a mop stick

A technology of mop rods and twist rods, which is applied in the field of mop rods, can solve the problems of insufficient solidity of the stainless steel lower rod, improved driving stability, complex structure, etc., and achieves the effects of large pitch and cross section, easy assembly, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

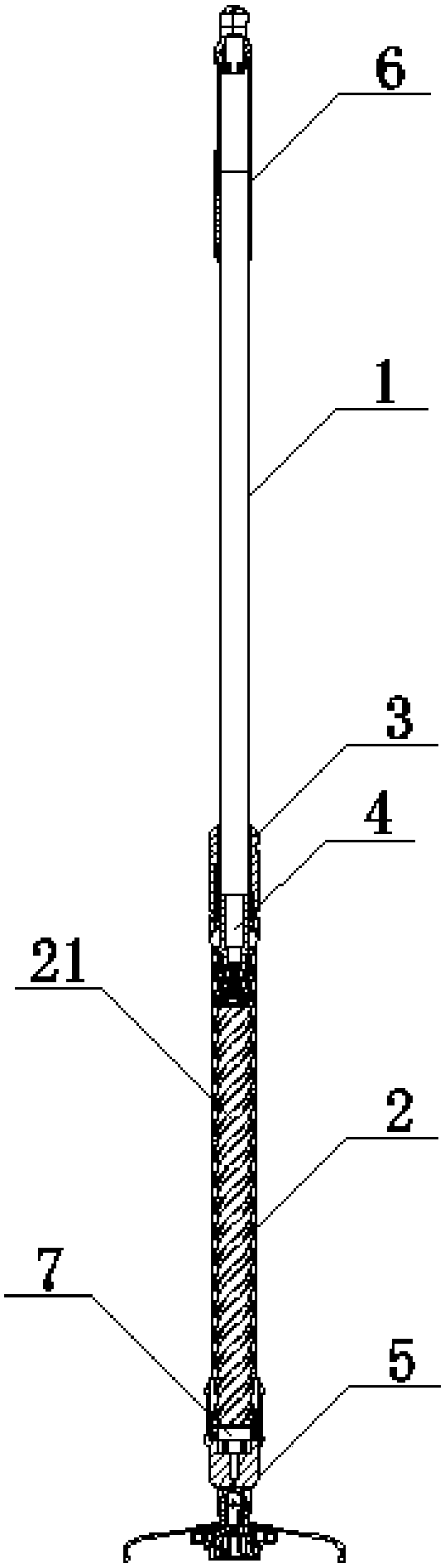

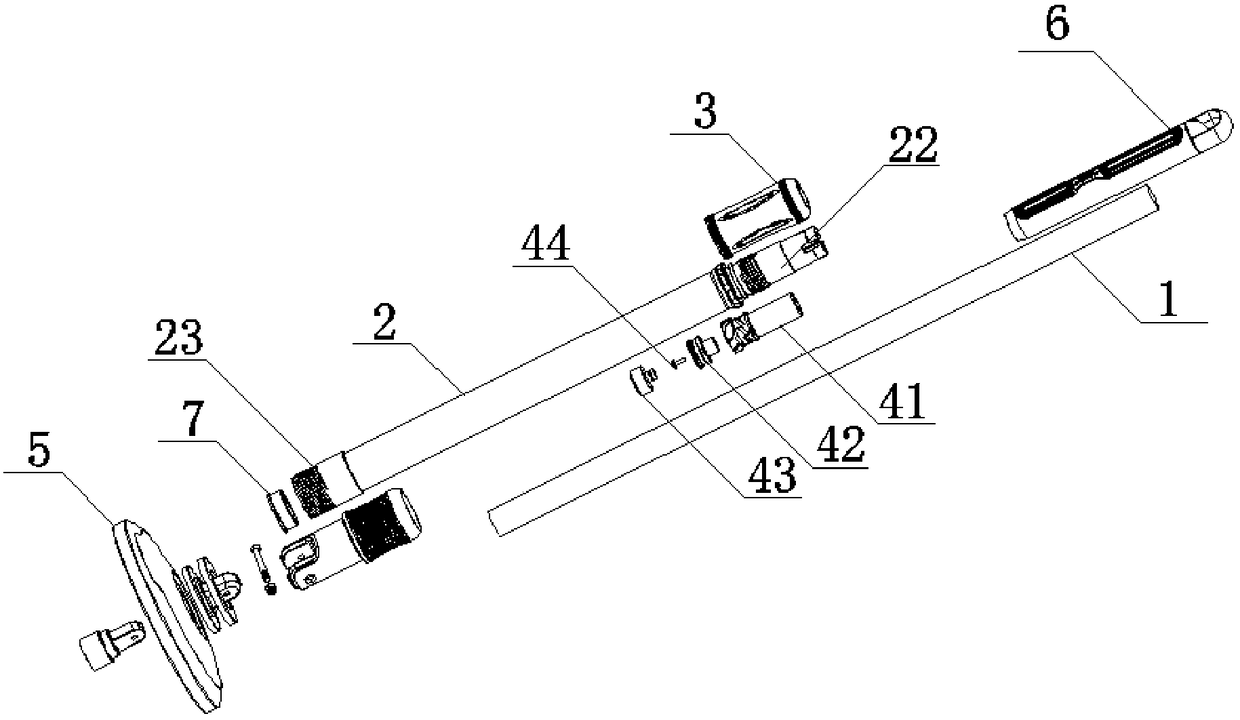

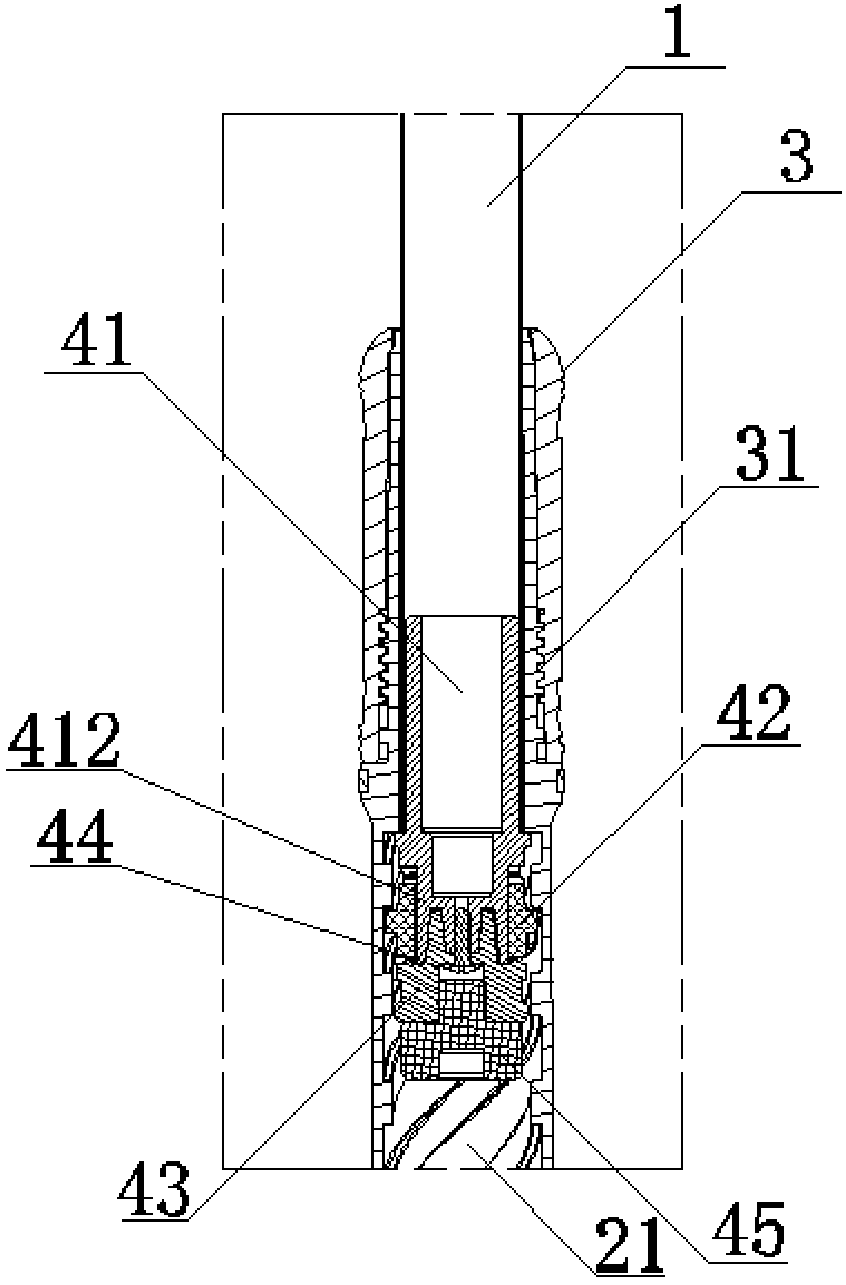

[0031] see Figure 1~6 , a mop rod, comprising a stainless steel pipe 1, a plastic twist rod 2 with multiple threads 21 on the inner wall, an outer lock sleeve 3 for locking the plastic twist rod 2 and the stainless steel pipe 1, and a plastic twist rod 2 inside The driving assembly 4 and the mop head assembly 5 fixedly connected with the lower end of the plastic twist rod 2 . The driving assembly 4 includes a clutch sleeve 41 , a clutch drive 42 , a clutch fixing base 43 and a screw 44 for fixing the clutch fixing base 43 to the clutch sleeve 41 . The clutch shaft sleeve 41 is fixedly riveted with the stainless steel pipe 1. The clutch bushing 41 and the clutch drive 42 are respectively provided with transmission gears 411 and 421 which can engage with each other, and the clutch drive 42 is also provided with a plurality of drive parts 422 which mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com