Elevator

A technology of elevators and control devices, which is applied to elevators, transportation and packaging, elevators, etc. in buildings, and can solve problems such as driving force limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

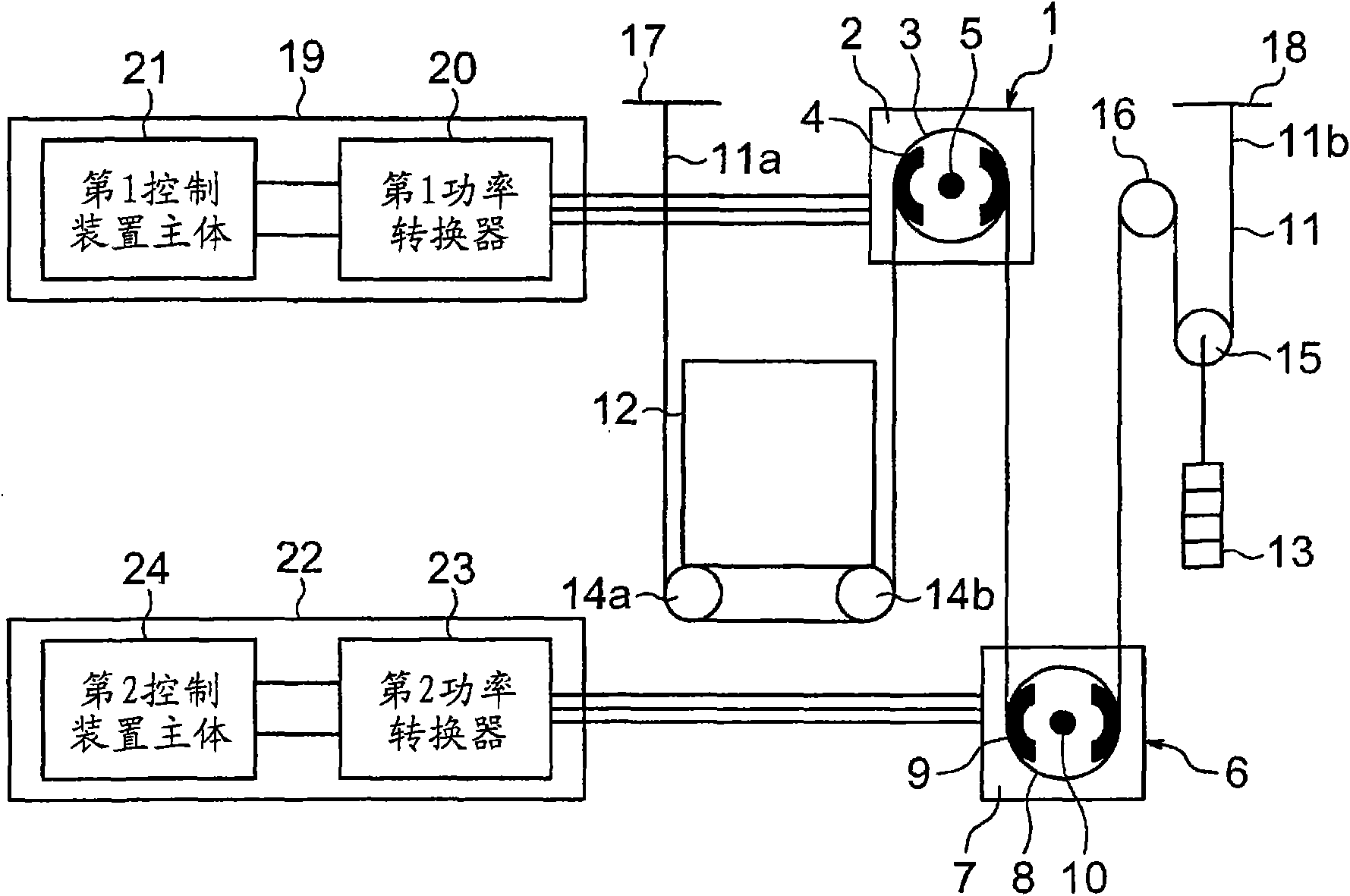

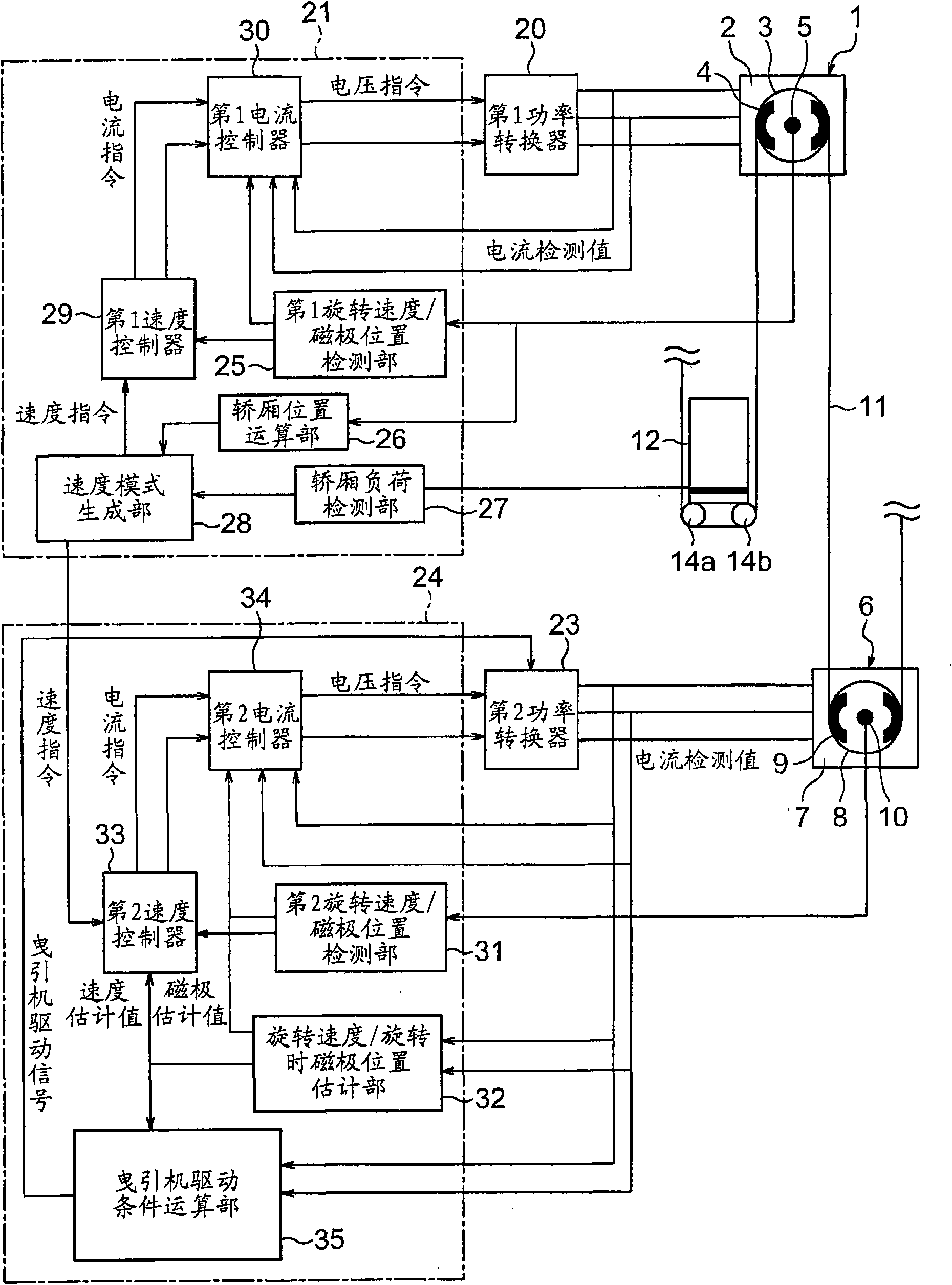

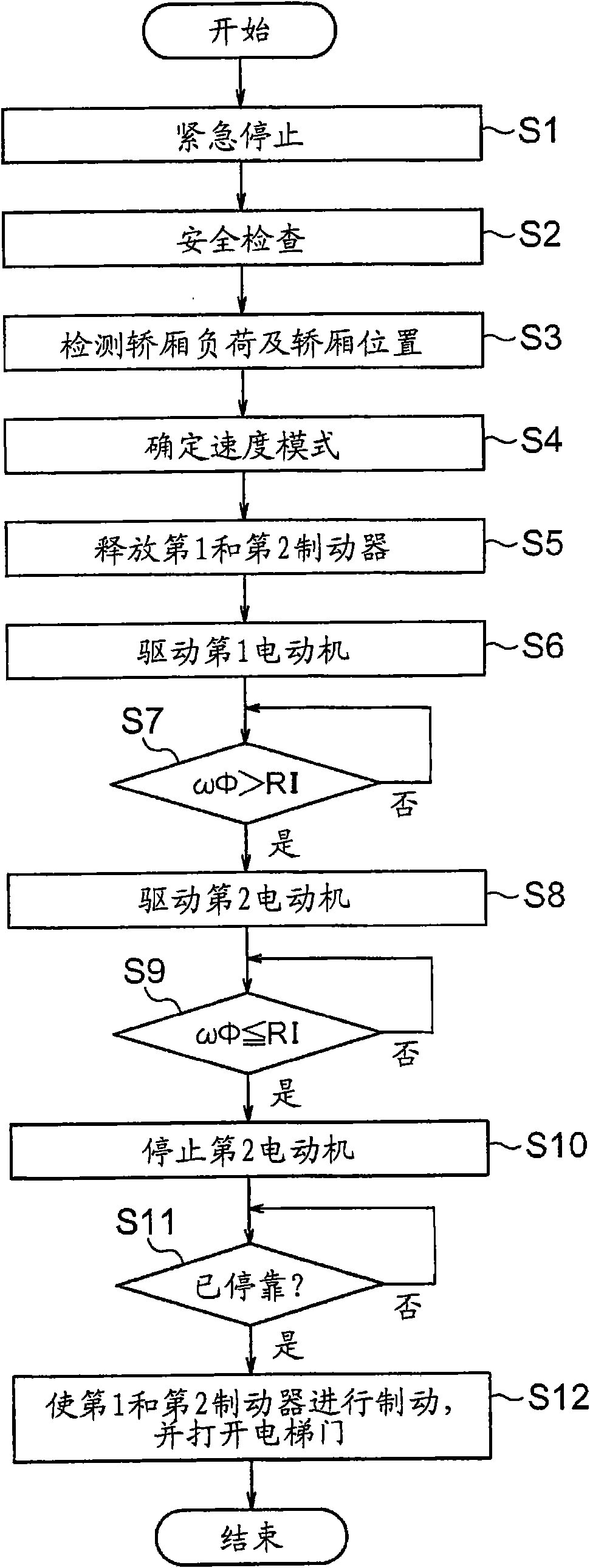

[0014] figure 1 It is a block diagram showing the elevator apparatus according to Embodiment 1 of the present invention. In the figure, the first hoisting machine 1 is provided on the upper part of the hoistway. The first traction machine 1 has a first motor 2, a first drive sheave 3 rotated by the first motor 2, a first brake 4 for braking the rotation of the first drive sheave 3, and a The first encoder 5 that generates a signal corresponding to the rotation of the sheave 3 is driven. The first drive sheave 3 and the first motor 2 are arranged coaxially.

[0015] The second traction machine 6 is provided at the lower part of the hoistway. The second traction machine 6 has a second motor 7, a second driving sheave 8 rotated by the second motor 7, a second brake 9 for braking the rotation of the second driving sheave 8, and a The second encoder 10 that generates a signal corresponding to the rotation of the sheave 8 is driven. The 2nd drive sheave 8 and the 2nd electric m...

Embodiment approach 2

[0051] under, Figure 5 It is a configuration diagram showing an elevator apparatus according to Embodiment 2 of the present invention. In Embodiment 1, the elevator apparatus of the 2:1 rope system was shown, and in Embodiment 2, the elevator apparatus of the 1:1 rope system is demonstrated.

[0052] In the drawing, first and second hoisting machines 1 and 6 are provided on the upper part of the hoistway. A plurality of (only one is shown in the figure) first main ropes 41 serving as suspension means are wound around the first drive sheave 3 . A plurality of (only one is shown in the figure) second main ropes 42 serving as suspension means are wound around the second drive sheave 8 . The car 12 is connected to one end of the first main rope 41 and one end of the second main rope 42 . That is, the car 12 is suspended by the first and second main ropes 41 and 42 .

[0053] A first counterweight 43 is connected to the other end of the first main rope 41 . The second counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com