Range switch

A technology of a band switch and a main body, applied in the field of band switches, can solve the problems of increasing production costs, increasing the assembly steps of the production line, unable to adjust the torque, etc., and achieving the effect of reducing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

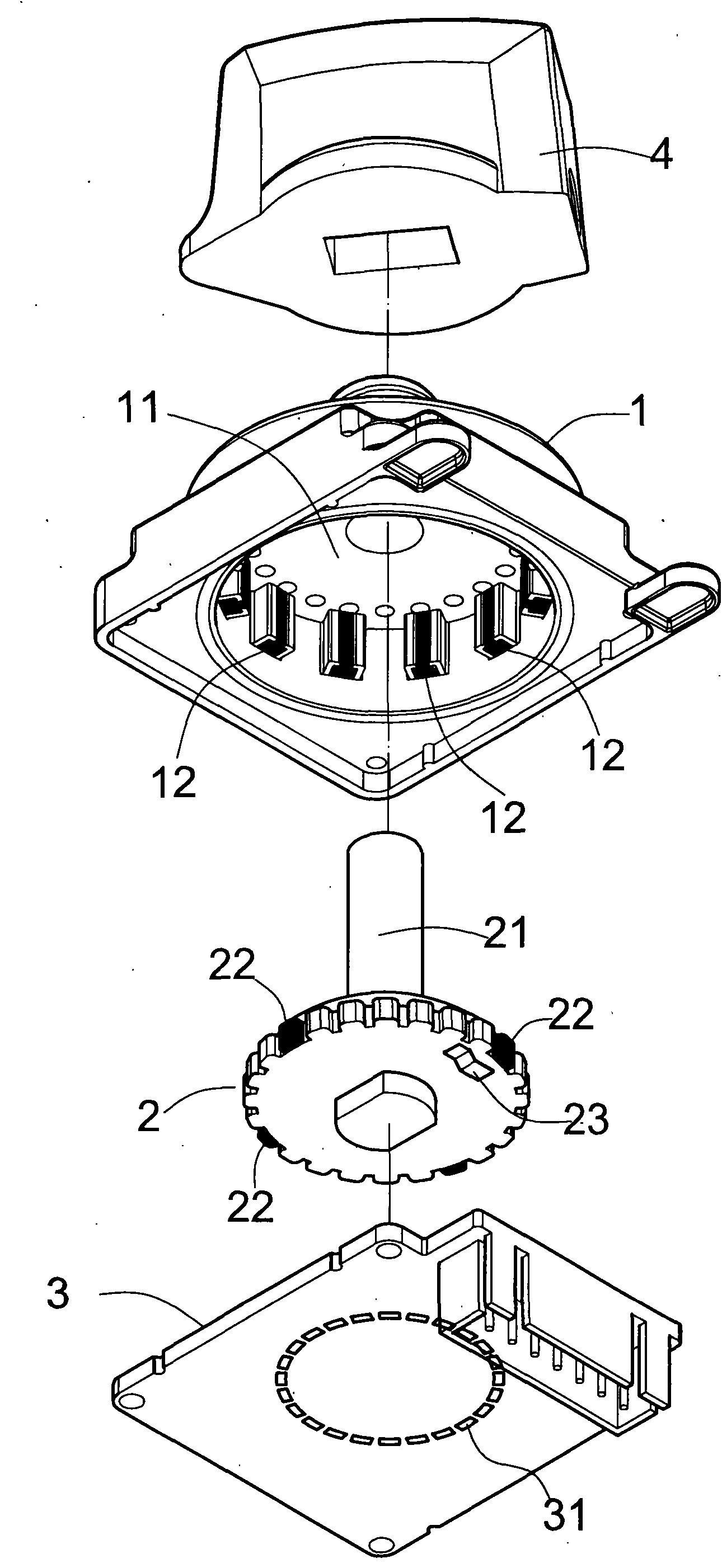

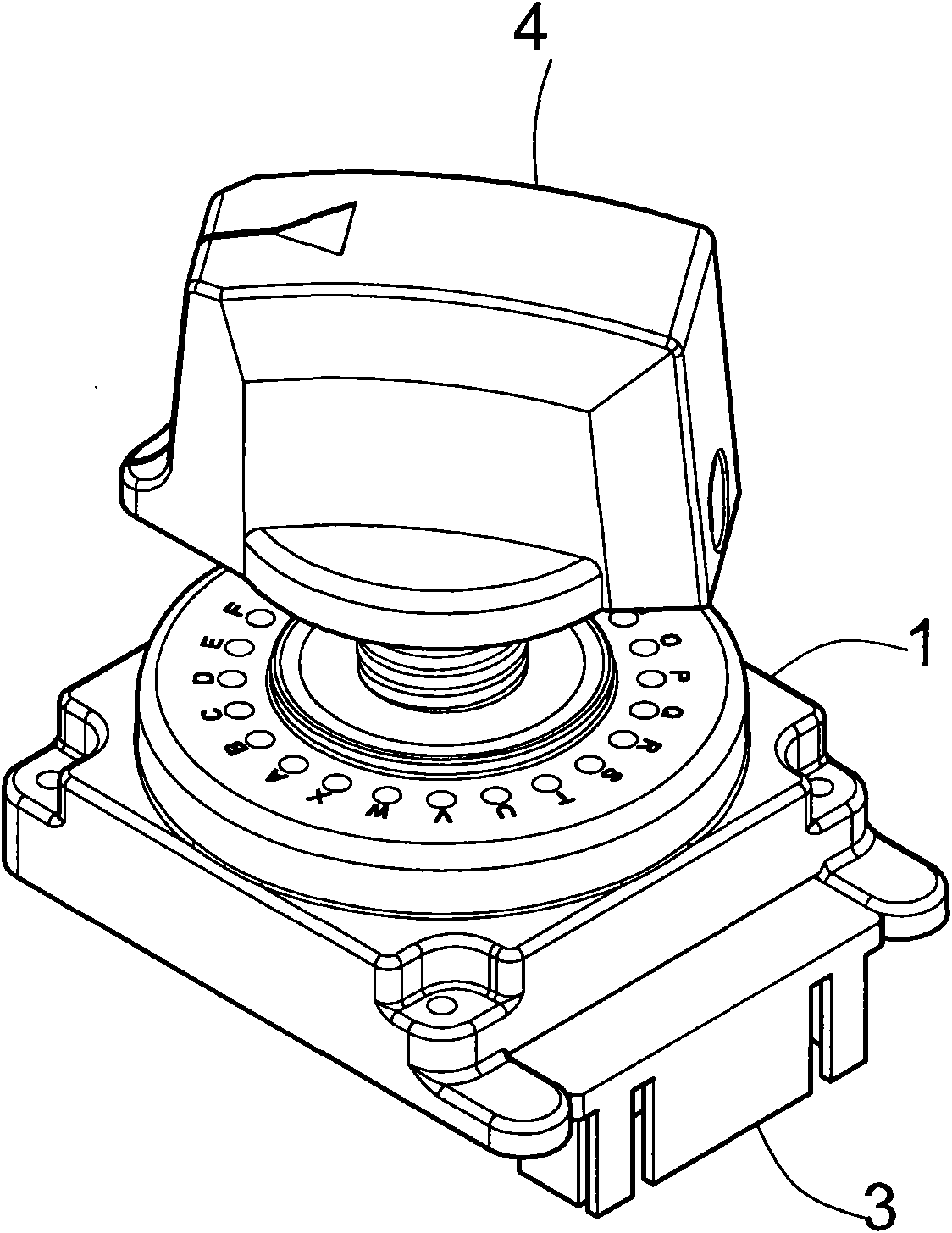

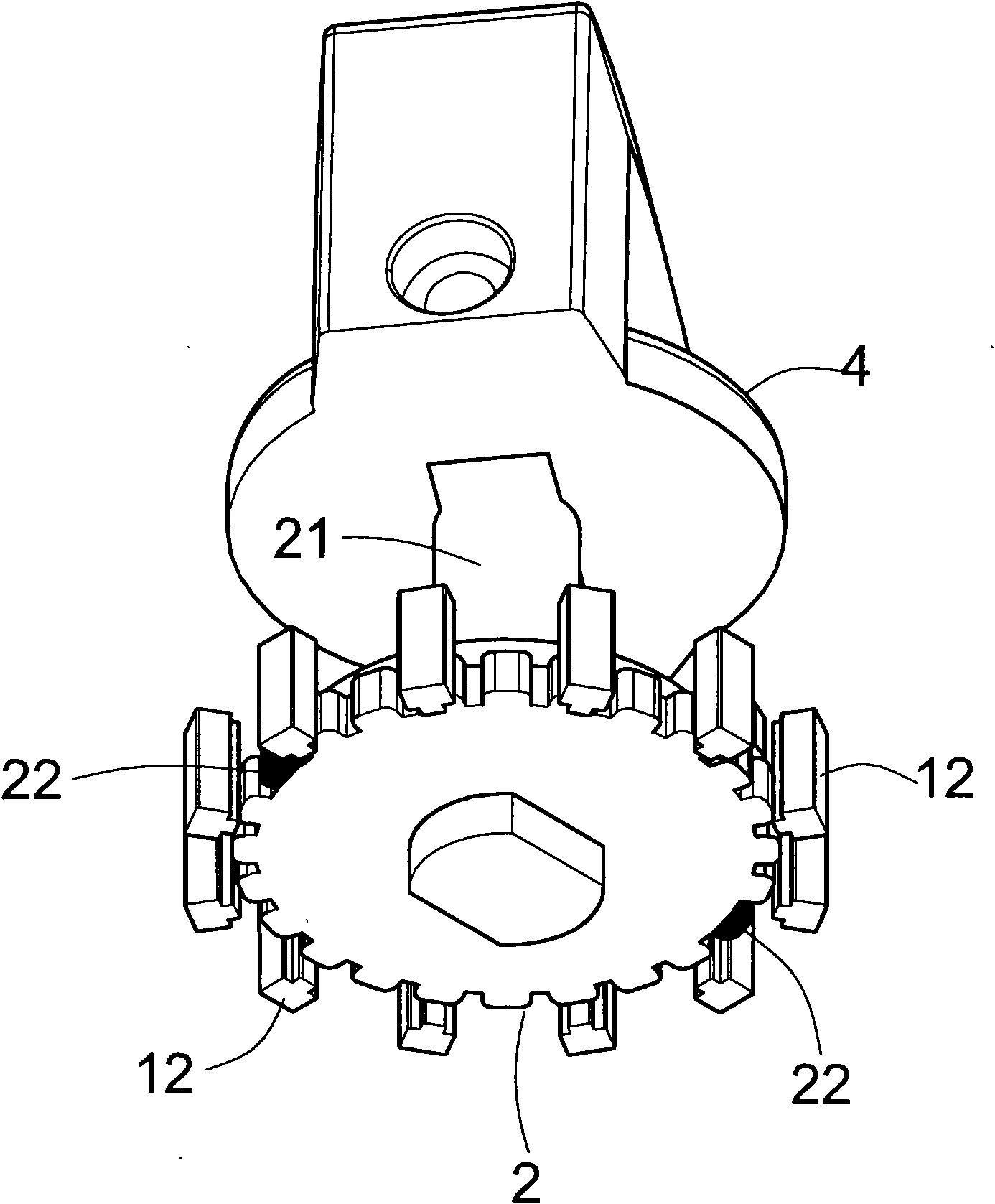

[0022] The main body 1 has an accommodating area 11;

[0023] The rotating part 2 is assembled in the accommodation area 11 of the main body 1. The rotating part 2 is arranged on the main body 1 with a through shaft 21. The bottom surface of the rotating part 2 is equipped with at least one magnetic body 22 (or metal body) and at least one contact piece. twenty three;

[0024] The bottom cover 3 is used to cover the accommodating area 11 of the main body 1, and the magnetic bodies 32 are arranged at equal distances in a ring shape, and at least one electronic component 31 can be directly or indirectly contacted with the contact piece 23 of the rotating part 2, and the bottom cover 3 The electronic component 31 is provided with resistance elements with different coefficients; the magnetic body 32 is a magnet, a permanent magnet, an electromagnet or an electromagnetic coil, and the electromagnetic coil can input electric energy to generate a magnetic field.

[0025] In the band...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com