Rotor, its manufacturing method, and electric vehicle

A manufacturing method and rotor technology, applied in the manufacture of motor generators, electric vehicles, electric components, etc., can solve problems such as no records

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below. The same reference signs are attached to the same or corresponding parts in some cases, and the description thereof will not be repeated.

[0030] In the embodiments described below, when referring to the number of objects, the amount, and the like, the scope of the present invention is not necessarily limited to the number of objects, the amount, and the like unless otherwise described. In addition, in the following embodiments, each constituent element (element) is not an essential element of the present invention unless otherwise specified. In addition, when there are a plurality of embodiments below, it is originally planned that the configurations of the respective embodiments can be appropriately combined unless otherwise specified.

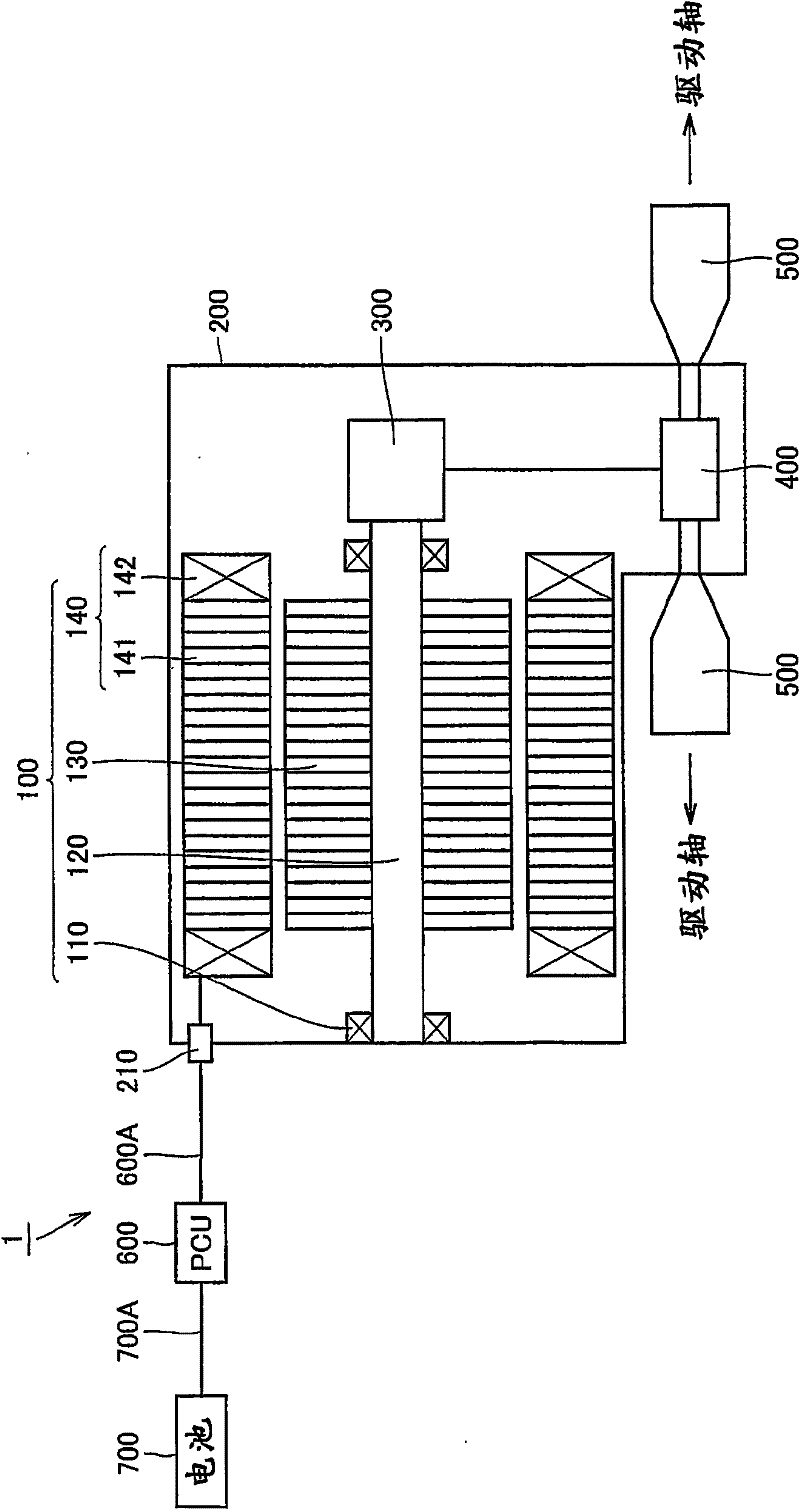

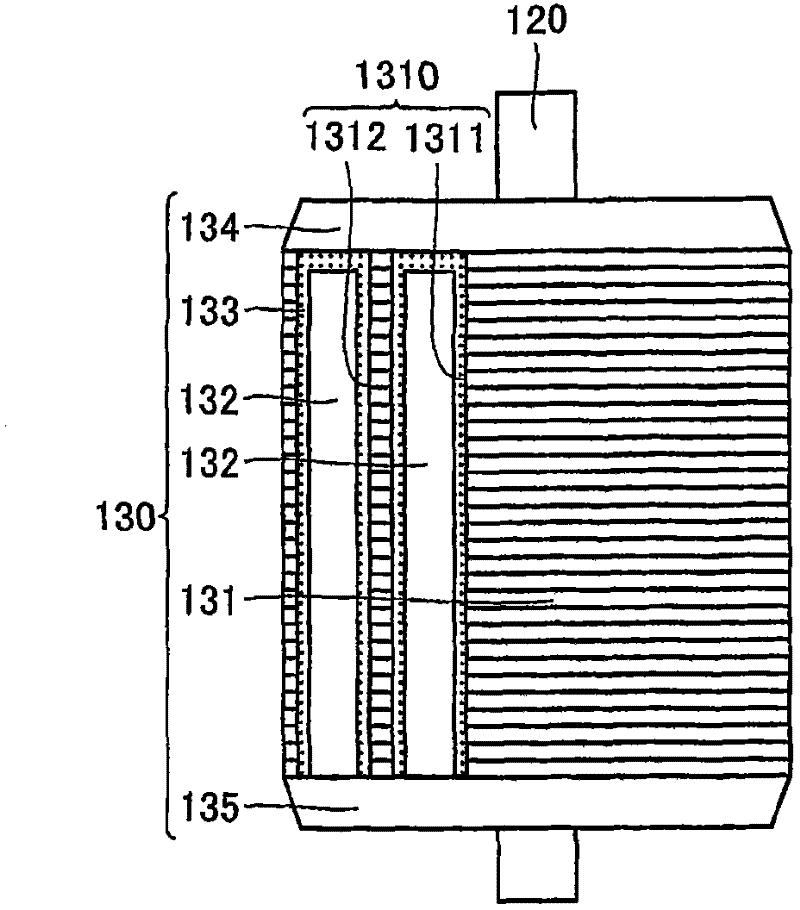

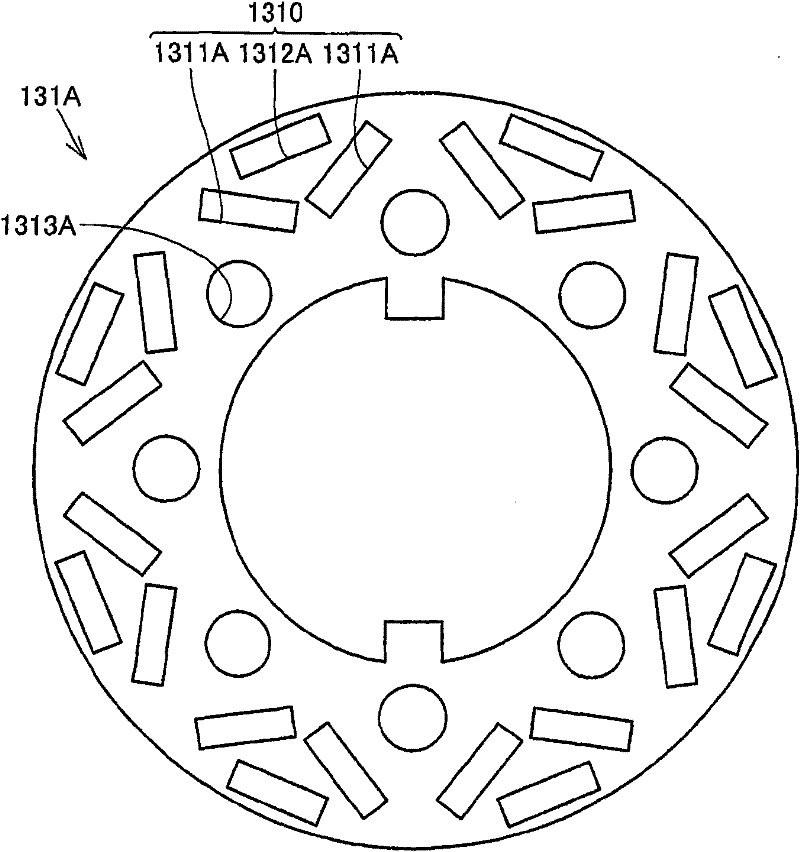

[0031] figure 1 It is a figure schematically showing the structure of the drive unit using the rotor which concerns on one Embodiment of this invention. exist figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com