Coil unit of electromagnetic contactor and assembling method thereof

A technology of electromagnetic contactor and coil unit, which is applied in the direction of electromagnetic terminals/connectors, electromagnetic relays, detailed information of electromagnetic relays, etc., and can solve problems such as increased product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

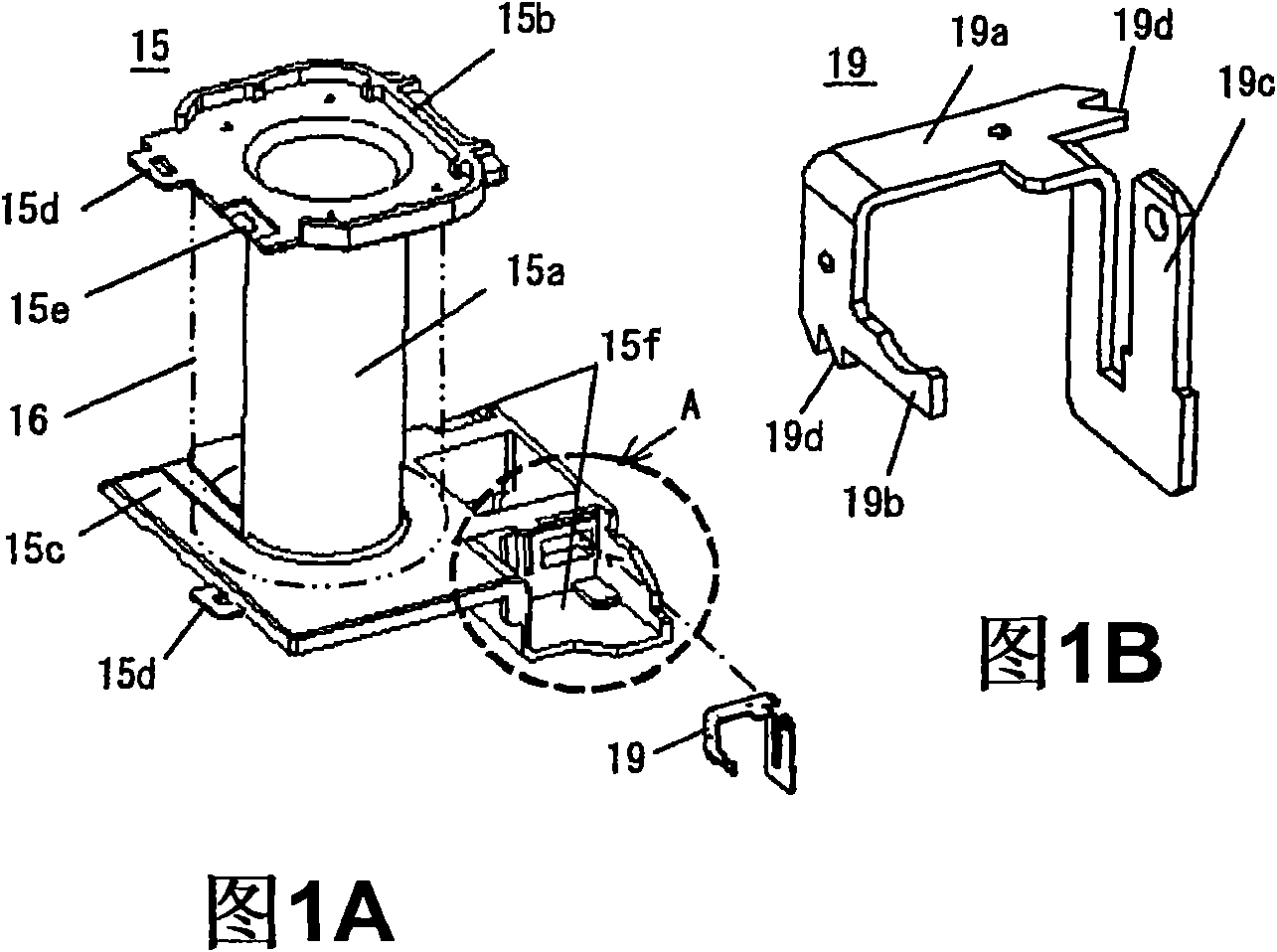

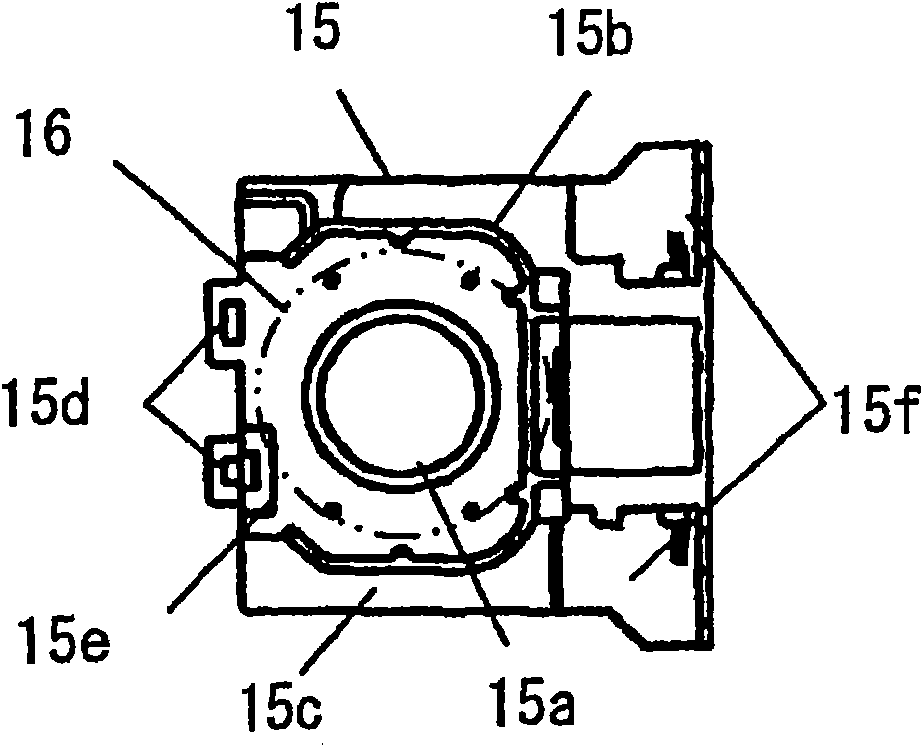

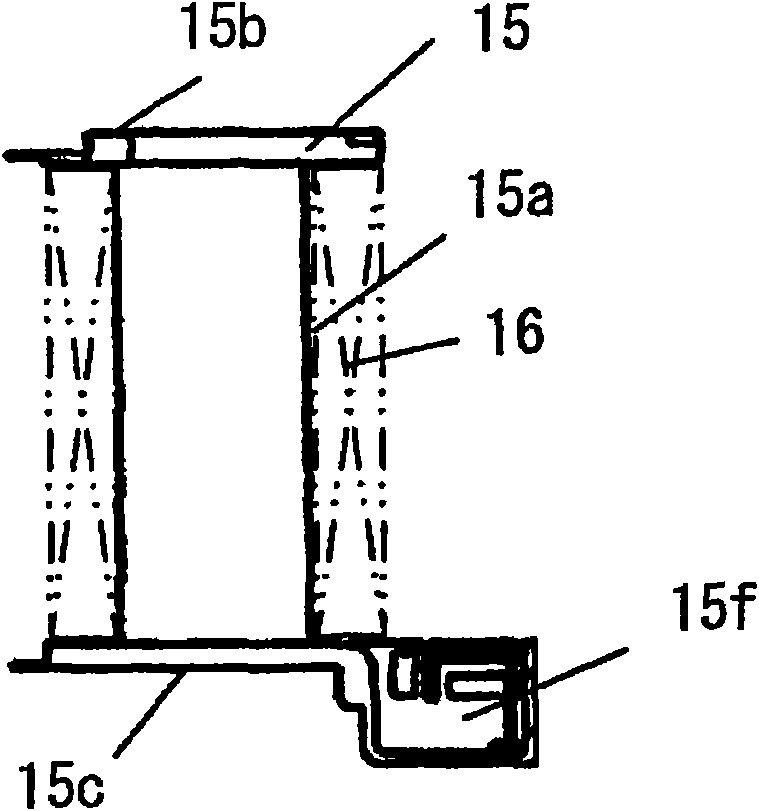

[0063] In the following, the application will be installed in the Figures 8A to 8C The double-coil unit of the working electromagnet on the electromagnetic contactor shown in is the object, based on Figure 1A to Figure 7C The examples shown in are illustrative of embodiments of the invention. here, Figure 1A is a perspective view showing the structure of a bobbin of a single coil unit according to an example of the present invention, Figure 1B is shown to be press fit into the Figure 1A A perspective view of the structure of the terminal metal piece on the spool shown in, Figure 2A is showing Figure 1A A plan view of the external shape of the spool shown in, Figure 2B is showing Figure 2A A side view of the external shape of the spool shown in, image 3 is showing Figure 1A An enlarged perspective view of the terminal metal mounting base in the portion indicated by the arrow A in, Figure 4 is shown attached by a press fit with Figure 1A of the terminal me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com