Method for preparing transparent light mask

A photomask and transparent technology, applied in the field of exposure, can solve the problems of increasing the production cost of transparent photomasks, affecting the exposure quality, etc., and achieve the effect of simplifying the alignment and exposure process and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preparation method of the transparent photomask provided by the embodiment of the technical solution will be further described in detail below with reference to the drawings and examples.

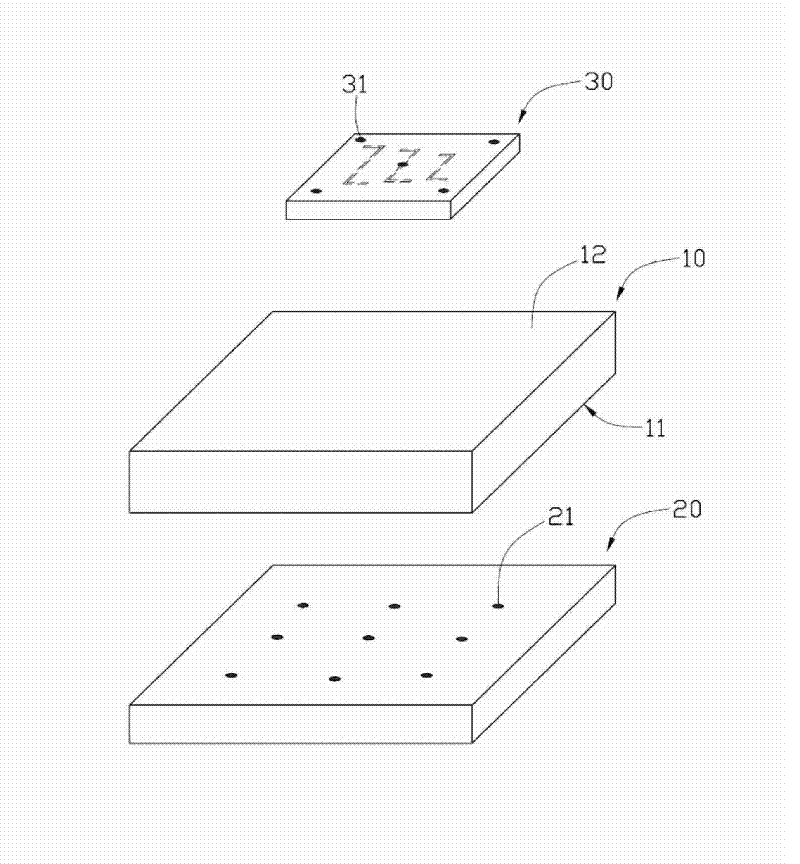

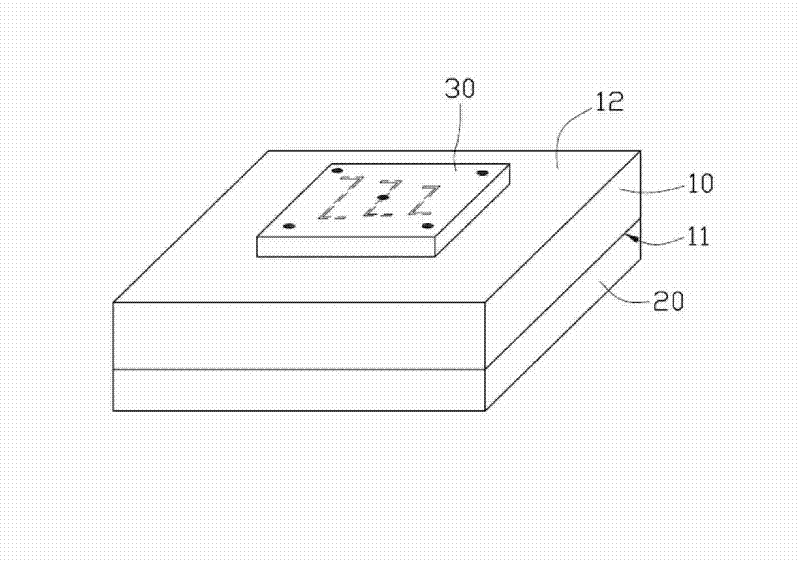

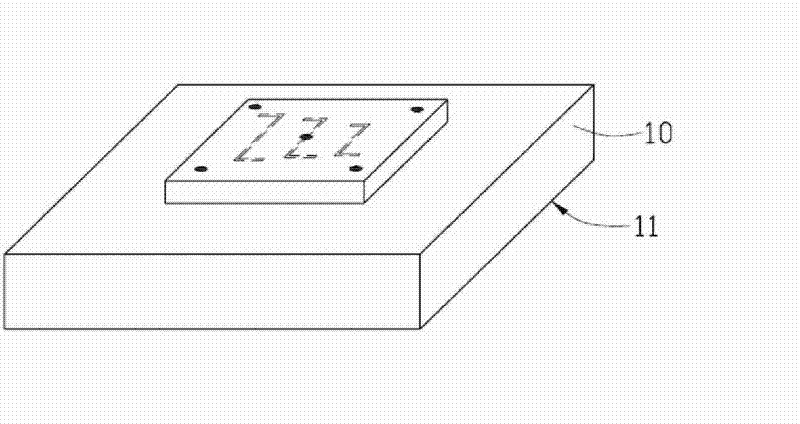

[0015] Please also refer to Figure 1 to Figure 4 , the preparation method of the transparent photomask provided by the embodiment of the technical solution, which includes the following steps:

[0016] In the first step, a transparent substrate 10 , a reference plate 20 and a patterned photomask 30 are provided.

[0017] see figure 1 , the transparent substrate 10 can be made of glass, resin or other transparent materials, and has a first surface 11 and a second surface 12 opposite to each other. The transparent substrate 10 may have a built-in vacuum adsorption device for adsorbing and fixing the patterned photomask 30 on the transparent substrate 10 , or may be a substrate provided with positioning grooves in the prior art. In this embodiment, the transparent substrate 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com