Machinery for installing light partition battens

A lightweight partition board and installation machine technology, applied in construction, building structure, processing of building materials, etc., can solve the problem of affecting the overall strength and flatness of the wall, difficult to meet on-site construction, low safety factor, etc. problems, to achieve the effect of ensuring construction safety and installation quality, improving construction efficiency, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

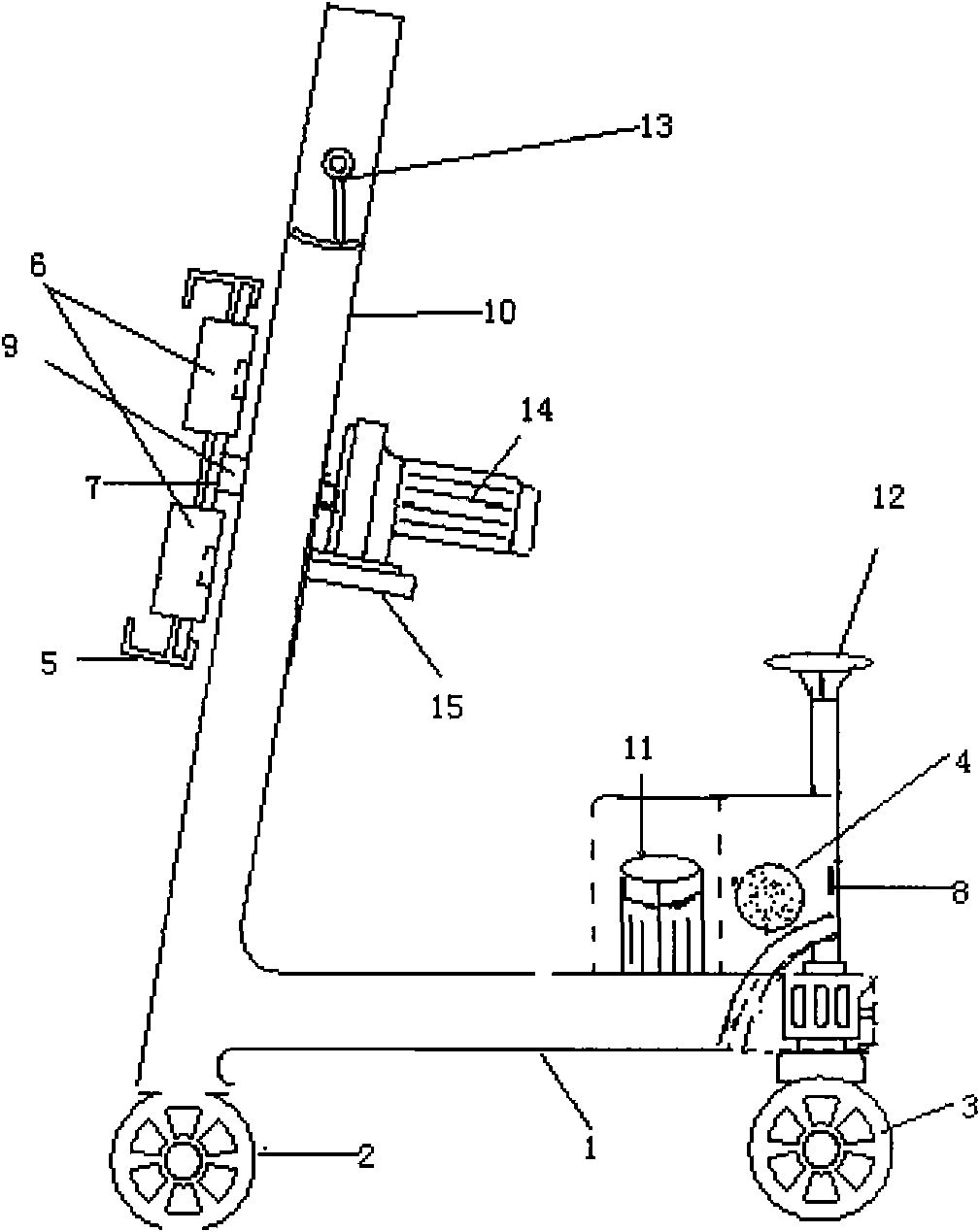

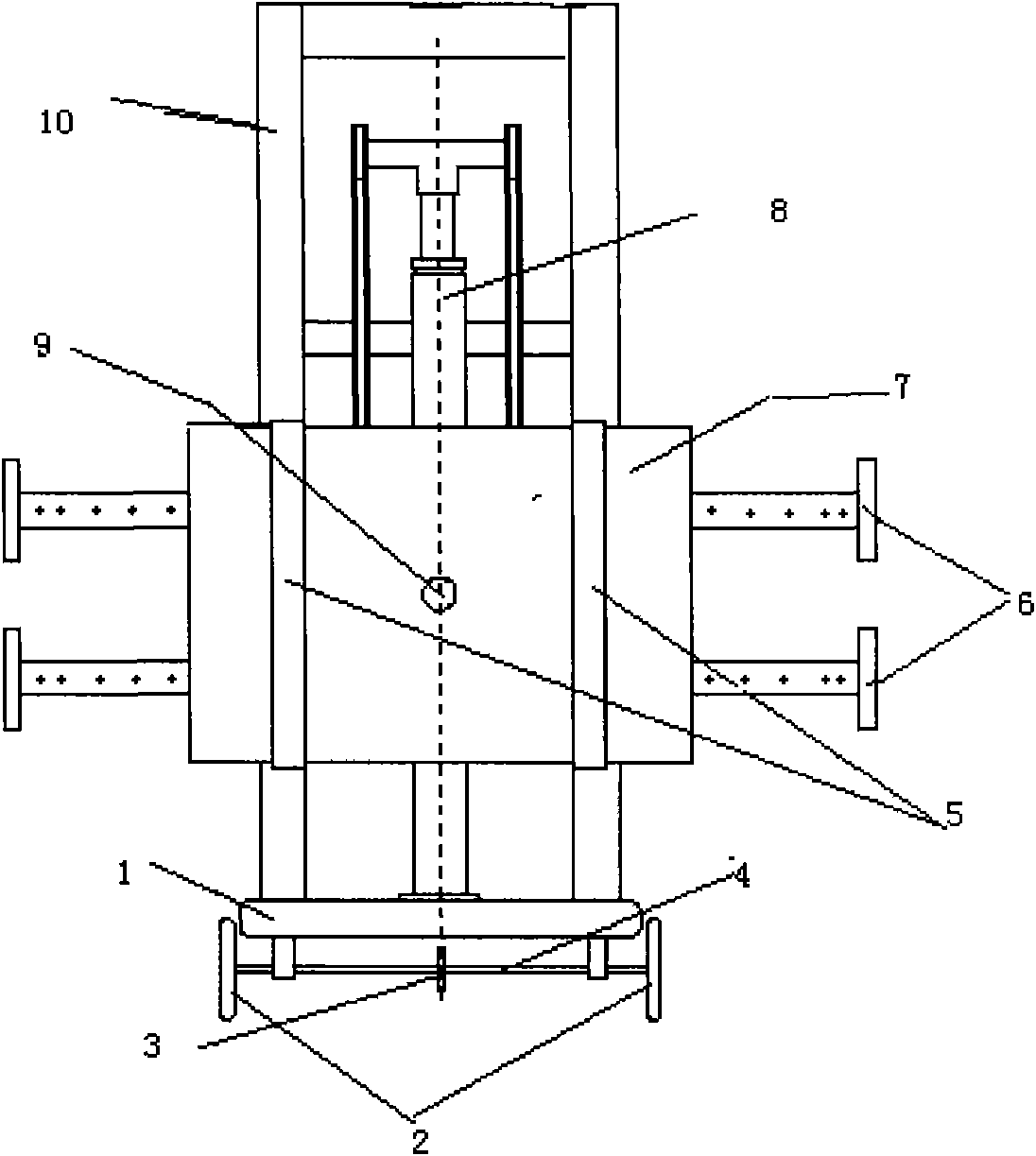

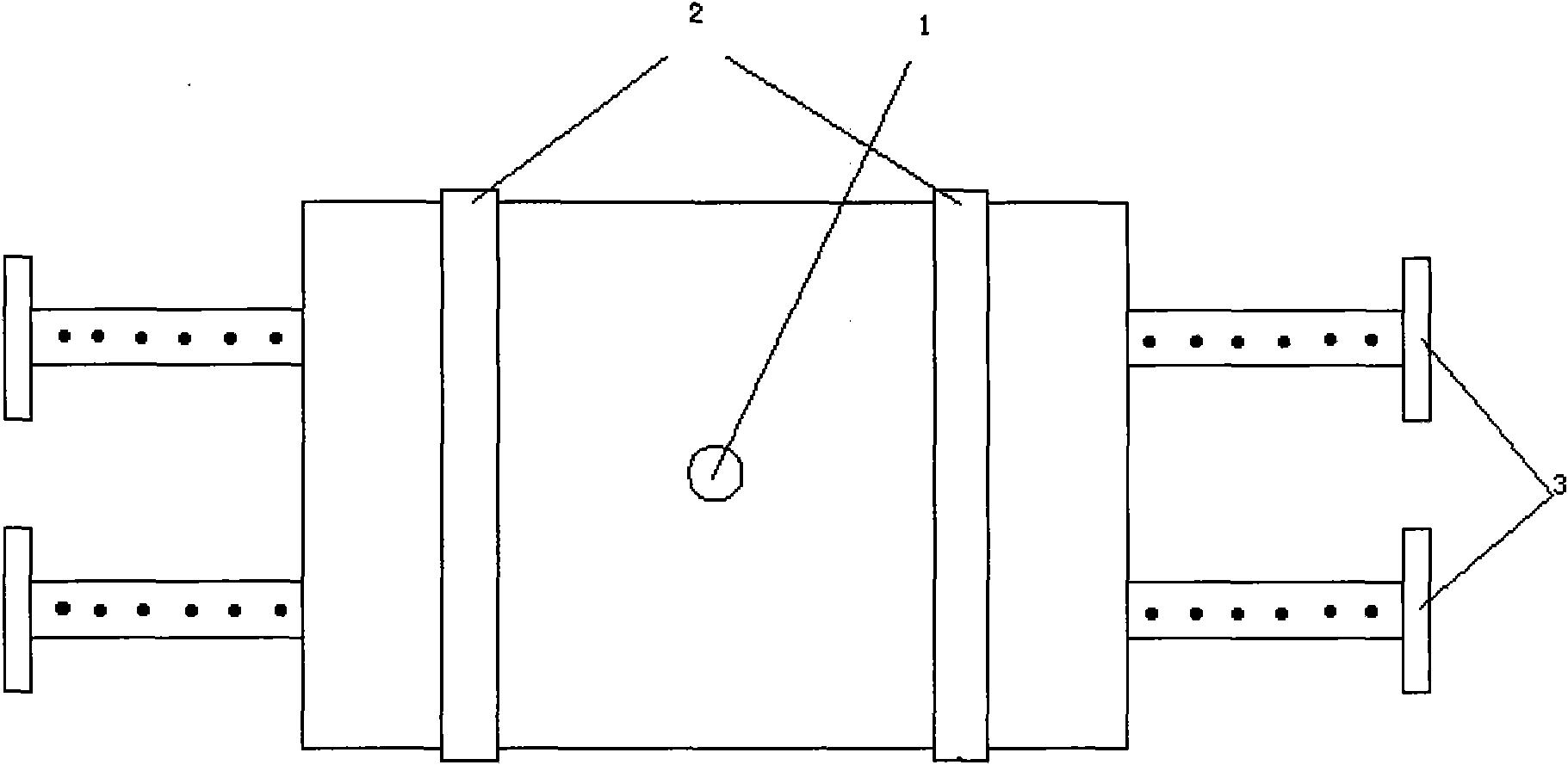

[0021] Embodiment: As shown in the figure, before construction, first assemble the installation machine. Open and fix the door frame 1.10 and the base 1.1, connect the sleeve 1.9 on the supporting device 1.7 with the shaft at the front end of the wall panel angle adjustment device 1.14, and fix the horizontal pocket board 4 and the longitudinal pocket board 6 on the supporting device ( Such as image 3 ), install and debug the walking drive device 1.11 and the hydraulic power unit 1.4, if an external power supply is used, connect the external power supply to the power interface 1.8, check the control handle 1.12, and do all the preparations before installation.

[0022] After placing the lightweight partition board horizontally and sideways on the pallet at the bottom of the pallet device and fixing it securely, adjust the mechanical angle of the rear traveling wheel according to the construction site conditions, and drive the front traveling wheel 1.2 to move the machine to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com