Master device of efficient earth gravity engine

A technology of earth gravity and engine, which is applied in the direction of engine, machine/engine, mechanical equipment, etc., can solve the problems of undiscovered technical success cases, few records, and lack of center of gravity balance, etc., so as to facilitate rapid popularization, popularization and application, and low cost , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

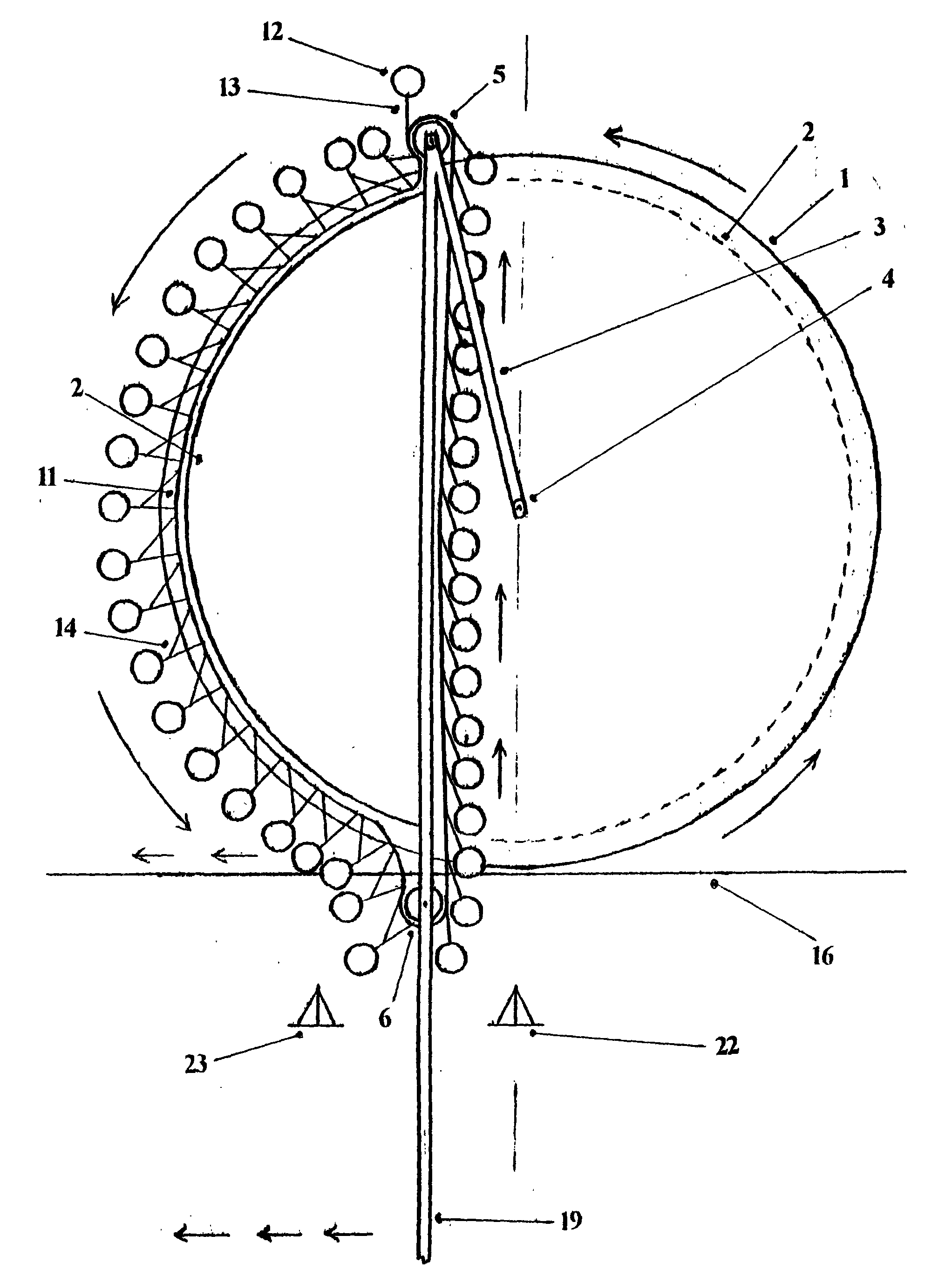

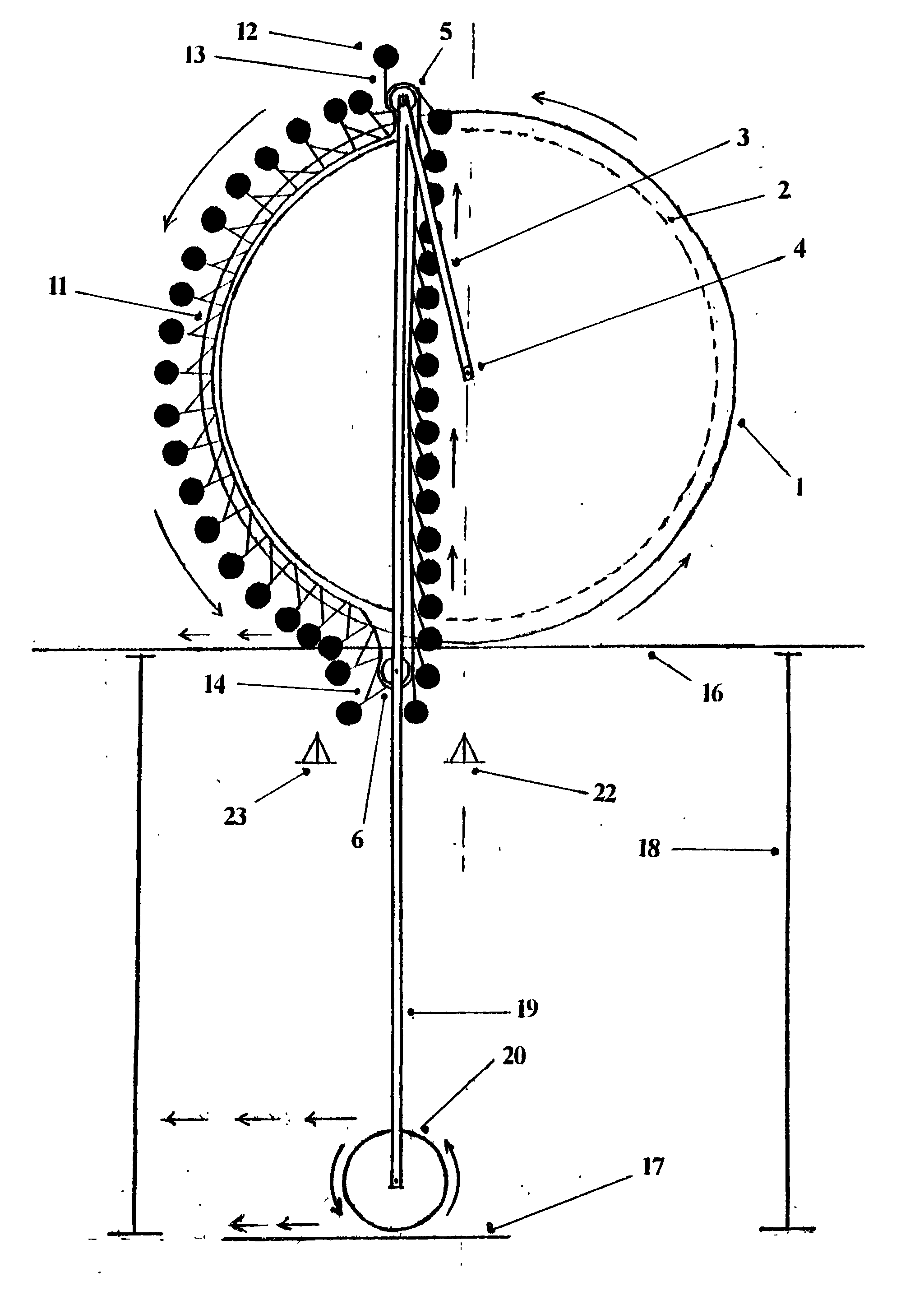

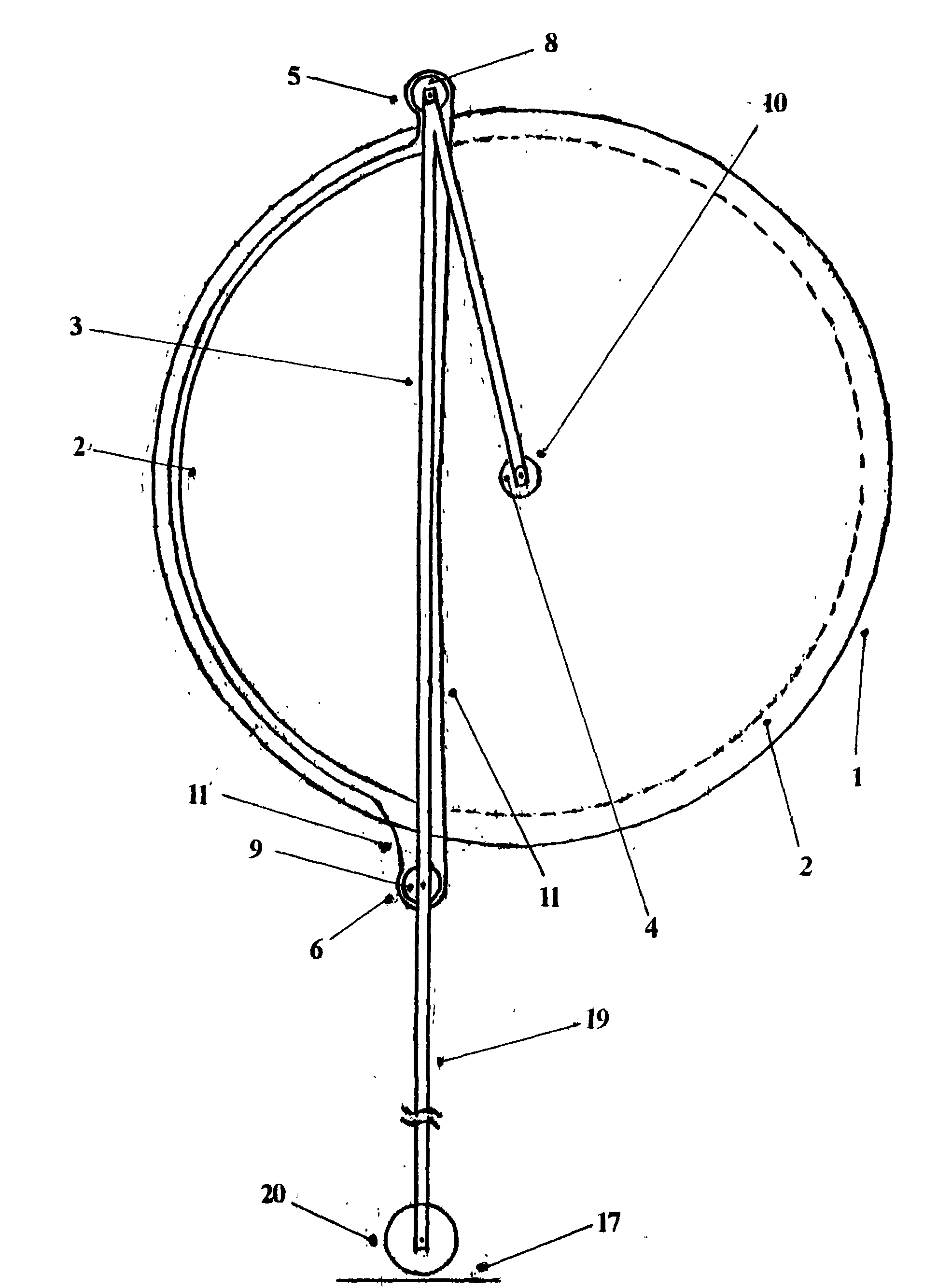

[0015] exist figure 1 Among them, in the middle of the energy output bracket wheel (1), the center shaft (4) connecting the bracket wheel is set and integrated. A large chain pulley (2) and a large support rod frame (3) are arranged on the central axis (4) of the support wheel and are movably connected to form a whole. The upper chain pulley (5) that connects top is set on the top of big support rod frame (3), and the middle part of big support rod frame (3) is set and connects lower chain pulley (6), and above chain pulley (5), big The outer diameter surface of the chain pulley (2), the lower chain pulley (6) is provided with the connection ballast chain belt (11), and many small supports with equal spacing are set on the outer diameter surface of the ballast chain belt (11) Rod (13), small dragline (14), ballast (12). One end of the small support bar (13) is connected with the ballast (12), and the other end is movably connected with the ballast chain belt (11), and one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com