A kind of composite layer leather laminated glass and its manufacturing method

A technology of laminated glass and composite layer, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of insufficiently beautiful finishes, fragile moving doors, and low utilization rate of the usable area. , to achieve the effect of effectively utilizing the usable area of the house, selecting a large color pattern, and reducing the load-bearing of the house

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

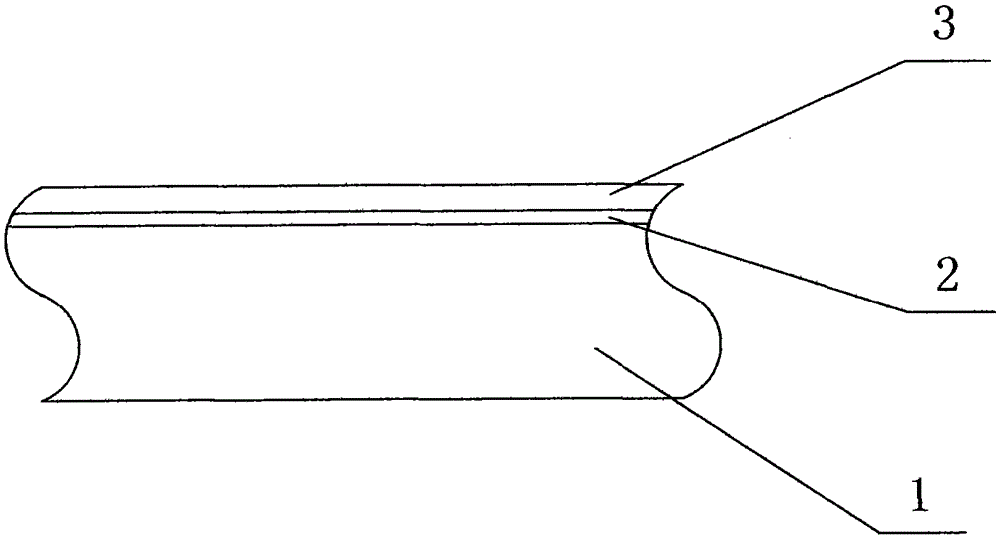

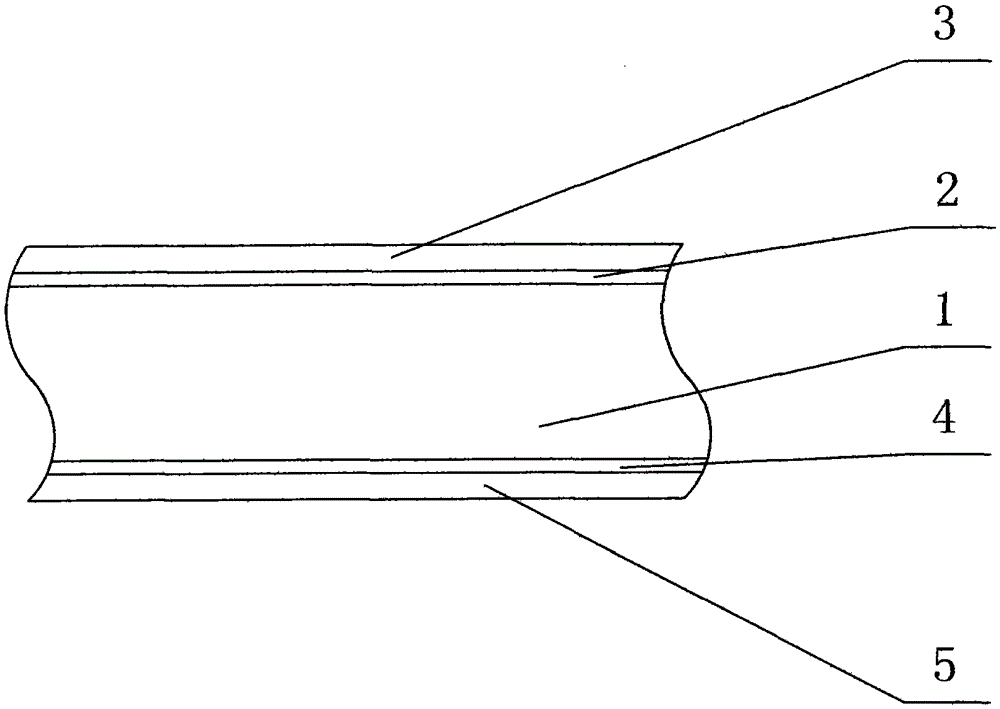

[0032] Such as figure 1 As shown, a composite layer leather laminated glass comprises a bottom layer 1, an upper middle layer 2, and an upper layer 3, which is a three-layer composite layer leather laminated glass; the bottom layer 1 is a float white glass layer, and the upper middle layer Layer 2 is a glass interlayer, and the upper layer 3 is an artificial leather layer; the thickness of the bottom layer 1 is 5mm, the thickness of the upper middle layer 2 is 0.38mm, and the thickness of the upper layer 3 is 0.75mm; the artificial leather layer, glass interlayer Layers and float white glass layers are laminated from top to bottom and connected by sintering.

[0033] The artificial leather layer is an XK-002PU polyurethane leather layer.

[0034] Specific processing steps:

[0035] (1). The processed materials are firstly cleaned with anhydrous ethyl benzophenone special cleaning agent, and then the artificial leather layer, the glass interlayer film layer and the float glas...

Embodiment 2-7

[0041] The thickness of the bottom layer 1 is shown in Table 1:

[0042]

[0043] The rest are the same as embodiment 1.

Embodiment 8-11

[0045] The specific names of the upper layer 3 are shown in Table 2:

[0046]

[0047] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com