Counterflow focusing method and device implementing method

A focusing and focusing ring technology, which is applied in the direction of installation, color TV parts, TV system parts, etc., can solve the problems of inability to adapt to special CCM requirements, single-thread focusing speed limitation, and inability to achieve focusing accuracy, etc. problem, to achieve the effect of simple structure, convenient focusing and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

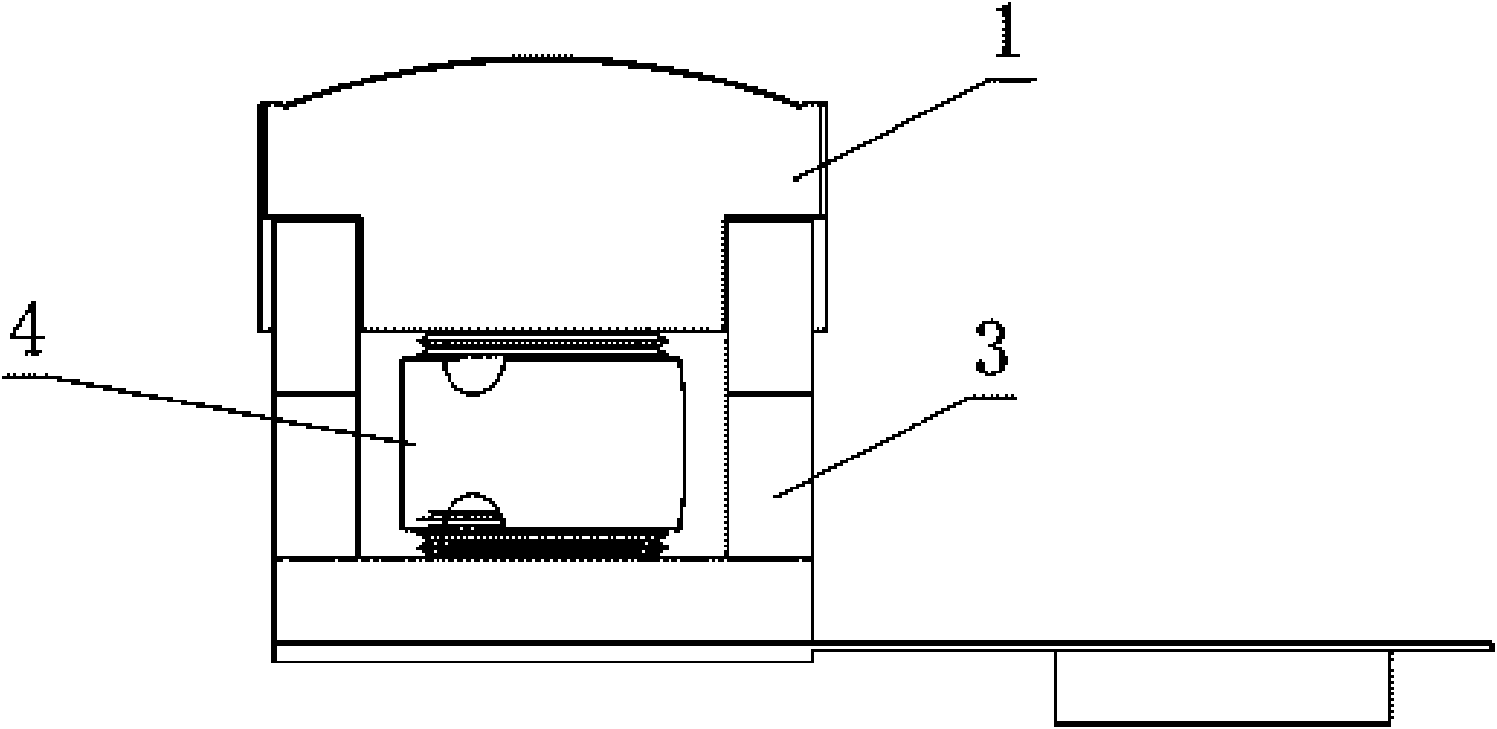

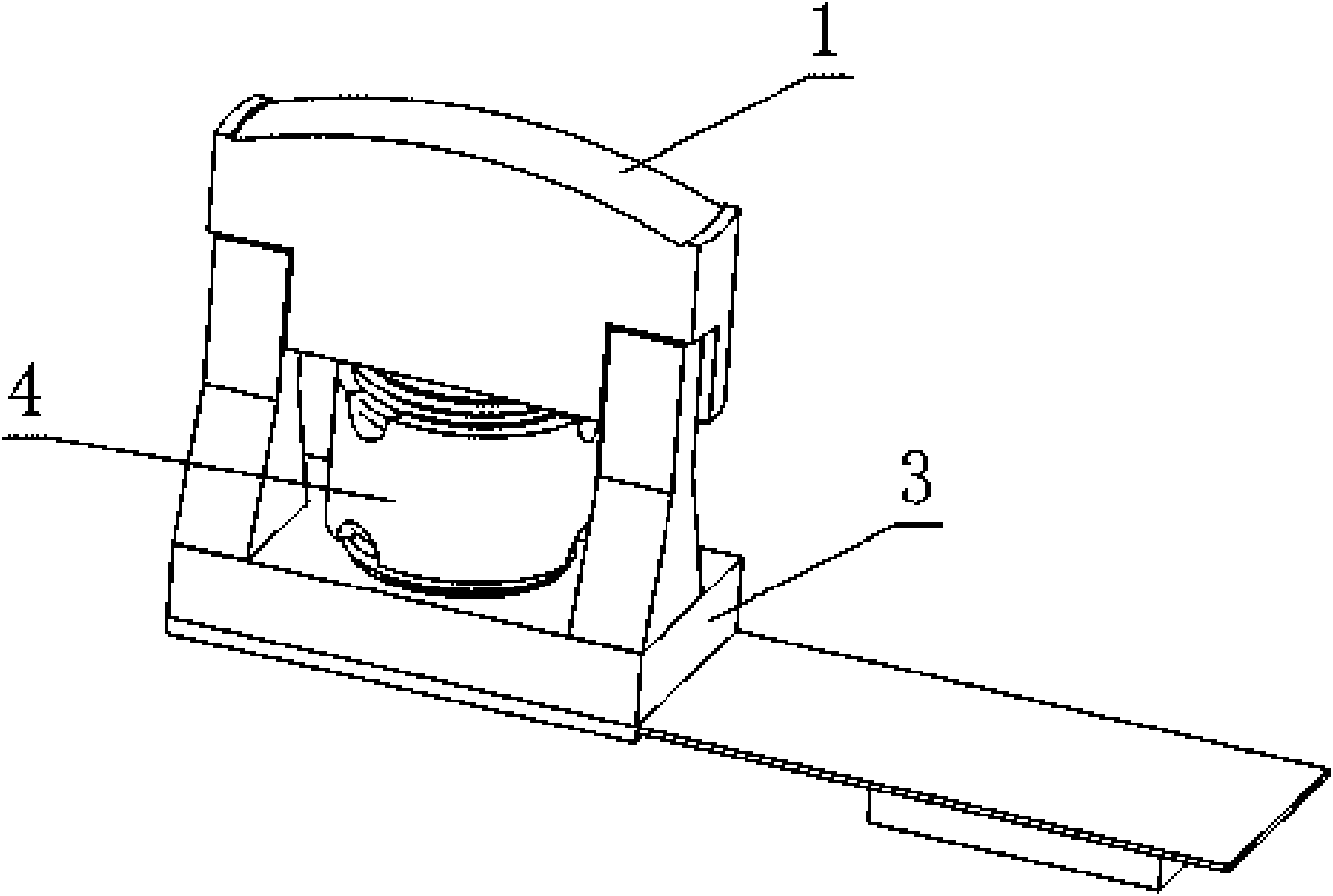

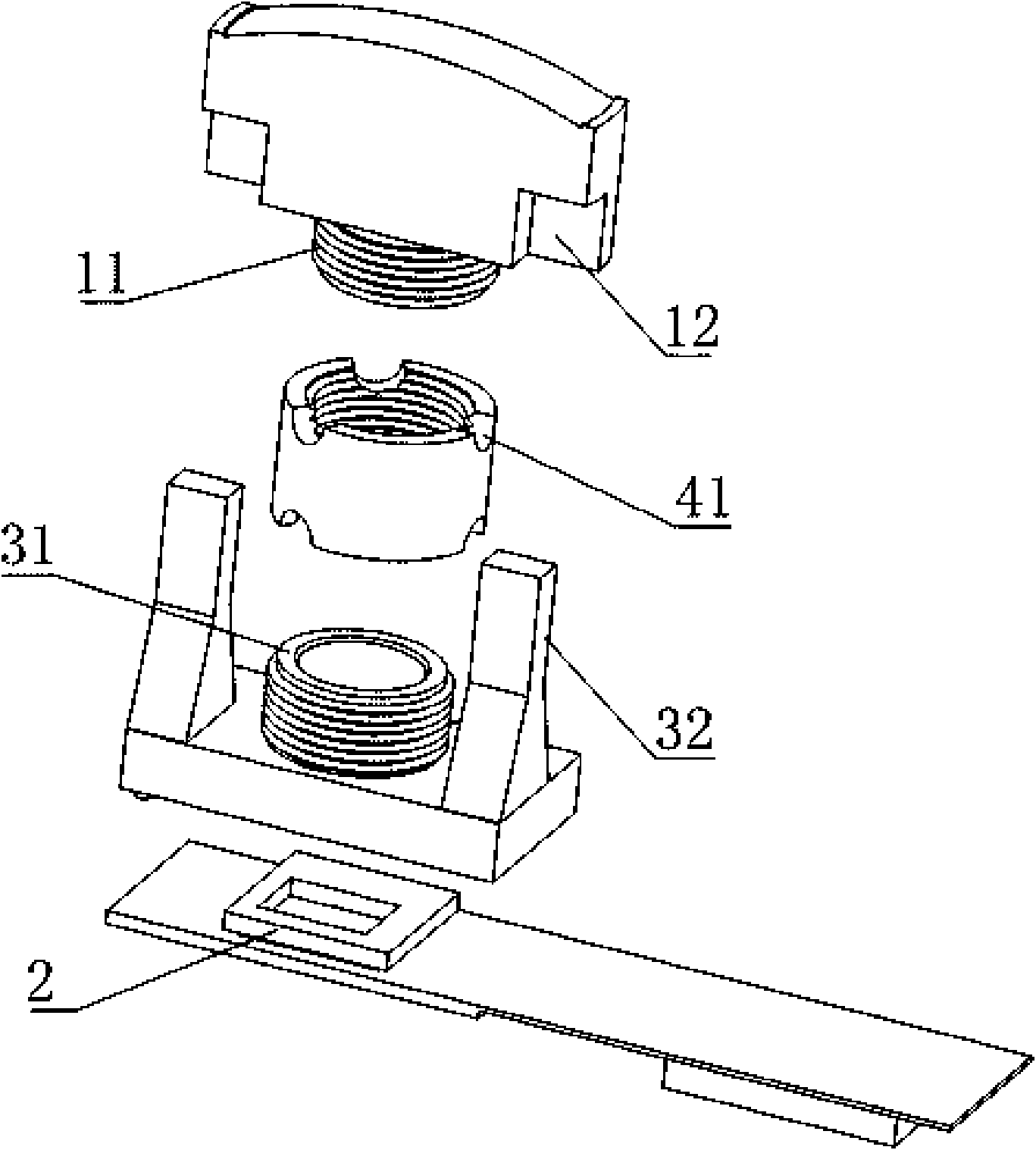

[0021] Example: see figure 1 , figure 2 with image 3 , a progressive focusing method provided by an embodiment of the present invention, which includes the following steps:

[0022] (1) A lens 1 is set to focus on the scene. A lower screwing part 11 with an external thread is provided at the center of the bottom of the lens 1, and a lens that can guide it along the optical axis is provided on both sides of the lower part of the lens 1. The chute 12 that slides up and down;

[0023] (2) An image sensor 2 and a mirror base 3 with a cavity in the lower part are arranged in the focus range of the lens 1 along the optical axis direction, the image sensor 2 is inserted into the cavity, and placed on the mirror base 3 It is provided with a through hole that allows the lens 1 to focus the scene onto the image sensor 2. The edge of the through hole protrudes upwards to form an upper screwed part 31 with external threads. On the upper screwed part 31 The external thread on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com