Chip package

A chip packaging and chip technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of influence, tape is not suitable for mass production, and the reliability of chip packaging is difficult to control the thickness of liquid adhesive. Good for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

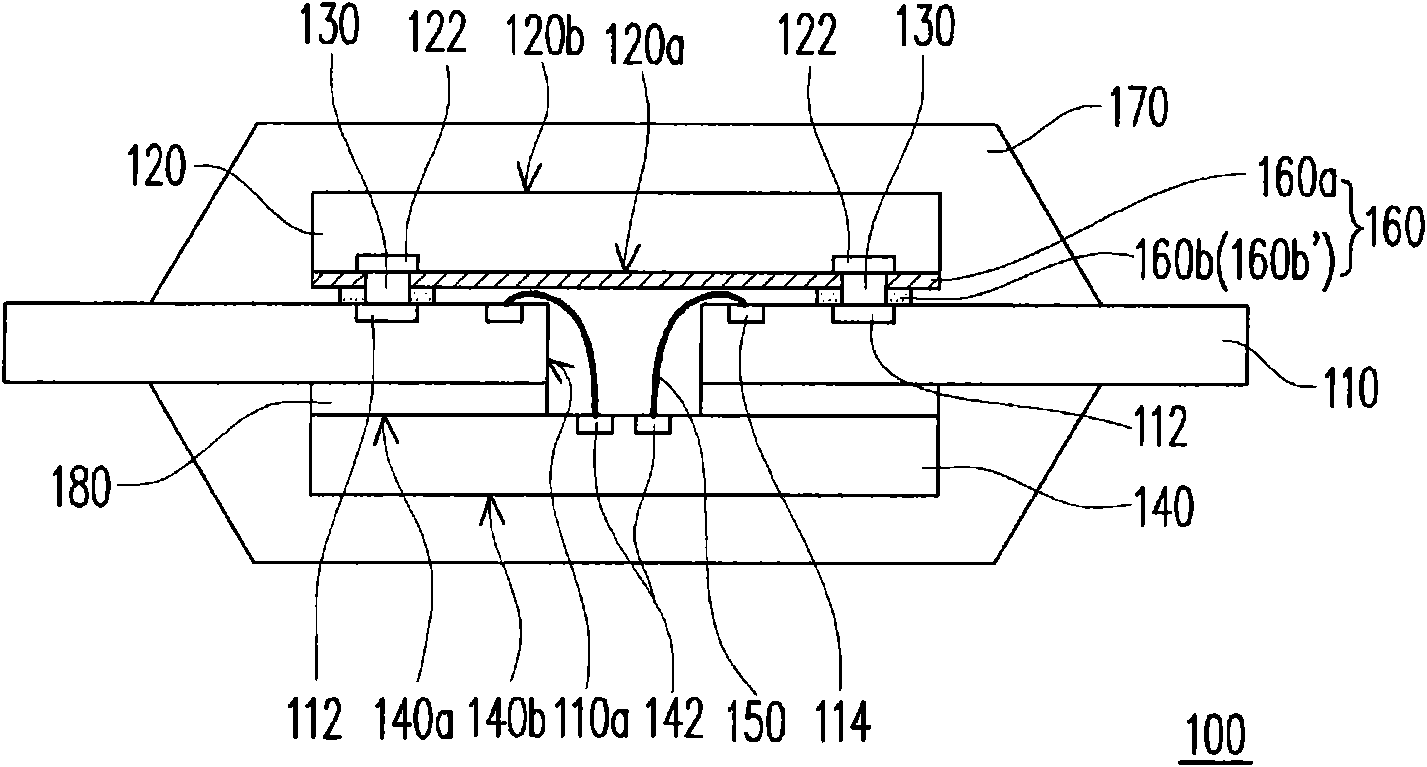

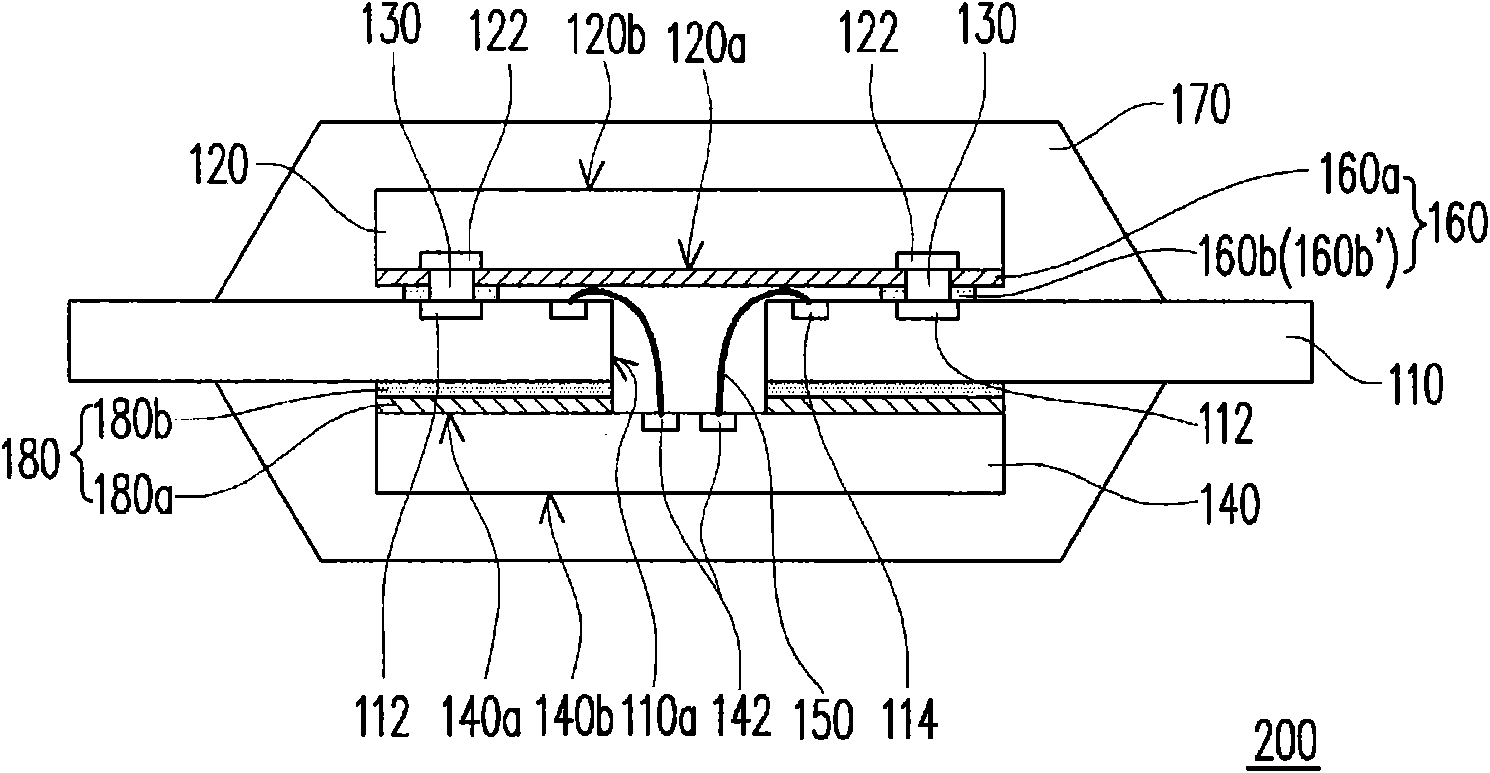

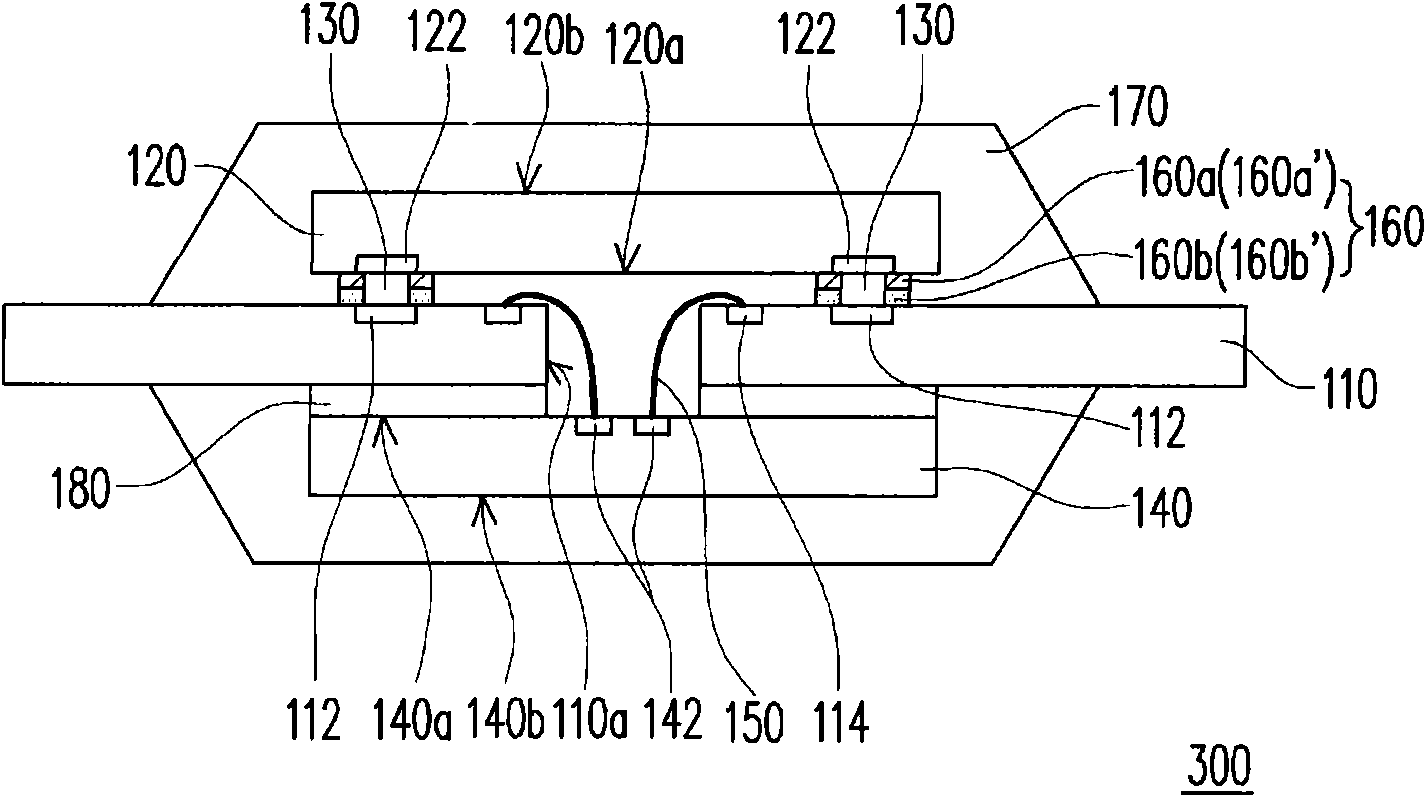

[0051] figure 1 It is a schematic cross-sectional view of a chip package according to the first embodiment of the present invention. Please refer to figure 1 , in this embodiment, the chip package 100 includes a carrier 110 having an opening 110a, a first chip 120, a plurality of bumps 130, a second chip 140, a plurality of bonding wires 150, a first adhesive layer 160 and an encapsulant 170 . The first chip 120 has a first active surface 120a and a first back surface 120b opposite to the first active surface 120a. The first chip 120 and the second chip 140 are disposed on the carrier 110 and located on two sides of the carrier 110 . The bumps 130 are disposed between the carrier 110 and the first active surface 120 a of the first chip 120 , and the first chip 120 is electrically connected to the carrier 110 through the bumps 130 . These bonding wires 150 are electrically connected to the carrier 110 and the second chip 140 , wherein each bonding wire 150 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com