Die casting quality on-line detection method

A detection method and die-casting technology, applied in the direction of testing metals, material inspection products, etc., can solve the problems of large human interference, low efficiency, and inability to do quantitative analysis, so as to improve the hit rate of defective products, improve production efficiency and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

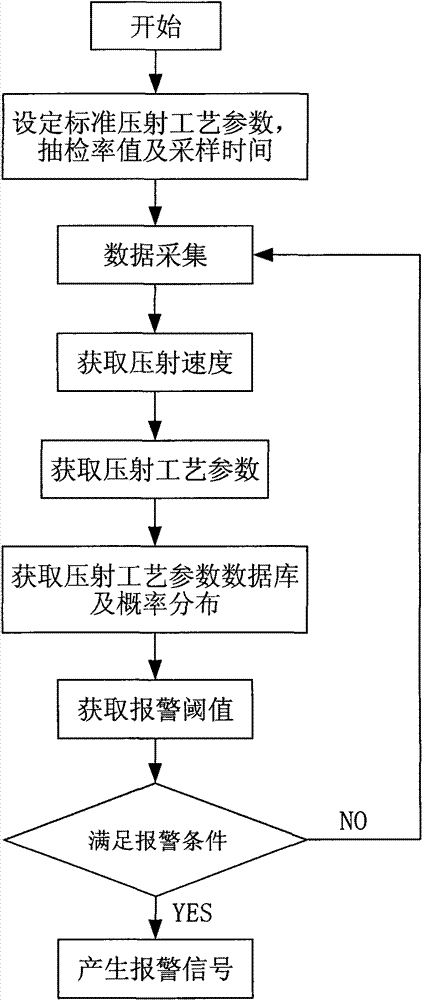

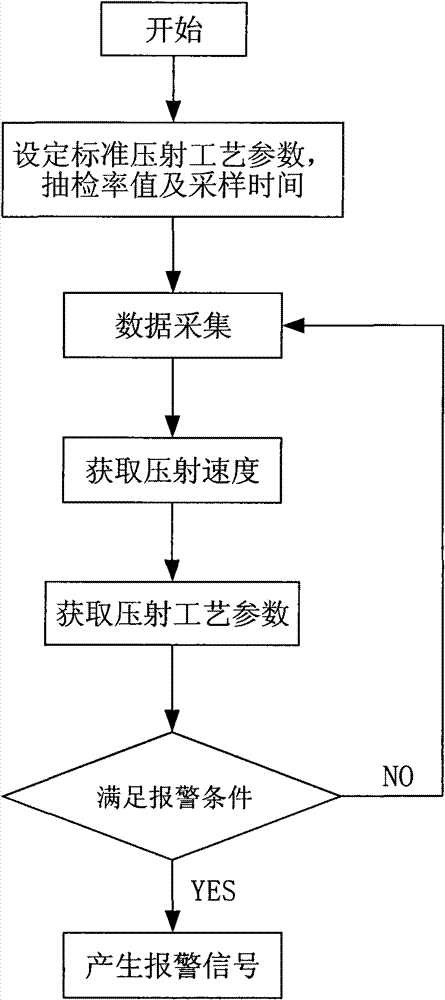

Method used

Image

Examples

Embodiment Construction

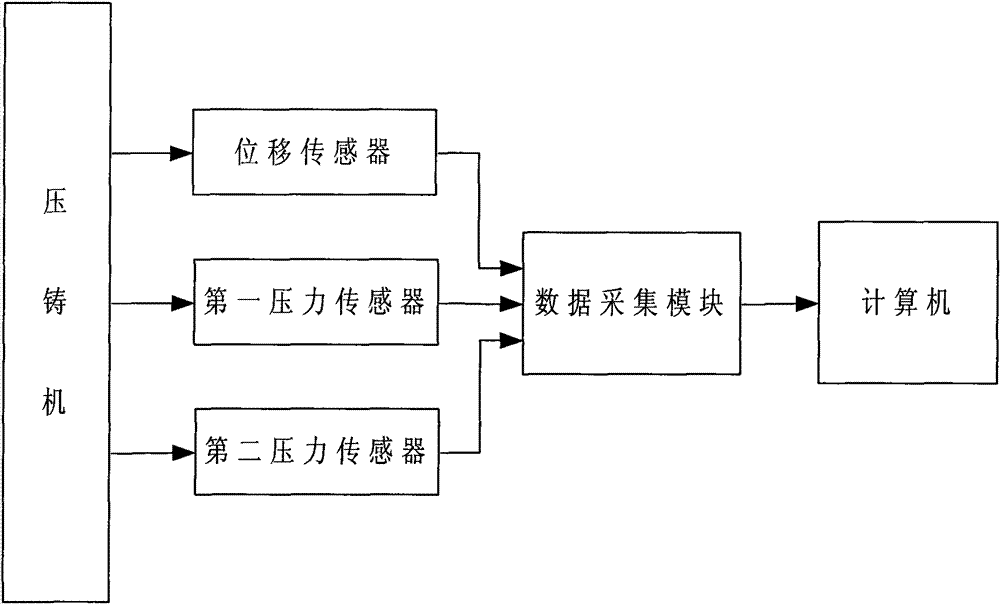

[0032] image 3 A schematic structural block diagram of a detection device used in the detection method of the present invention is shown. The device includes a displacement sensor, a first pressure sensor, a second pressure sensor, a data acquisition module and a computer. Wherein, the displacement sensor is connected with the hammer head of the die-casting machine to detect the position of the hammer head; the displacement sensor is also connected with the data acquisition module. The first pressure sensor is connected with the rod chamber of the injection cylinder of the die-casting machine for detecting the pressure of the rod chamber, and the first pressure sensor is also connected with the data acquisition module. The second pressure sensor is connected with the rodless chamber of the injection cylinder of the die-casting machine to detect the pressure of the rodless chamber, and the second pressure sensor is also connected with the data acquisition module. The data ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com