Method for recycling phosgene in continuous production process of toluene di-isocyanate

A technology for the production process of toluene diisocyanate, which is applied in the field of phosgene recovery in the continuous production process of toluene diisocyanate, can solve the problems of high cost, poor operation stability and high risk of phosgene recovery process, and achieve improved operation stability, The effect of low recovery and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is used to illustrate the present invention, but does not limit the protection scope of the present invention.

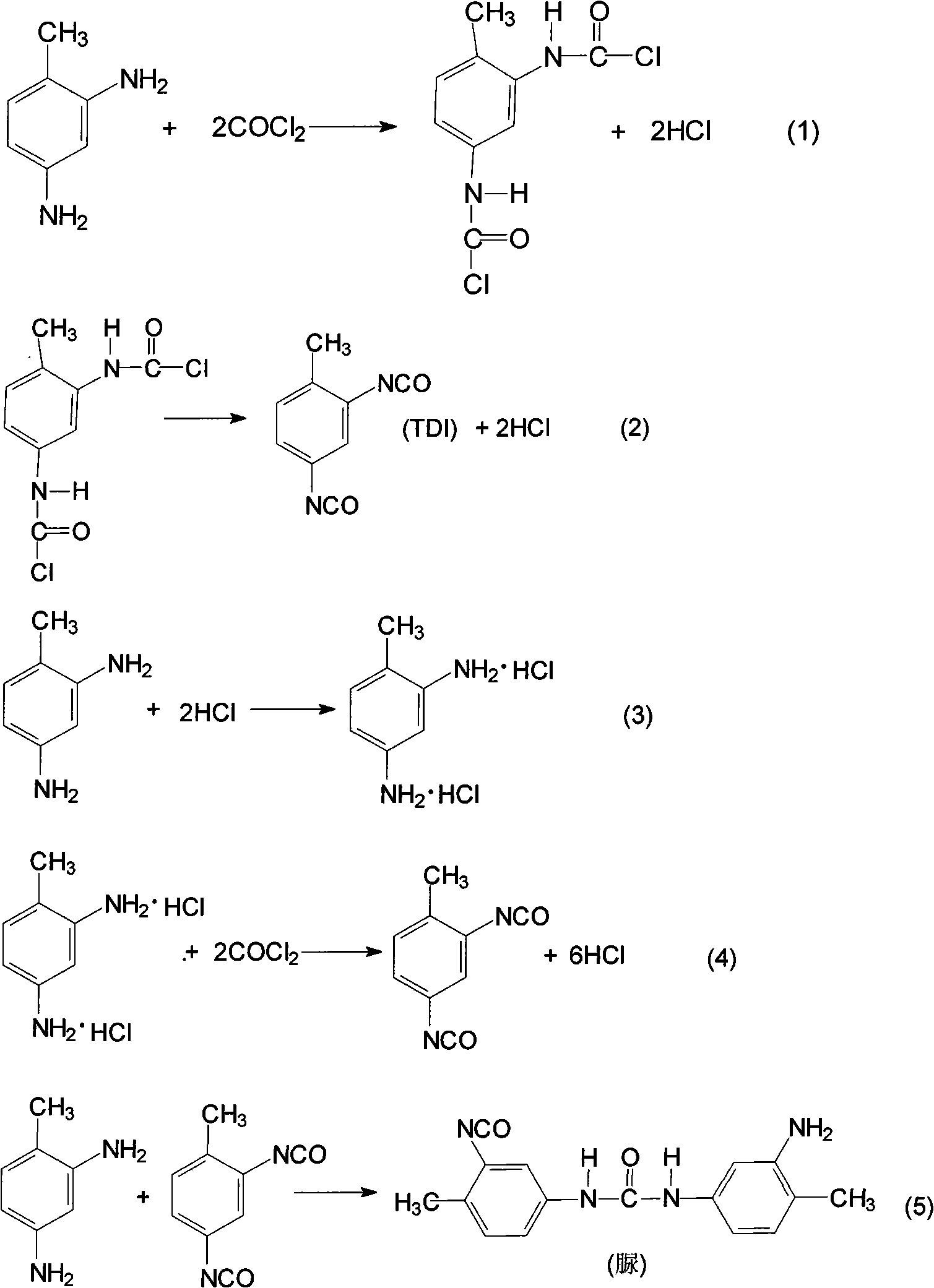

[0026] This example relates to the recovery of phosgene during the continuous preparation of toluene diisocyanate (TDI) by liquid-phase phosgenation of toluene diamine in o-dichlorobenzene (ODCB). The percentage composition in each stream refers to the mass percentage.

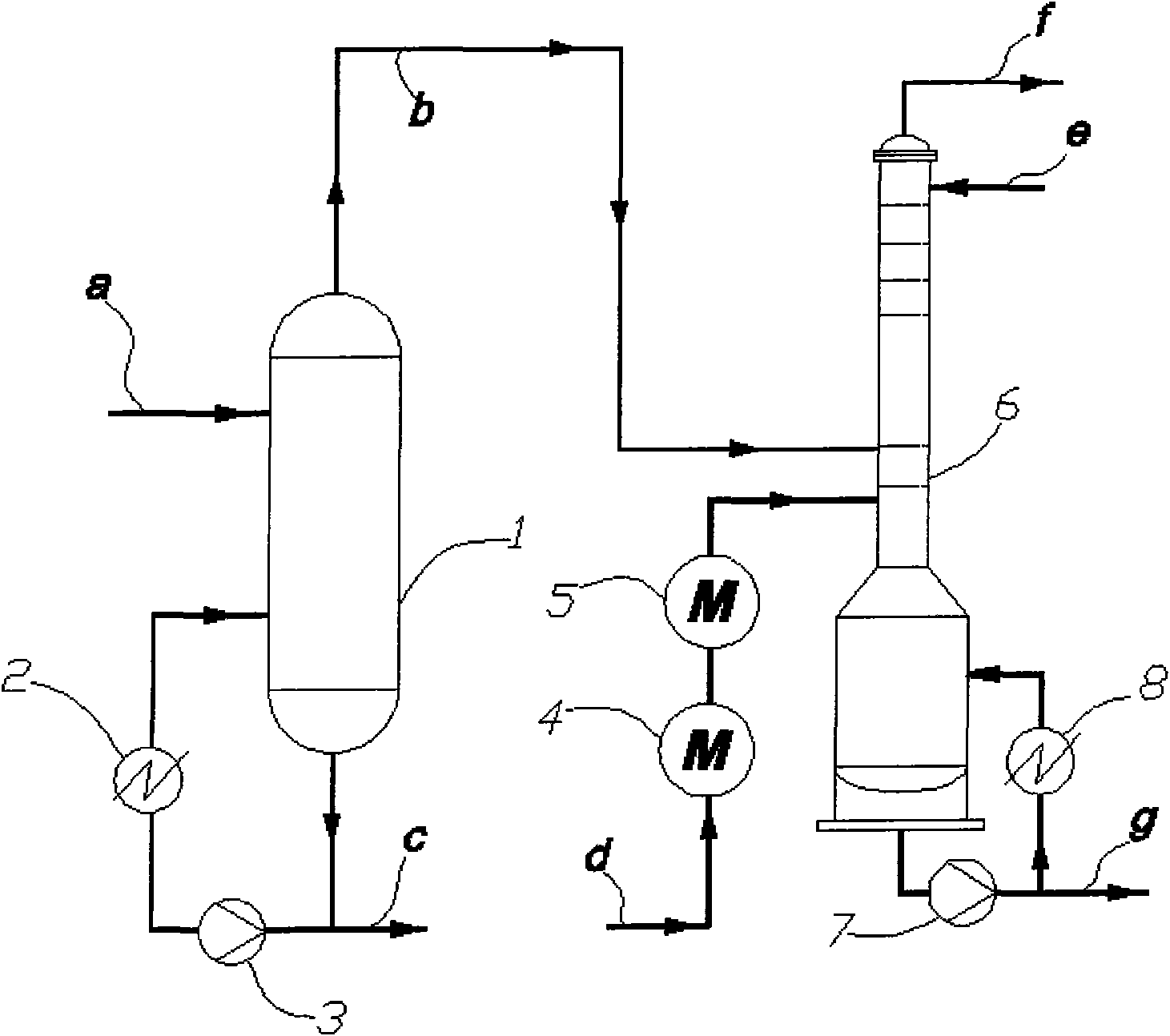

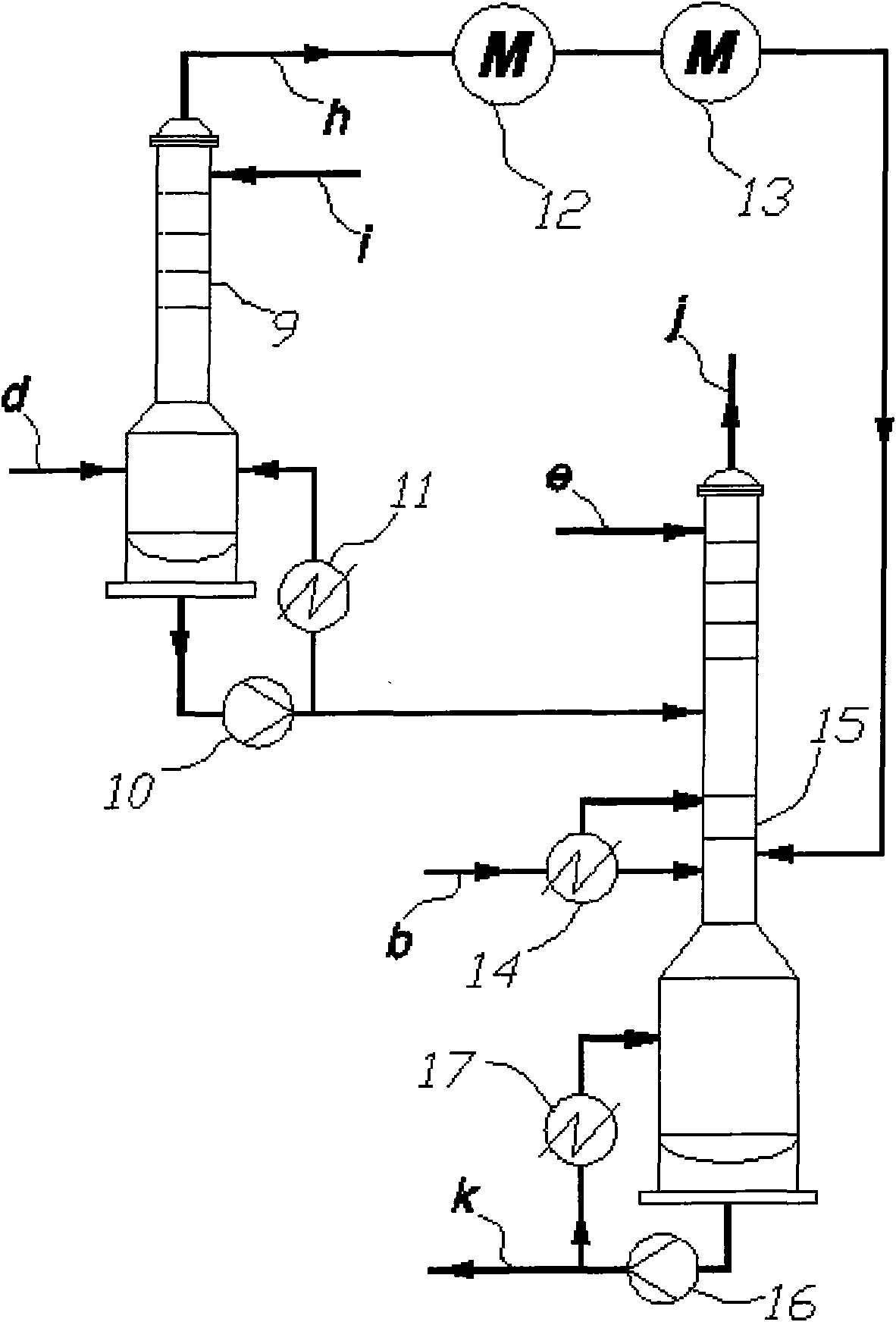

[0027] The first phosgene absorption tower is a spray tower, and the upper part of the tower is equipped with a wire mesh demister to remove the liquid droplets in the tower gas; The gas stream d (from degassing, hydrogen chloride stripping section) is 5 ℃, absolute pressure 0.12MPa, its mass flow rate is 5000kg / hr, containing 81.9% phosgene, 17.4% hydrogen chloride, 0.6% carbon tetrachloride and trace The ODCB and carbon dioxide enter the bottom of the first phosgene absorption tower; there are 6 upward liquid nozzles built in the lower part of the first phosgene absorption ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap