Self-compensating rotary angle device for dicing saw

A corner device and self-compensation technology, which is applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of easy wear, large vibration, low corner accuracy and processing accuracy of dicing machines, and achieve the elimination of empty distance and performance Safe and reliable, solve the effect of low corner accuracy and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

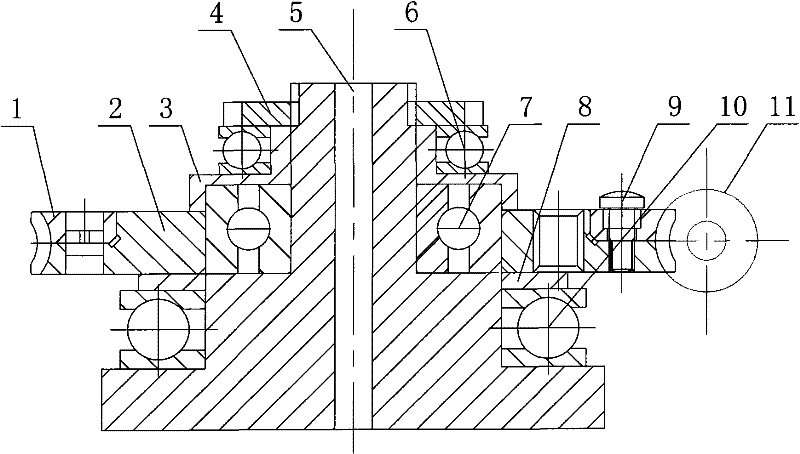

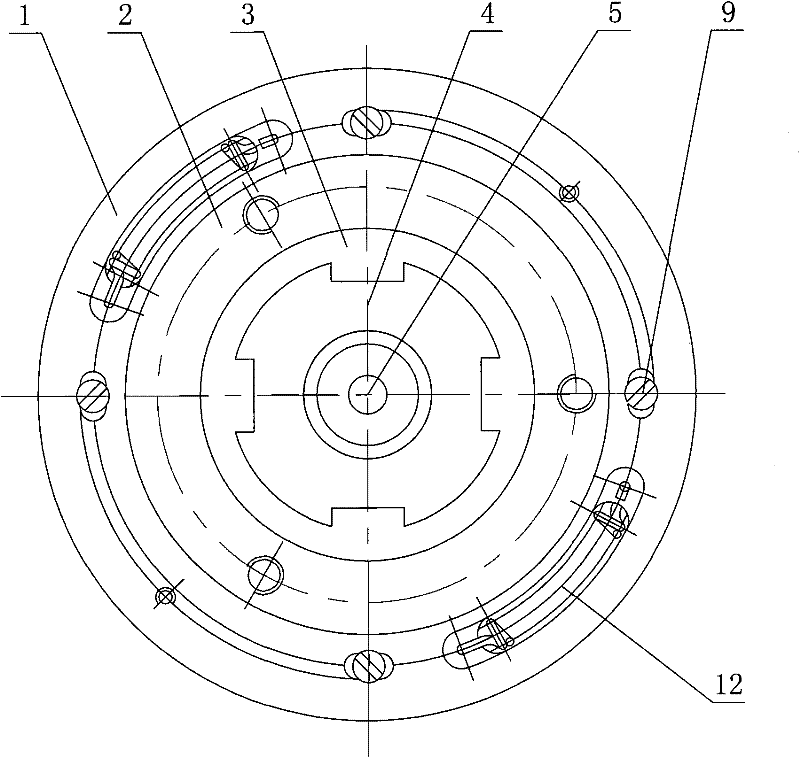

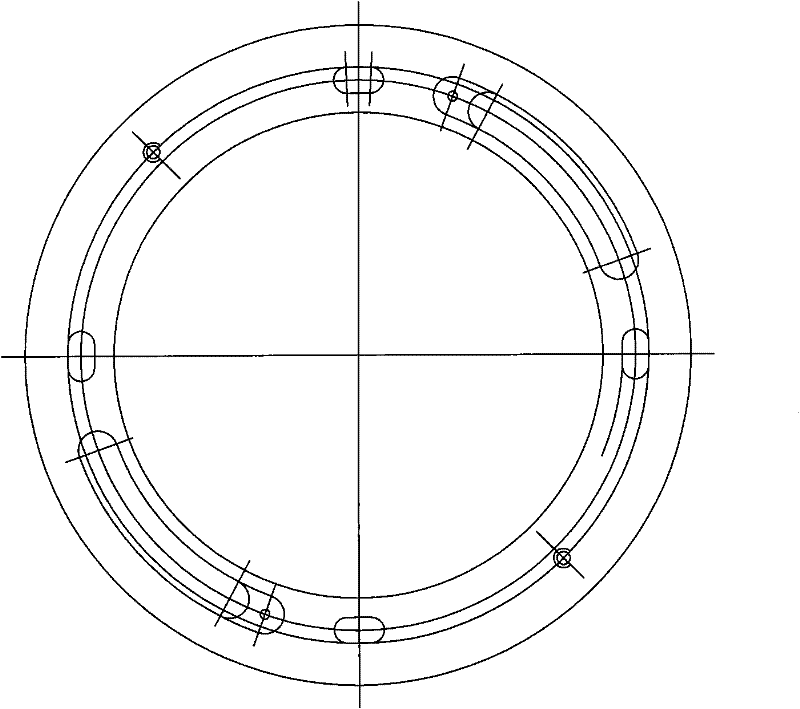

[0015] according to Figure 1-2 The present invention is described in detail. The present invention includes an assembled worm gear assembled on the central shaft 5, a worm 11 meshing with the assembled worm gear, a bearing, a locking nut 4, and the like. Among them: the assembled worm gear is composed of two parts: the upper worm gear 1 and the lower worm gear 2, the upper worm gear 1 is set on the boss of the lower worm gear 2, and the peripheral surfaces of the upper and lower worm gears 1 and 2 are complete and respectively constitute the upper and lower parts of the split worm gear. Tooth surface, the upper and lower tooth surfaces are in close contact with the left and right tooth surfaces of the same tooth slot of the worm 11. In order to ensure the self-compensation of the assembled worm gear and eliminate the idle travel of the worm gear when it reverses, it is especially embedded in the assembled worm gear. There are tension springs 12, such as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com