Thick steel board

A technology of thick steel plate and display plate, which is applied in the field of thick steel plate and can solve the problems that the characteristics cannot be fully satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0205] Experimental example 1 (experimental example of the steel plate of the first invention)

[0206] By the usual smelting method, various molten steels with the chemical composition shown in the following Tables 1 and 2 are smelted, and after cooling the molten steel to form a slab, hot rolling and rolling are carried out under the conditions shown in the following Tables 3 and 4. After cooling, various steel plates (thickness: 60mm) were obtained. In addition, in Table 1 below, REM is added in the form of a mischmetal containing about 50% of La and about 25% of Ce. In addition, "-" in the following Tables 1 and 2 indicates that no element was added.

[0207]

[0208]

[0209] 【table 3】

[0210]

[0211] 【Table 4】

[0212]

[0213] For each of the obtained steel sheets, the base metal structure (hardness of pseudo-polygonal ferrite, average area ratio), solid solution B amount, mechanical properties (tensile properties of the base metal, impact properties of...

experiment example 2

[0234] Experimental example 2 (experimental example of the steel plate of the second invention)

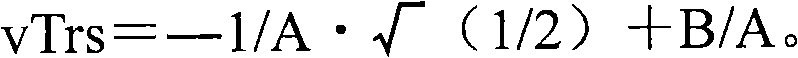

[0235] By the usual smelting method, smelting various molten steels with the chemical composition shown in the following Tables 7 and 8, after cooling the molten steel to form a slab, hot rolling and rolling are carried out under the conditions shown in the following Tables 9 and 10. After cooling, various steel plates (thickness: 60mm) were obtained. In addition, in the following Tables 7 and 8, REM is added in the form of misch metal containing about 50% of La and about 25% of Ce. In addition, "-" in the following Tables 7 and 8 indicates that no element was added. Also in Tables 7 and 8, the value of [1000×([Ca]+2×[S]+3×[O])] (hereinafter referred to as “A” value) is also displayed at the same time.

[0236]

[0237]

[0238]

[0239]

[0240] For each of the obtained steel plates, the hardness of the pseudo-polygonal ferrite, the average area ratio, the amount of...

experiment example 3

[0250] Experimental example 3 (experimental example of the steel plate of the third invention)

[0251] By the usual smelting method, various molten steels having the chemical composition shown in the following Tables 13 and 14 are smelted, and after cooling the molten steel to form a slab, hot rolling and rolling are carried out under the conditions shown in the following Tables 15 and 16. After cooling, various steel plates (thickness: 60 mm) were obtained. In addition, in the following Table 13, REM is added in the form of misch metal containing about 50% of La and about 25% of Ce. In addition, "-" in the following Tables 13 and 14 indicates that no element was added.

[0252]

[0253]

[0254]

[0255]

[0256]For each of the obtained steel plates, the hardness of the pseudo-polygonal ferrite, the average area ratio, the amount of solid solution B, and the mechanical properties (tensile properties of the base material, impact properties of the base material) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com