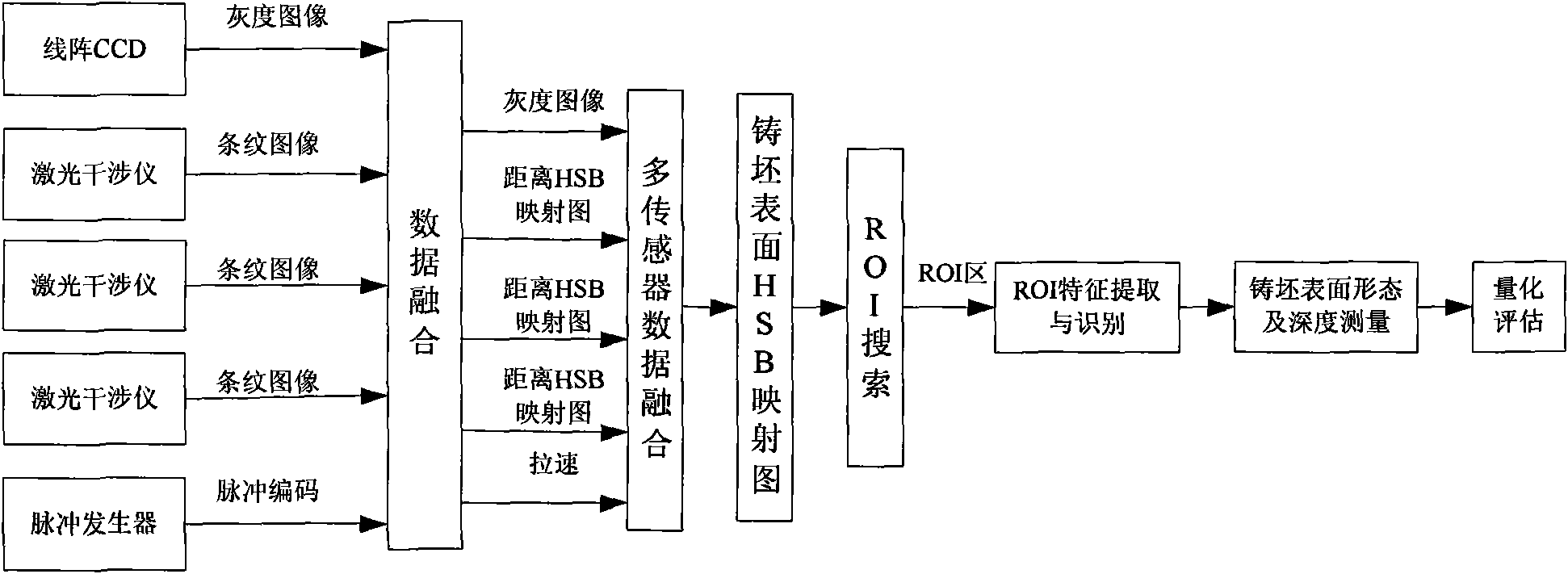

[0018] The idea of this high-temperature continuous casting slab surface defect form and depth online non-destructive testing method is as follows: 1. Obtain the distance lattice of the slab surface in a certain width area on the high-temperature slab surface from the measuring device through the measuring device; 2. Distance points of several different width areas The array constitutes a distance one-dimensional lattice in the transverse direction, and the number of areas in the transverse direction is determined by the scanning frequency of the measuring device and the number of installations of the measuring device; 3. The combination of several distance one-dimensional lattices in the transverse direction constitutes the surface distance two four-dimensional lattice; four, convert the two-dimensional distance lattice into two-dimensional distance lattice HSB map; five, carry out image processing and ROI search on the two-dimensional distance lattice HSB map, can quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com