Plasma display panel

A display panel, plasma technology, used in alternating current plasma display panels, tube structural parts, discharge tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

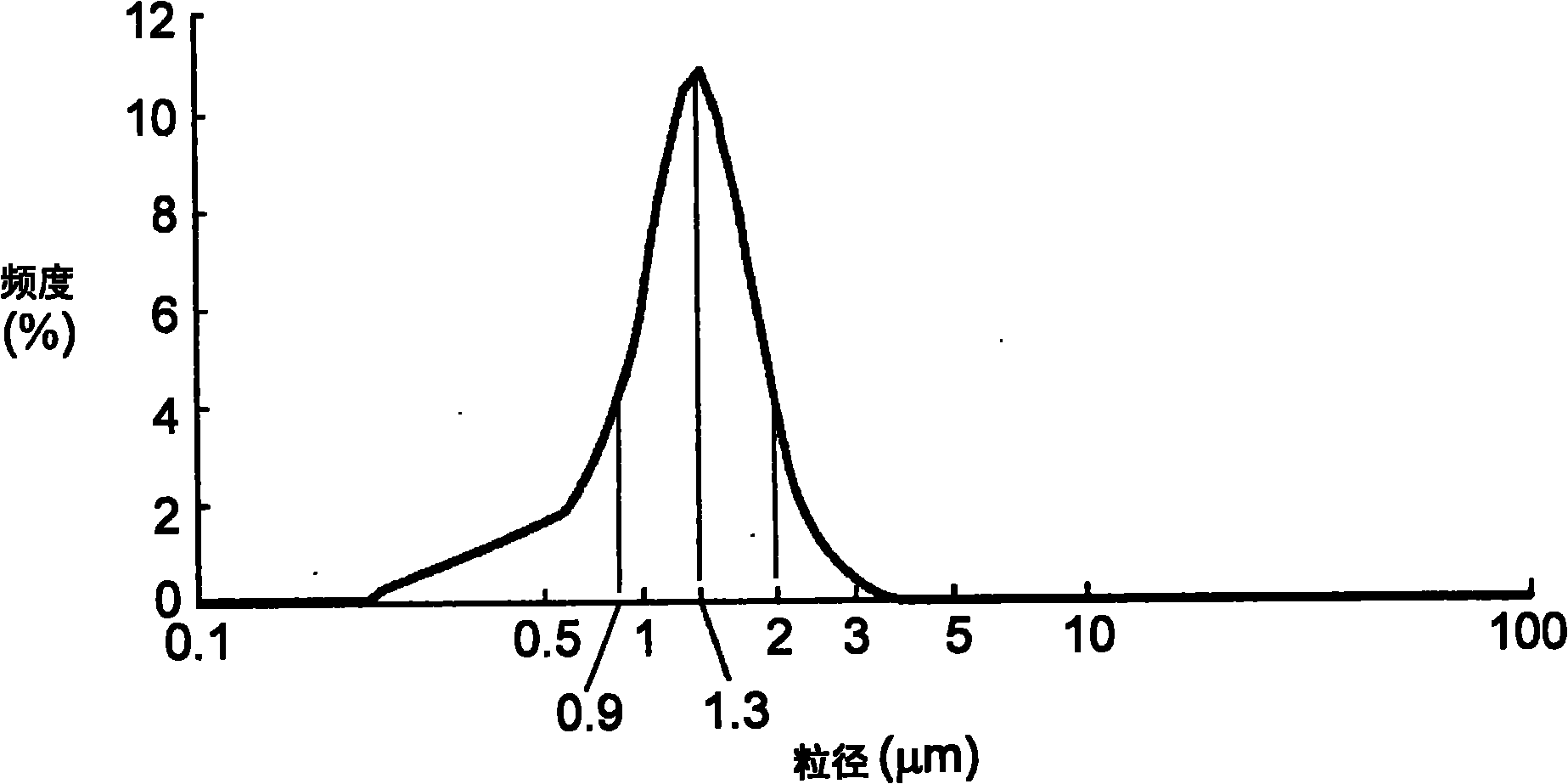

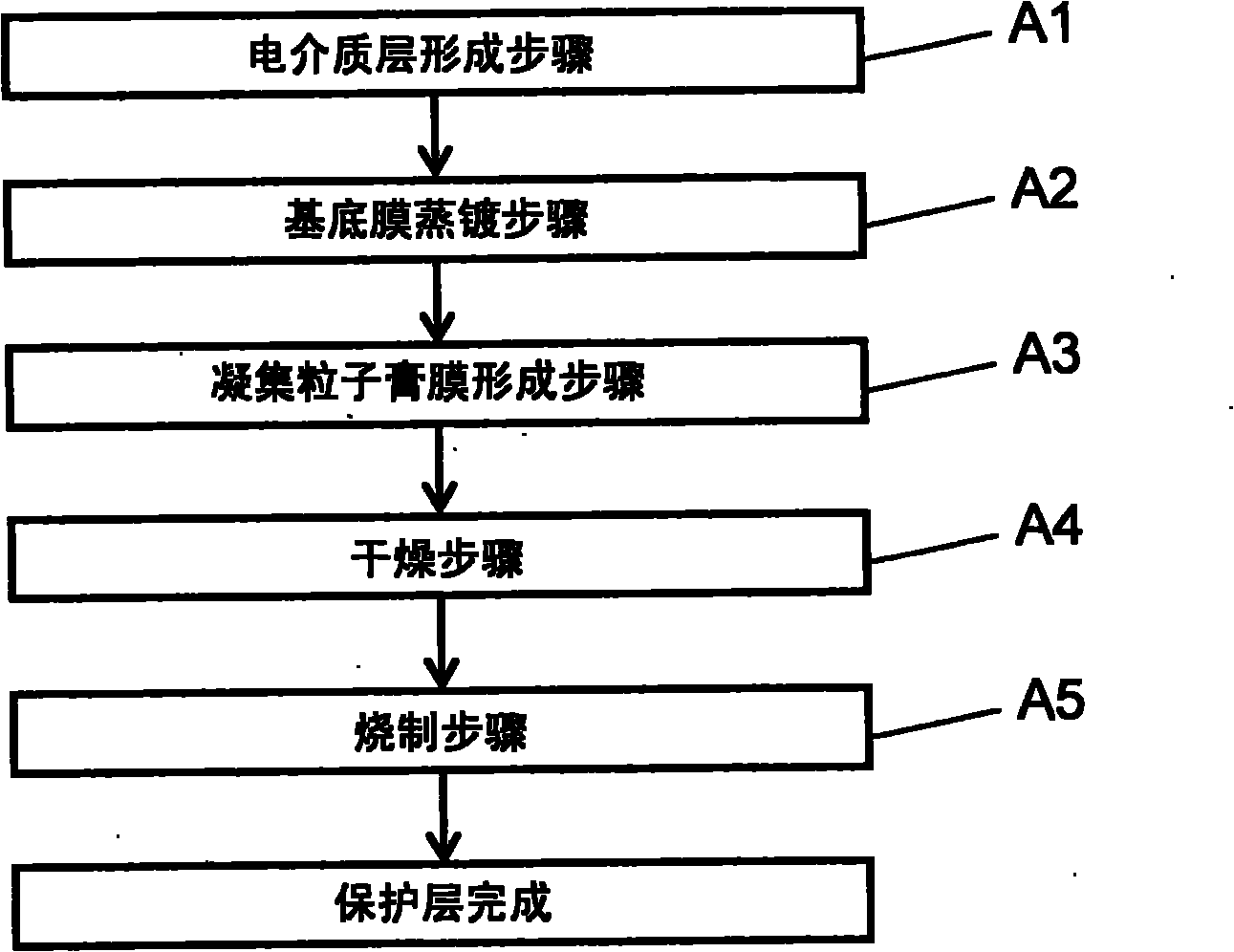

Method used

Image

Examples

Embodiment approach

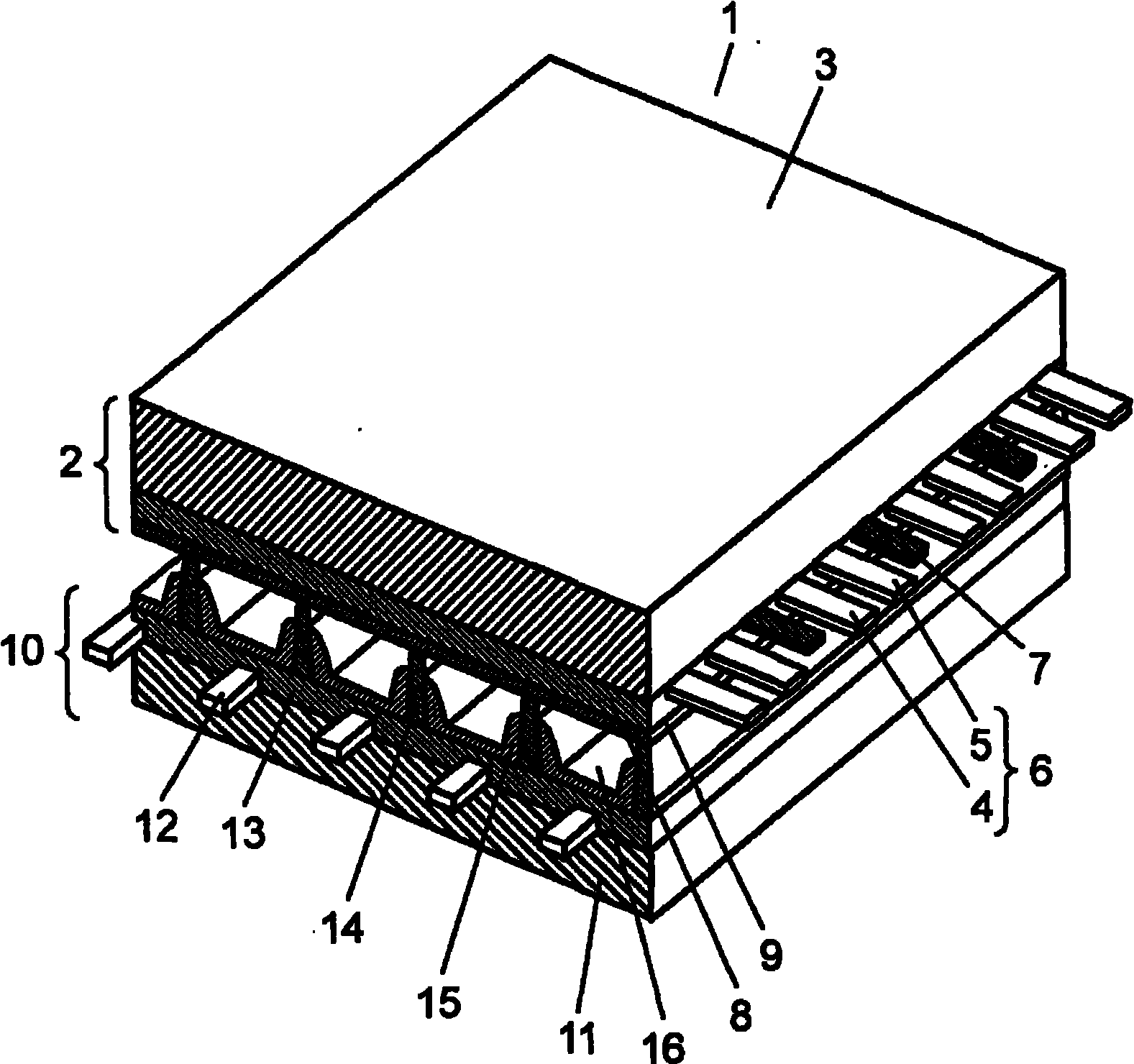

[0030] figure 1 It is a perspective view showing the structure of the PDP in the embodiment of the present invention. The basic structure of the PDP is the same as that of a common AC surface discharge type PDP. Such as figure 1 As shown in the PDP 1, a front panel 2 composed of a front glass substrate 3 and the like and a rear panel 10 composed of a rear glass substrate 11 and the like are opposed to each other. The outer peripheral portion of the PDP 1 is hermetically sealed by a sealing material made of glass frit or the like. Discharge gas such as Ne and Xe is sealed at a pressure of 400 Torr to 600 Torr in the discharge space 16 inside the hermetically sealed PDP 1 .

[0031] On the front glass substrate 3 of the front panel 2, a plurality of display electrodes 6 composed of a pair of strip-shaped scan electrodes 4 and sustain electrodes 5 and black stripes (light shielding layers) 7 are arranged in parallel to each other. A dielectric layer 8 functioning as a capac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap