Tightening mechanism

A technology of adjusting screw and adjusting screw, applied in the direction of mechanical equipment, belt/chain/gear, transmission device, etc., can solve the problems of low efficiency, high cost and high manufacturing cost of the tensioner, and achieve strong practicability and reduce axial The effect of distance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

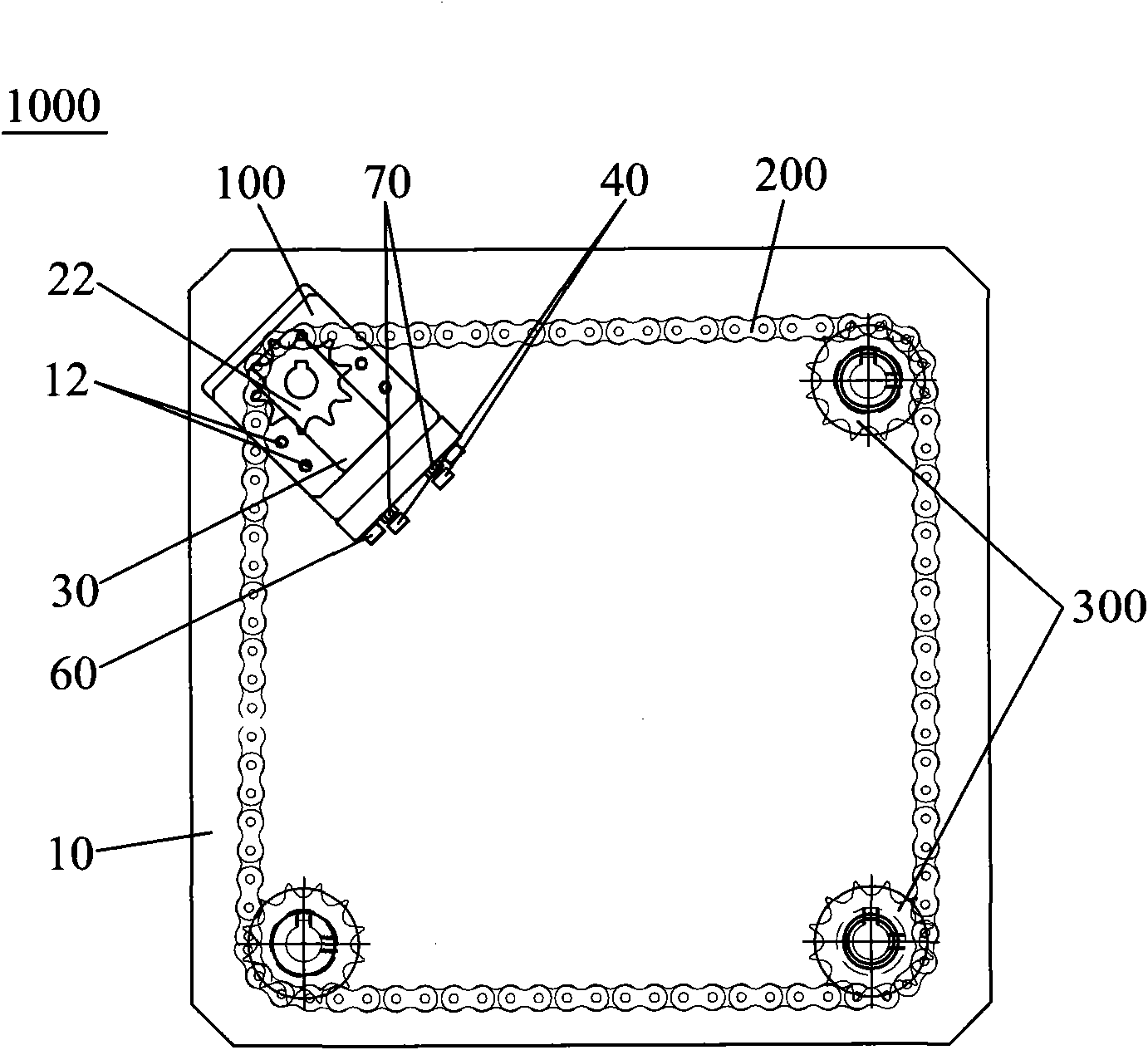

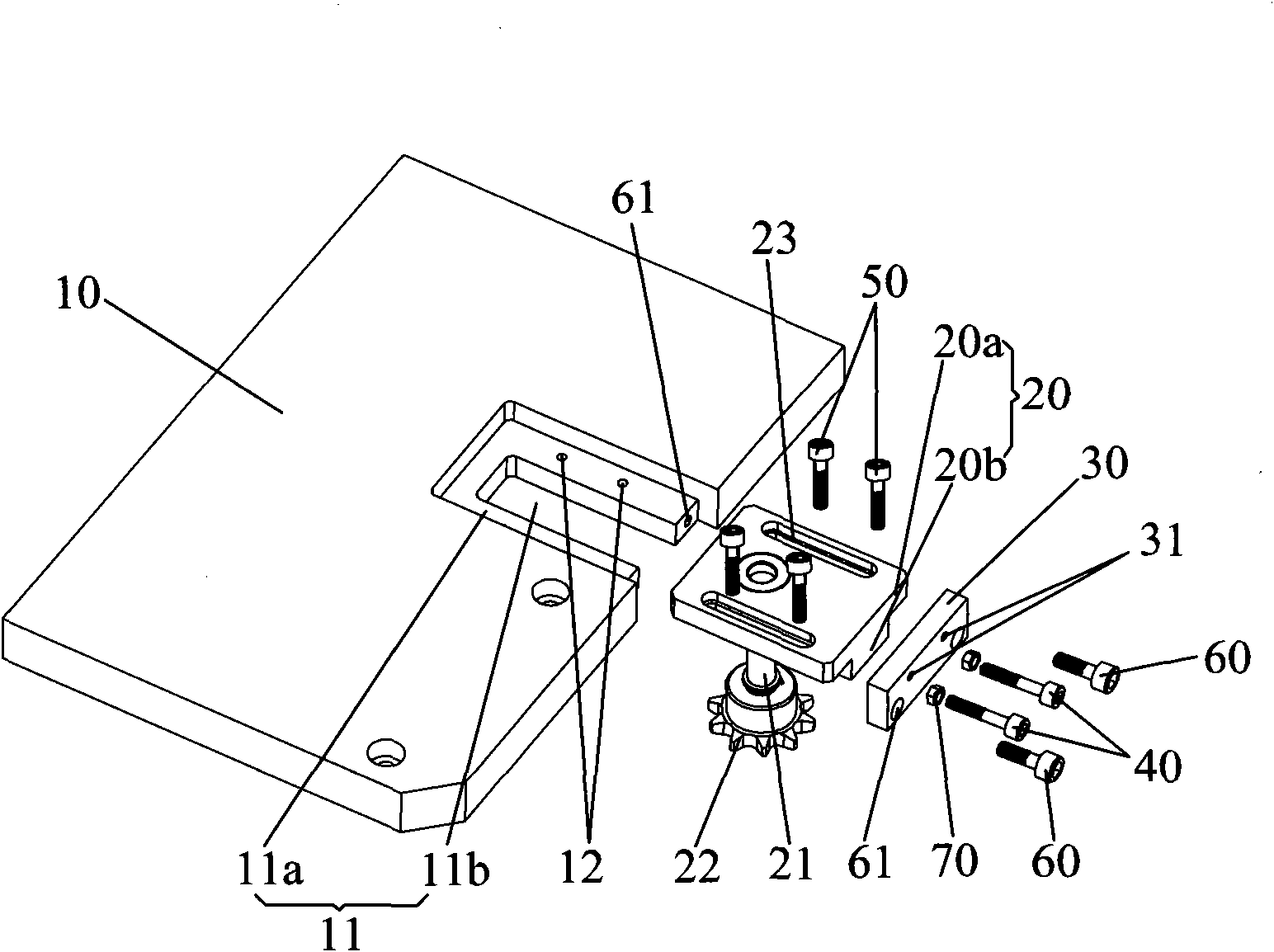

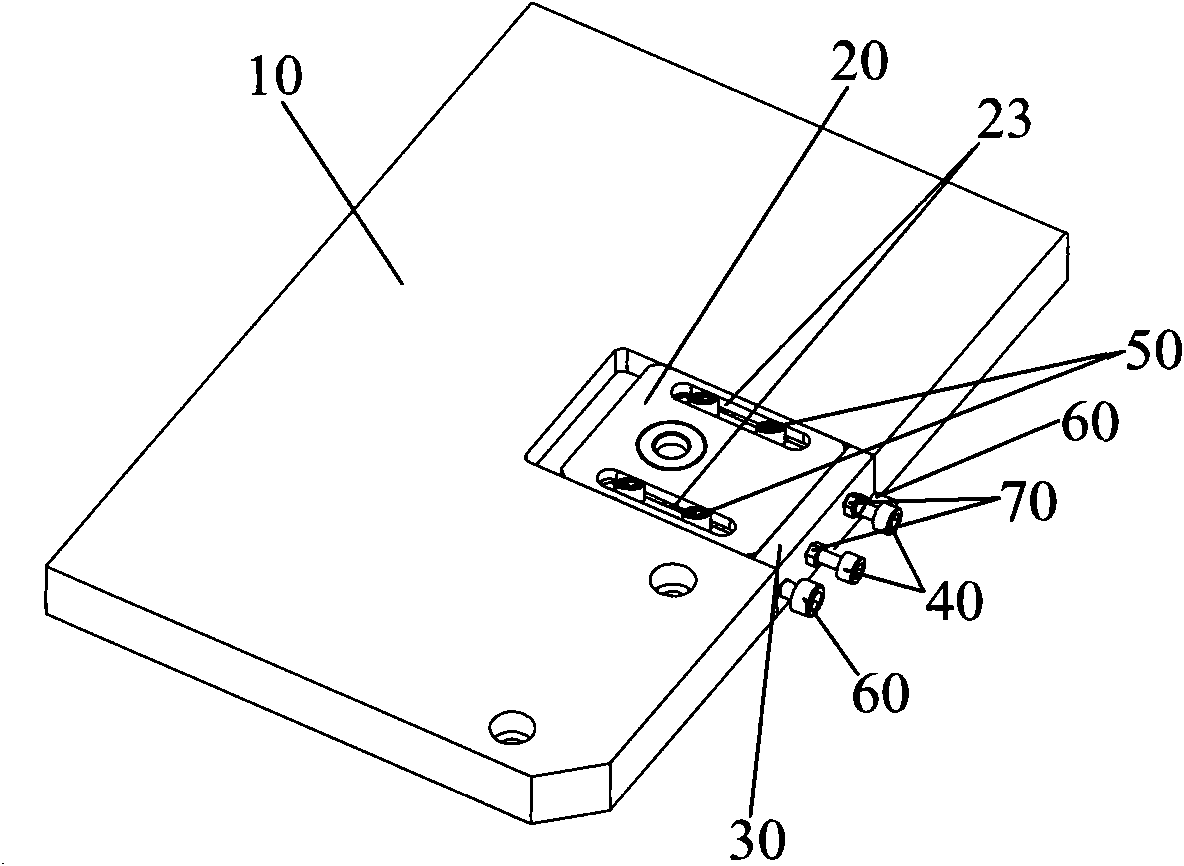

[0027] figure 1 It is a schematic diagram of the structure of the device 1000 of the first embodiment of the application of the tightening mechanism of the present invention, such as figure 1 As shown, the device 1000 includes three fixed wheels 300 , a chain 200 , and a tightening mechanism 100 . combine figure 2 , the tightening mechanism 100 includes a fixed plate 10, a slider 20, a stopper 30, an adjusting screw 40 and a positioning screw 50. In this embodiment, the number of the adjusting screw 40 and the positioning screw 50 is two . The fixing plate 10 is provided with a straight guide groove 11 , and the opening of the straight guide groove 11 is arranged on one side of the fixing plate 10 . The slider 20 is engaged and slidably connected with the straight guide groove 11, the slider 20 is equipped with a support shaft 21 protruding from the straight guide groove 11, and a tensioning wheel 22 is installed on the support shaft 21, The opening ends of the stopper 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com