Drying device for heating by combining medium waves, short waves and spraying

A technology of heating device and drying device, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., which can solve the problems of low work efficiency, secondary pollution of the paint surface, and dust in the furnace, and achieve operational efficiency. Convenience, efficiency improvement, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

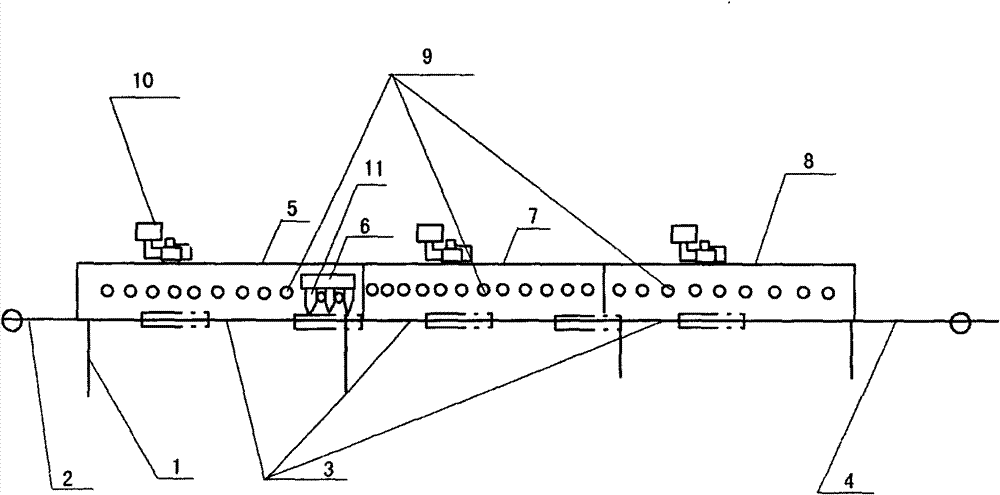

[0008] in figure 1 Among them, the present invention is a drying device combining medium wave, short wave and jet heating. It includes a control part and a body 1. The body 1 includes a transmission belt, the transmission belt is a Teflon mesh, and the control part is set as a microcomputer PLC The control system, the conveyor belt includes the following parts in turn: the feeding section 2, the heating section 3 and the discharging section 4. The bottom of the feeding section, the heating section and the discharging section are equipped with moving wheels, and the heating section 3 is provided with a heating drying section. Drying device, the top of the heating and drying device is equipped with a pressure fan 10, the heating and drying device is equipped with a K-type temperature measuring thermocouple device, and the temperature sensing test sockets of the temperature measuring thermocouple device are distributed in the IR1 medium wave heating device 5. Air knife Jet heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com