Secondary reflection light gathering and heat collecting device with compound curved surface

A secondary reflection and compound curved surface technology, applied in the field of solar energy concentration and heat collection, can solve the problems of lack of design freedom for a single paraboloid, increase cost and floor space, reduce concentration ratio, etc., to achieve increased degrees of freedom , Increase the concentration ratio, the effect of increasing the concentration ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

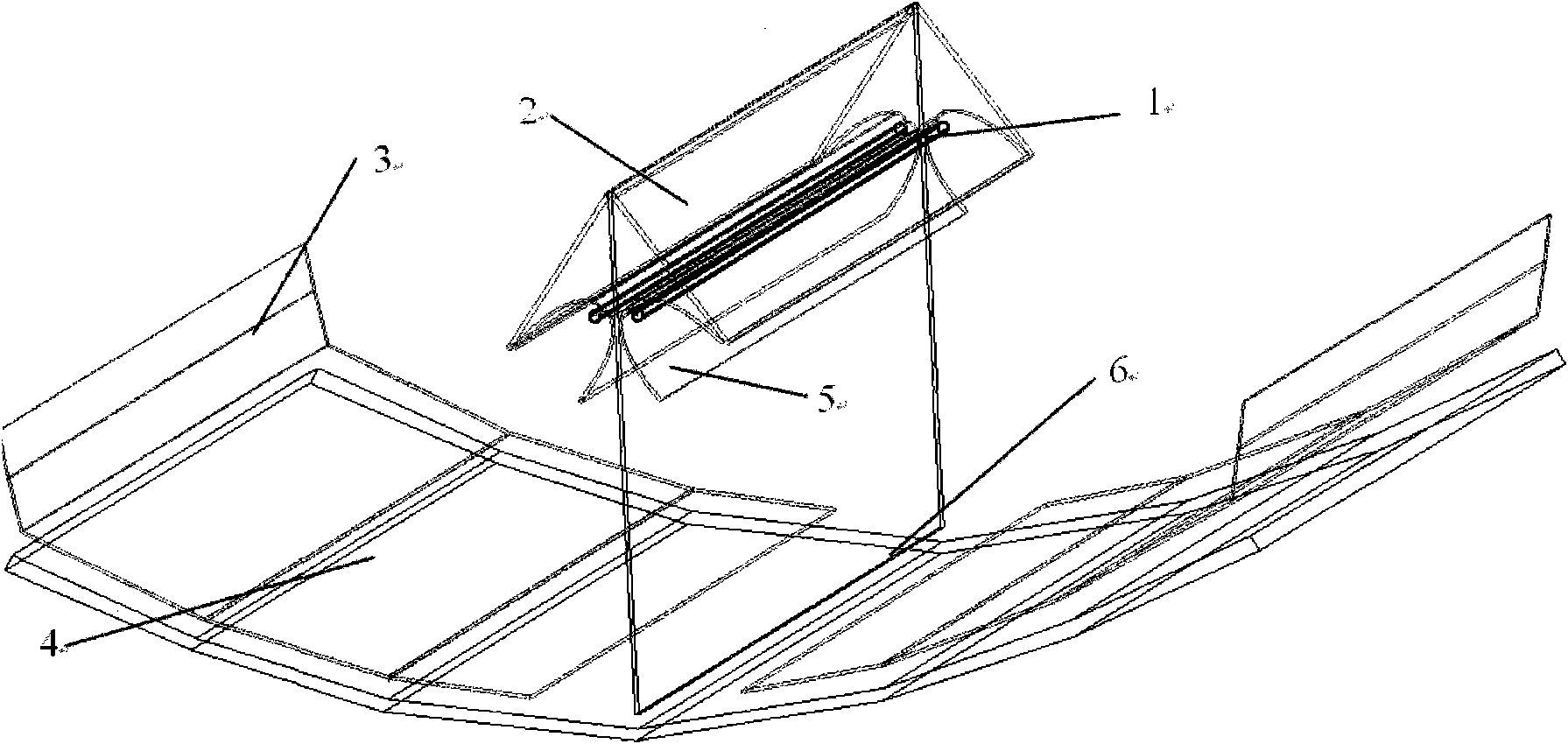

[0031] The trough solar concentrator makes sunlight incident on the receiving surface along the axial direction through the tracking system, and the light falling on the compound arc primary reflector (4) is reflected and converged into the compound parabolic secondary reflector (5) , the angle between the light entering (5) and its axis should be smaller than its maximum acceptance angle during design, and according to the characteristics of the compound parabolic concentrator, all the light will reach the heat collecting tube (1) at last like this. All reflectors and heat collecting tubes are fixed by the support frame (6). The light diagram of the double-pipe reflector with three arcs as the primary reflector (2) and the compound parabolic condenser with an acceptance angle of 30°C as the secondary reflector (3) is as follows figure 2 shown.

Embodiment 2

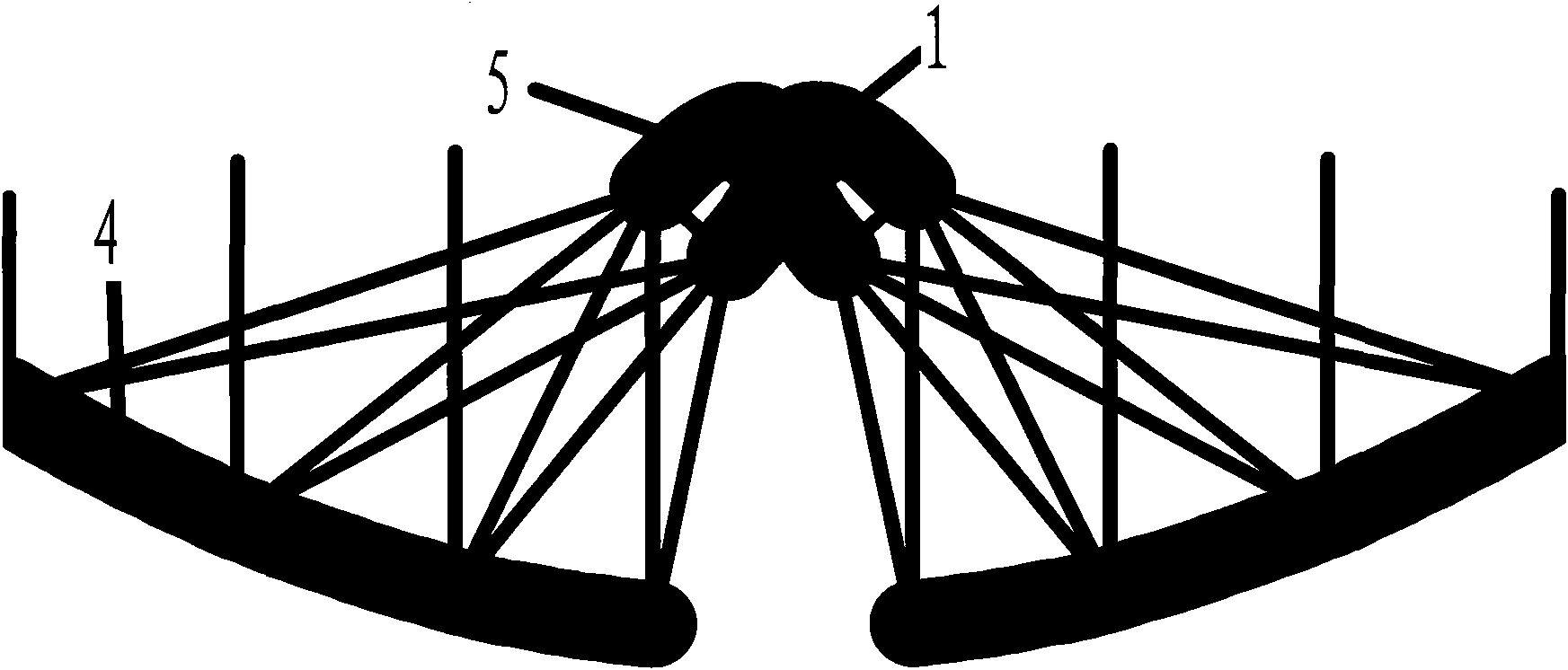

[0033] The trough solar concentrator makes sunlight incident on the receiving surface along the axial direction through the tracking system, and the light falling on the compound arc primary reflector (4) is reflected and converged into the compound parabolic secondary reflector (5) , the light reaches the heat collecting tube (1) directly or through reflection. All reflectors and heat collecting tubes are fixed by the support frame (6). Two arcs are used as the primary reflector (2). In order to increase the concentration ratio, or to use a plane bracket, the design of the composite circular arc primary reflector (4) can be improved. The design diagram is as follows image 3 , its disadvantage is that there is some light loss in the lighting range.

Embodiment 3

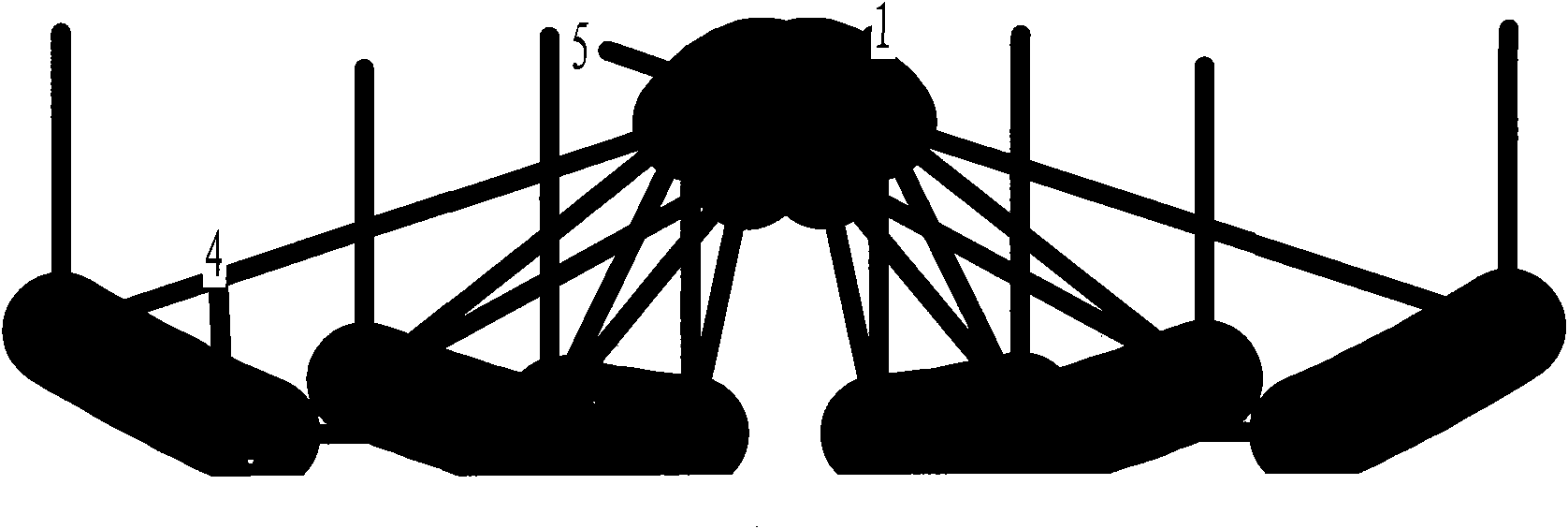

[0035] The trough solar concentrator makes sunlight incident on the receiving surface along the axial direction through the tracking system, and the light falling on the compound arc primary reflector (4) is reflected and converged into the compound parabolic secondary reflector (5) , the light reaches the heat collecting tube (1) directly or through reflection. All reflectors and heat collecting tubes are fixed by the support frame (6). Two arcs are used as the primary reflector (2). In order to save manufacturing cost, the compound circular arc primary reflector (4) can only use one size of arc, but the position of each arc needs to be adjusted. Design drawing such as Figure 4 , the disadvantage is that the concentration ratio is relatively small compared with the design of arcs connected together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com