Flexography vacuum aluminizing product with anti-counterfeit mark, vacuum aluminizing system and production process

A technology of vacuum aluminum plating and anti-counterfeiting marking, applied in the field of packaging materials and decorative materials, can solve the problems of high production cost and complicated process, and achieve the effect of good anti-counterfeiting effect, clear layers and thick heavy metal texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

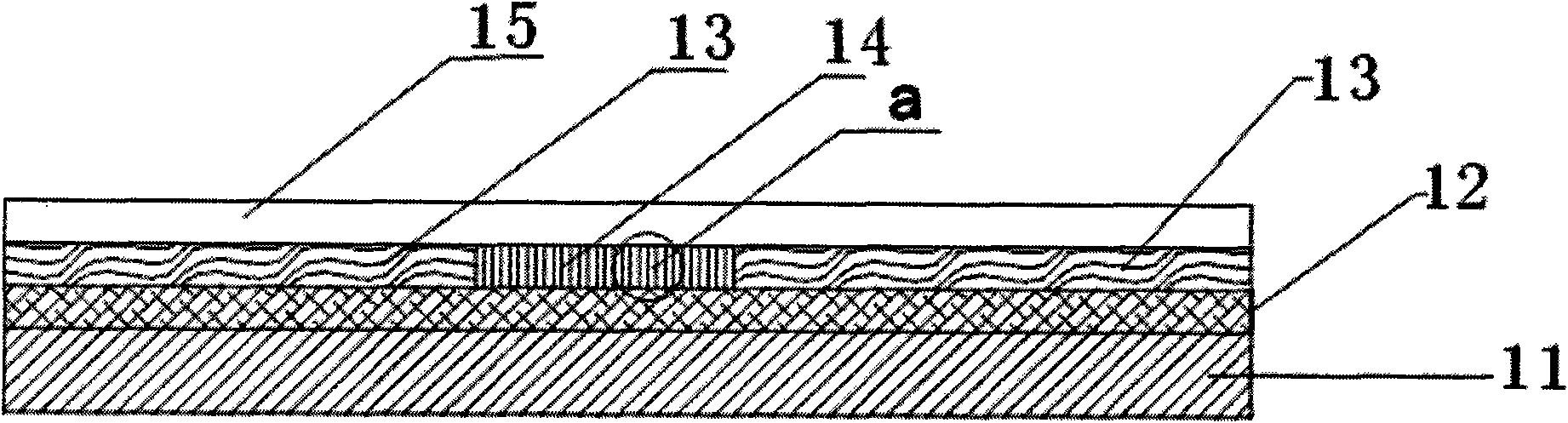

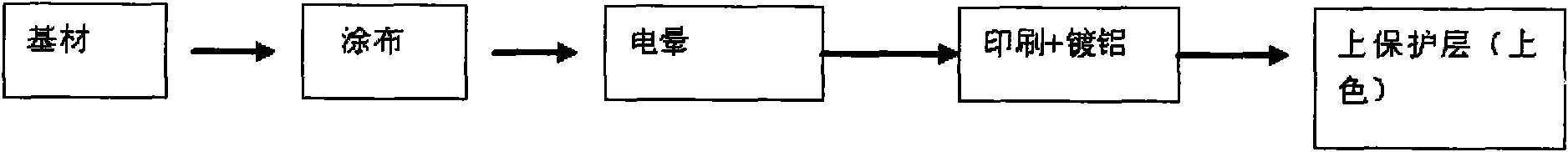

[0038] In this embodiment, a kind of flexographic printing vacuum aluminum plating product with anti-counterfeiting mark is referenced figure 1 , 4 , including the base material 11 laid on the bottom layer and the coating layer 12, the aluminum plating layer 13 and the protective layer 15 covered thereon in turn, and the plating layer forming the anti-counterfeiting mark pattern 14 is laid between the coating layer 12 and the protective layer 15. Aluminum layer 13; base material can be the film of different kinds, different thickness also can be the paper or cardboard of different quantitative; The pattern of metal texture formed by the distribution and arrangement has high precision and clear layers, distinct dark and bright, lifelike and thick.

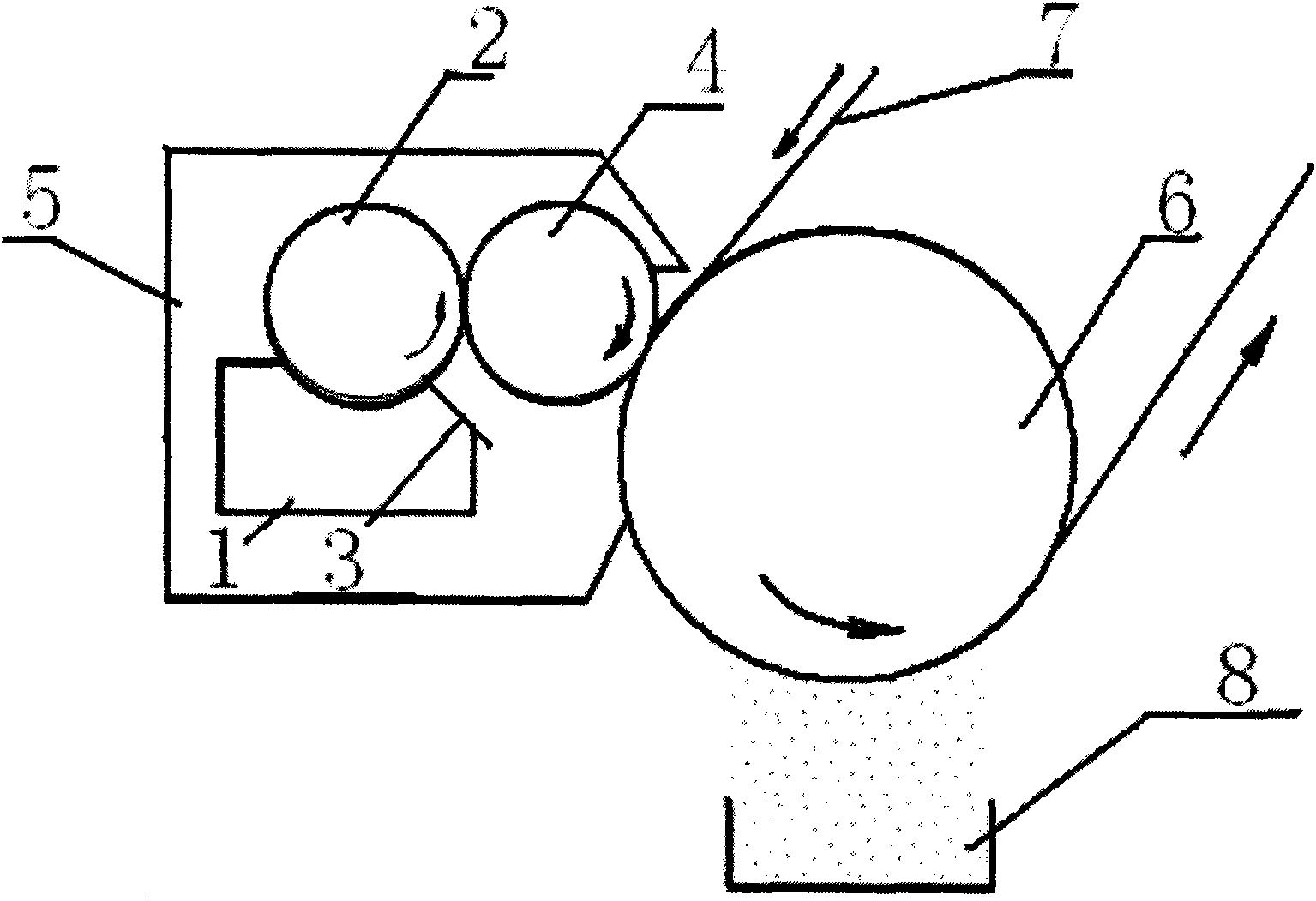

[0039] Vacuum aluminum plating system reference for preparing the above-mentioned flexo printing vacuum aluminum plating products with anti-counterfeiting marks image 3 , a set of flexographic printing mechanism is installed in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com