Environment-friendly automatic feeding system of three-roller grinder

A three-roll mill, an environmentally friendly technology, applied in grain processing and other directions, can solve the problems of long waiting time for the grinding slurry to be lifted, high labor intensity of operators, low grinding efficiency, etc. The effect of improving production efficiency and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

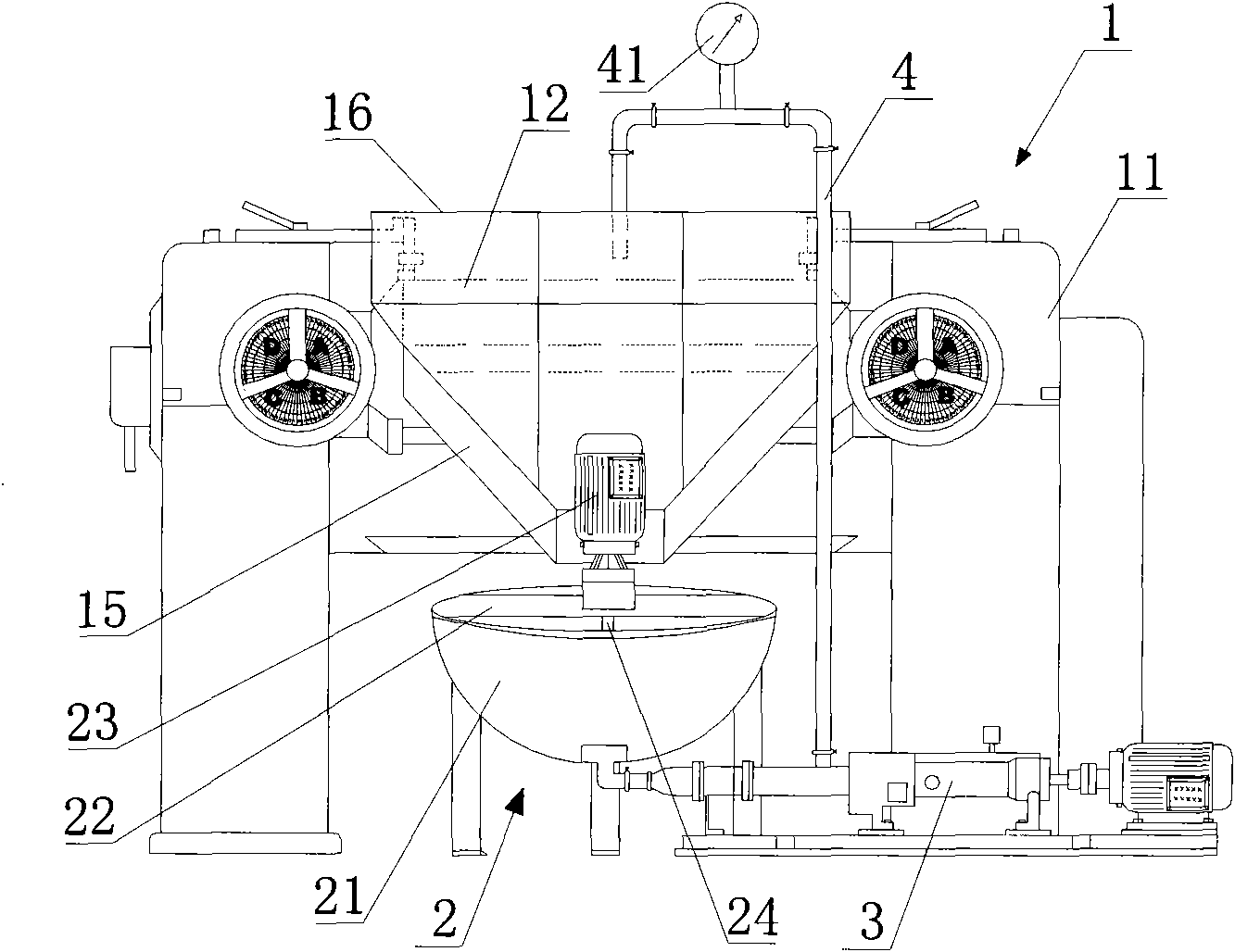

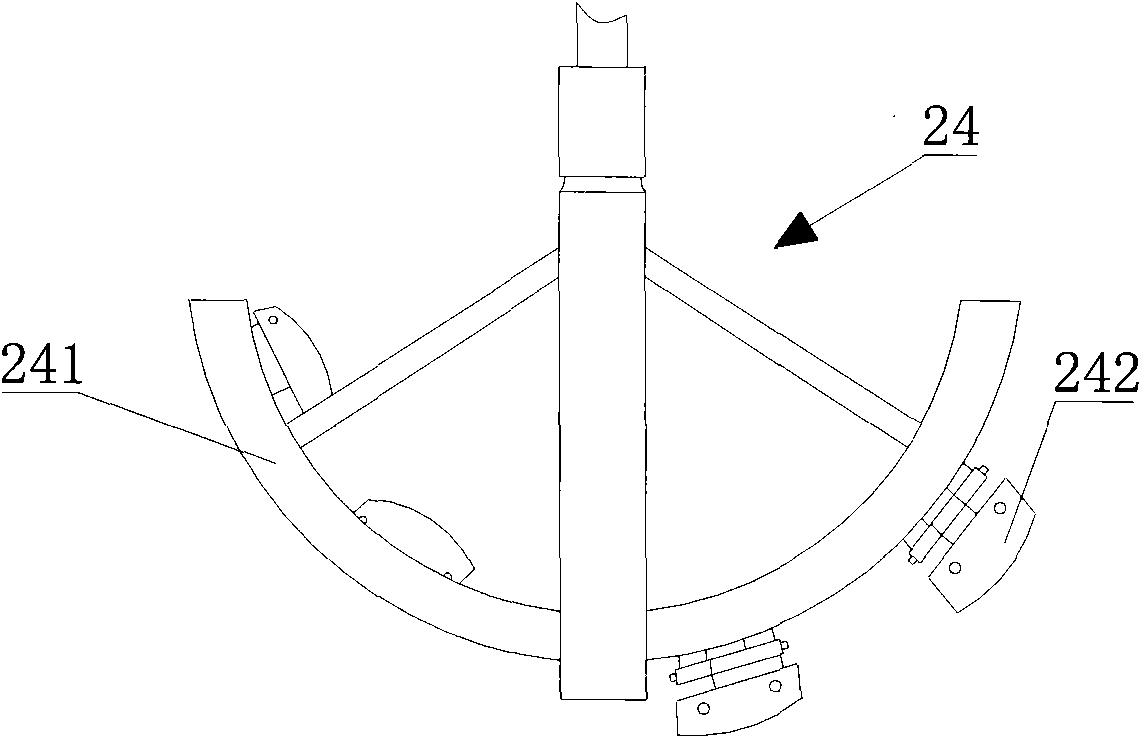

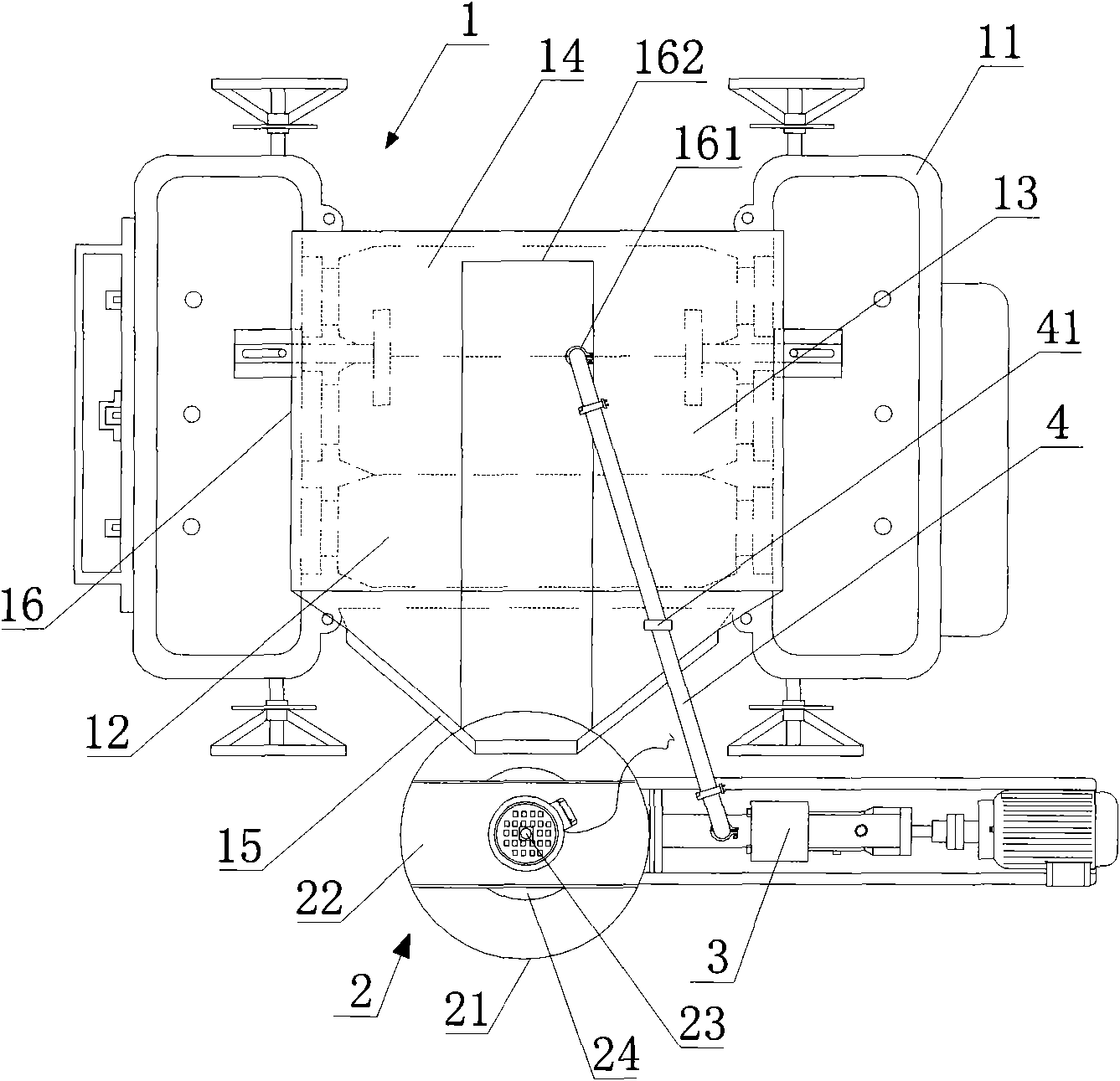

[0023] see Figure 1-3 Shown, a kind of three-roll grinder automatic environmental protection feeding system, it comprises three-roll grinder 1, and this three-roll grinder 1 comprises iron frame 11, the front roller that is installed on the iron frame 11 12. The middle roller 13, the rear roller 14, and the scraper discharge hopper 15 installed in front of the front roller 12; a slurry turnover pot 2 with a stirring device is located below the scraper discharge hopper 15 of the three-roll grinder 1, and a The feed end of the screw pump 3 communicates with the bottom of the slurry turnover pot 2 through pipe fittings, and the discharge end of the screw pump 3 is connected with a pipe fitting group 4, and the other port of the pipe fitting group 4 is set on the middle roller 13 and the rear roller 14 at the top of the room.

[0024] The front roller 12, the middle roller 13, the rear roller 14 of the three-roll mill 1 and the top of the scraper discharge hopper 15 installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com