Hardcoat compositions

A technology of composition and hard coating, which is applied in the direction of coating, instrument, photoplate process of patterned surface, etc., can solve the problem of limited release characteristics, and achieve low peeling force, good release characteristics, and high oil contact angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

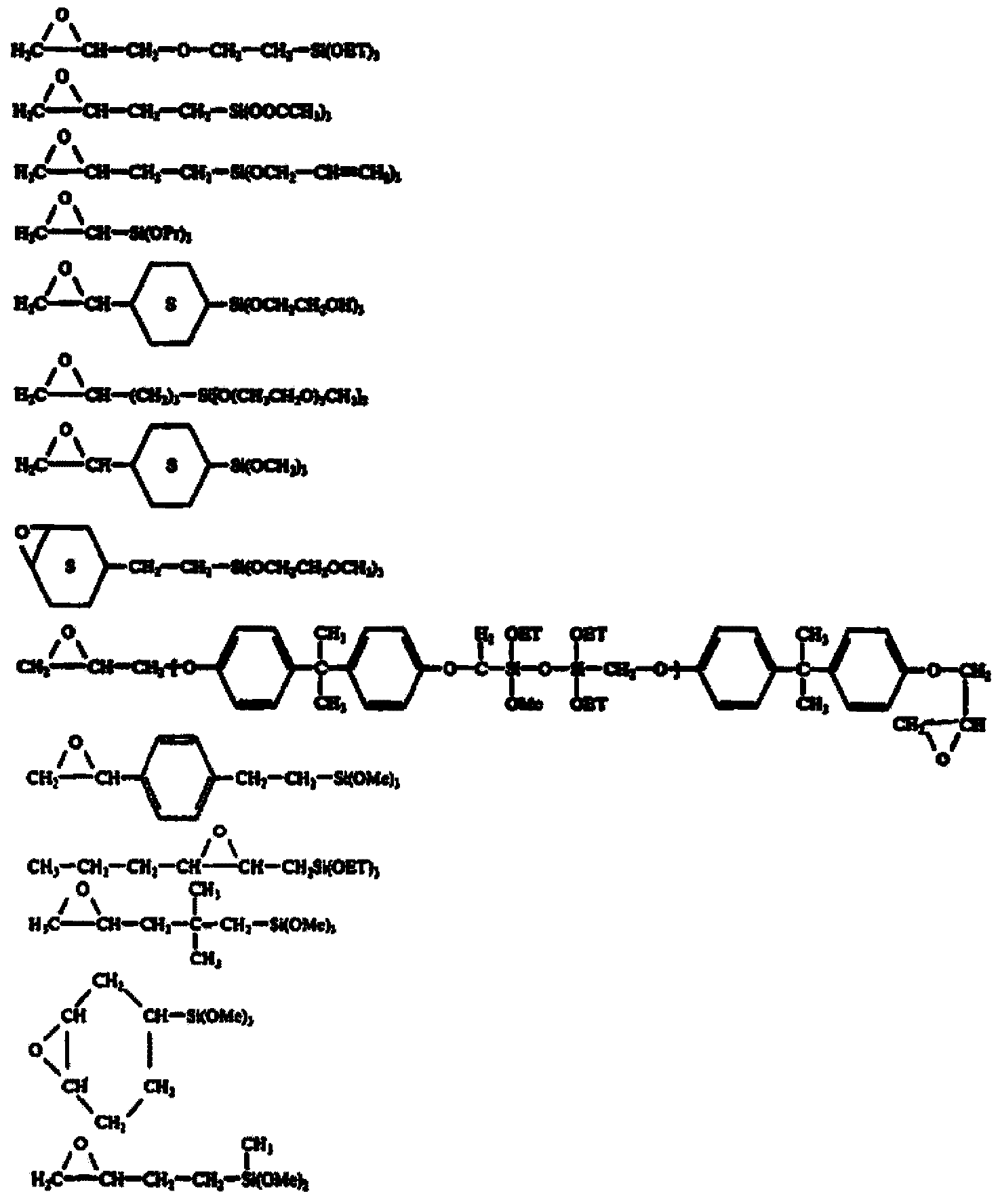

[0076] The preparation of most of the above epoxy-terminated silane compounds is described in US Patent No. 3,131,161.

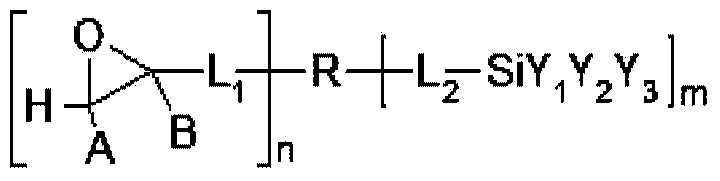

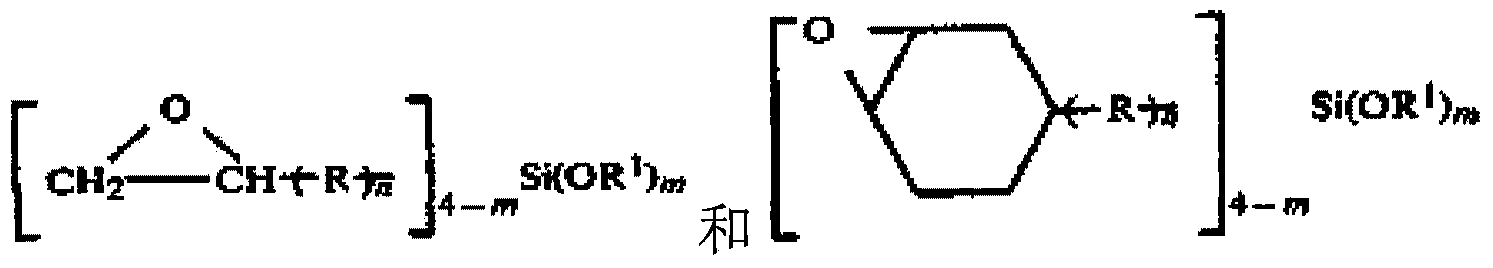

[0077] Other useful epoxy-terminated silanes are epoxy-terminated silanes represented by the formula:

[0078]

[0079] in

[0080] m is 1 to 6 (preferably 1 to 4),

[0081] n is 0 or 1 (preferably 1),

[0082] p is 1 to 6 (preferably 1 to 4), and

[0083] R 1 is H or an alkyl group of 1 to 10 carbon atoms (preferably an alkyl group of 1 to 4 carbon atoms).

[0084] In addition to any of the aforementioned epoxysilanes, partially hydrolyzed or condensed epoxysilanes which are further curable upon exposure to light in the presence of a photoacid generator may also be used in the present invention, alone or in combination with unhydrolyzed epoxysilanes. These partial hydrolysates can be obtained by silane OR 1 Formed by partial hydrolysis of the group. Thus, the term "precondensate" includes siloxanes in which some or all of the silicon atoms are bon...

example

[0317] Objects and advantages of this invention are further illustrated by the following examples, but the particular materials and amounts thereof recited in these examples, as well as other conditions and details, should not be construed to unduly limit this invention.

[0318] Material

[0319] Materials used in the examples are shown in Table 1.

[0320]

[0321]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com