Manufacturing method of solid-state battery

A manufacturing method and solid-state battery technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing, and can solve the problems of uneven lamination, high interface impedance and low energy density, and extrusion of battery materials. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

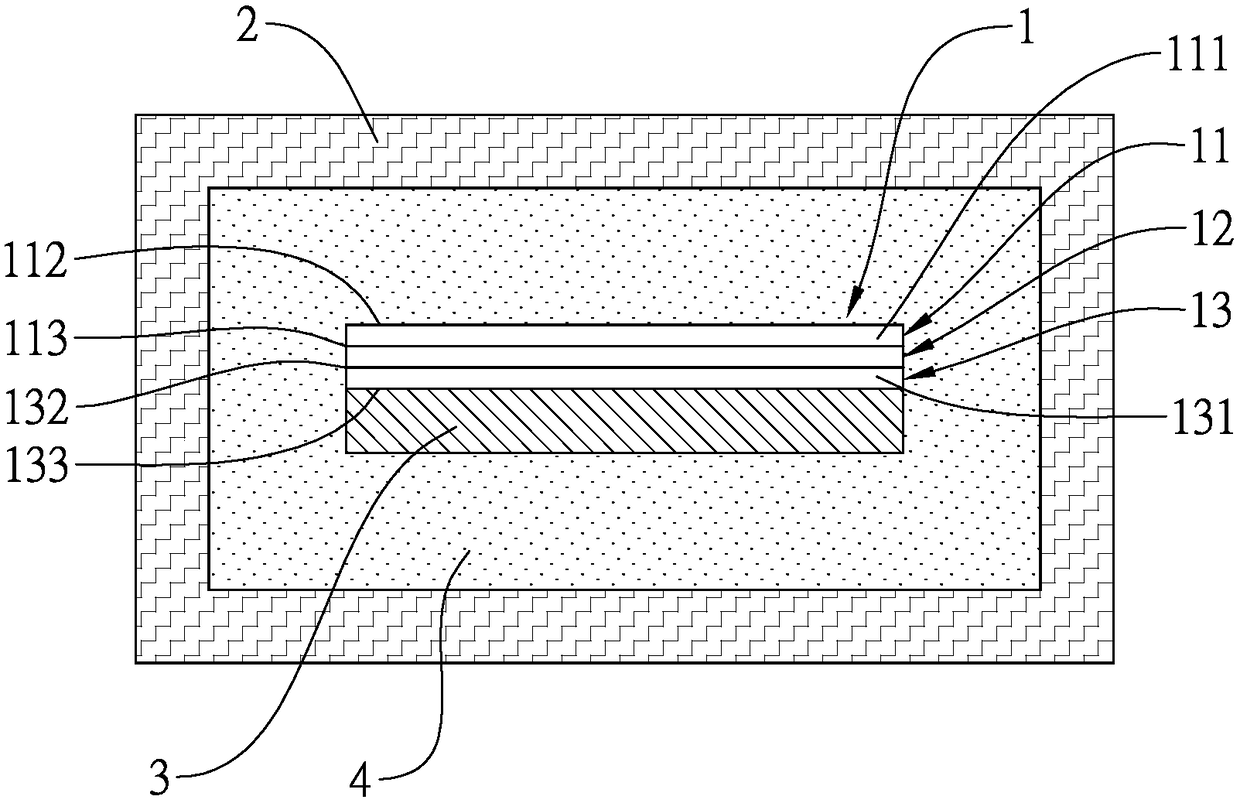

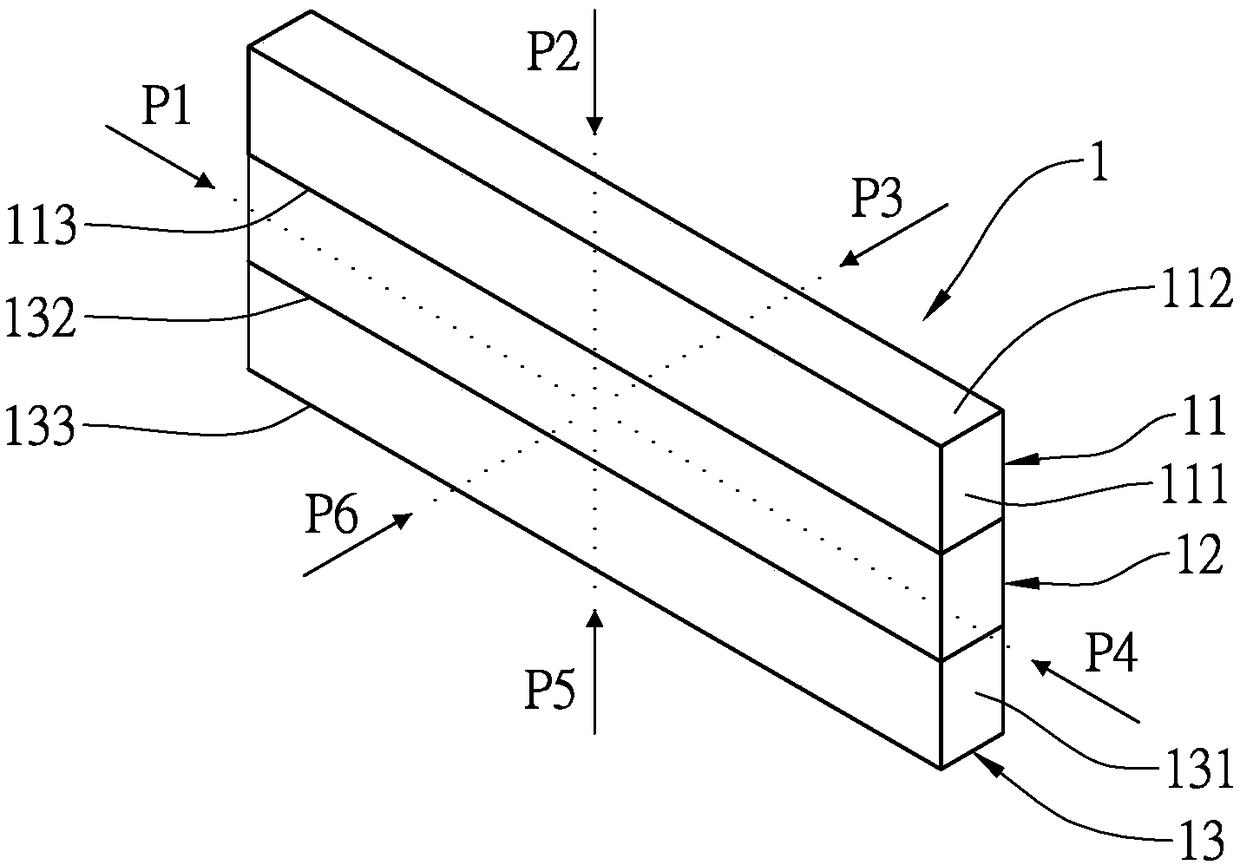

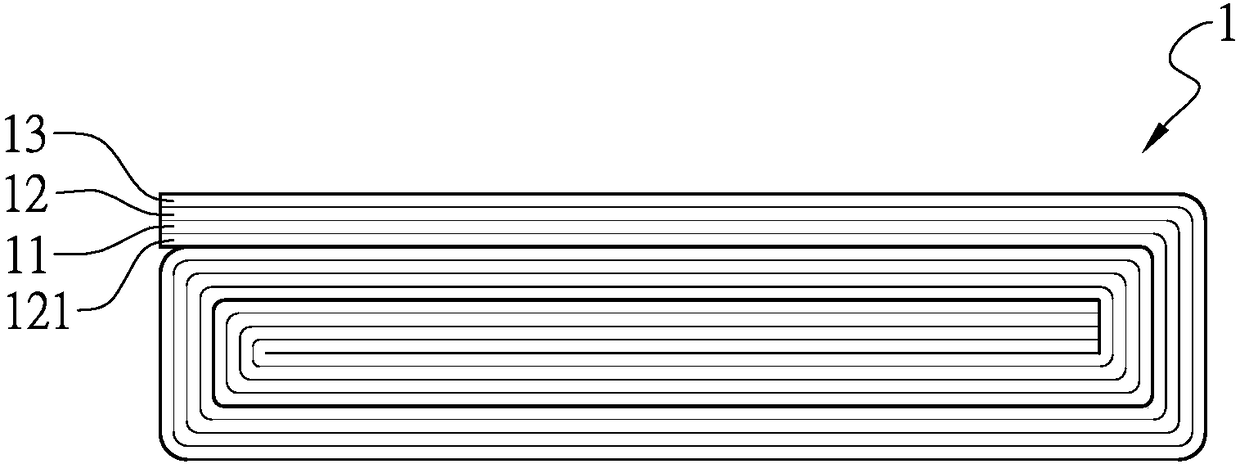

[0033] see figure 1 , 2 As shown, it is the first embodiment of the manufacturing method of the solid-state battery of the present invention, comprising the following steps:

[0034] Step a. Provide a battery unit 1, the battery unit 1 includes a positive electrode sheet 11, a solid electrolyte layer 12 and a negative electrode sheet 13 stacked in sequence, the positive electrode sheet 11 includes a first collector layer 111 and is respectively bonded to the first The positive electrode material layers 112 , 113 on both sides of the collector layer 111 , the negative electrode sheet 13 includes a second collector layer 131 and the negative electrode material layers 132 , 133 respectively bonded to the two sides of the second collector layer 131 .

[0035] Step b. Positioning the battery unit 1 on an additional circuit board 3 inside a pressure chamber 2 with a fluid medium 4 inside.

[0036] Step c. Provide a temperature control of 20-200°C and a pressure control of the medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com