Hand machine tool with brushed motor

A hand-held machine tool and motor technology, which is applied in the direction of manufacturing tools, electric components, electromechanical devices, etc., can solve the problems of geometric discontinuity, adverse effects on electrical safety, etc., and achieves improved electrical safety, improved mechanical buffering, and fast maintenance. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

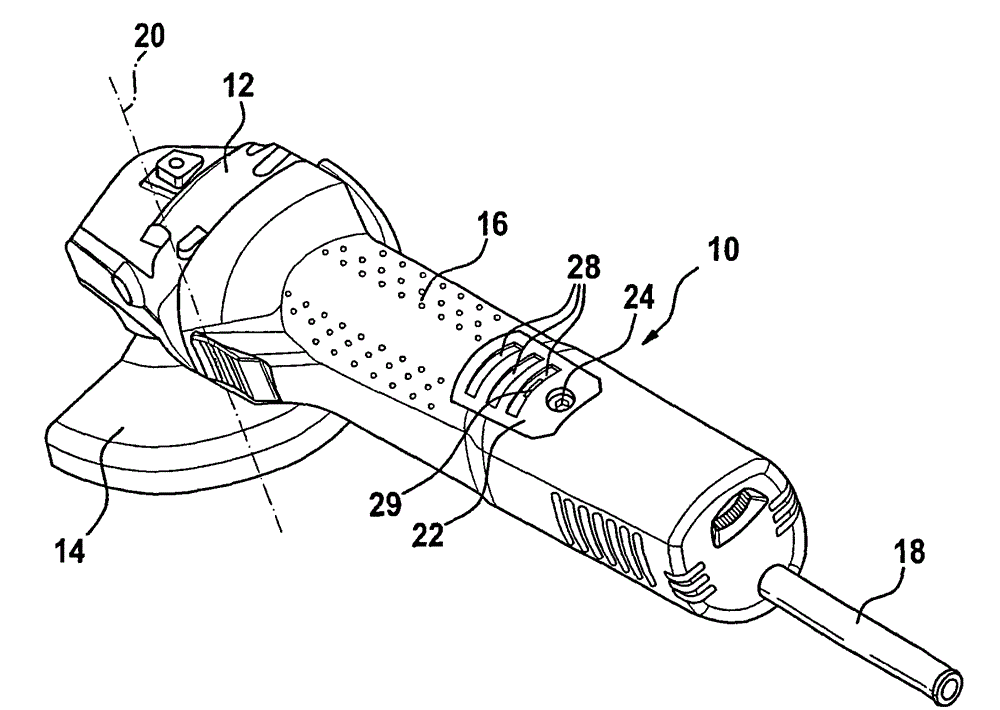

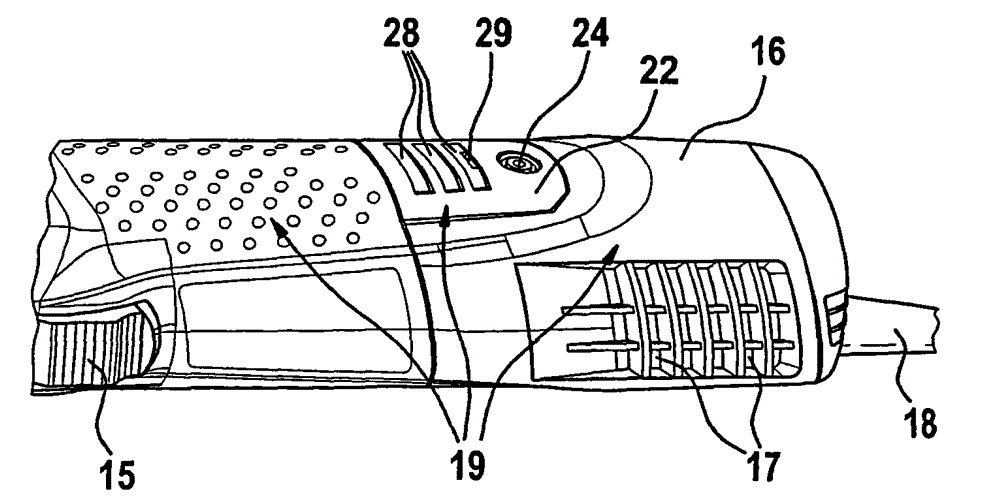

[0029] exist figure 1 The hand-held power tool shown in the center is designed as an angle grinder 10 and has a gear housing 12 made of metal at the front (to the left in the viewing direction). An output shaft (not shown) protrudes from the transmission housing downwards parallel to the vertical axis 20 of the angle grinder 10 in order to receive a grinding wheel (not shown), which is surrounded by a protective cover. A motor housing 16 in the form of a bowl is flanged behind the transmission housing 12, and this motor housing 16 receives a commutator motor or a brush motor, which is usually called a universal motor in hand-held power tools, from which Behind the motor extends a cable 18 for powering the motor.

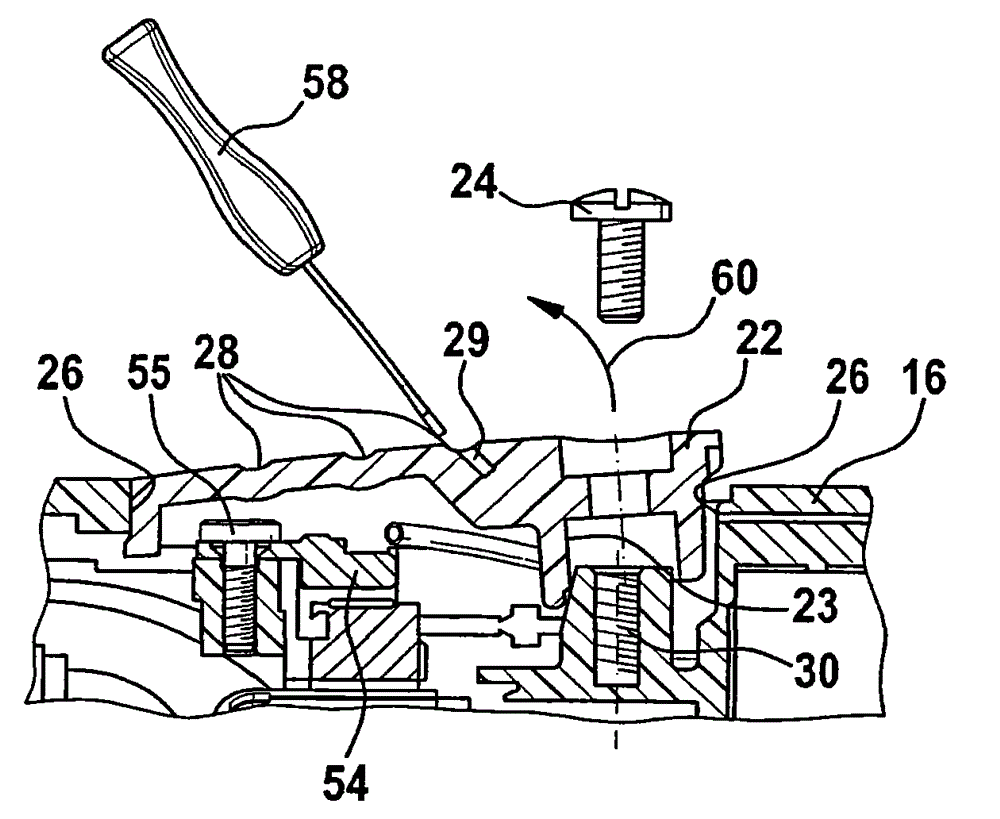

[0030] The motor housing 16 serving as a handle carries a cover 22 in the center of its upper side, which is fastened on the motor housing 16 flush with the contour by means of cover screws 24 and which here closes a maintenance opening 26 in a dust-tight manner. ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com