Silent chain

A technology of silent chain and chain, applied in the field of silent chain, can solve the problem of unable to adapt to the trend of silent chain mute, shorten the life of the chain, etc., and achieve the effect of prolonging the life, reducing the collision sound and alleviating the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

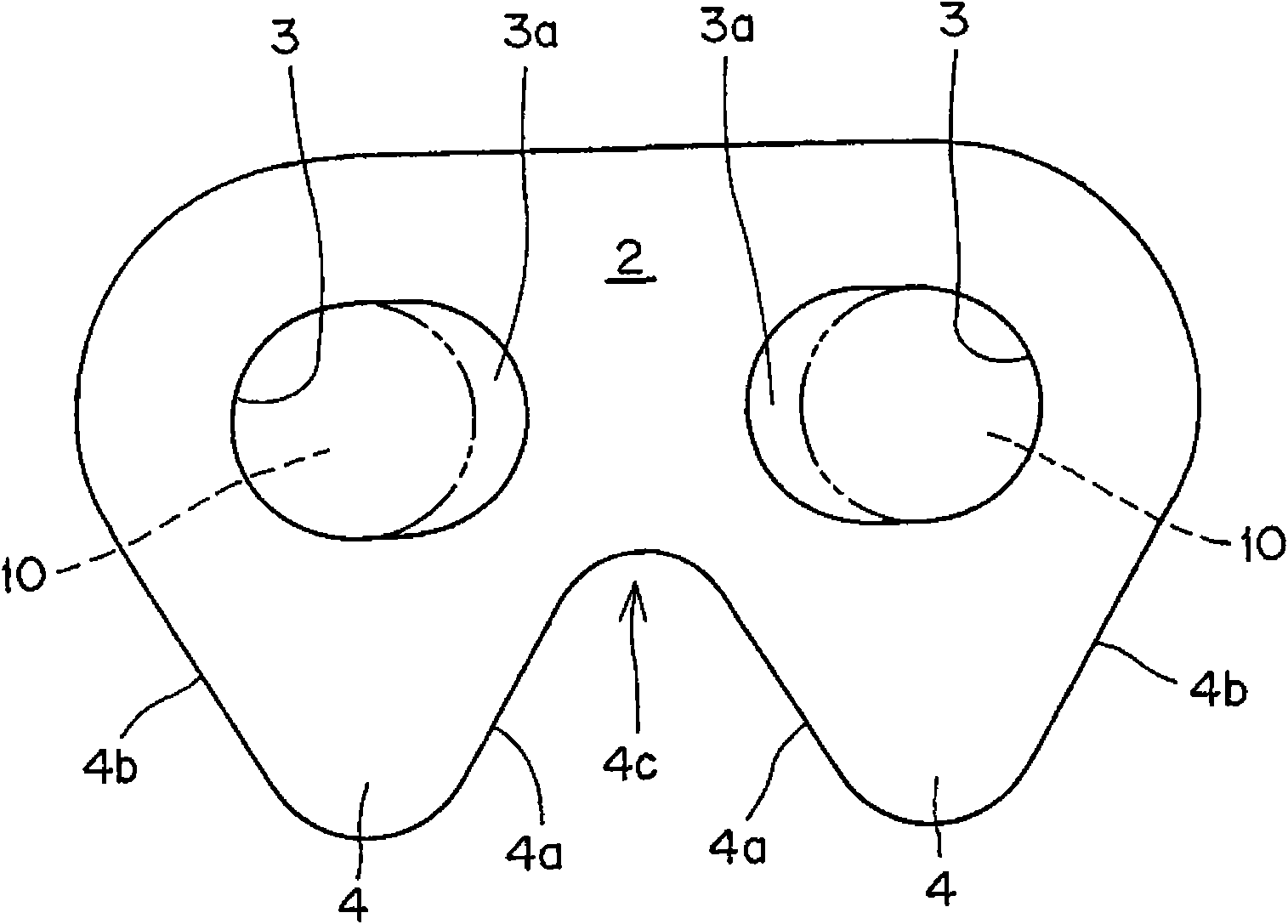

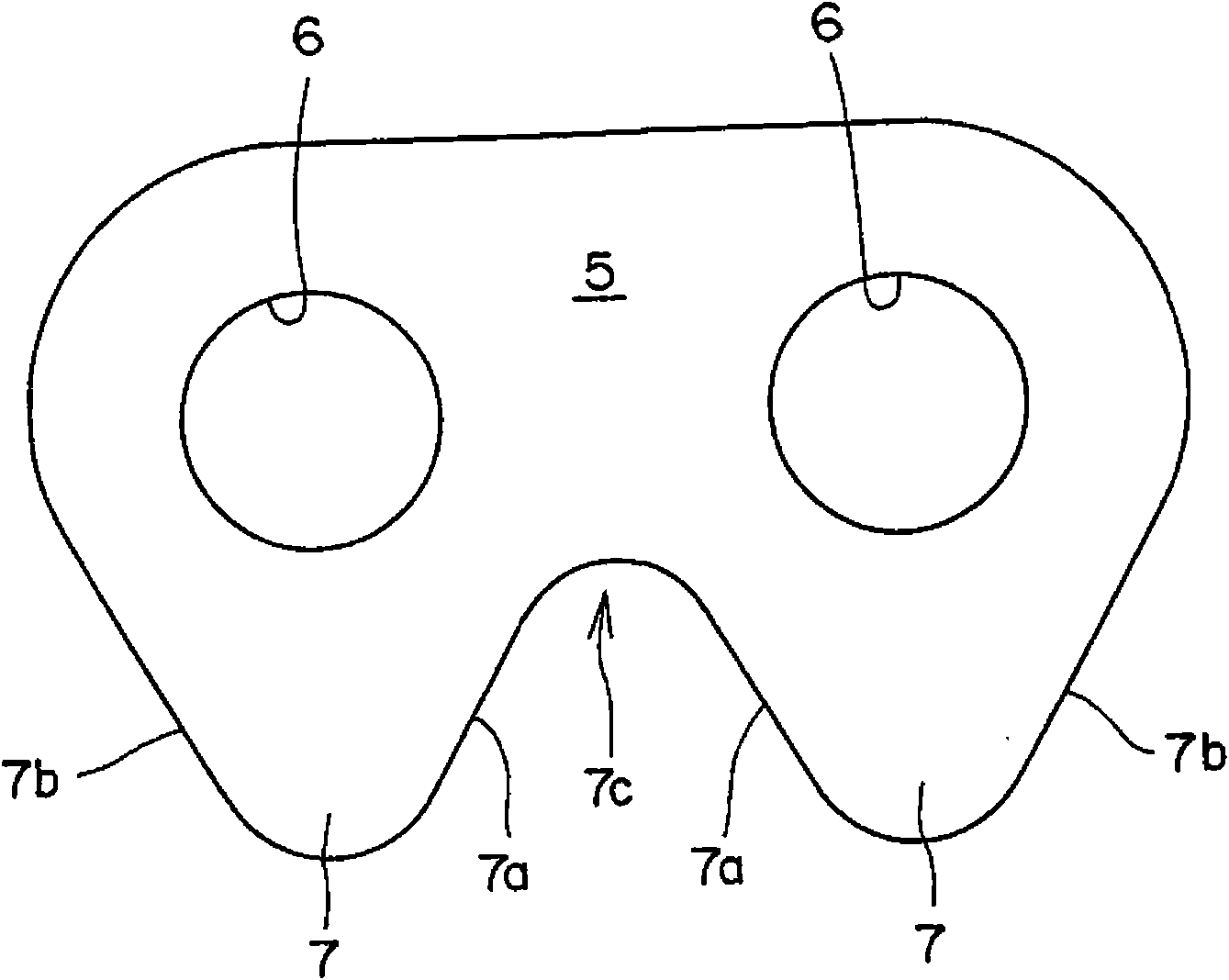

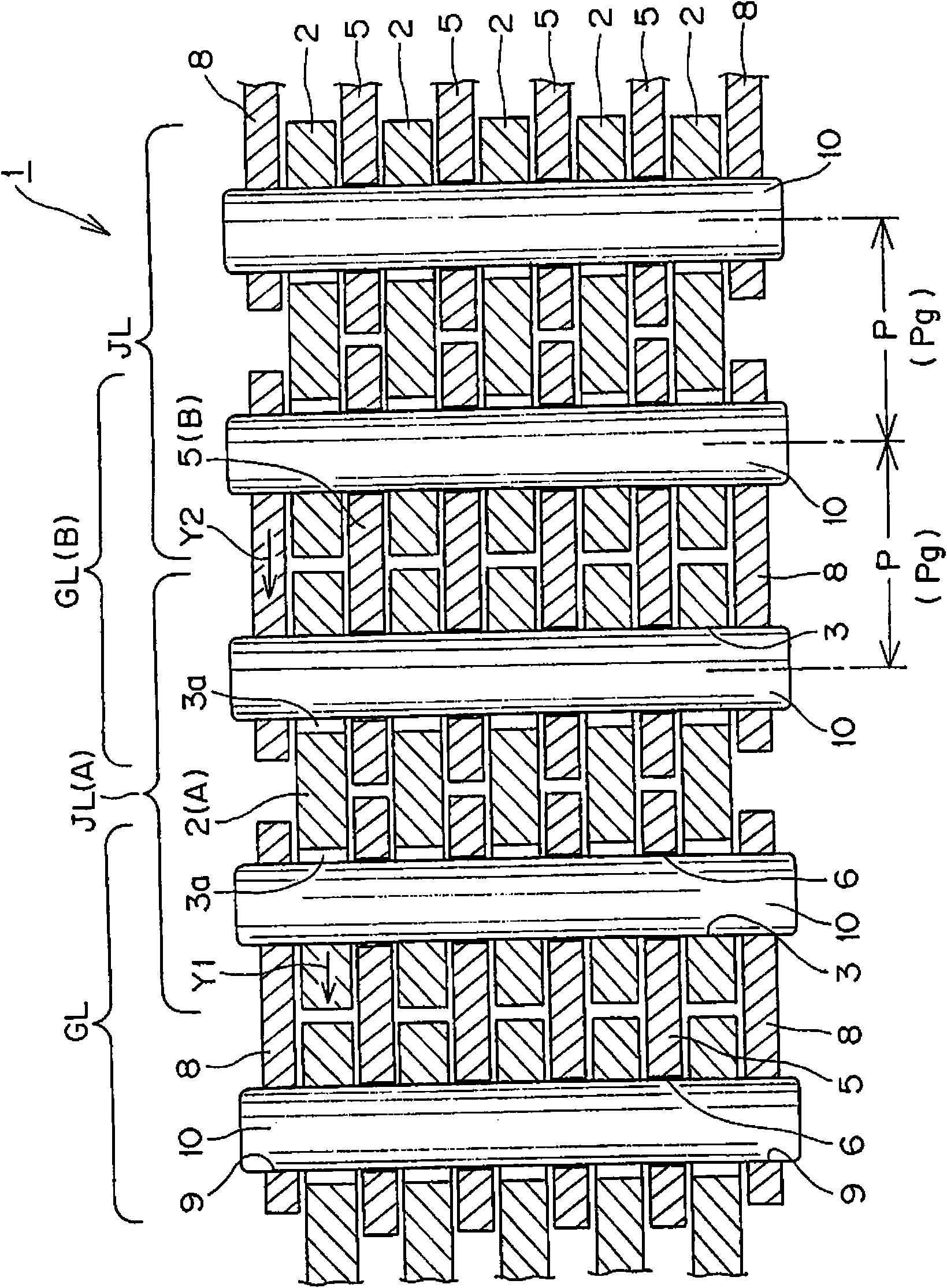

[0049] refer to Figure 1 to Figure 5 Example 1 of the present invention will be described. The silent chain 1 is formed by inserting connecting pins 10 into each pin hole 3, 6 to connect a plurality of inner tooth pieces 2 arranged as a non-guiding row JL and a plurality of middle tooth pieces 5 arranged as a guiding row GL, which will be described in detail below. narrative.

[0050] Such as figure 1 As shown, the inner tooth sheet 2 arranged as a non-guiding row JL has a pair of pin holes 3, 3 and a pair of teeth (double-strand teeth) 4, 4. The center of the sheet 2 is close to the elongated hole of the expanded portion 3a that expands inwardly.

[0051] Such as figure 2 As shown, the middle tooth piece 5 arranged as a guide row has a pair of pin holes 6, 6 and a pair of teeth (double-strand teeth) 7, 7, and the pin holes 6 are circular.

[0052] In addition, in figure 1 and figure 2 The middle symbols 4c and 7c are fork (crotch) parts. In addition, the inner to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com