Drive feeding mechanism of dual-linear motor

A technology of driving feed and double-line, which is applied in the direction of motor generator testing, etc., and can solve problems such as mechanical structure interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

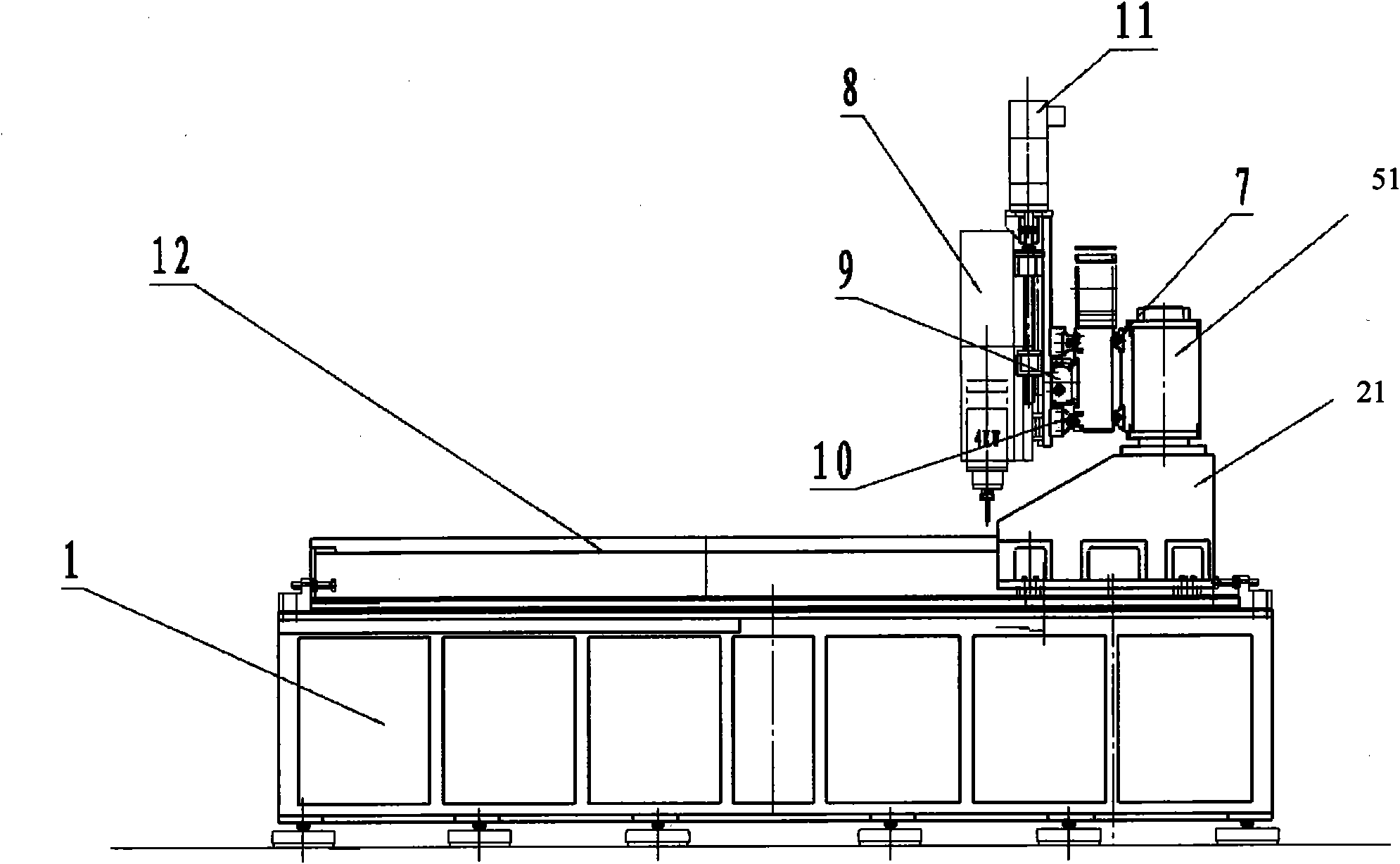

[0016] see Figure 1-4 , the invention discloses a double linear motor high-speed drive feed mechanism with a double articulated gantry frame combined structure. As shown in the figure: it includes basic bed 1, two sliding seats 21, 22, X direction linear motor 3, X direction linear guide rail 4, hinged beam seat plate 51, 52, beam 6, linear displacement guide rail 7, Z direction Electric spindle 8, Y direction linear motor 9, Y direction linear guide rail 10, Z direction servo motor 11, main workbench 12, auxiliary workbench 13.

[0017] The middle part of the basic bed 1 is the main workbench 12, and a set of two linear guide rails 4 in the X direction are respectively installed on both sides of the main workbench, and the secondary coil of the linear motor is arranged between the two linear guide rails. The primary coil of the linear motor is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com