Construction method of multi-drill high-pressure jet agitation based anti-seepage reinforcing equipment

A technology of high-pressure injection and construction method, applied in drilling equipment and methods, drilling equipment, infrastructure engineering and other directions, can solve the problems of large wear and tear of construction equipment, high labor intensity of workers, low construction quality, etc. The effect of increasing cement usage and increasing drilling depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

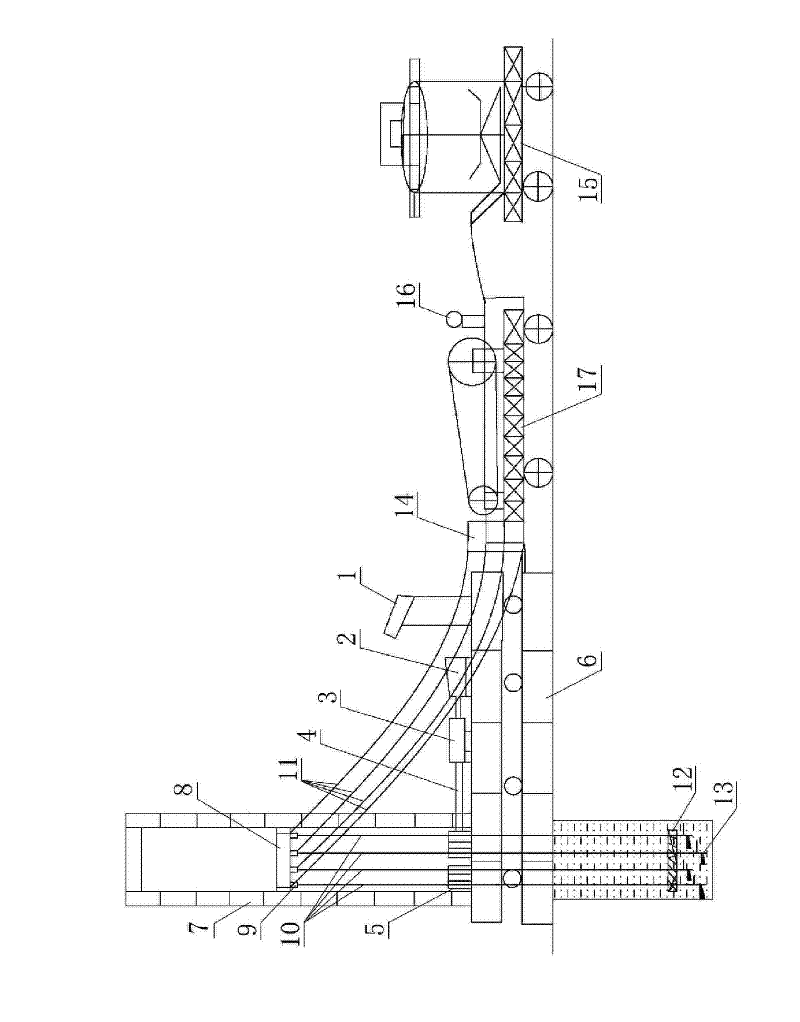

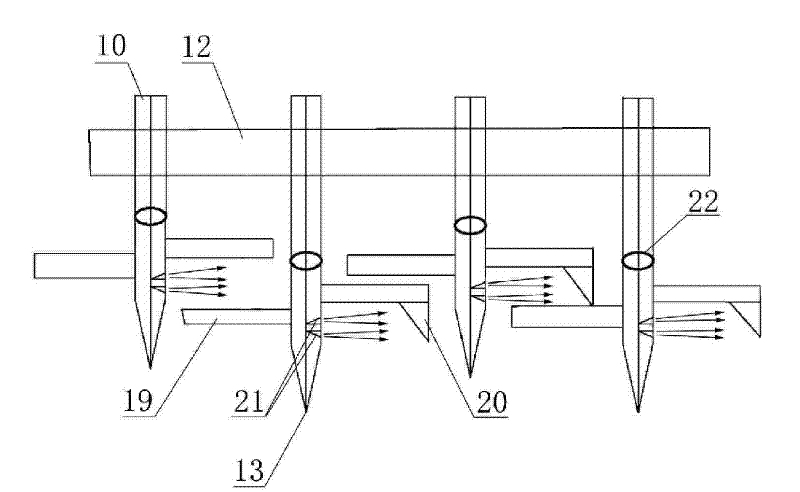

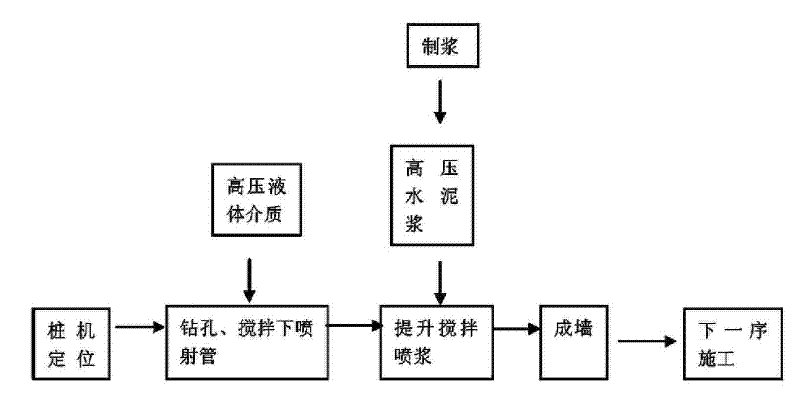

[0033] Examples see figure 1 , figure 2 As shown, this multi-drill high-pressure jet mixing foundation anti-seepage reinforcement equipment includes a drilling rig, a mixer 15 and a grouting system connected between the two. 1. The power mechanism 2, the speed change mechanism 3, the transmission mechanism 4 and the turntable 5. The turntable is located at the bottom of the drill frame 7 and is sequentially connected with the transmission mechanism 4, the speed change mechanism 3 and the power mechanism 2. There are three to five drill pipes 10, Its upper end is connected with drill frame crossbeam through hoisting mechanism 8, and its middle part is connected with the rotating disk 5 that drives drill rod to rotate, and its lower part is connected together by drill rod fixing device 12 between drill rod and drill rod, and the lower end of drill rod 10 is High-pressure drill bit 13, the side wall of the drill pipe above the drill bit is provided with an injection nozzle 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com