Anesthesia evaporator

An anesthesia vaporizer and vaporization chamber technology, applied in the field of anesthesia vaporizers, can solve the problems of occupying the external space of the vaporizer, unable to change the temperature of the vaporizer, complex structure and assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

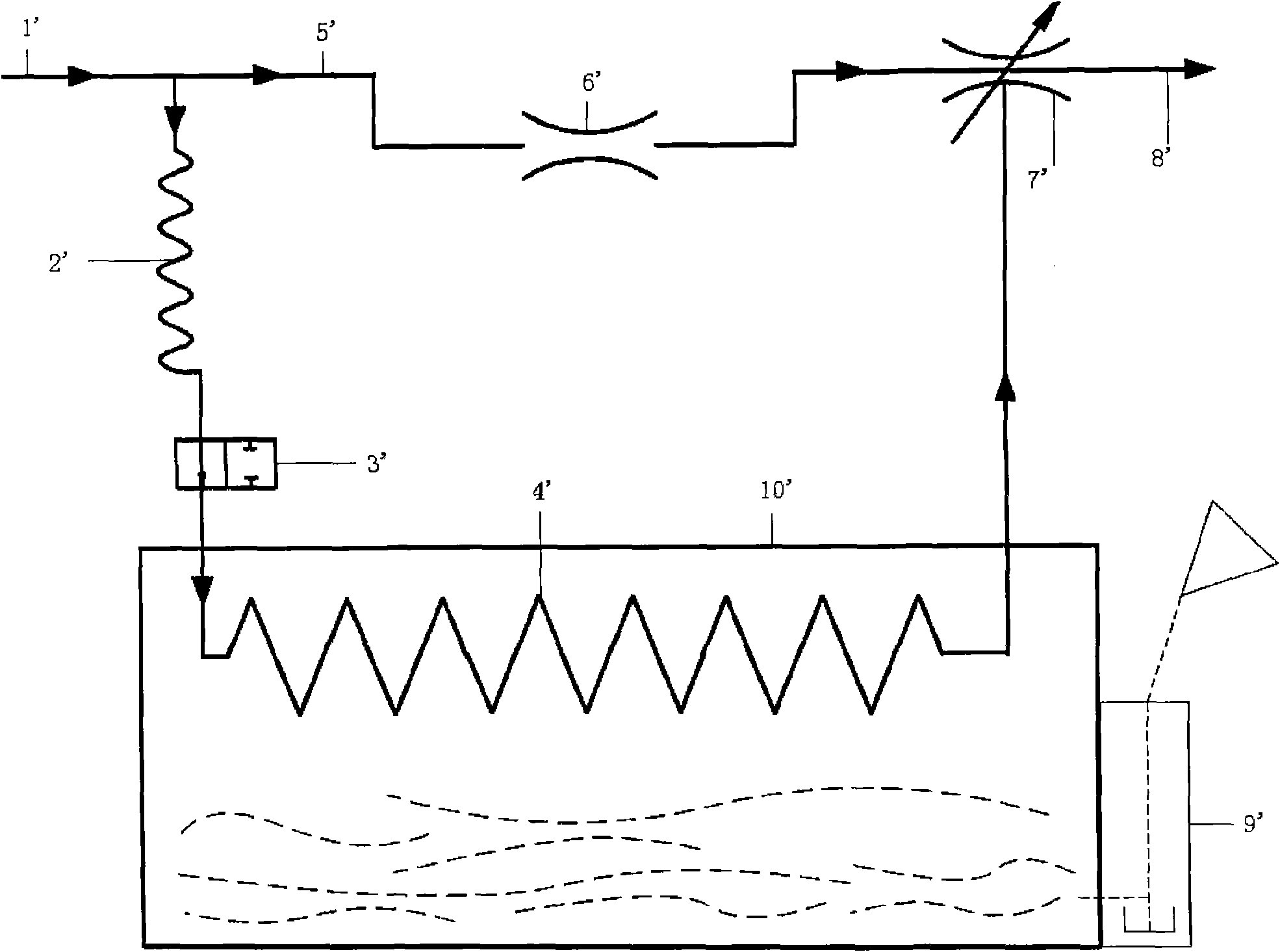

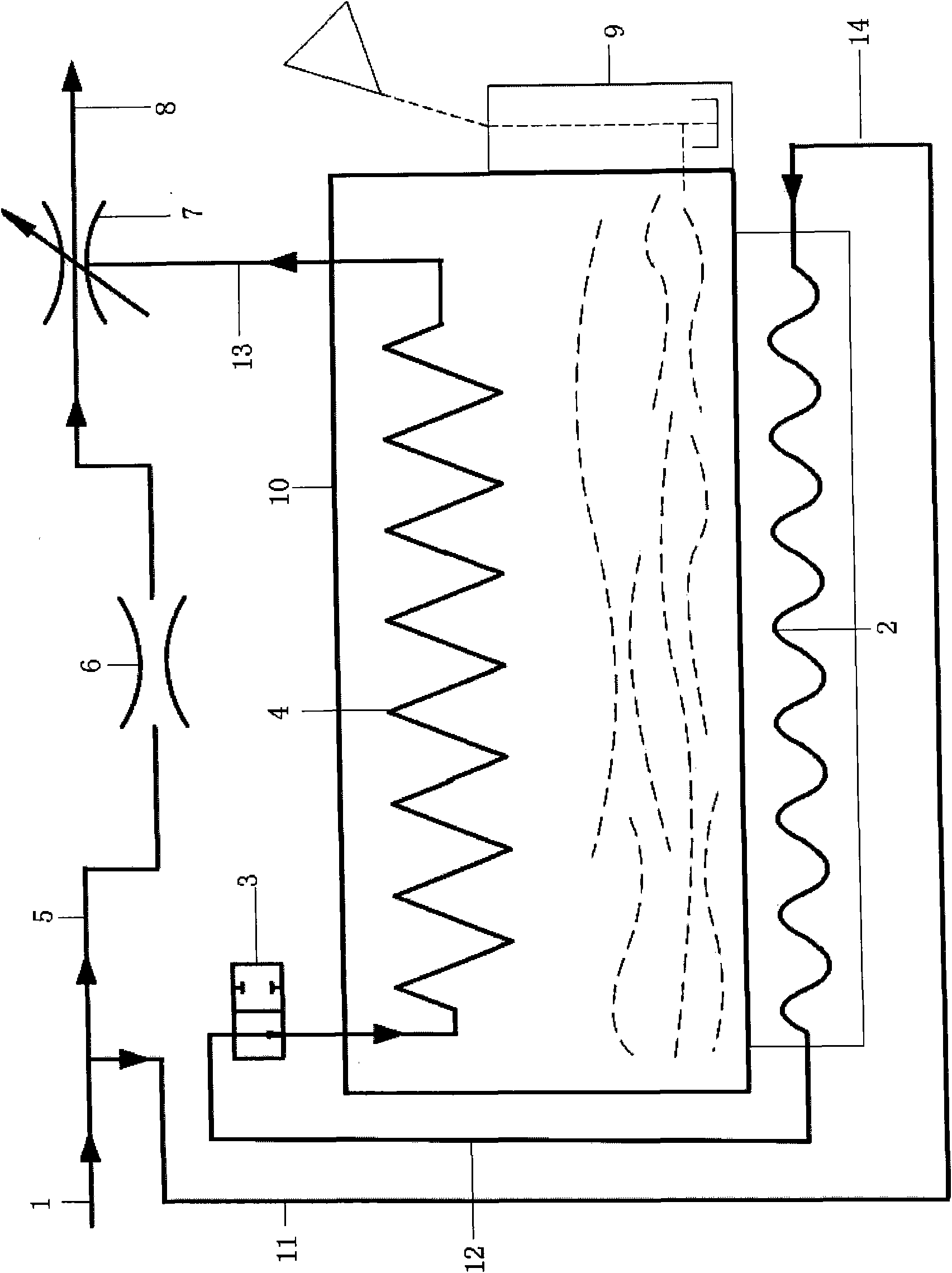

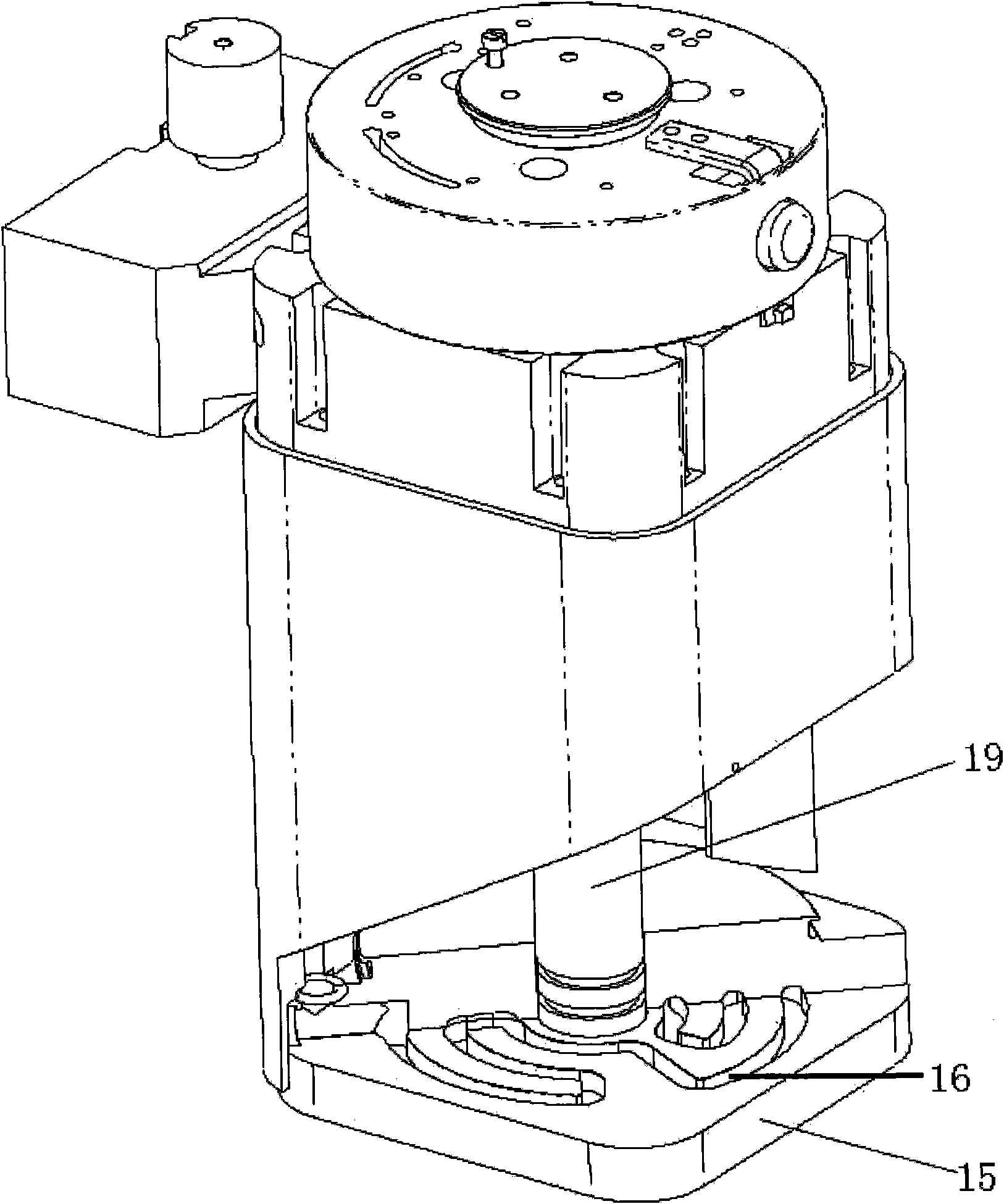

[0021] Such as Figure 2 to Figure 5 As shown, the anesthesia vaporizer in this embodiment includes a fresh gas inlet 1 , a mixed gas outlet 8 , an evaporation chamber 10 , a dosing unit 9 , a first gas branch 5 and a second gas branch 14 . Fresh gas inlet 1 is used to receive fresh gas. The mixed gas outlet 8 is used to output the mixed gas of fresh gas and anesthetic vapor. The evaporation chamber 10 can be made of metal with good thermal conductivity, and the evaporation chamber 10 has a cavity for storing anesthetics. The dosing unit 9 is used for perfusing anesthetic agent into the cavity of the evaporation chamber 10, and the dosing unit 9 communicates with the cavity through a channel.

[0022] The first gas branch 5 is provided with a temperature compensation unit 6 and a concentration control unit 7 . The temperature compensation unit 6 is equivalent to a valve body that can change the vent diameter of the first gas branch 5, and it adjusts the vent diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com