Safety control double-valve for power-off protection type press machine

A technology of safety control and power-off protection, applied in the direction of presses, fluid pressure actuation system safety, fluid pressure actuation devices, etc., can solve problems such as functional defects, safety valves losing safety functions, etc., and achieve the effect of not being easily blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

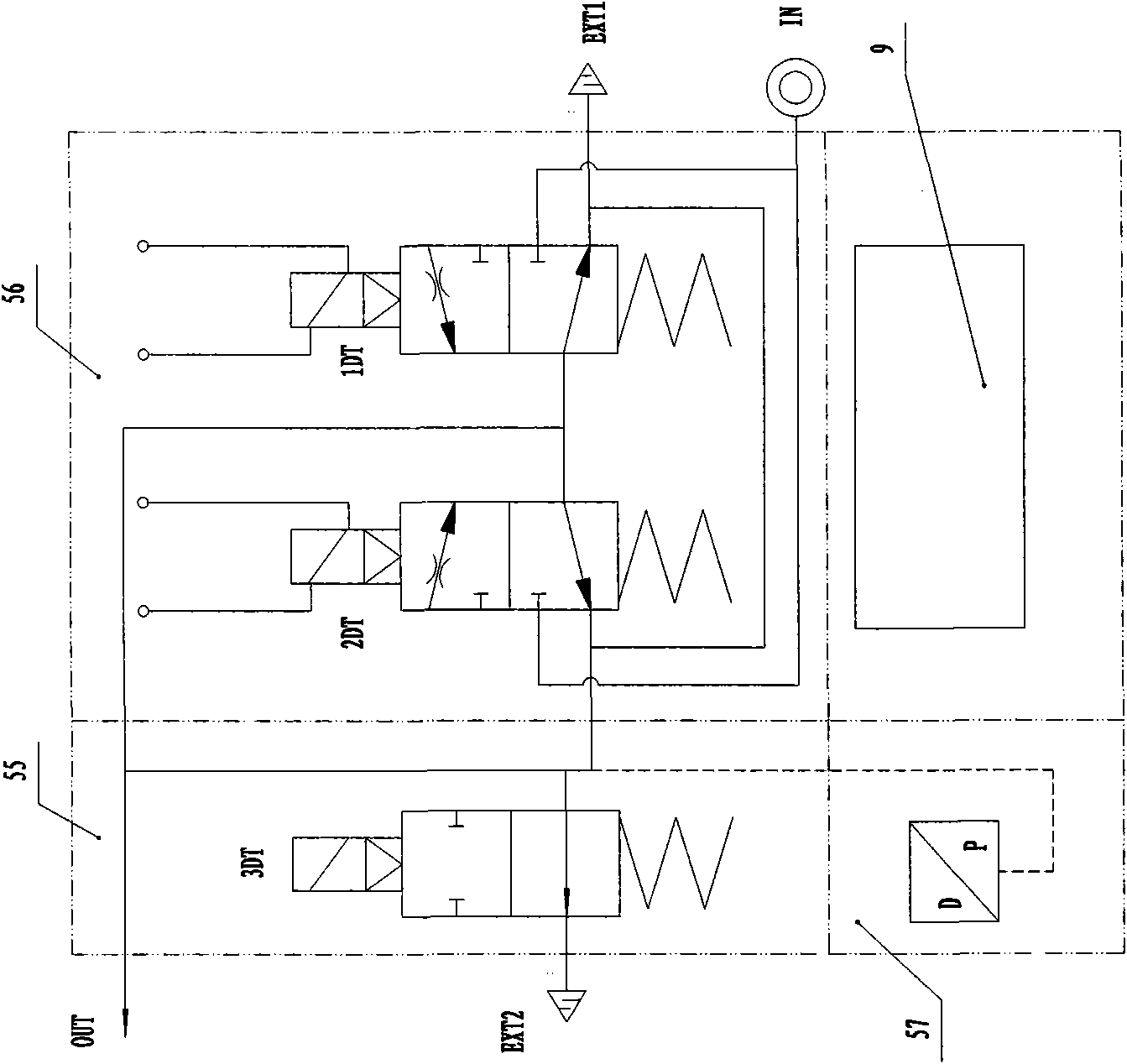

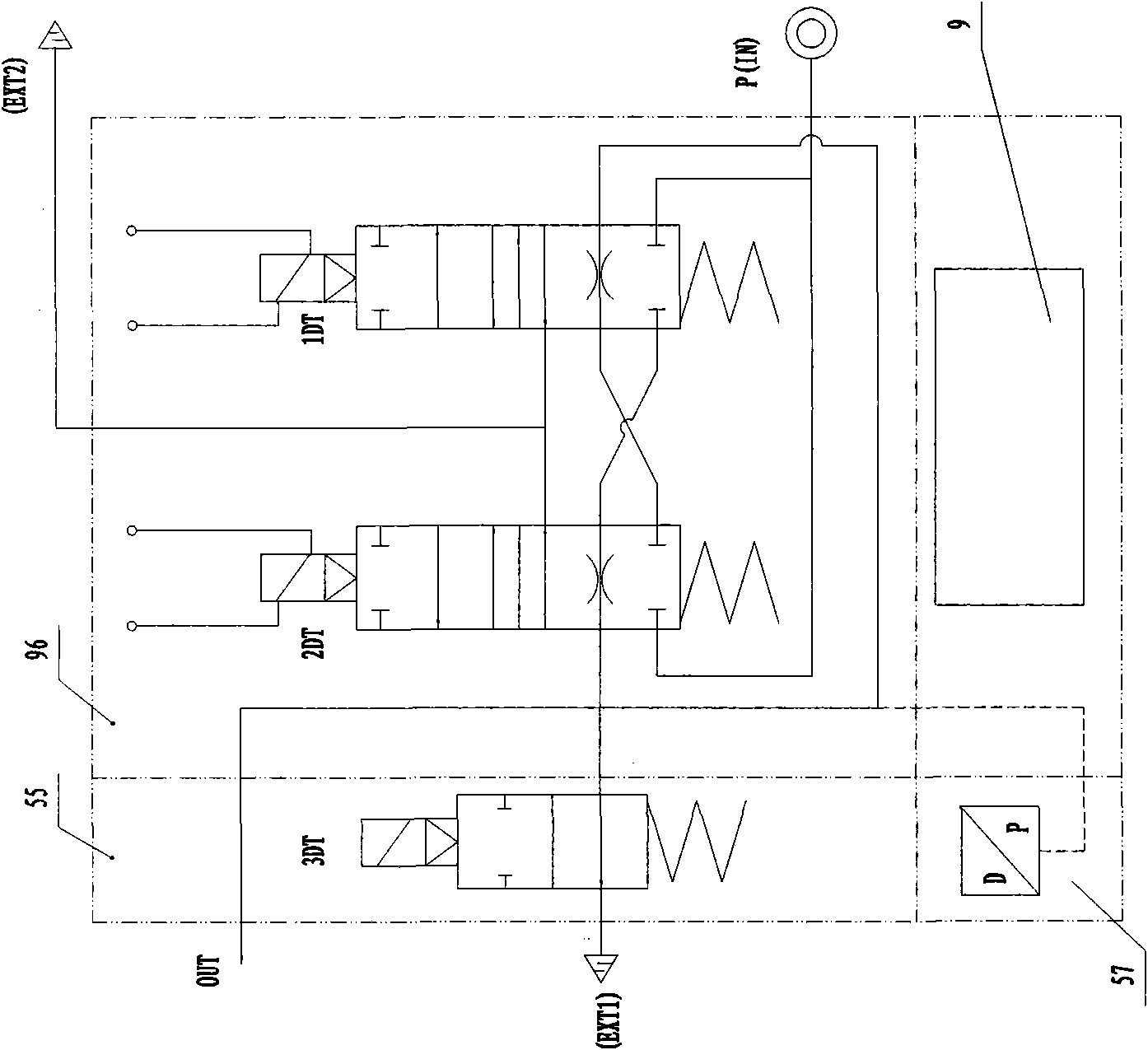

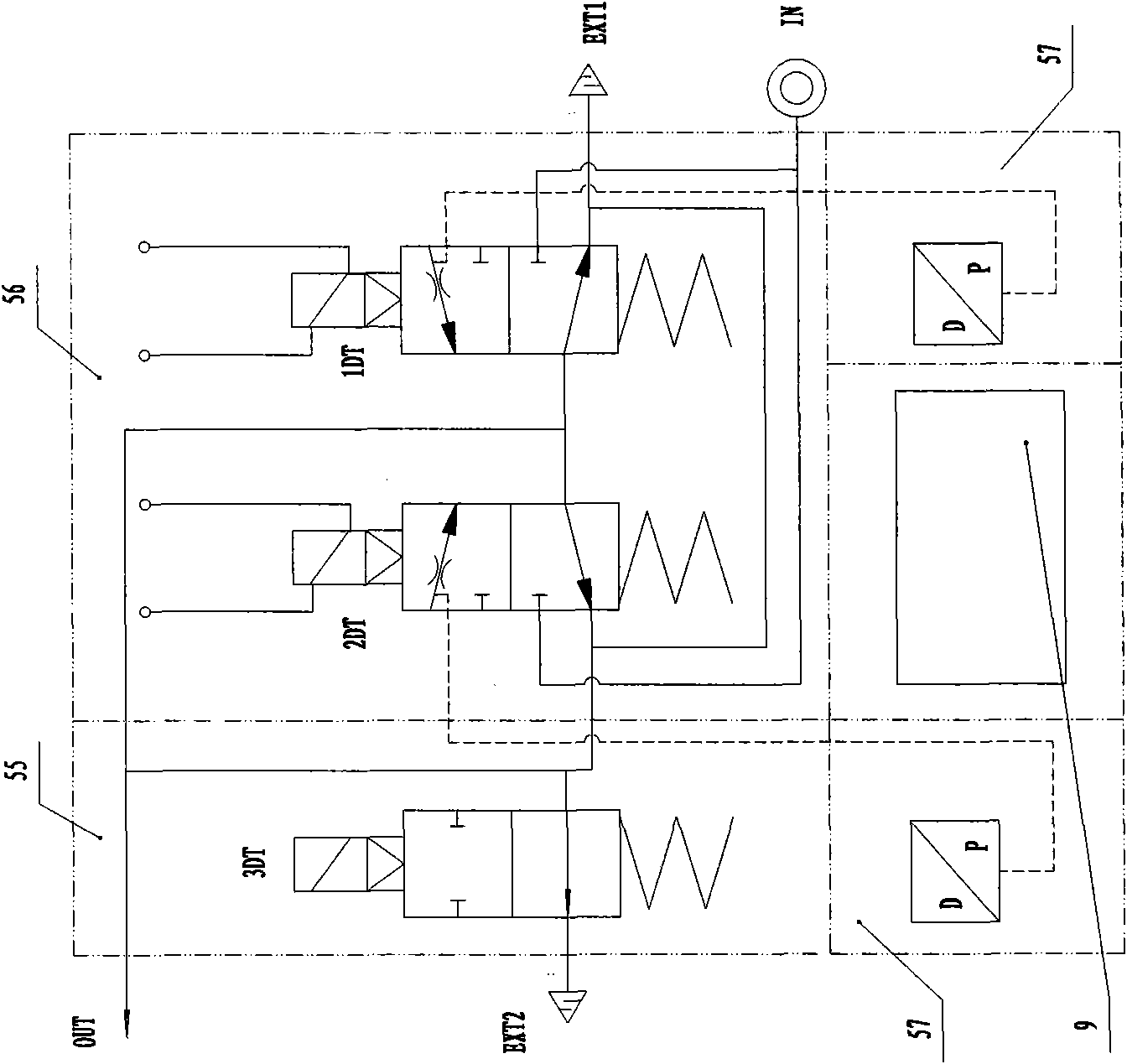

[0051] The safety control double valve includes a double valve and a safety valve, and the double valve includes a parallel double valve and a cross-flow double valve, and the parallel safety control double valve is composed of the parallel double valve and the safety valve. The cross-flow double valve and the safety valve constitute a cross-flow safety control double valve.

[0052] The design principle is: use Figure 1aThe first coil 1DT and the second coil 2DT in the coil 1 of the two pilot solenoid valves in the parallel double valve 56 in b, c, d or the cross-flow double valve 96 are energized at the same time to safely control the double valve If the air path from the lower valve port 62 to the compressed air output port OUT is high pressure, the gas-electric signal converter 57 provided on the air path from the lower valve port 62 to the compressed air output port OUT sends a high pressure signal. If the first coil 1DT and the second coil 2DT of the double valve are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com