Fully automatic bucket-cleaning plant

A barrel washing device, a fully automatic technology, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unsanitary, high production cost, and inability to remove dirt and scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

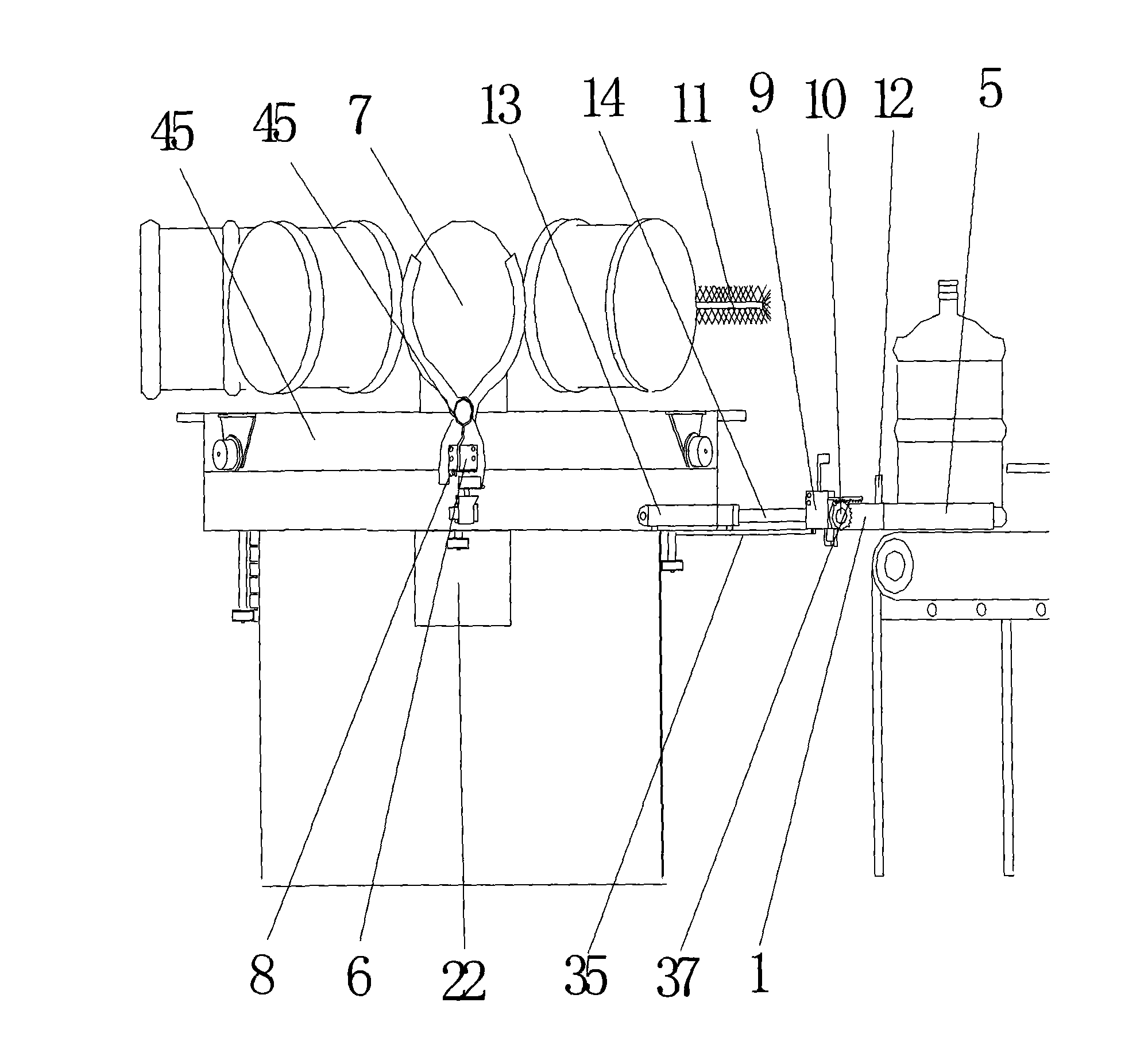

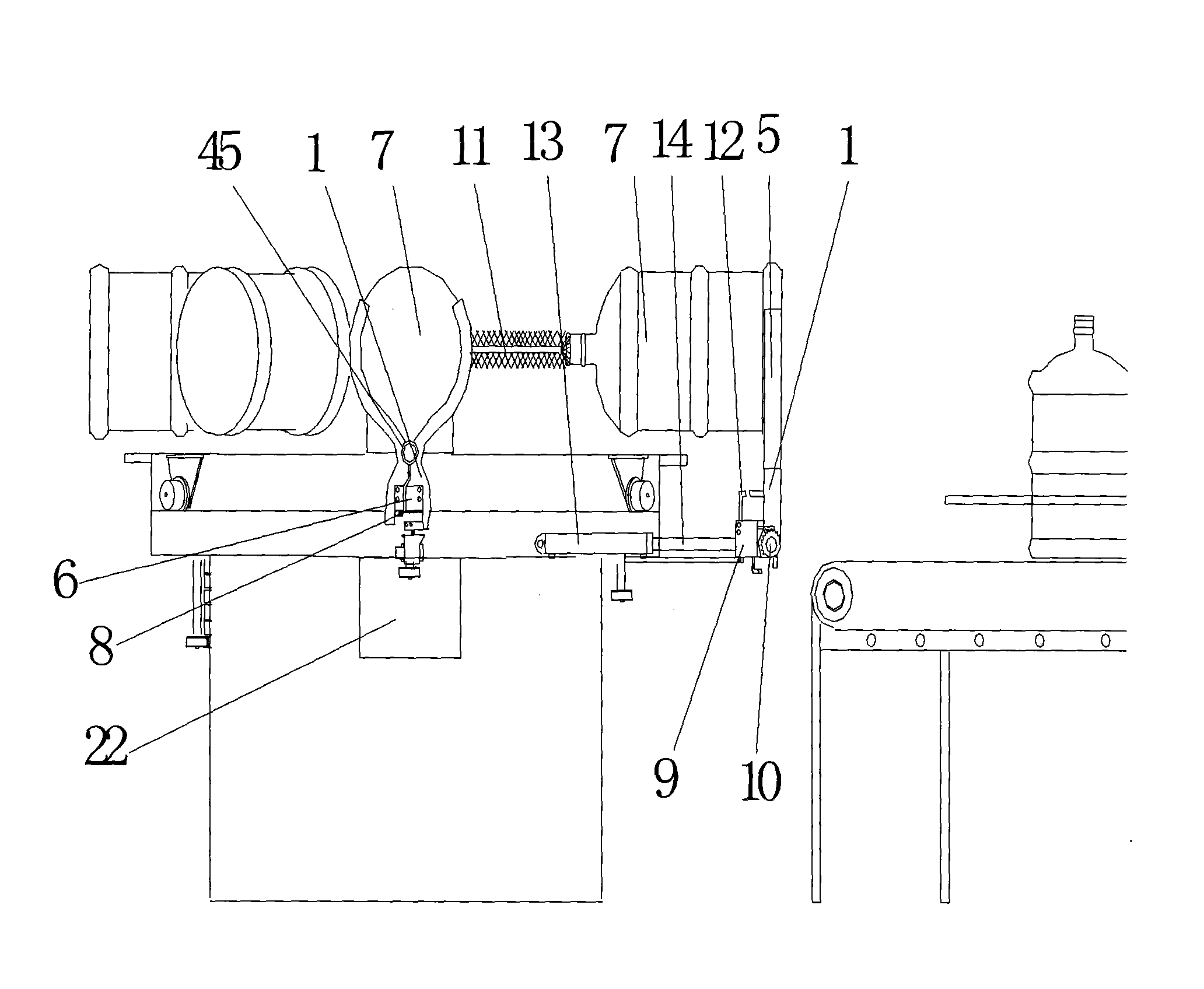

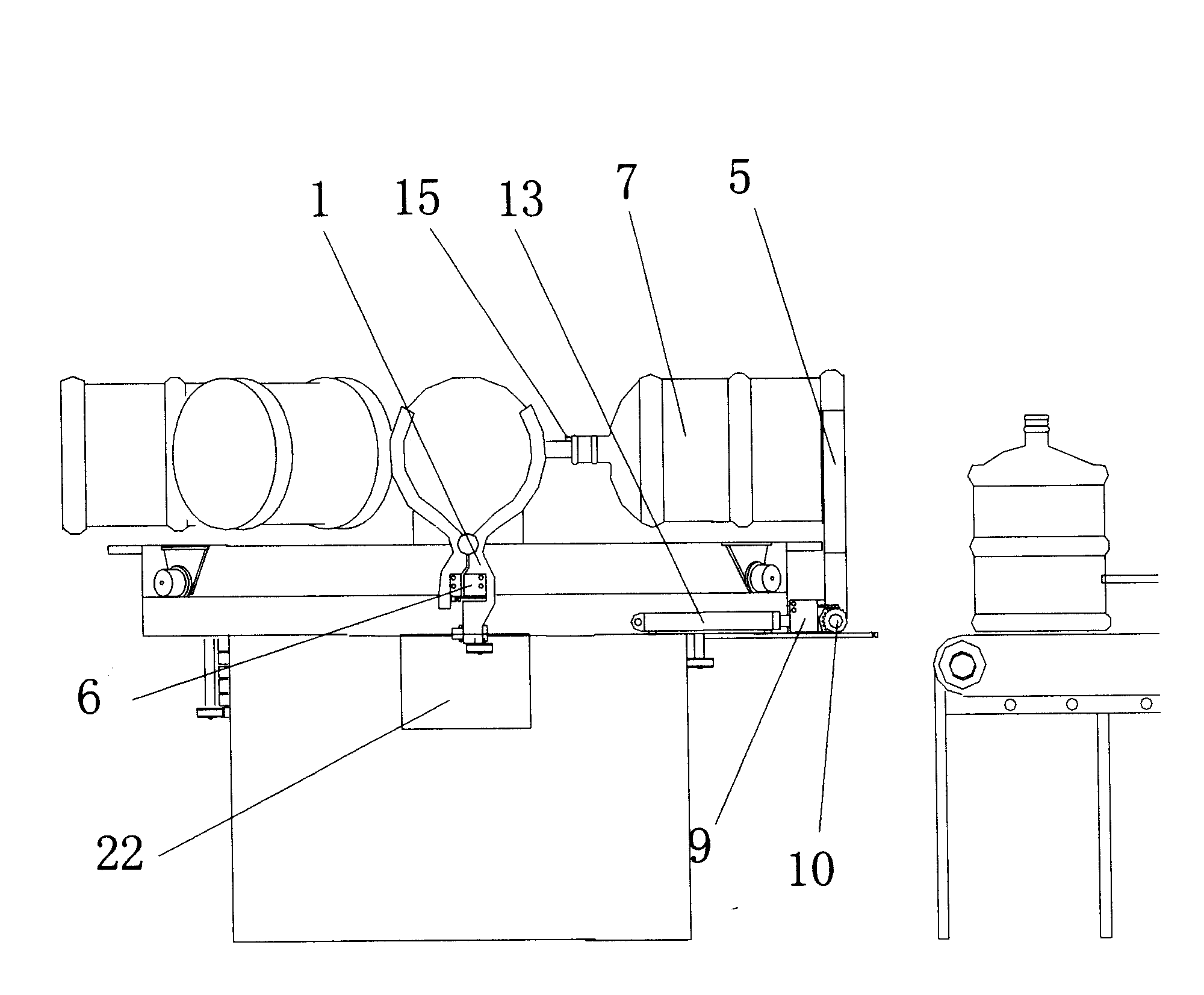

[0014] This cleaning device is mainly composed of a barrel clamping device (1), a cleaning device (2), a power rotating part (3) and a conveying part (4). Wherein the bucket clamping device (1) is provided with clamping bucket pliers (5), when the solenoid valve (6) is powered on, the bucket clamping pliers (5) will put the bucket (7) under the suction force of the solenoid valve (6) The bottom is clamped firmly. At this moment, the button (8) connects the power supply of the electromagnetic valve (9), and the gear (10) is dragged by the rack in the electromagnetic valve (9) to make the barrel clamp rise and reach an angle of 90 degrees with the electromagnetic valve (9). Align the mouth of the water bucket (7) with the washer (11), and press the button switch (12) at the same time to cut off the power to the cylinder (13). In (7), when the switch (15) of the washer (11) is pressed down by the mouth of the bucket (7), the washer (11) is automatically opened in the bucket (7),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com