Patents

Literature

40 results about "Anaesthetic vaporizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

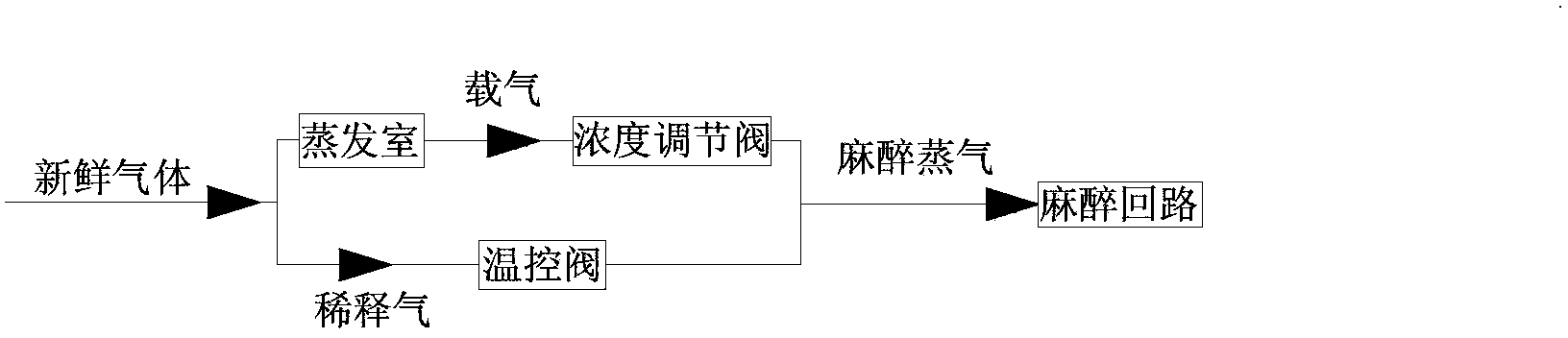

An anesthetic vaporizer is a device generally attached to an anesthetic machine which delivers a given concentration of a volatile anesthetic agent. It works by controlling the vaporization of anesthetic agents from liquid, and then accurately controlling the concentration in which these are added to the fresh gas flow. The design of these devices takes account of varying: ambient temperature, fresh gas flow, and agent vapor pressure.

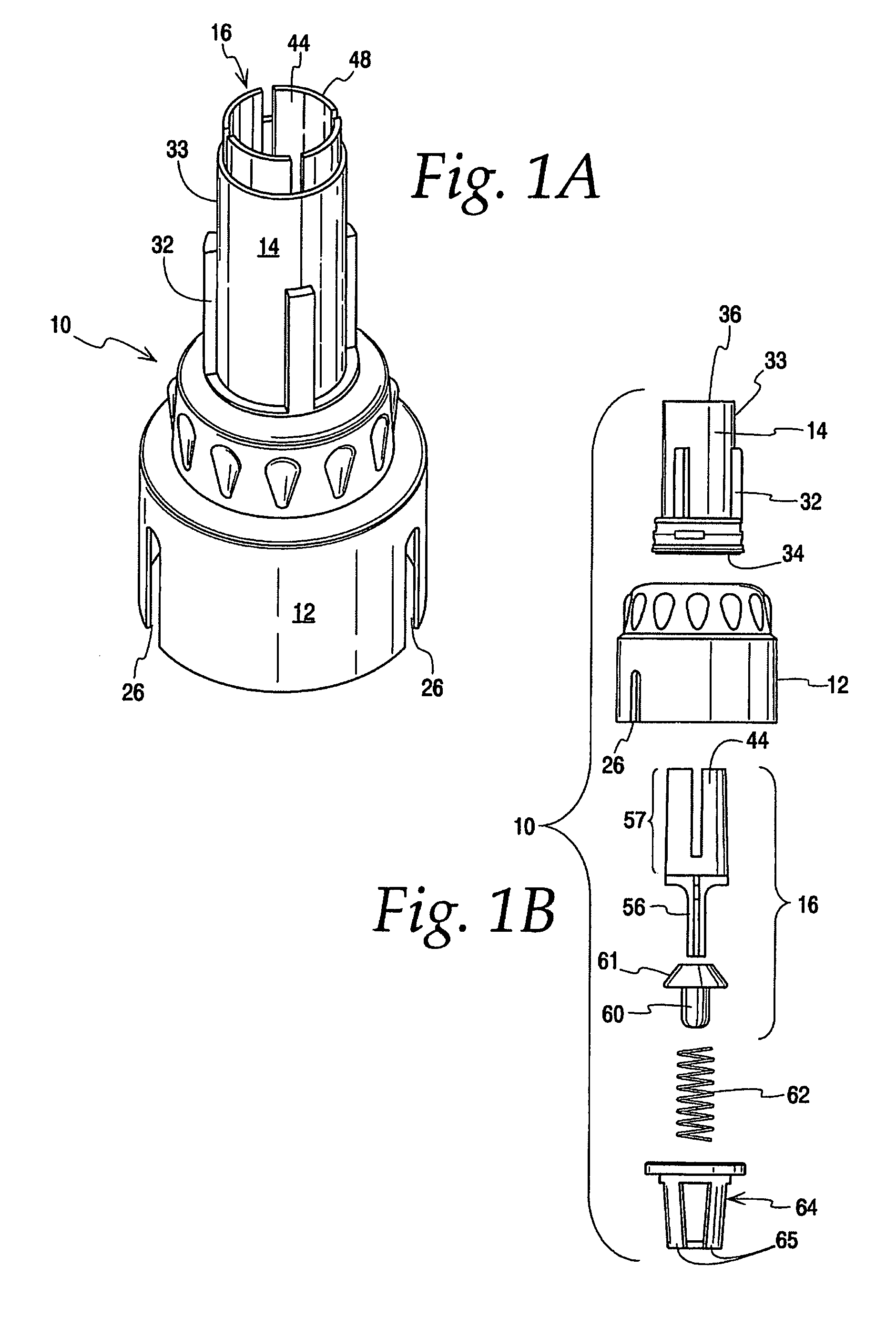

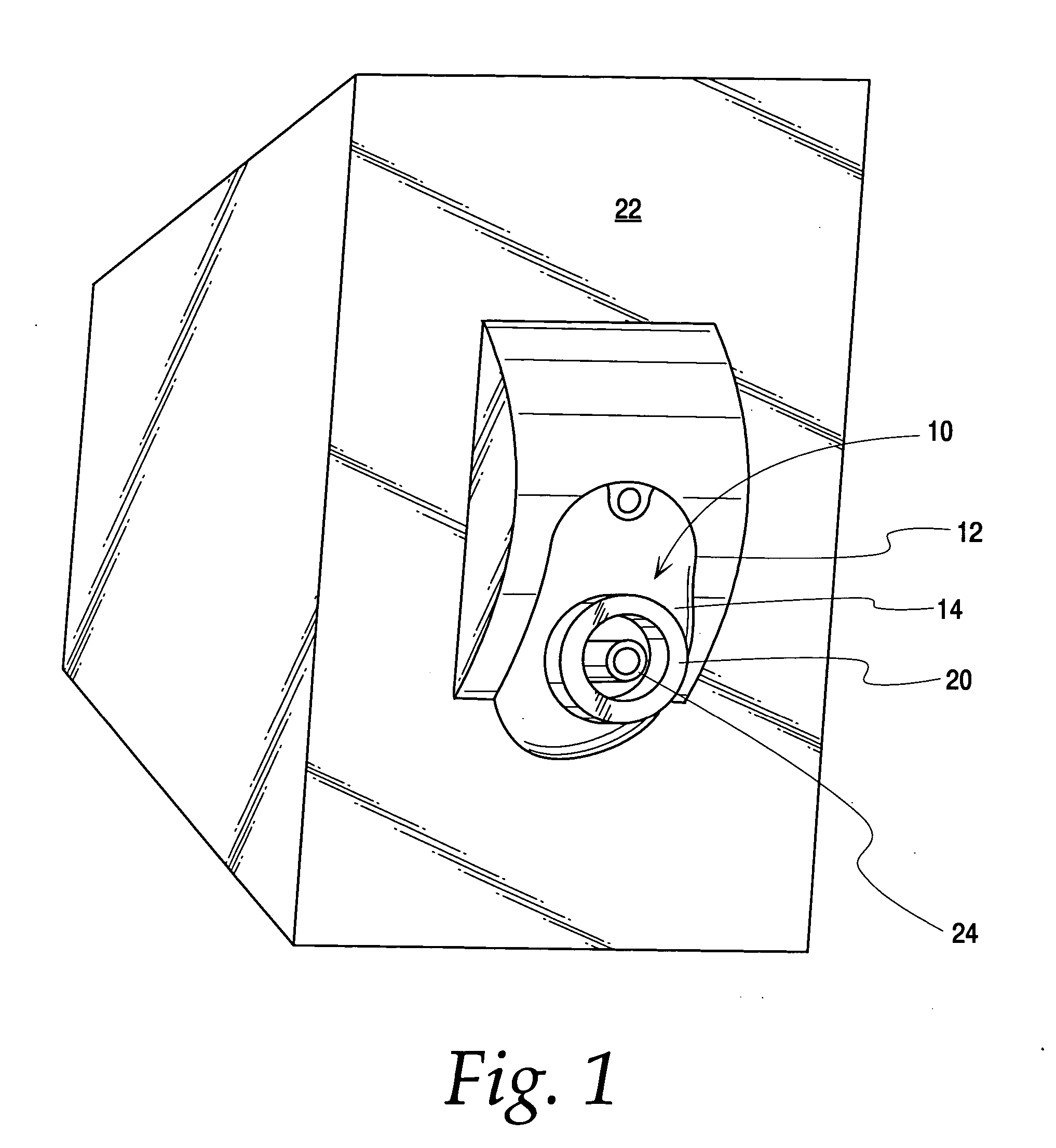

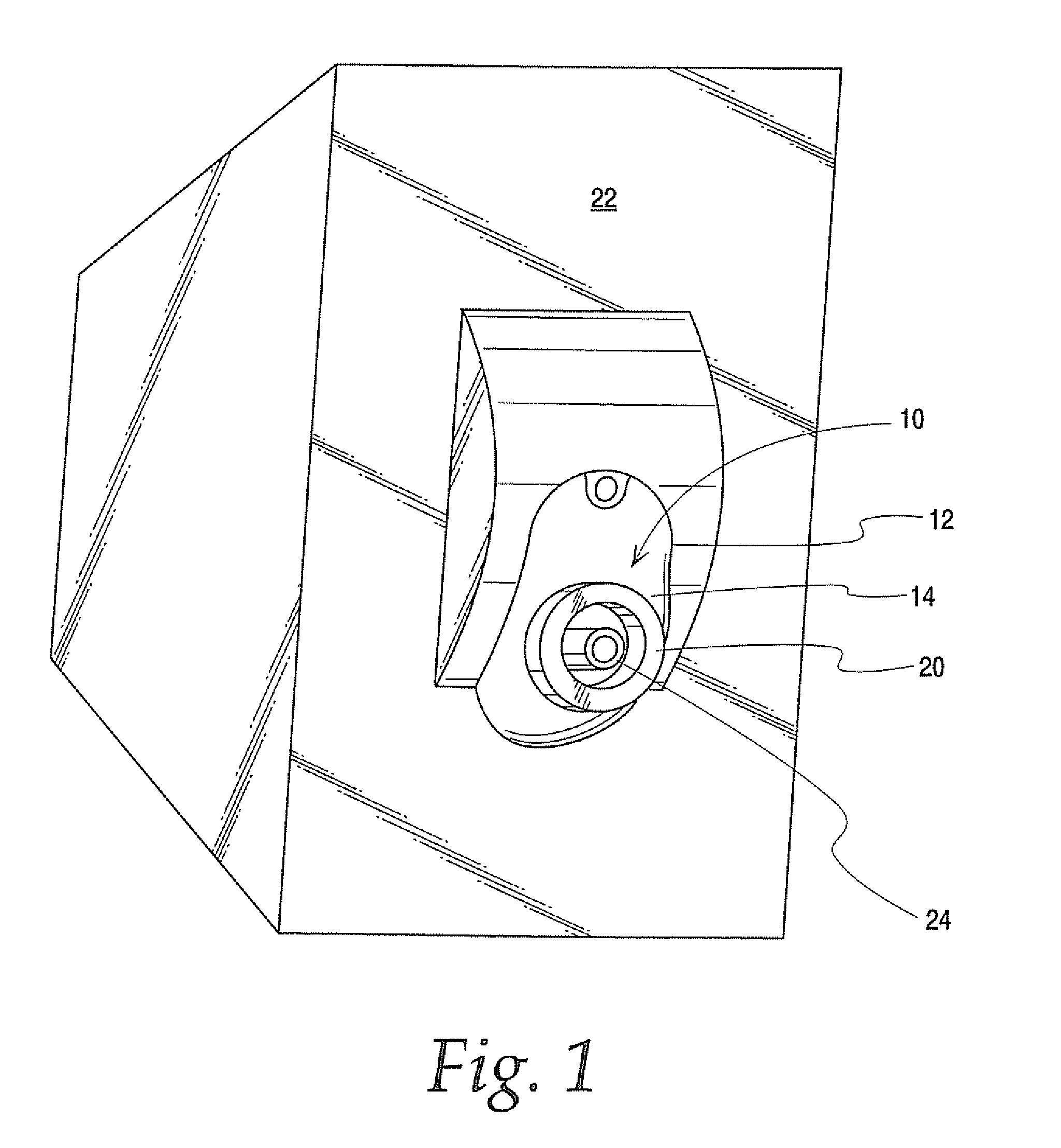

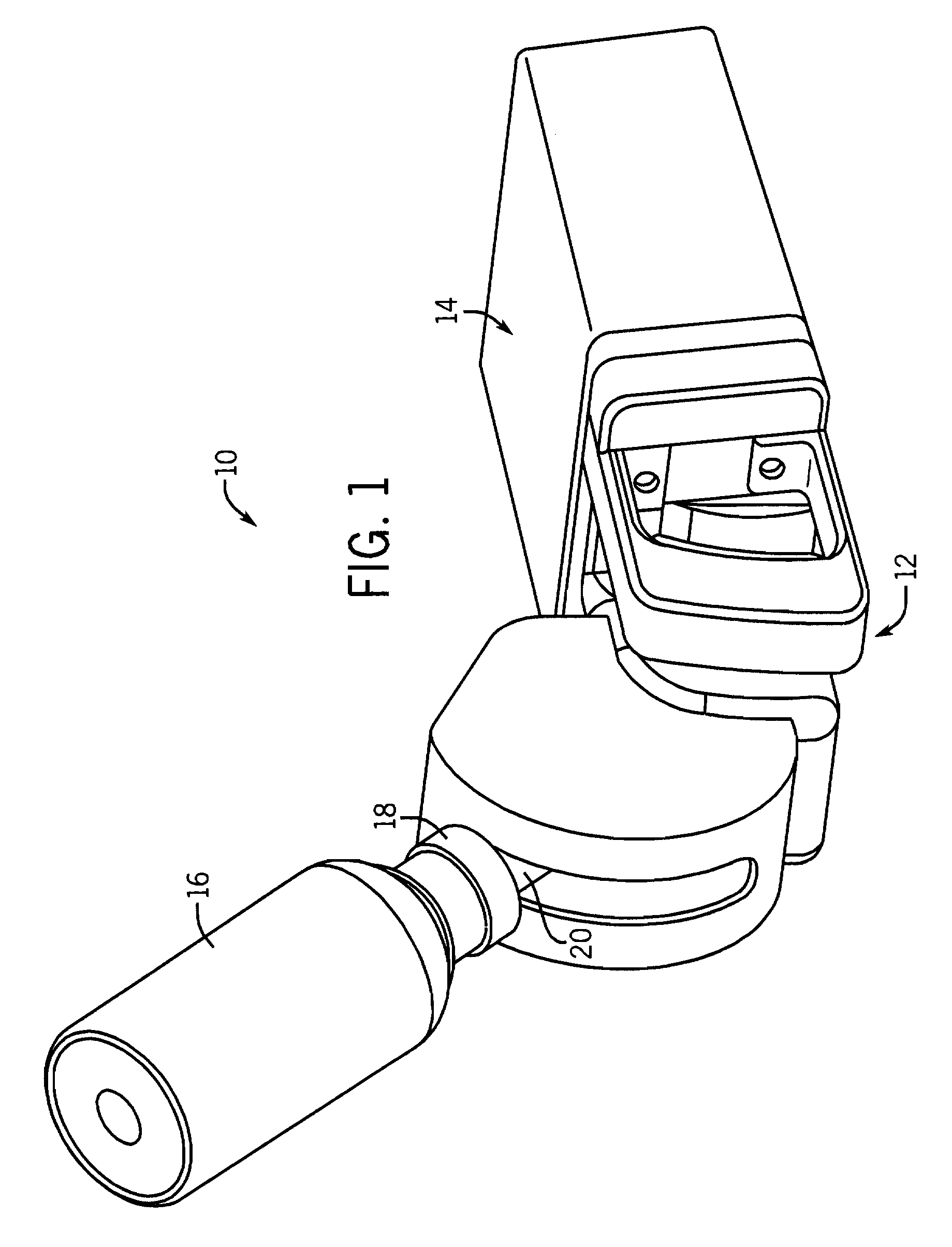

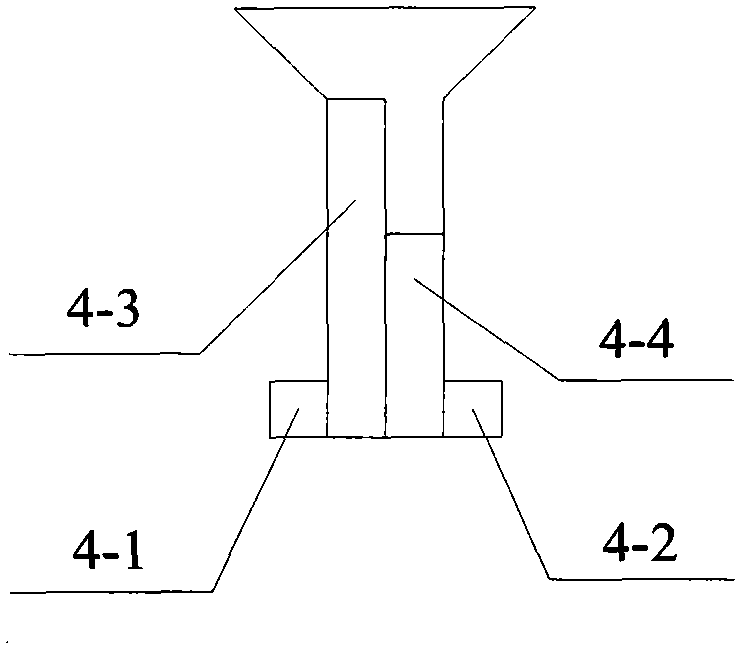

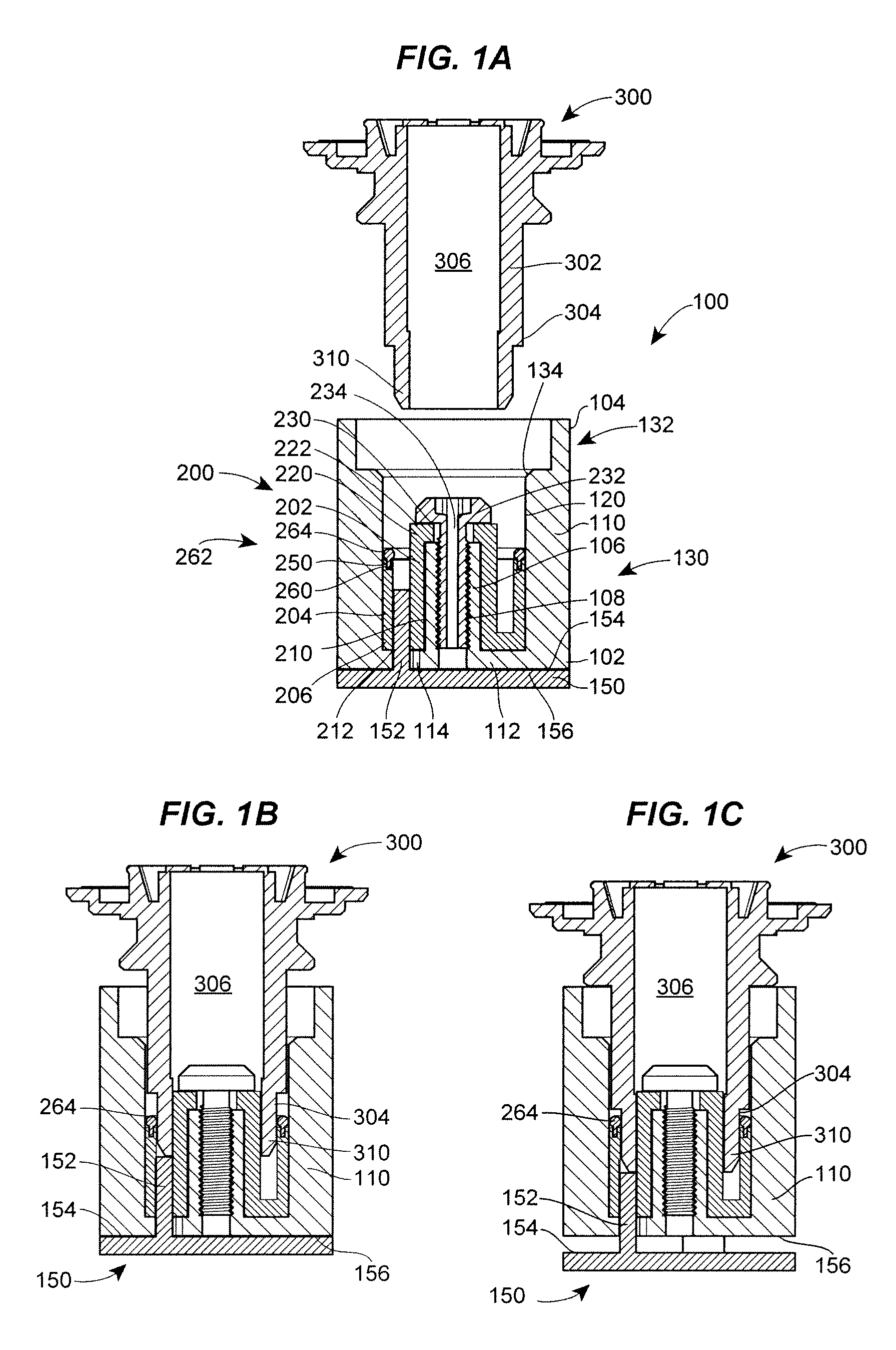

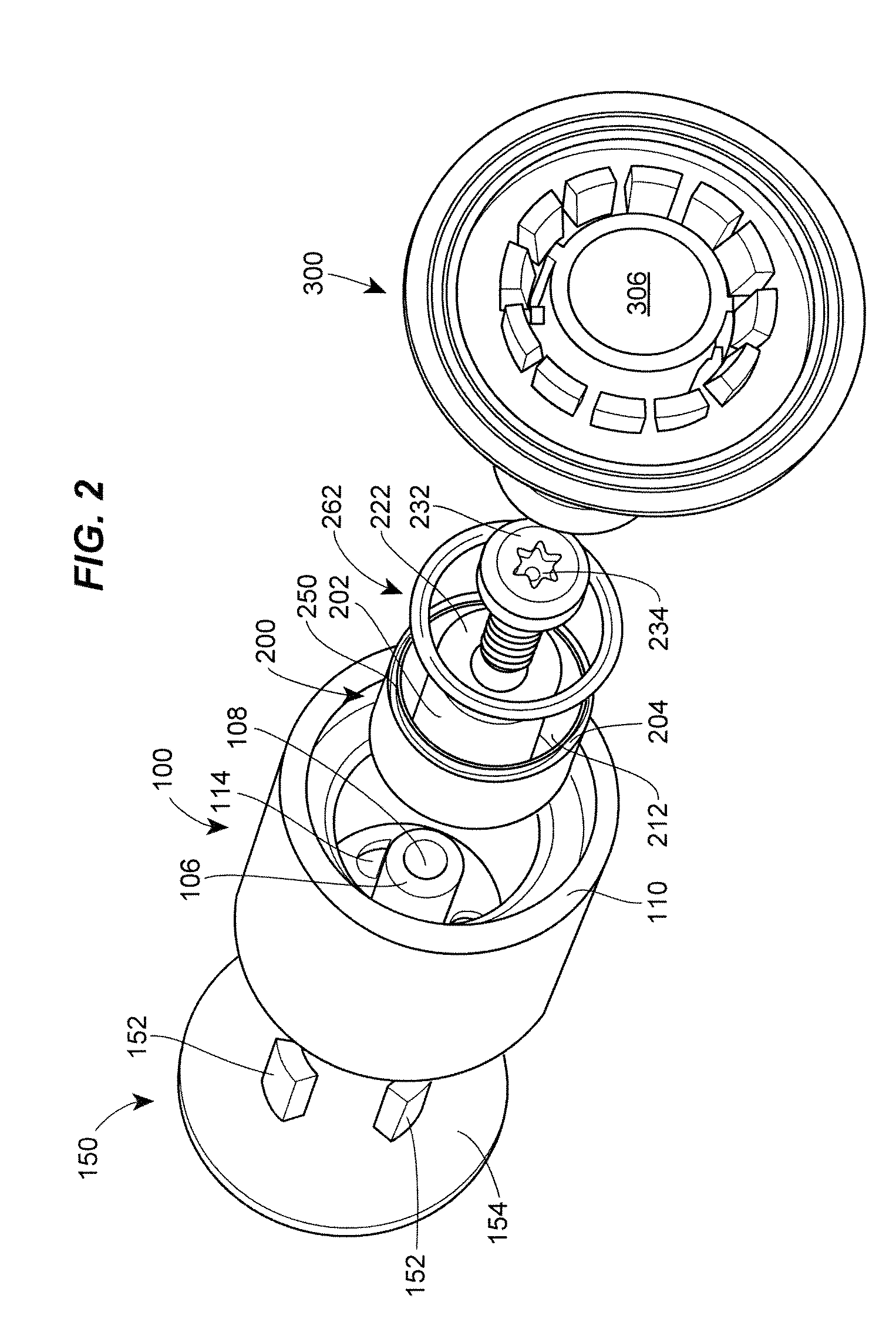

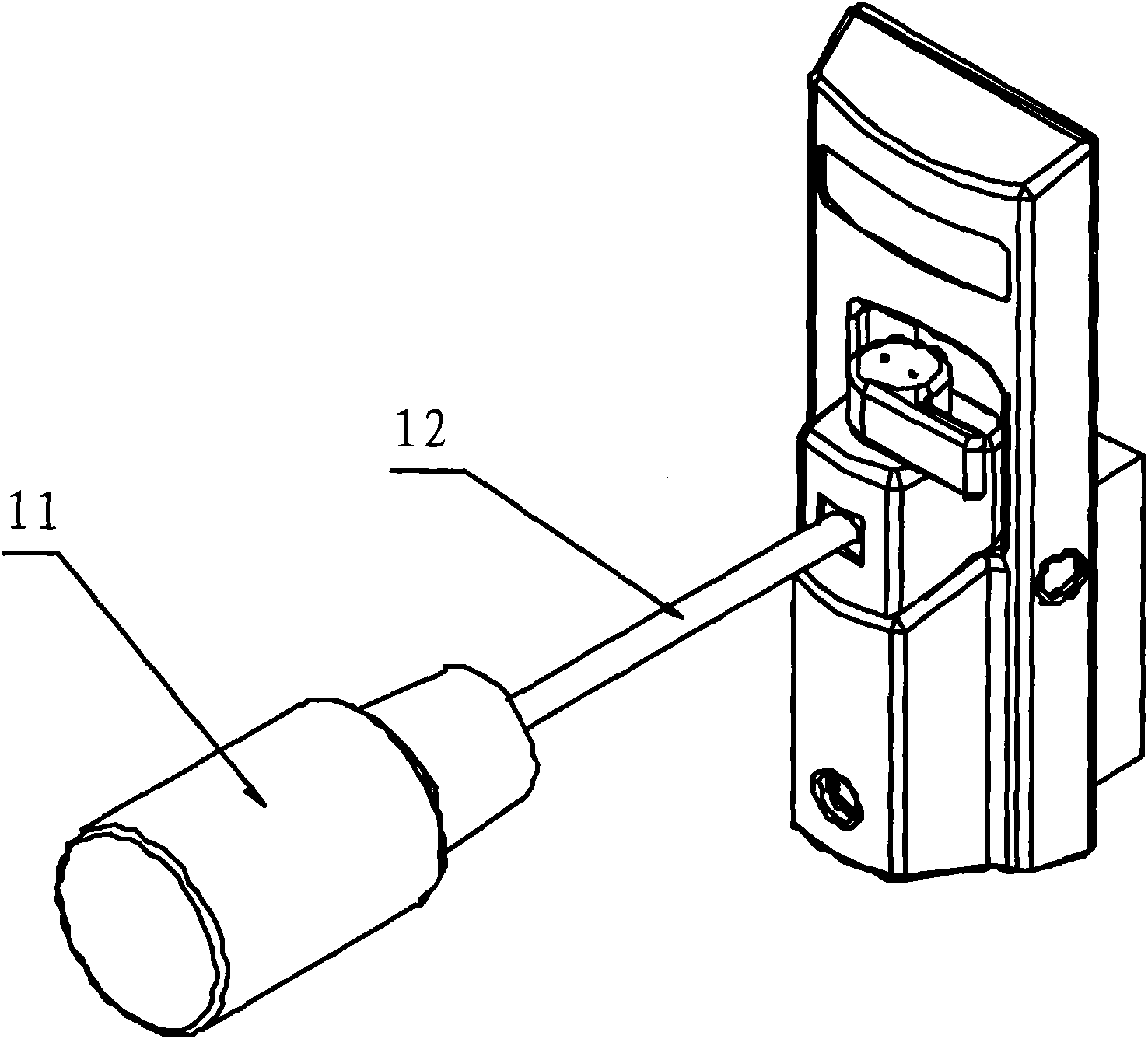

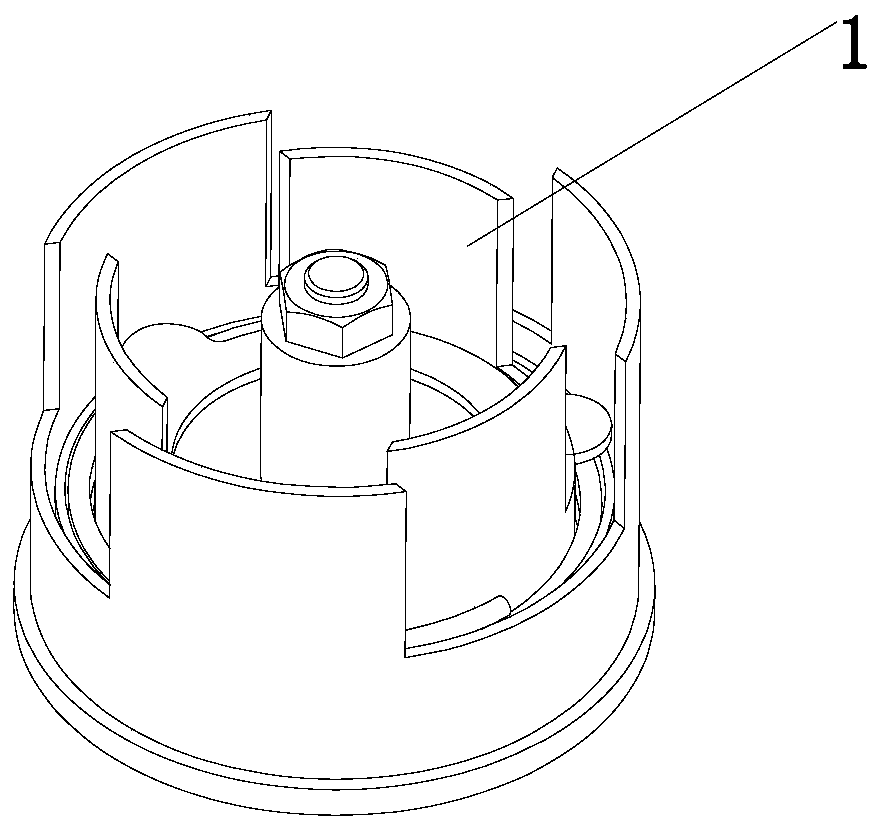

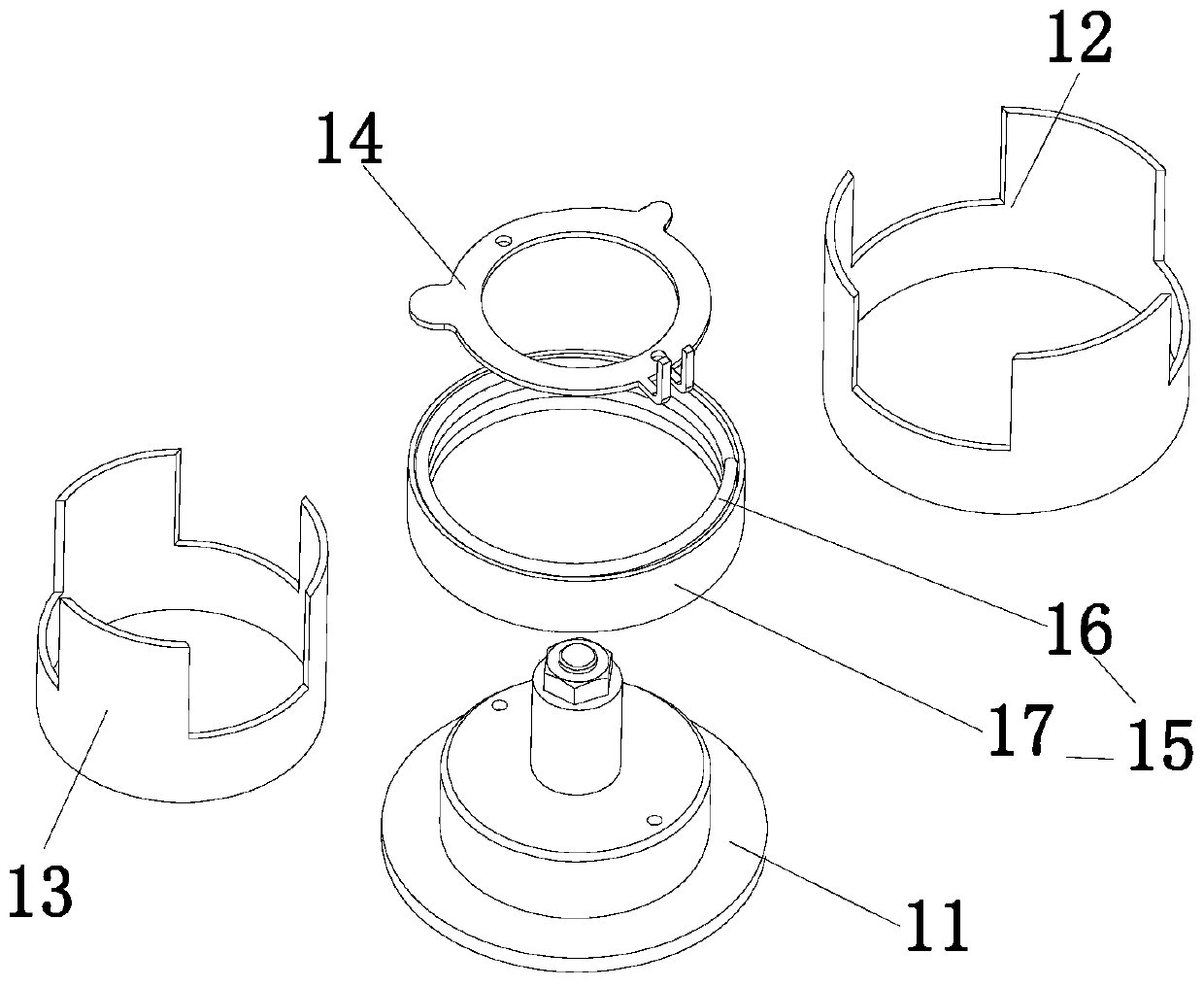

Adapters for use with an anesthetic vaporizer

ActiveUS20070204932A1RespiratorsPharmaceutical containersIntensive care medicineAnesthetic agent vaporizer

Adapters are provided for establishing fluid communication between an anesthetic agent container and an anesthetic vaporizer having a fluid port. The adapter may be mountable on the vaporizer to cooperate with the spout of an anesthetic agent container or may be mountable on an anesthetic agent container to cooperate with the fluid port of an anesthetic vaporizer to provide a sealing and / or retaining relationship therebetween.

Owner:BAXTER INT INC +1

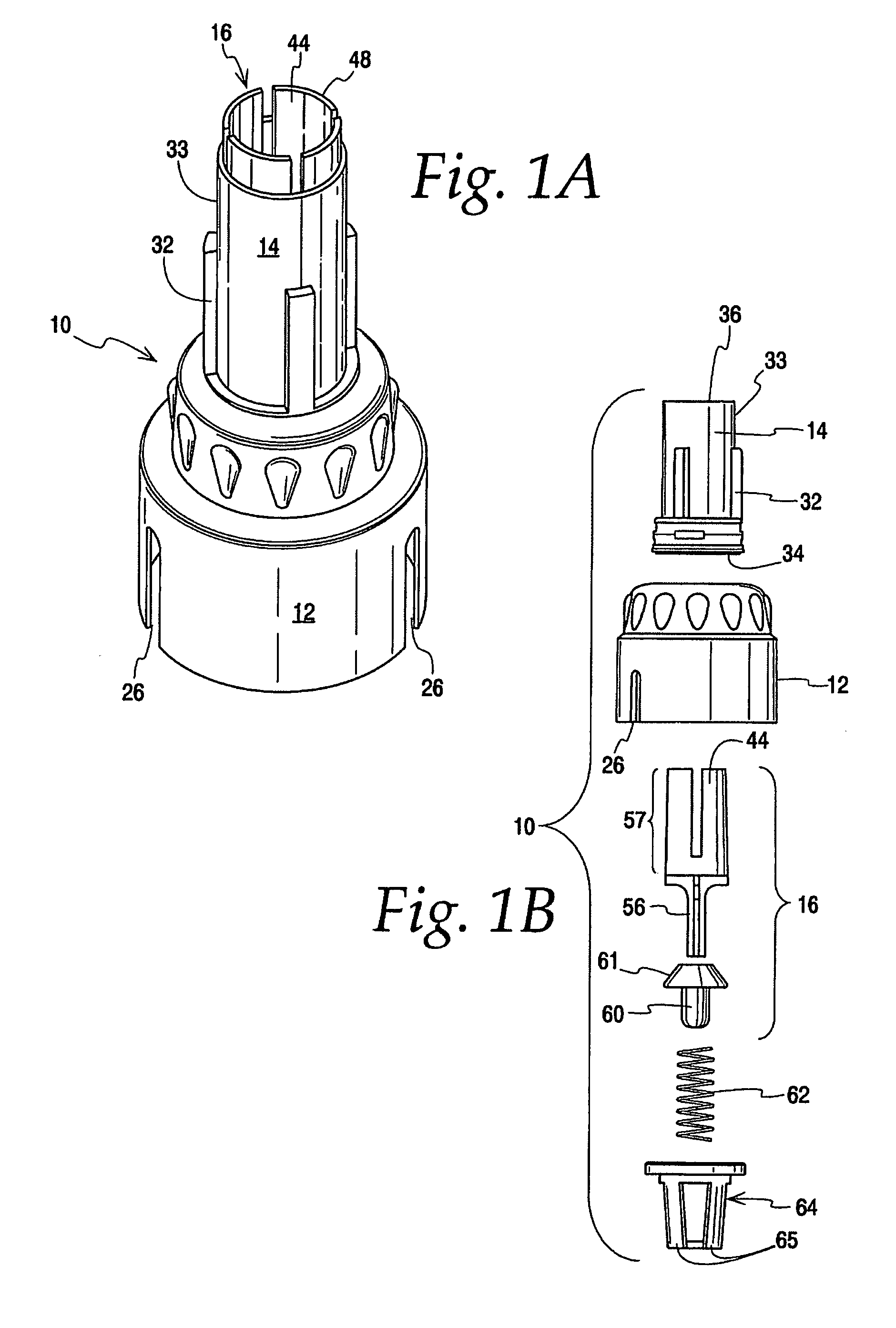

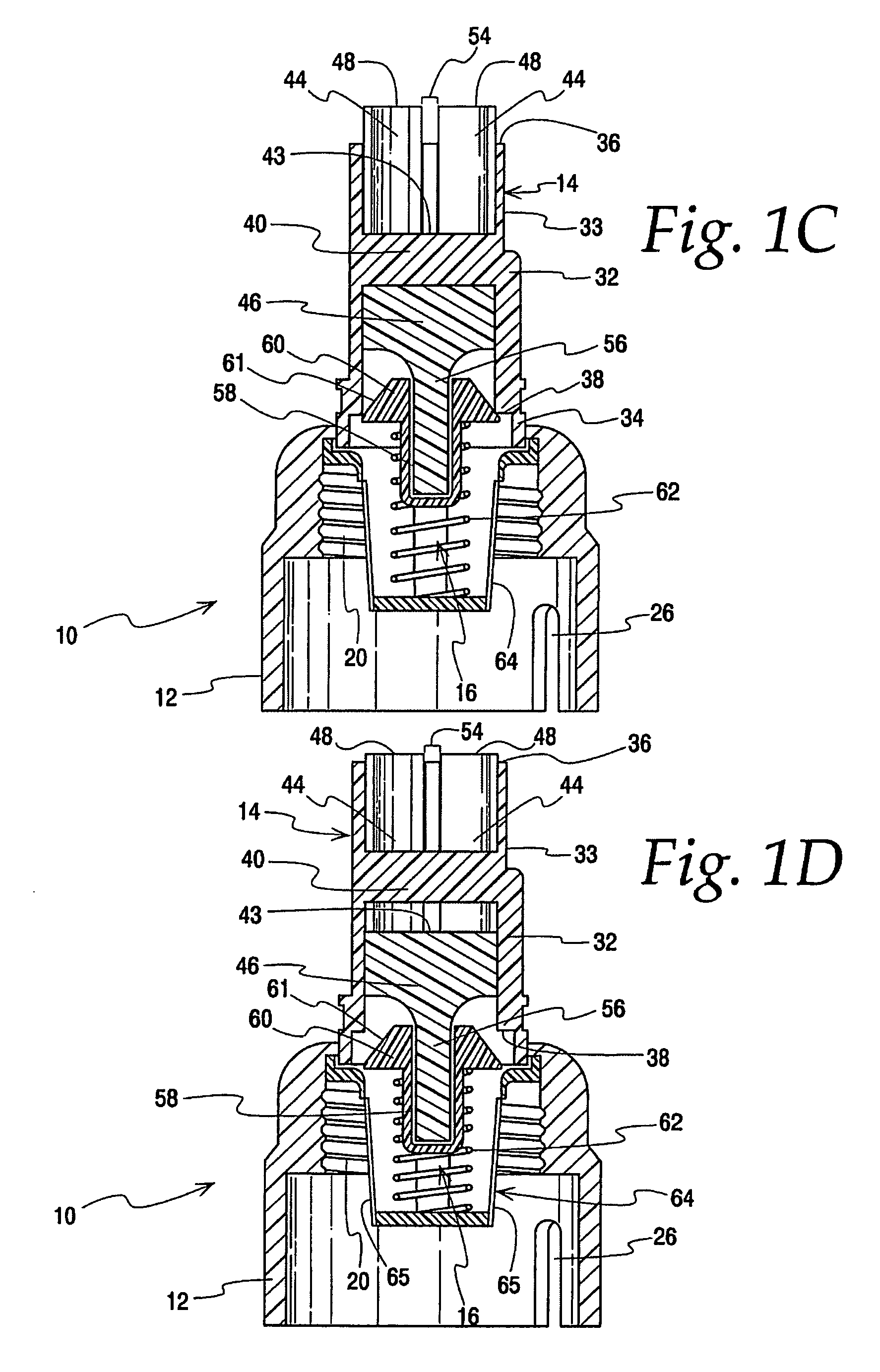

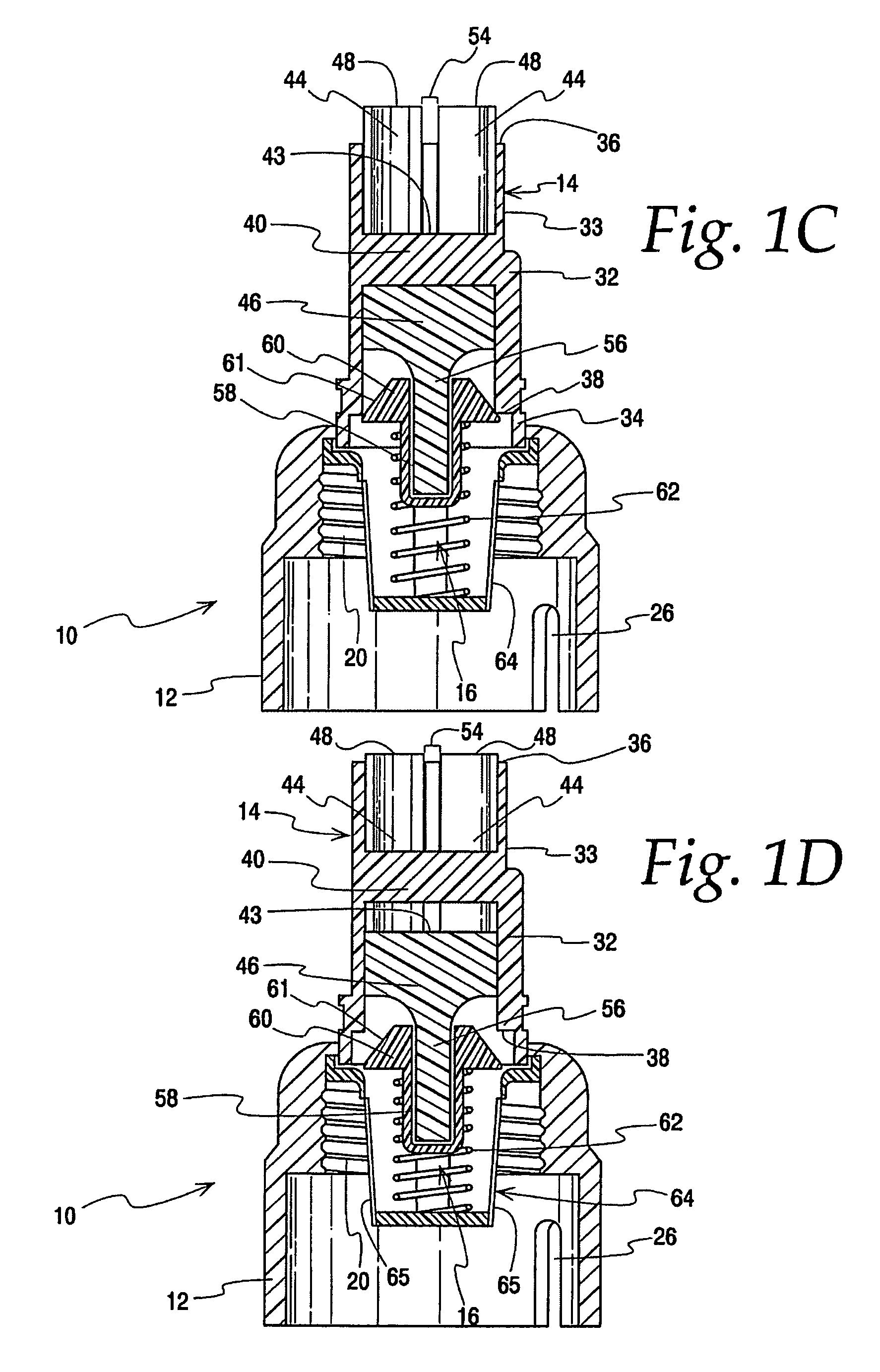

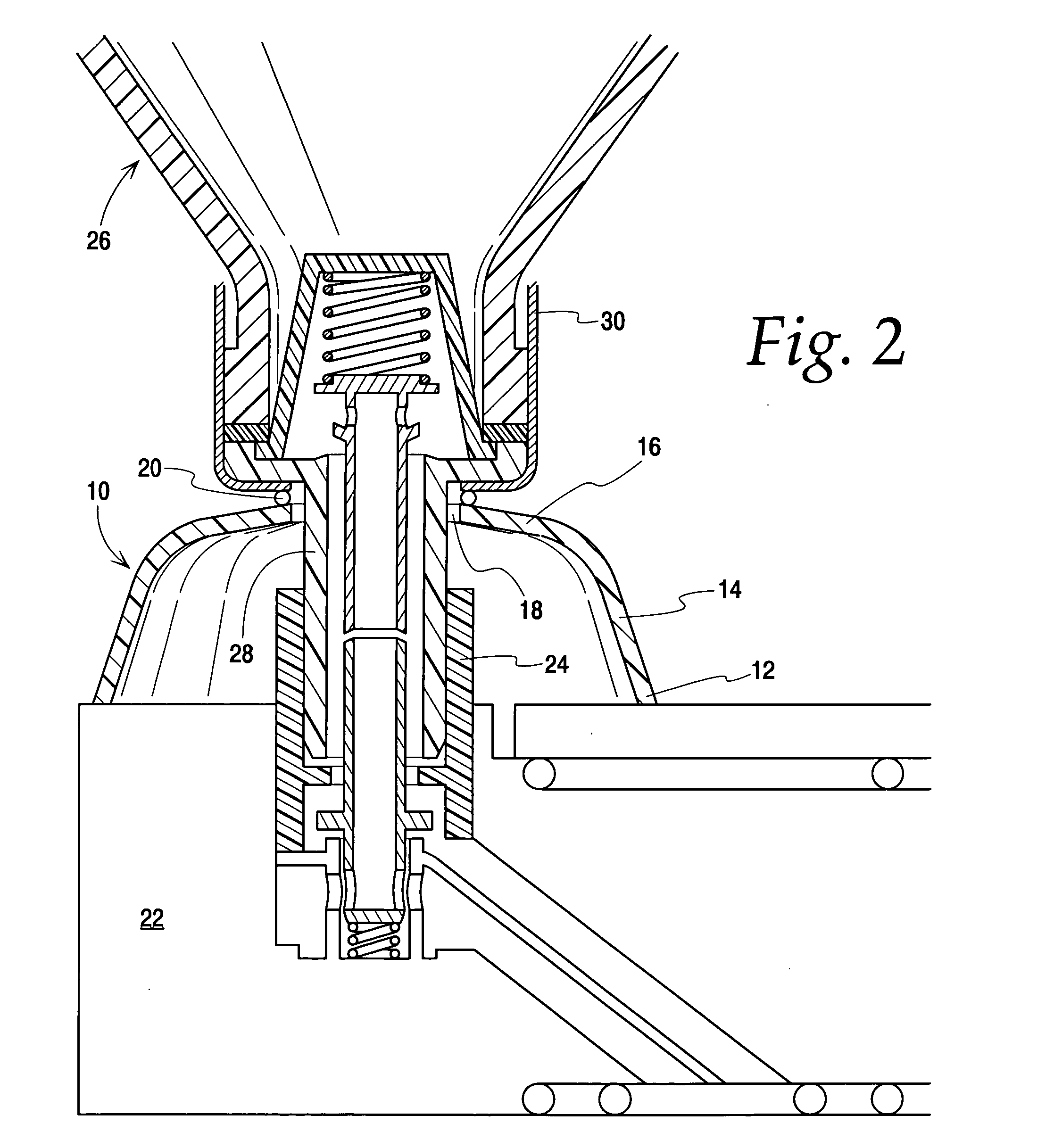

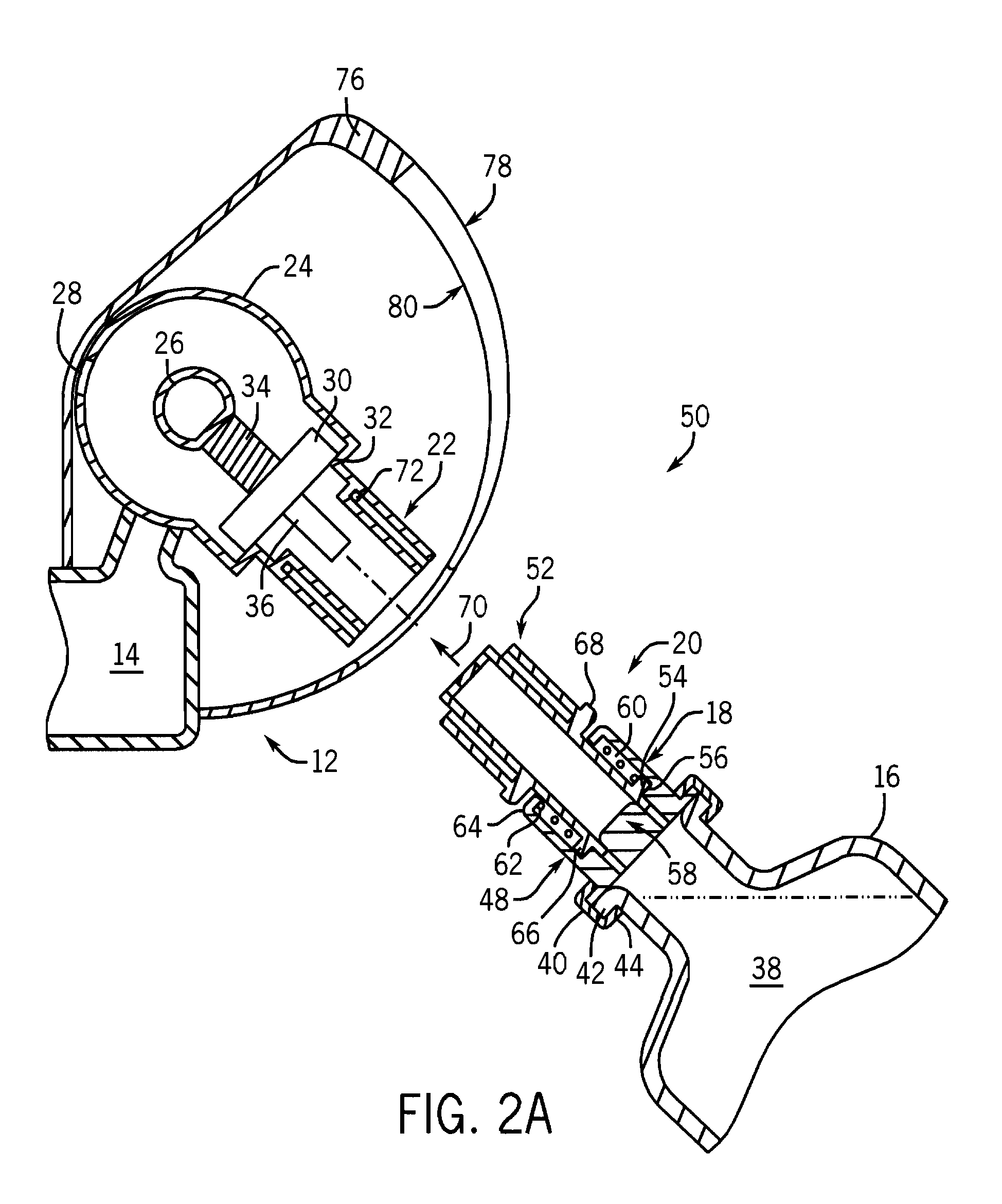

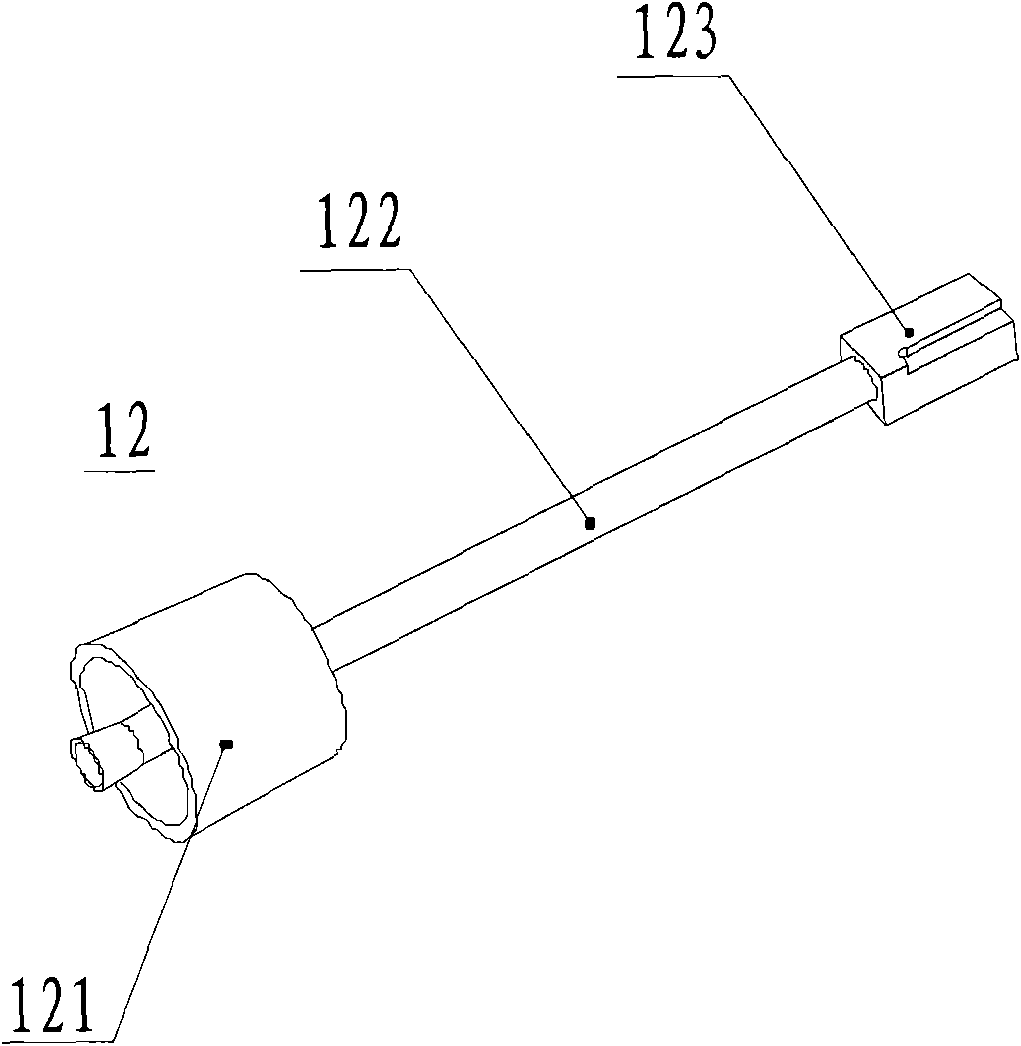

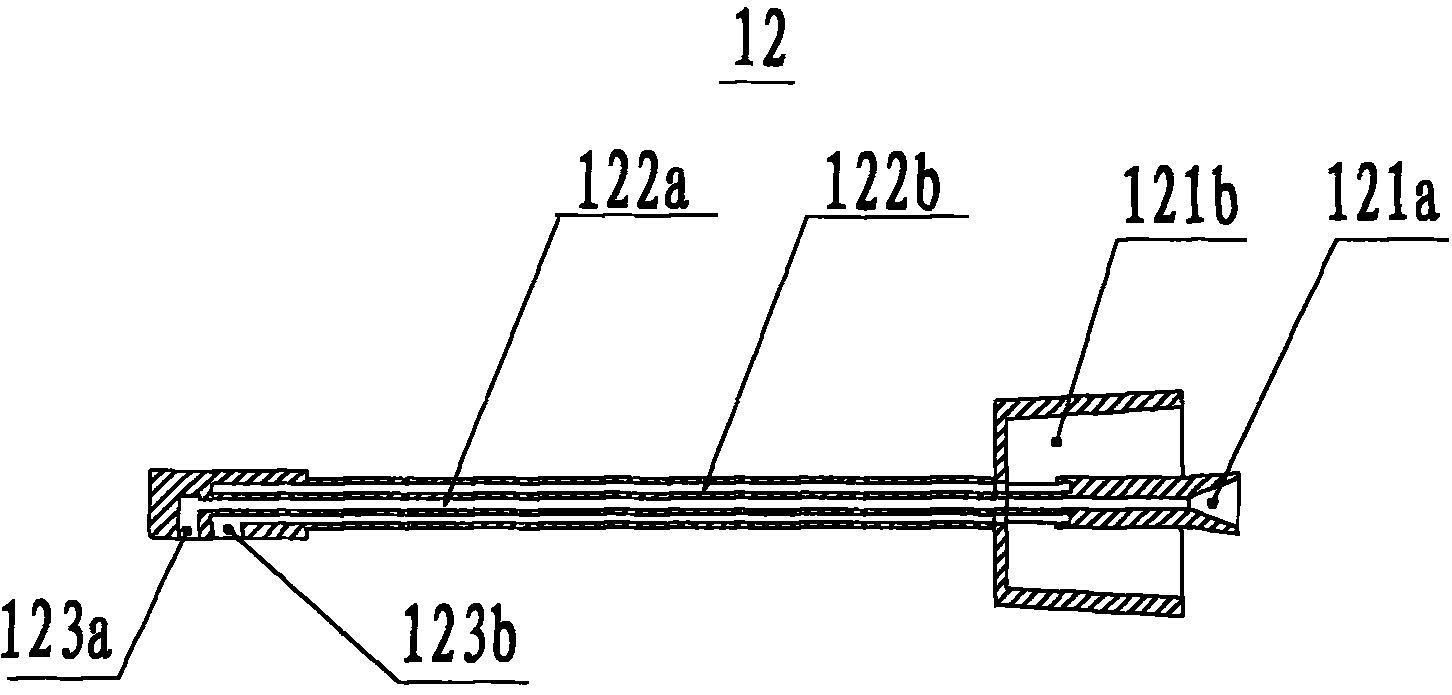

Adapter for an anesthetic vaporizer

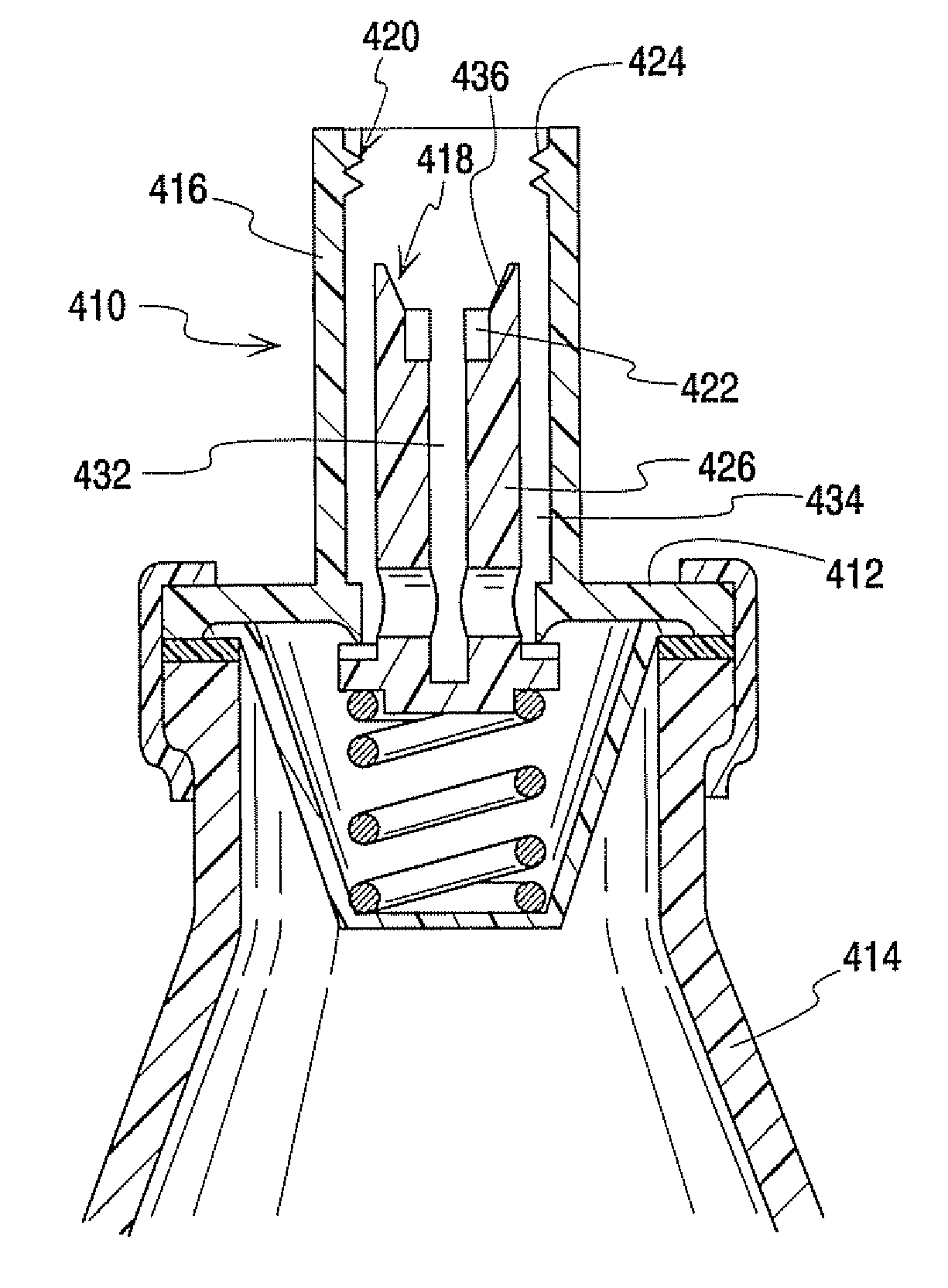

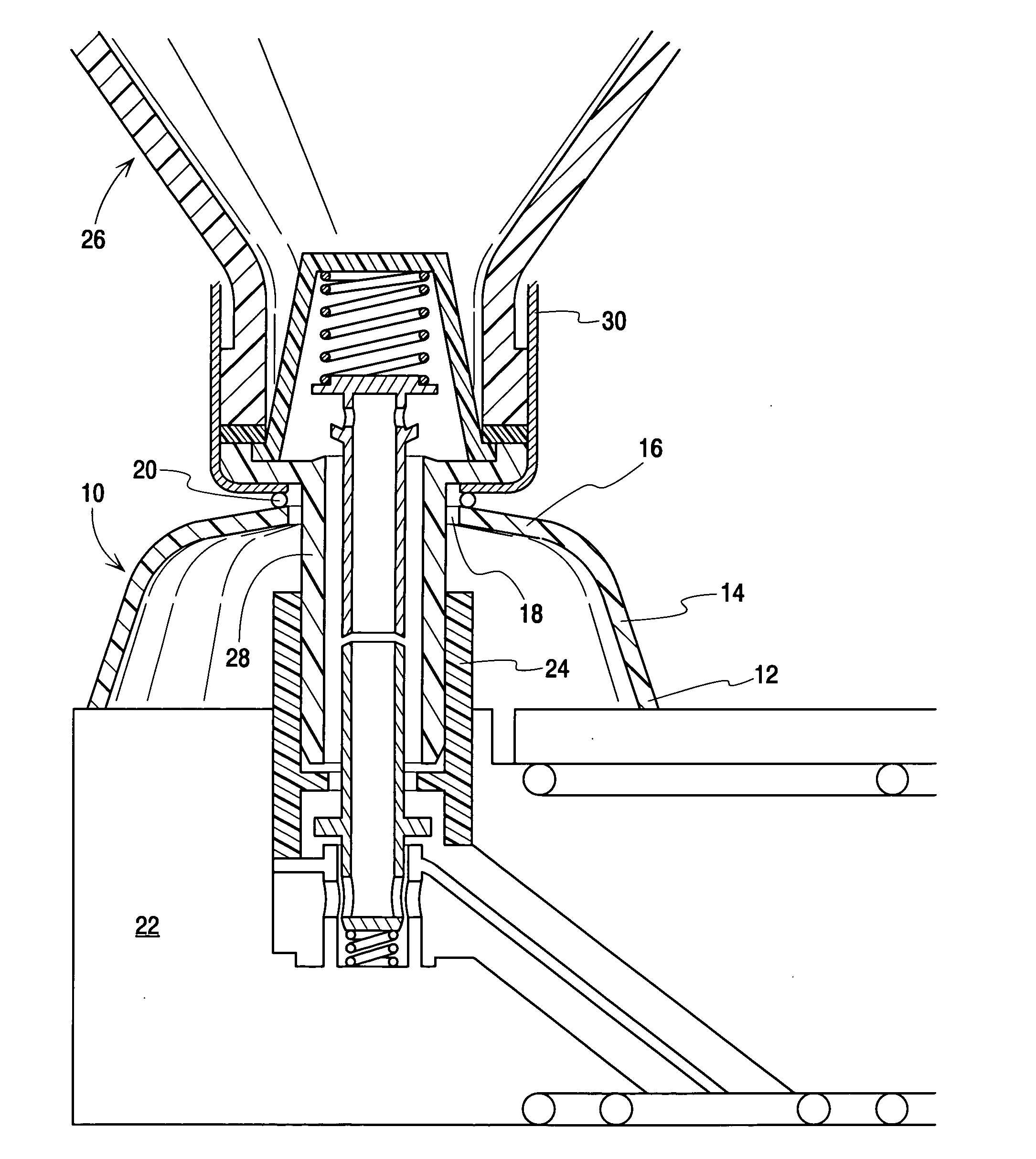

An adapter is provided with a base mountable on a bottle containing a liquid anesthetic agent. A spout extending upwardly from the base is received by an inlet port of an anesthetic vaporizer having a movable valve assembly and a stationary portion, such as a radial ledge. The spout includes a stationary contact member configured to contact and open the vaporizer valve assembly when the spout is inserted into the inlet port. The adapter also includes a movable valve assembly that is contacted and opened by the stationary portion of the inlet port when the spout is inserted into the inlet port. The contact member and adapter valve assembly are arranged such that, when the spout is inserted into the inlet port, the contact member opens the vaporizer valve assembly before the stationary portion of the inlet port opens the adapter valve assembly.

Owner:BAXTER INT INC +1

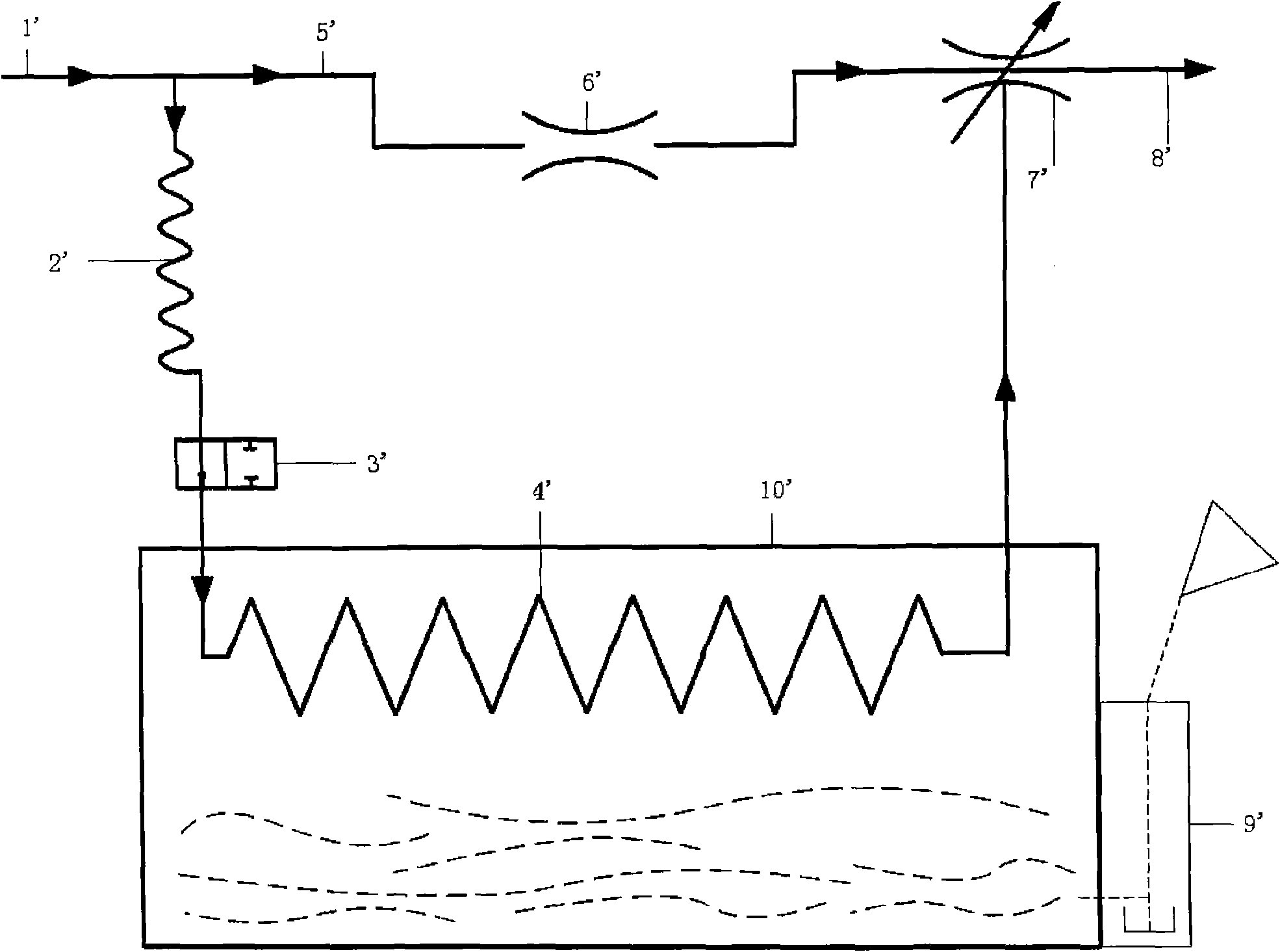

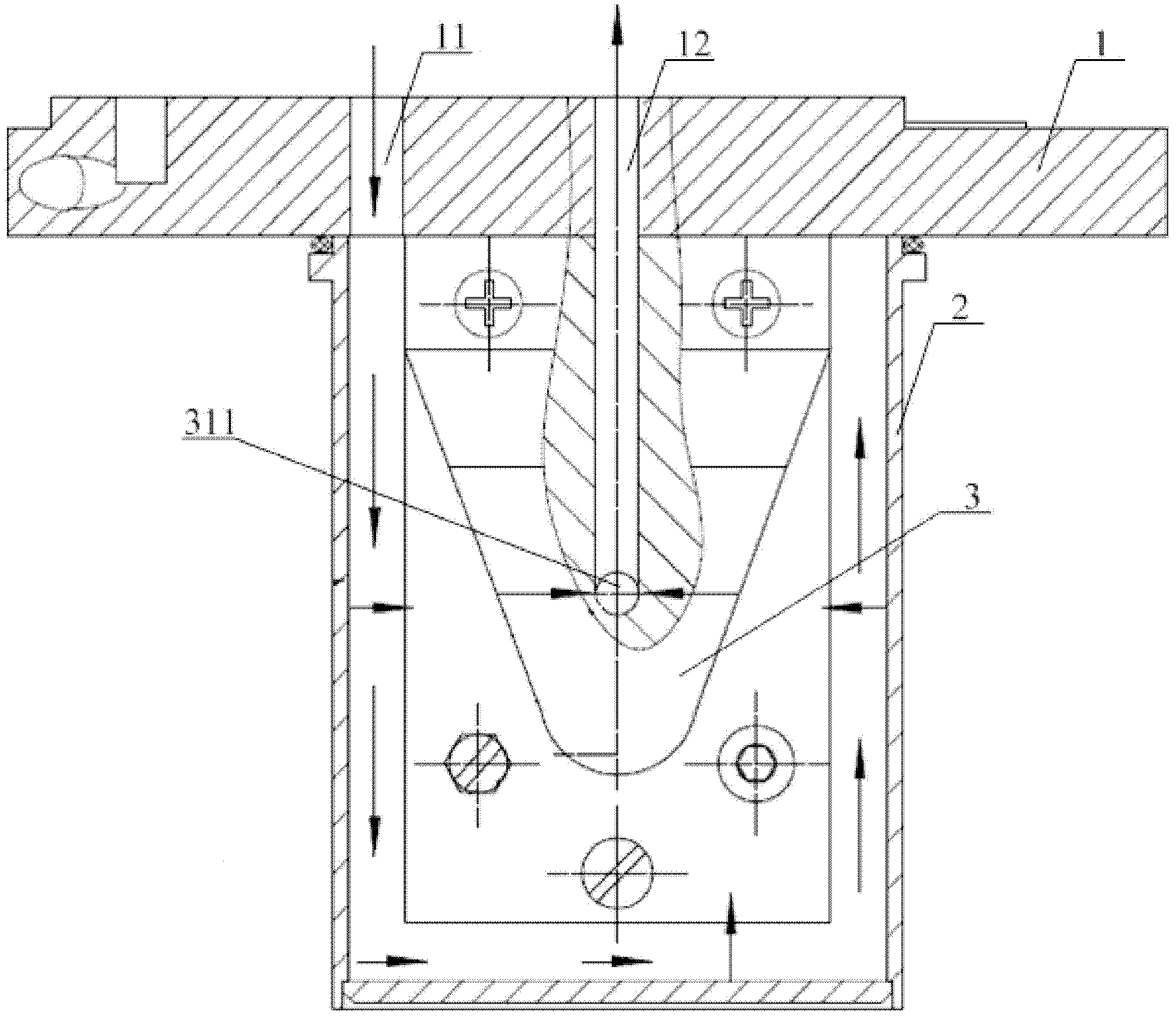

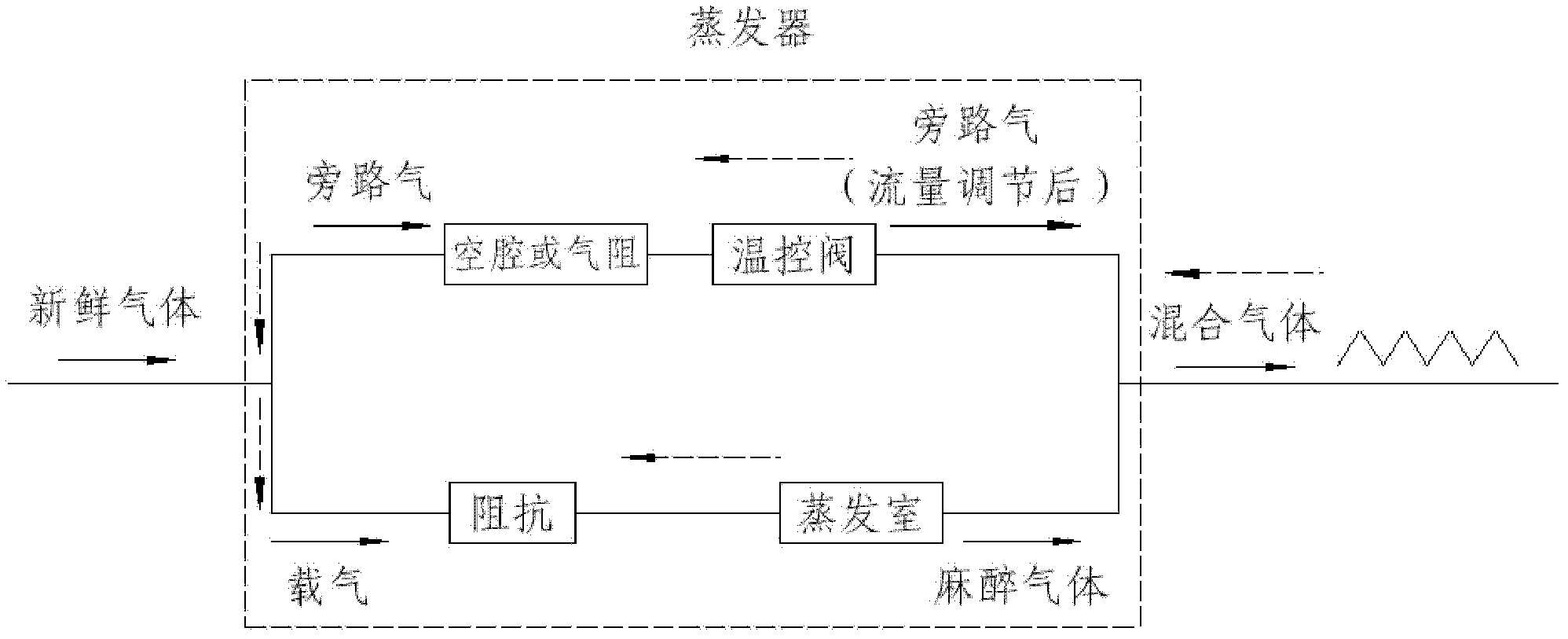

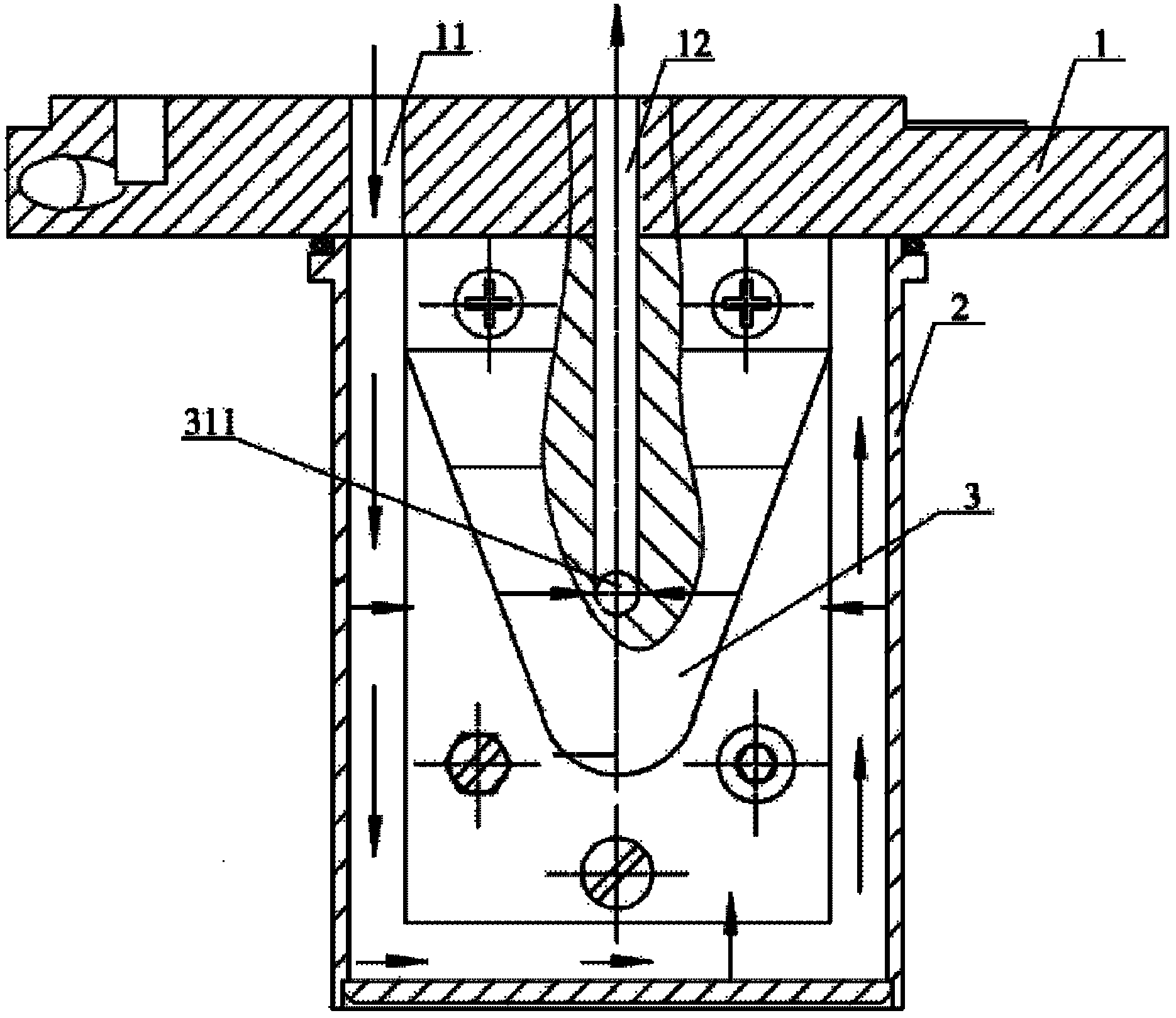

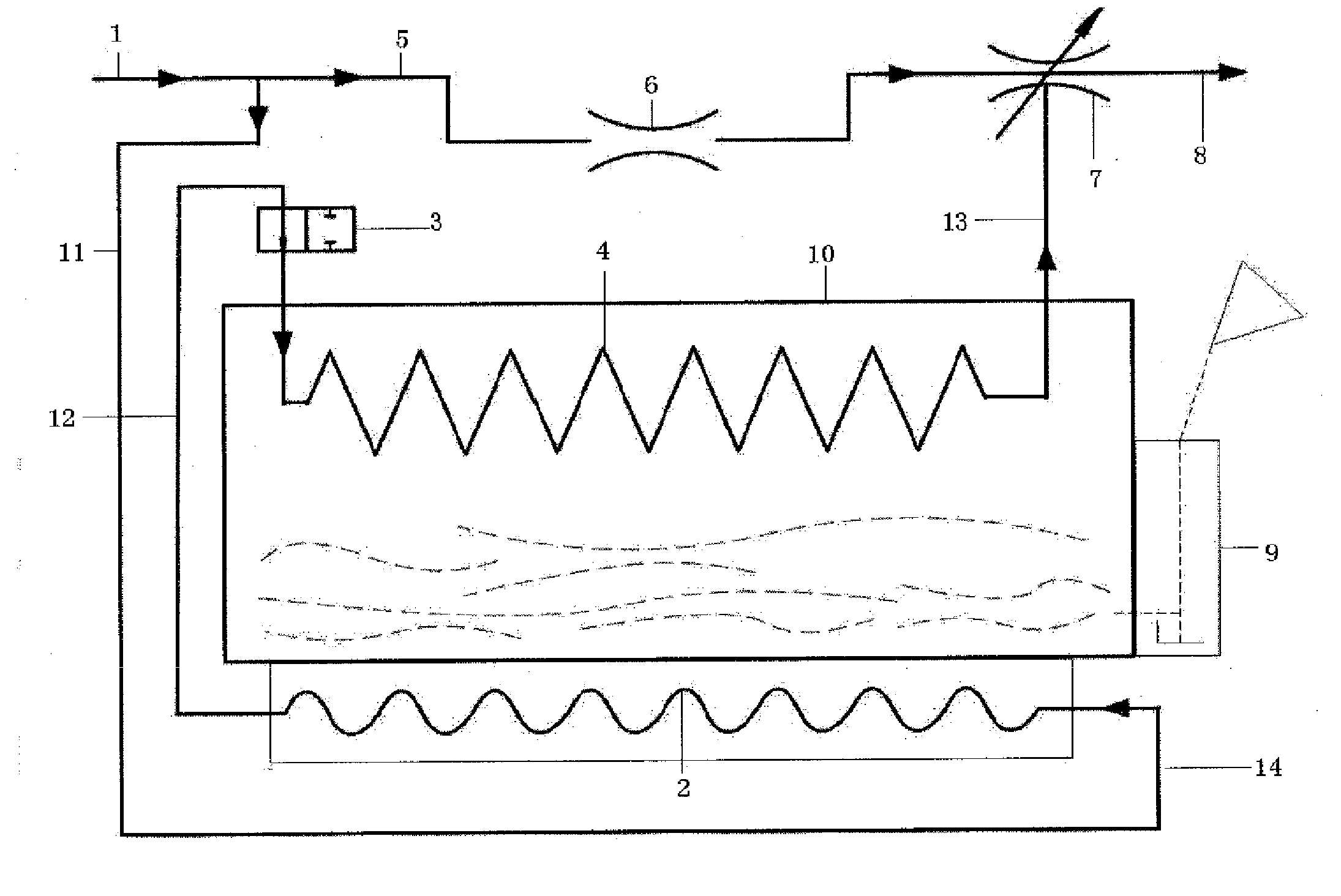

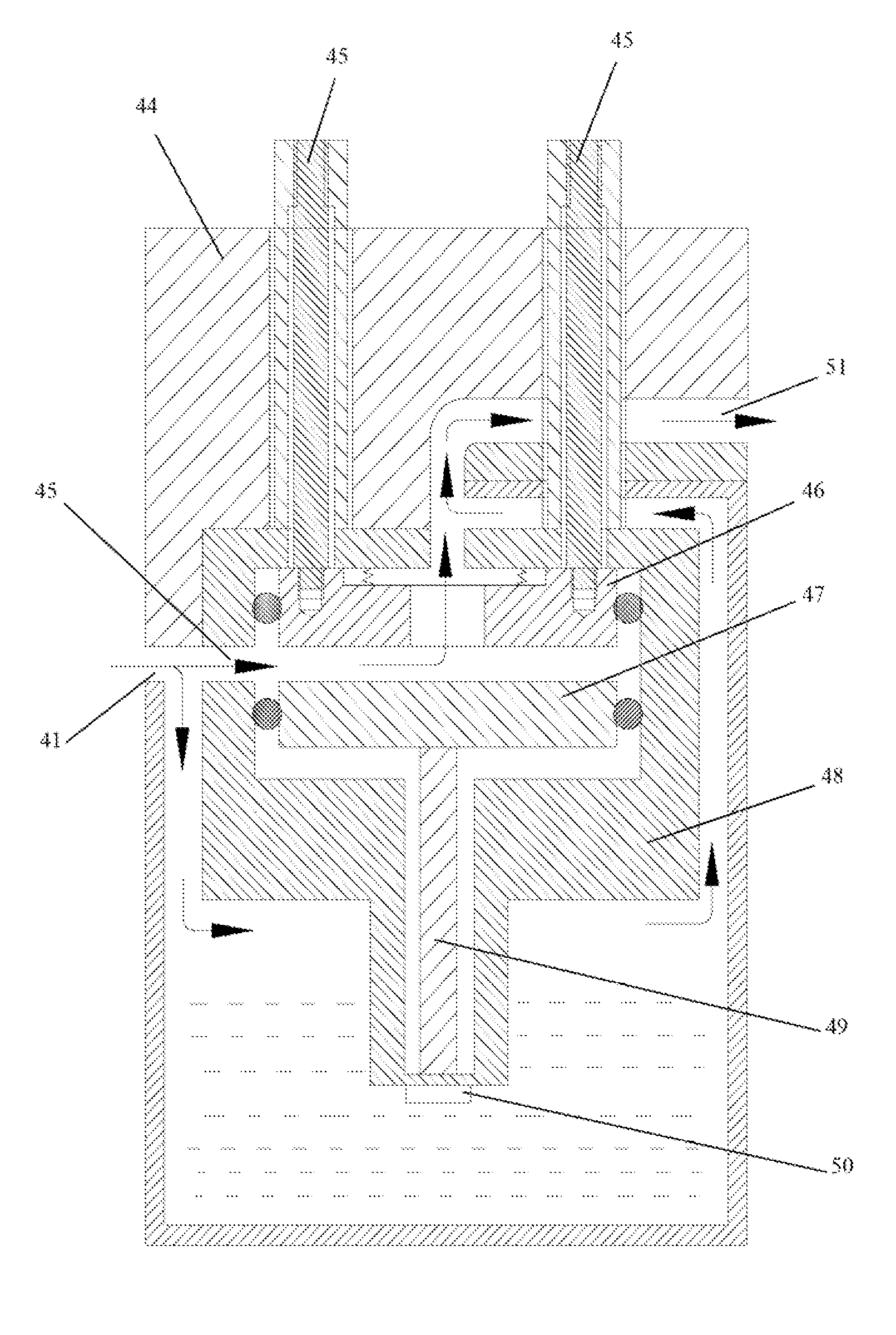

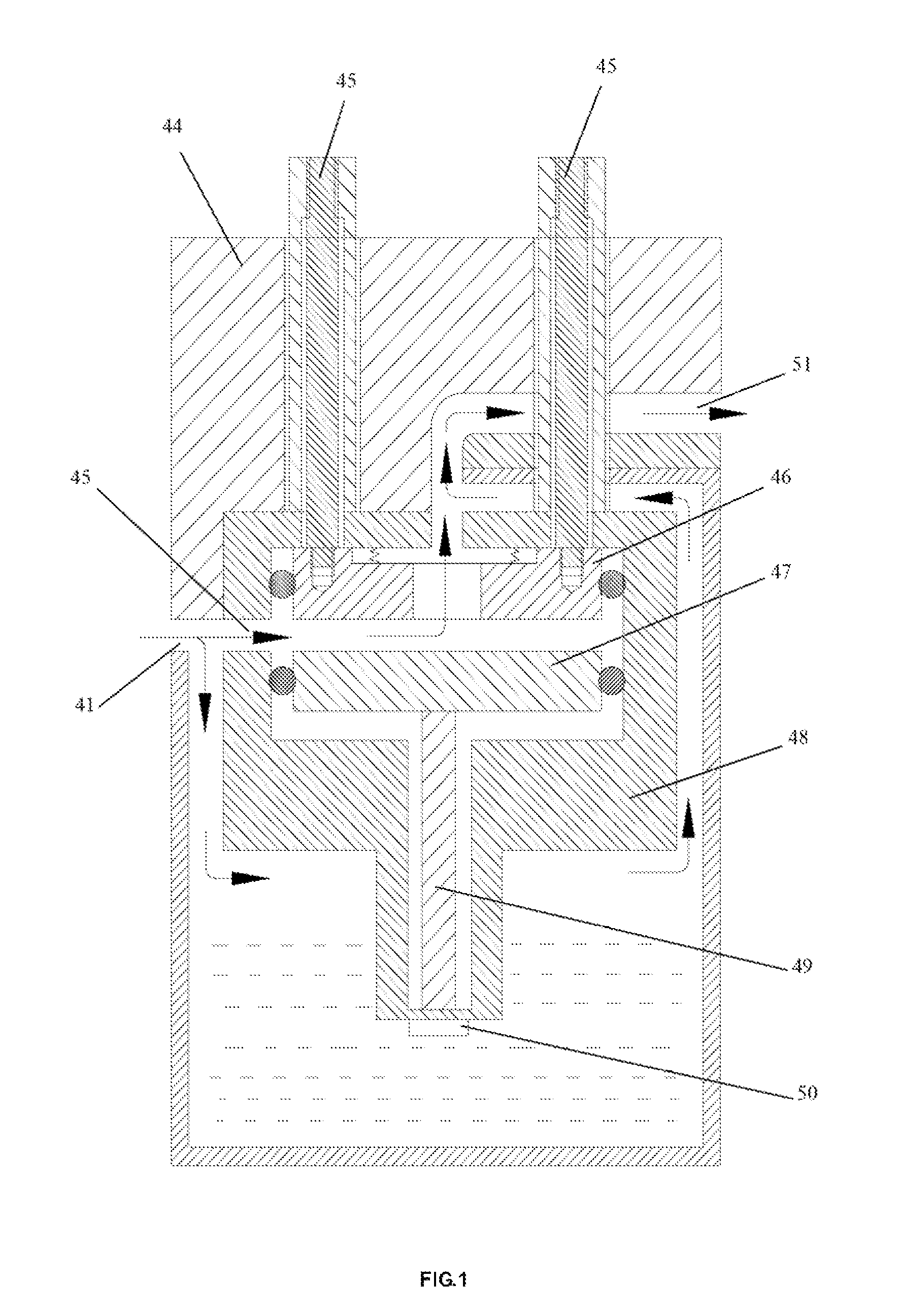

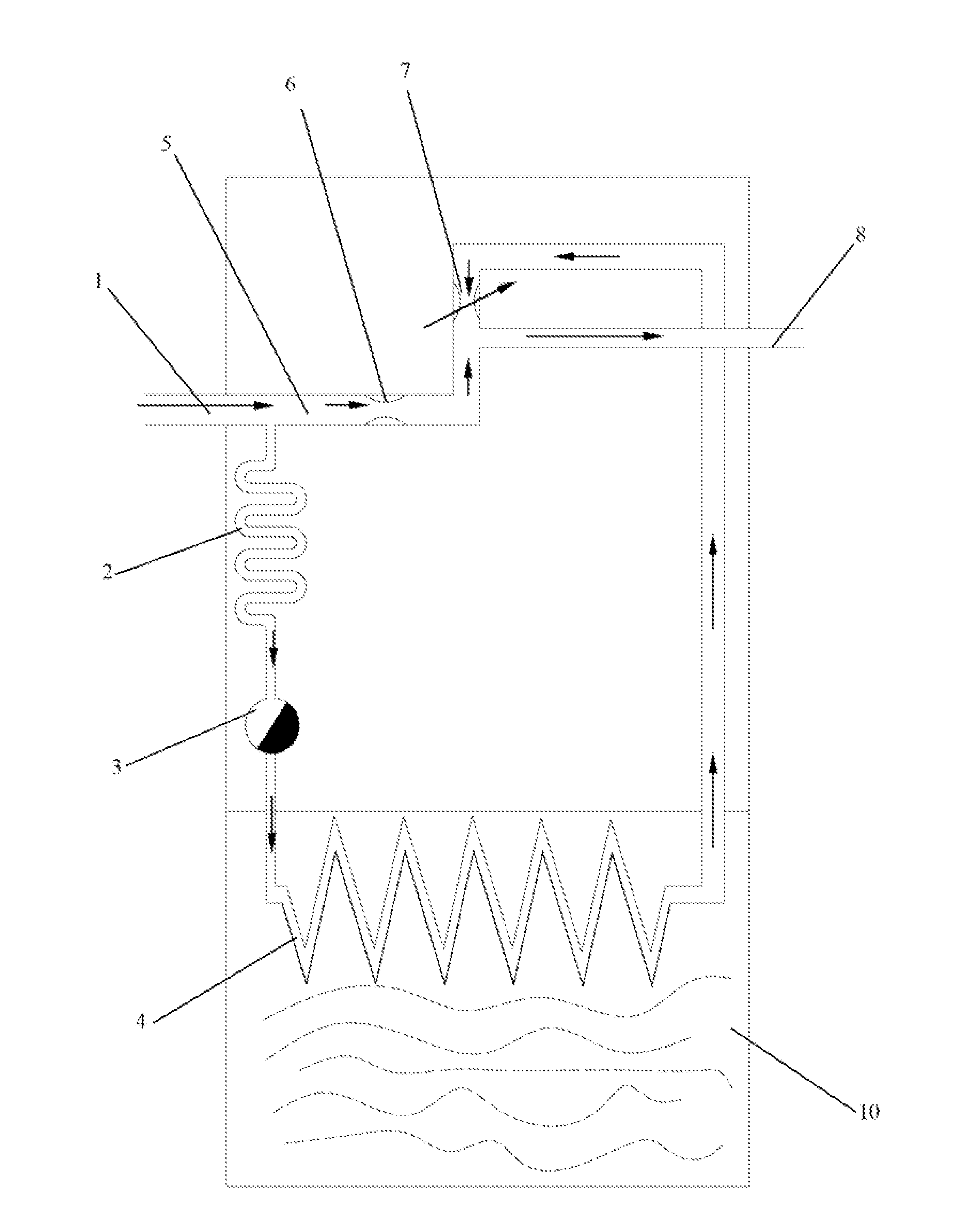

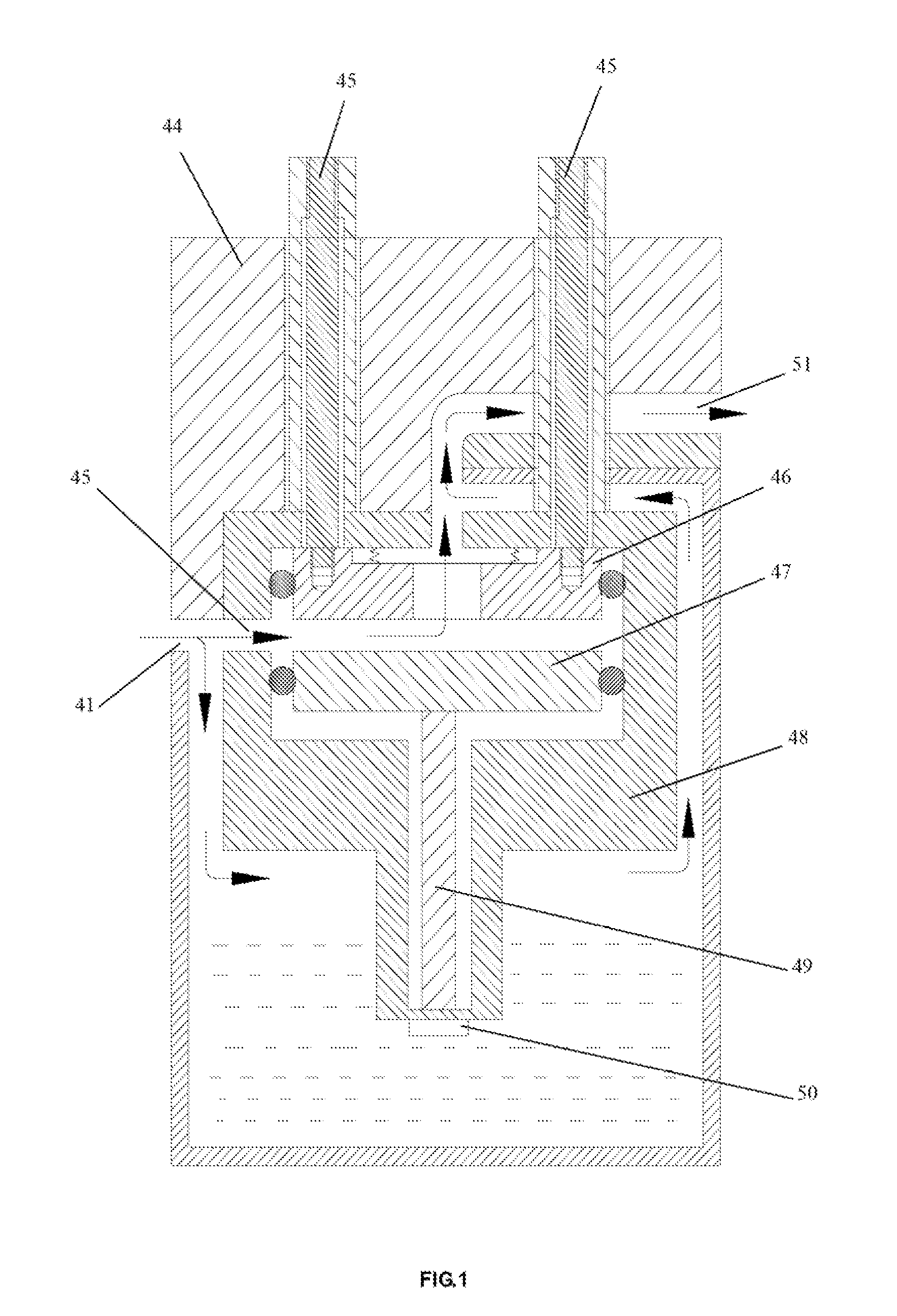

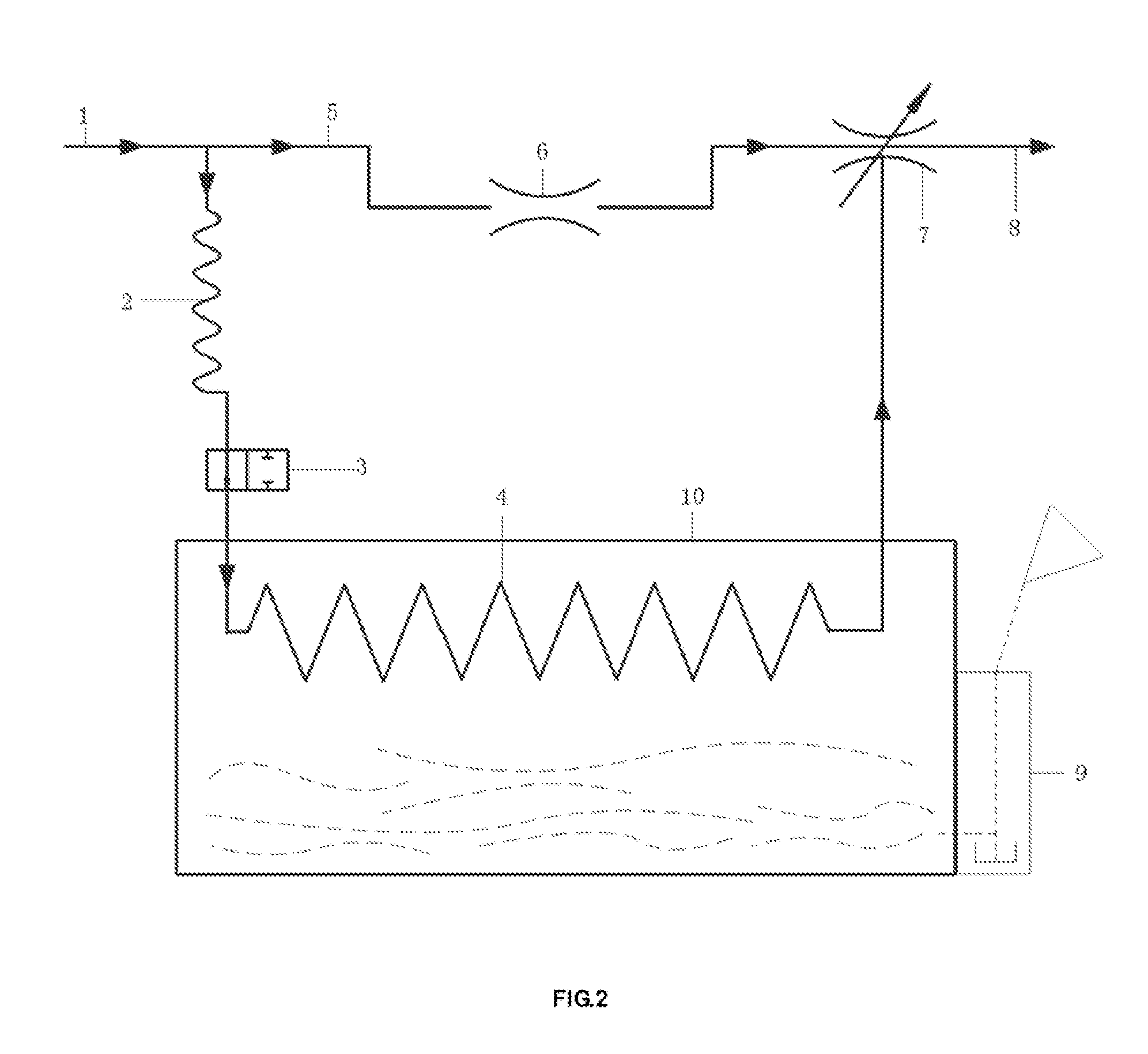

Anesthesia evaporator

The invention discloses an anesthesia evaporator, comprising a fresh gas inlet, a mixed gas outlet, a first gas branch, a second gas branch and an evaporation chamber; wherein the evaporation chamber is provided with a cavity containing anesthetic, the first gas branch is connected with the fresh gas inlet and the mixed gas outlet, the second gas branch comprises a first gas passage, a pressure compensation unit, a second gas passage, a medication core unit and a third gas passage, wherein the pressure compensation unit is provided with a curve continuous closed aeration channel, the medication core unit is provided with a soaking part directly contacted with anesthetic in the cavity, the fresh gas inlet, the first gas passage, the aeration channel, the second gas passage, the medication core unit, the third gas passage and the mixed gas outlet are connected in sequence, the pressure compensation unit is arranged in the cavity and provided with a heat conductor which is directly contacted with anesthetic for heat transmission, and the aeration channel is opened on the heat conductor. The anesthesia evaporator can realize stable output of concentration of anesthetic steam in mixed gas.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Adapter for an anesthetic vaporizer

An adapter is provided with a base mountable on a bottle containing a liquid anesthetic agent. A spout extending upwardly from the base is received by an inlet port of an anesthetic vaporizer having a movable valve assembly and a stationary portion, such as a radial ledge. The spout includes a stationary contact member configured to contact and open the vaporizer valve assembly when the spout is inserted into the inlet port. The adapter also includes a movable valve assembly that is contacted and opened by the stationary portion of the inlet port when the spout is inserted into the inlet port. The contact member and adapter valve assembly are arranged such that, when the spout is inserted into the inlet port, the contact member opens the vaporizer valve assembly before the stationary portion of the inlet port opens the adapter valve assembly.

Owner:BAXTER INT INC +1

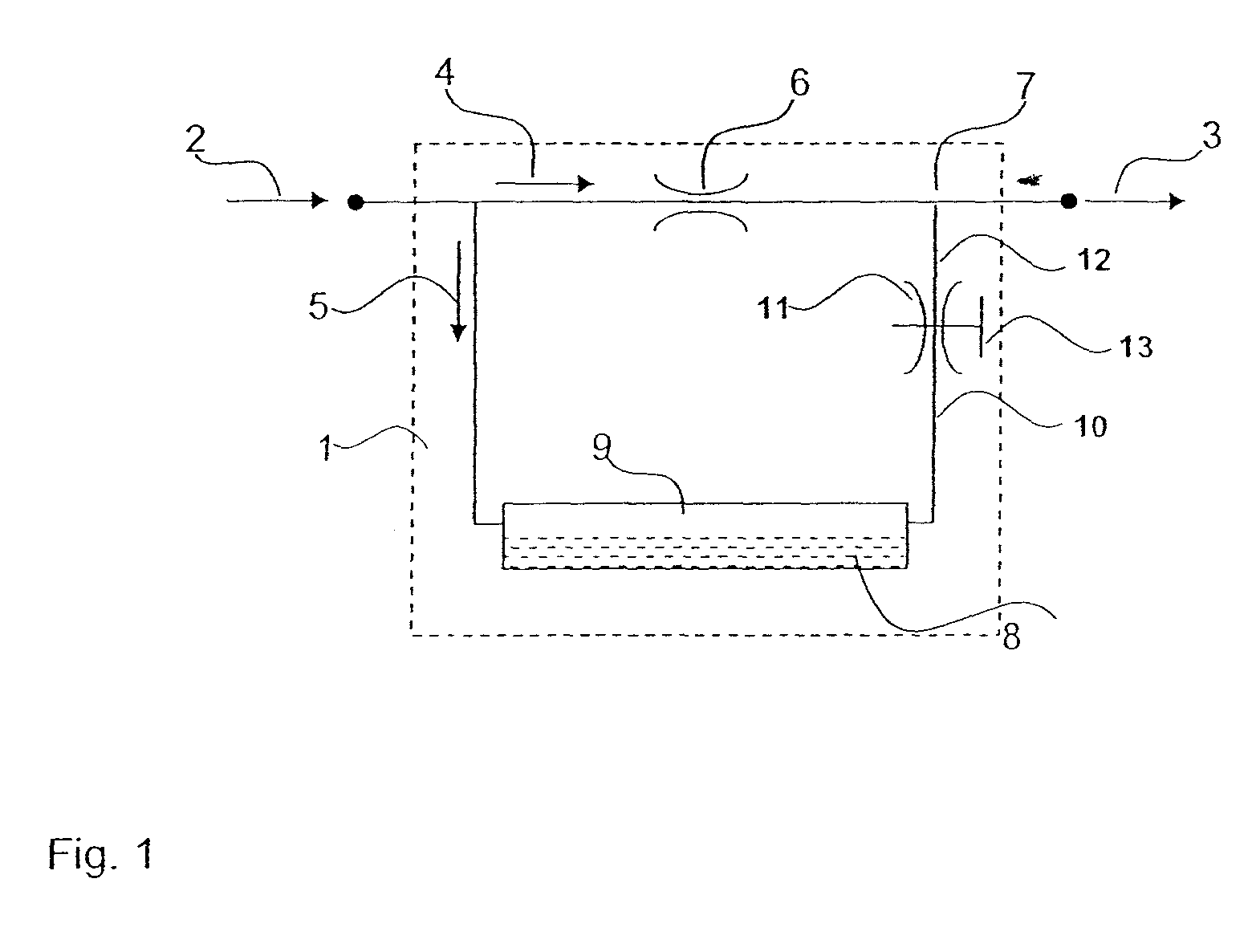

Device for recovering anaesthetic

InactiveUS6488028B1Easy to controlQuick cutRespiratorsBreathing filtersAnesthetic AgentAbsorption filter

A device for recovering anaesthetic. During the administration of inhaled anaesthetic, the device is connected to a patient. It includes an anaesthetic evaporator for supplying anaesthetic to the patient and an absorption filter for absorption and desorption of the medium. The device includes a body placed between the absorption filter and the patient with the gases breathed by the patient passing across the body and the anaesthetic evaporating on the surface thereof. The absorption filter is in the form of a flat element placed in the flow path of a gas breathed by the patient and contains fibers of active carbon. The absorption filter is movably arranged in a housing between a position in which substantially all the gases breathed pass through the filter and the position in which a small portion of the gases breathed passes therethrough.

Owner:HUDSON RCI +1

Adapters for use with an anesthetic vaporizer

InactiveUS20070204931A1Efficient retentionRespiratorsSolid materialAnesthesiaAnesthetic agent vaporizer

Adapters are provided for establishing fluid communication between an anesthetic agent container and an anesthetic vaporizer having a fluid port. The adapter may be mountable on the vaporizer to cooperate with the spout of an anesthetic agent container or may be mountable on an anesthetic agent container to cooperate with the fluid port of an anesthetic vaporizer to provide a sealing and / or retaining relationship therebetween.

Owner:BAXTER INT INC +1

Adapters for use with an anesthetic vaporizer

ActiveUS7784504B2RespiratorsPharmaceutical containersIntensive care medicineAnesthetic agent vaporizer

Adapters are provided for establishing fluid communication between an anesthetic agent container and an anesthetic vaporizer having a fluid port. The adapter may be mountable on the vaporizer to cooperate with the spout of an anesthetic agent container or may be mountable on an anesthetic agent container to cooperate with the fluid port of an anesthetic vaporizer to provide a sealing and / or retaining relationship therebetween.

Owner:BAXTER INT INC +1

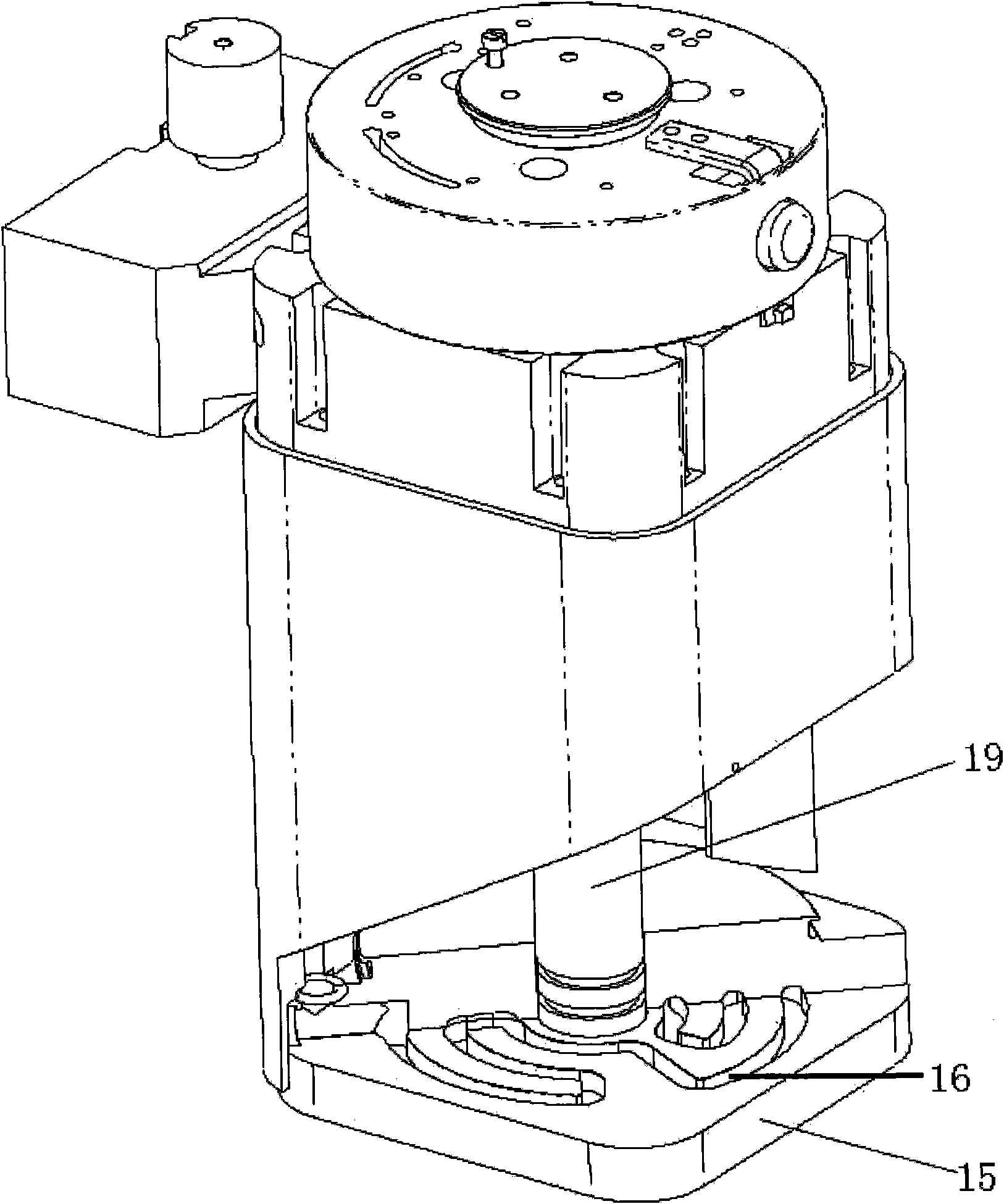

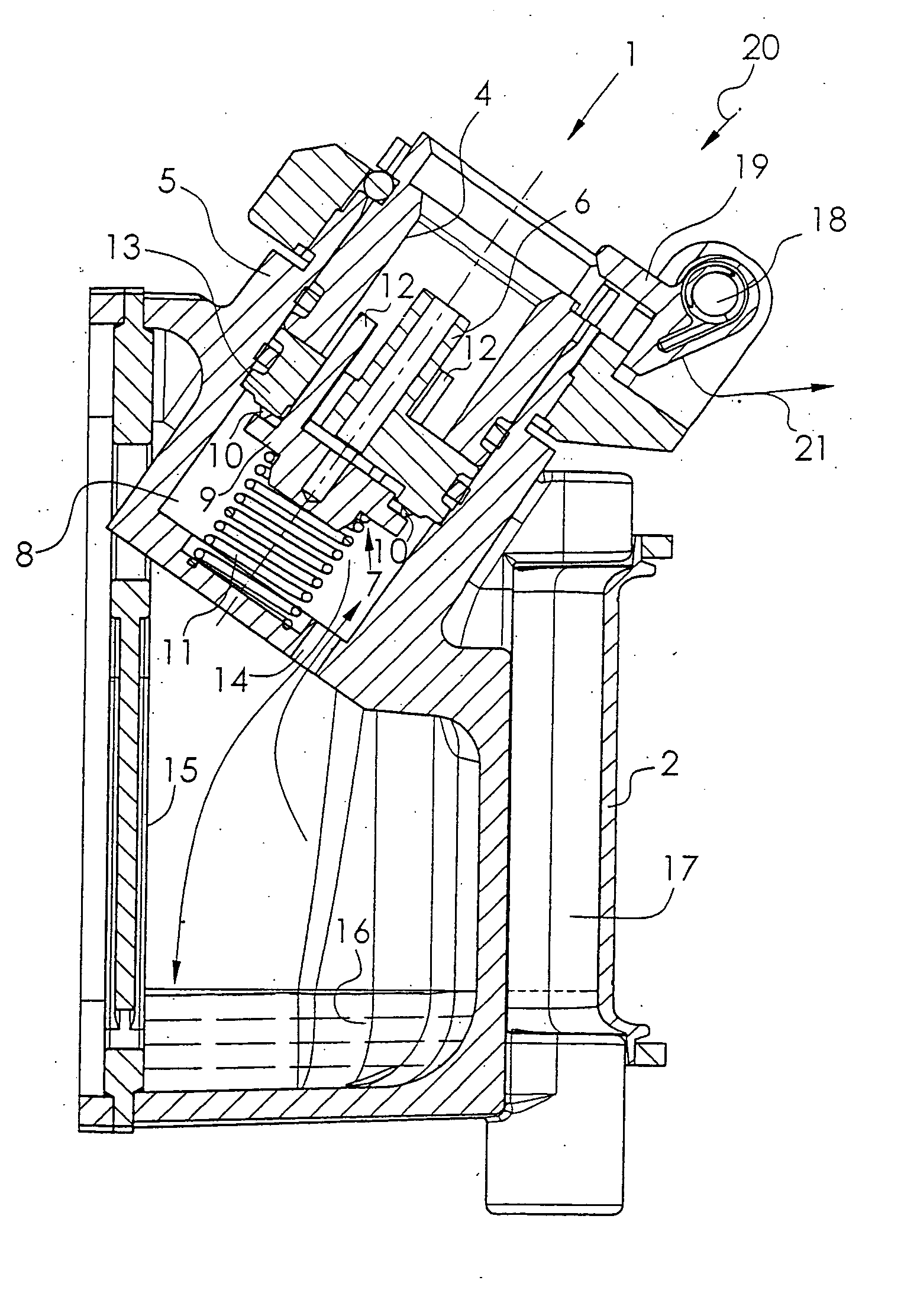

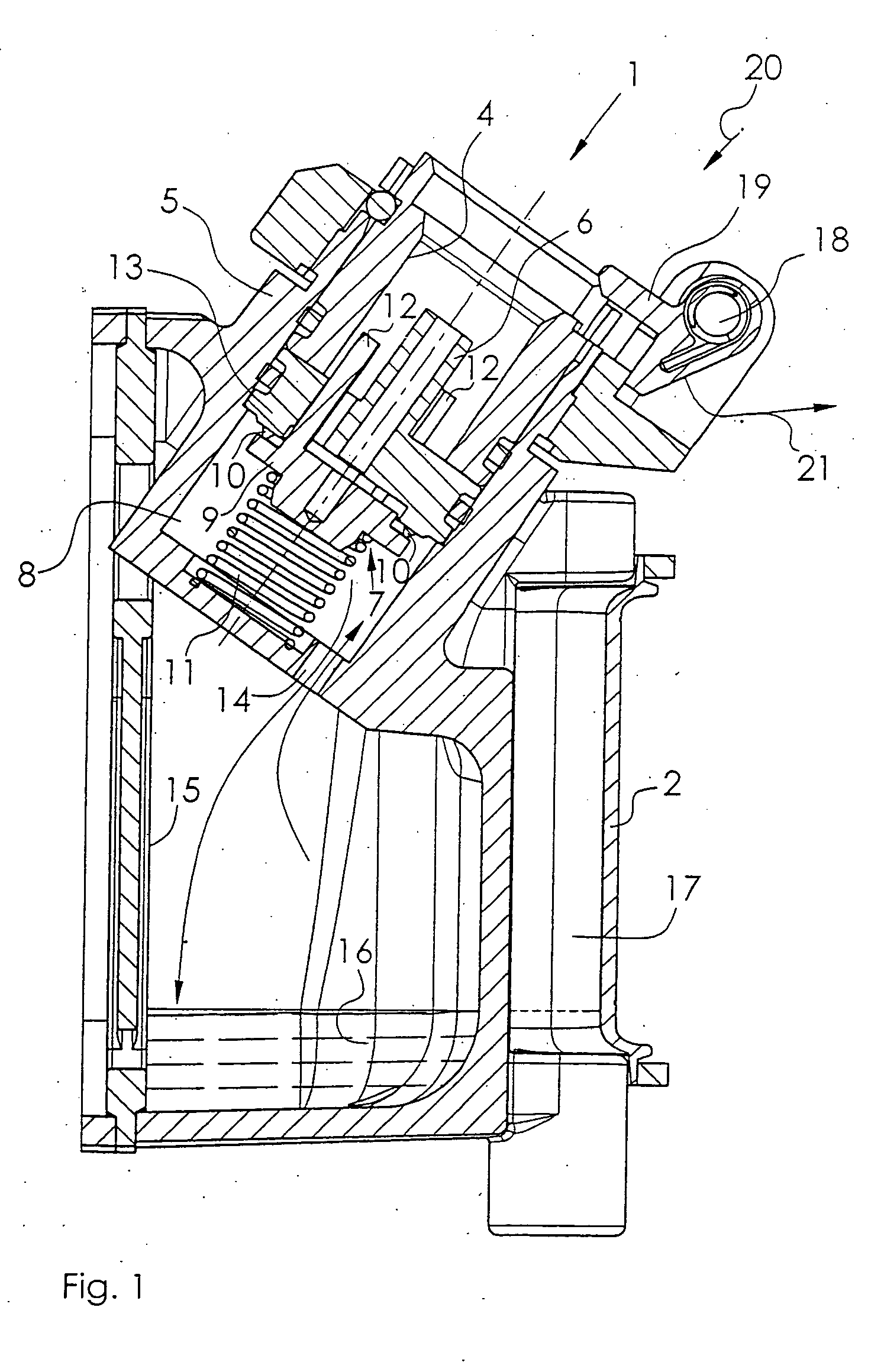

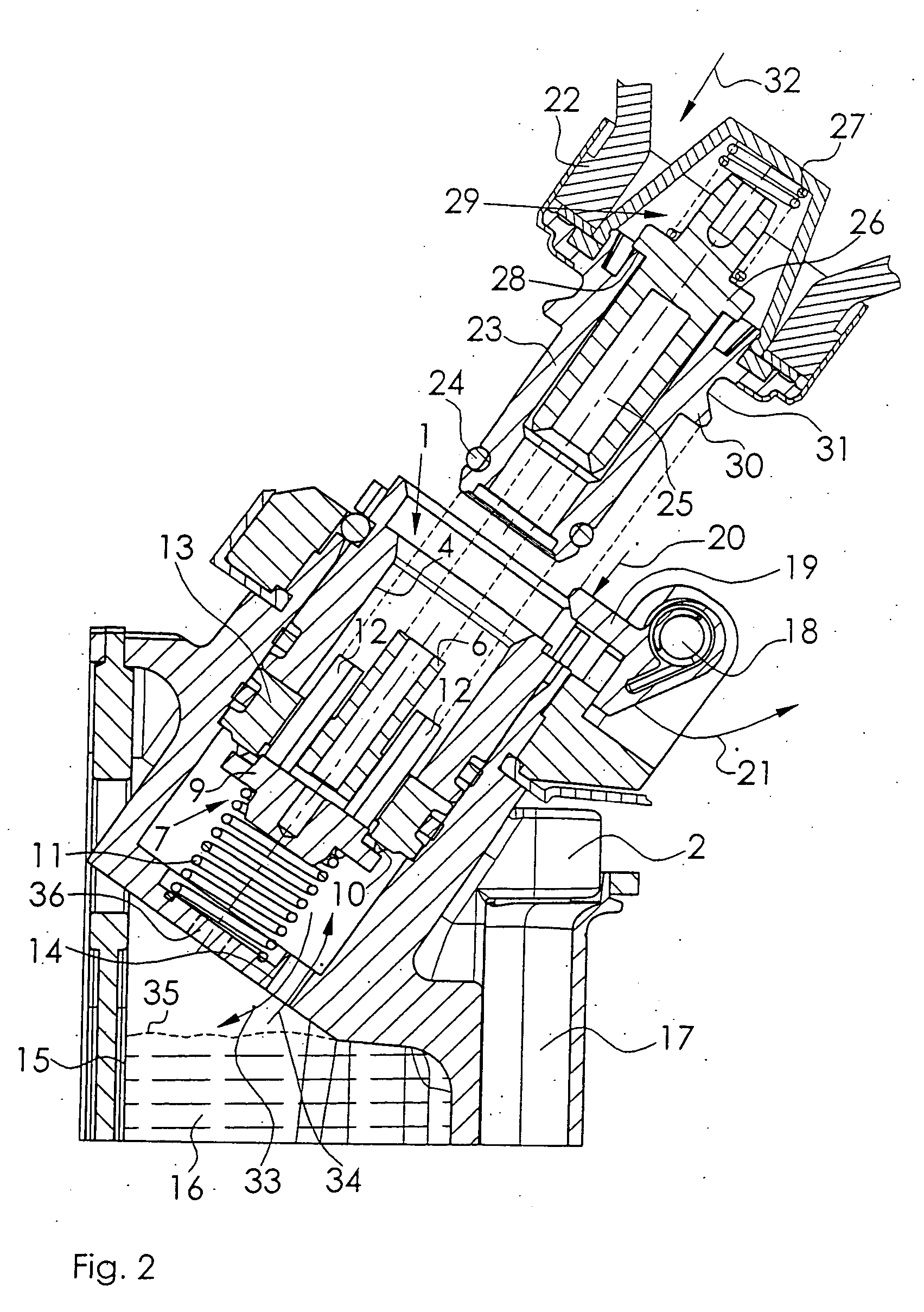

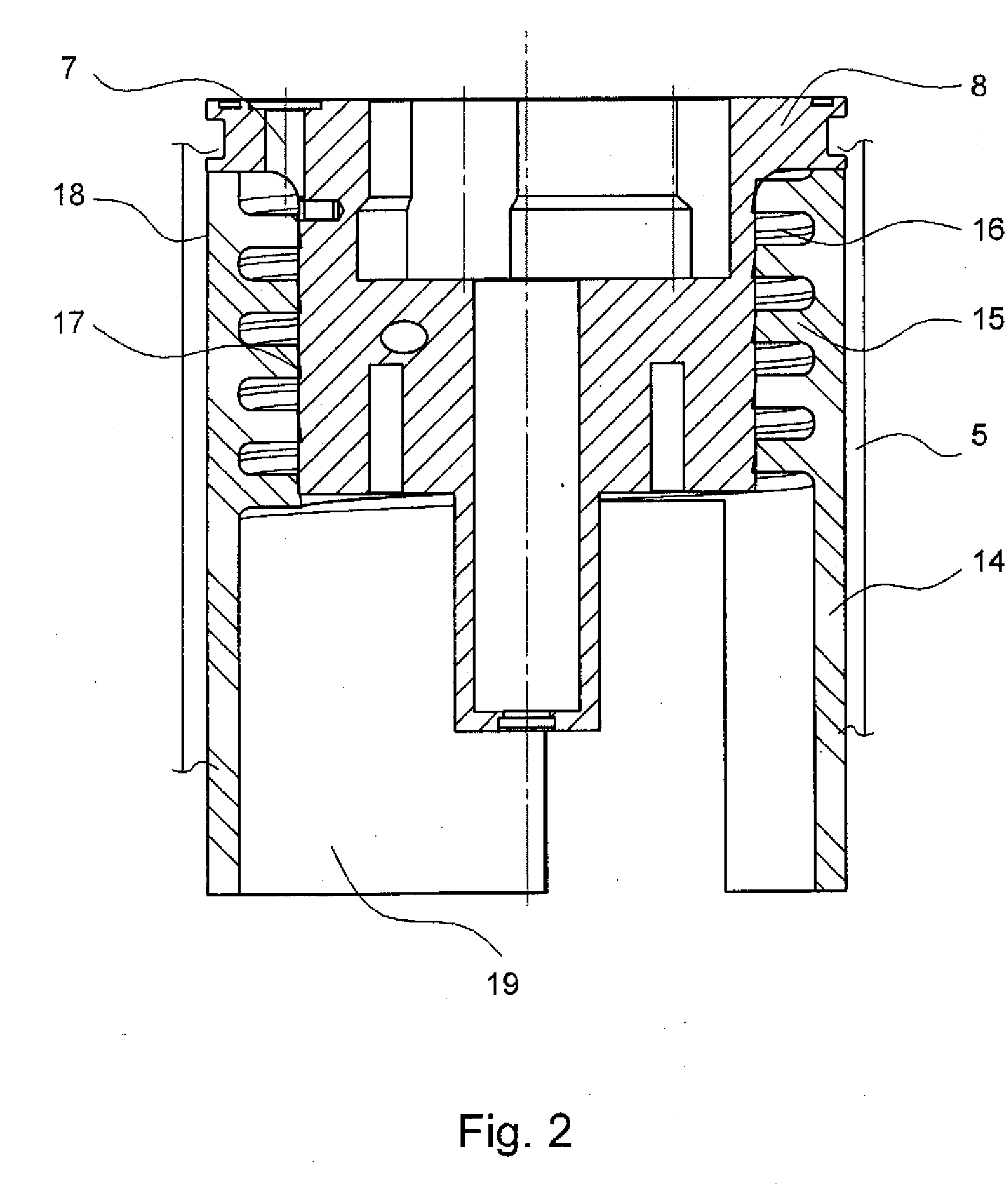

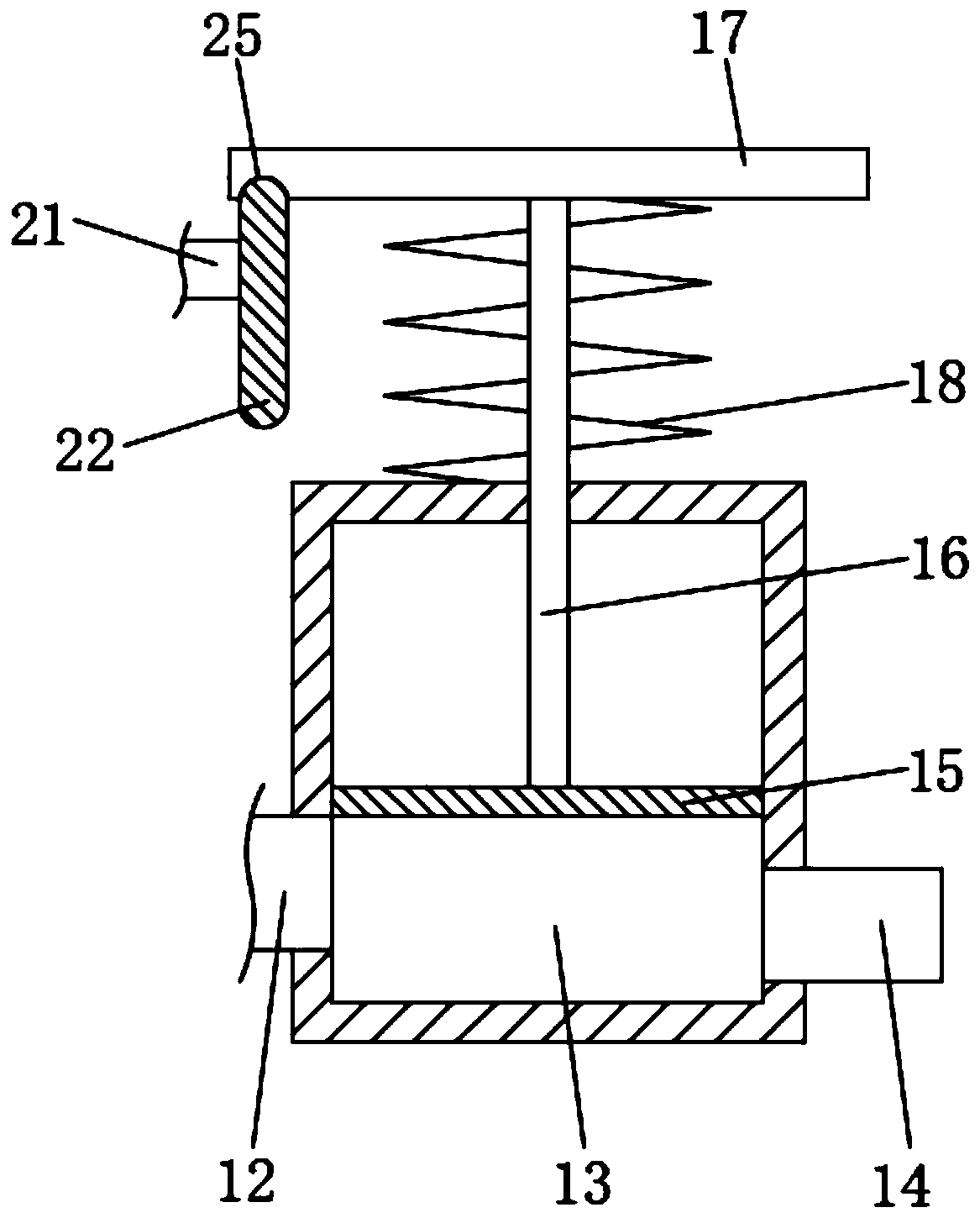

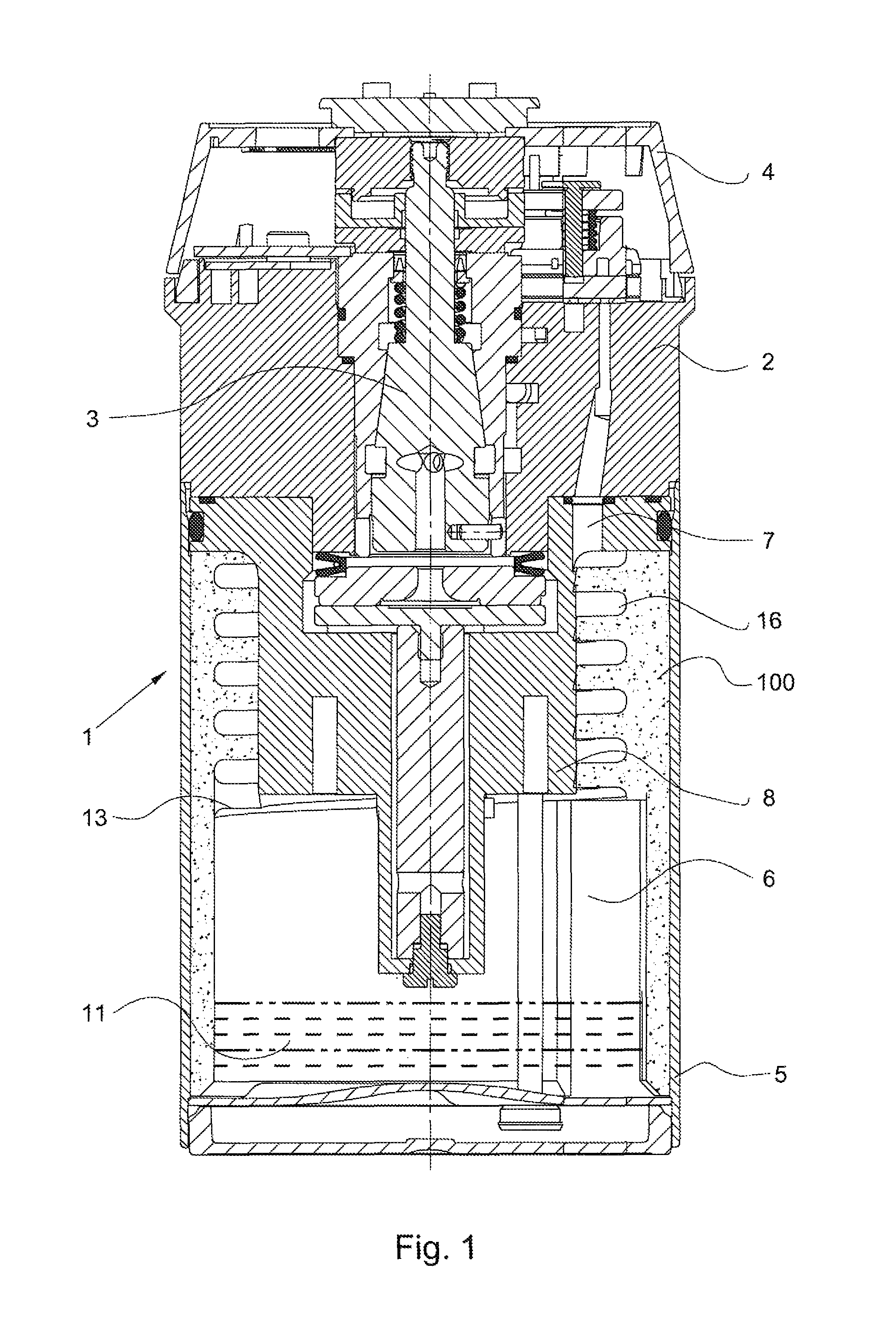

Filling device for an anesthetic evaporator

ActiveUS20060048842A1Increase capacityReduce the pressing forceRespiratorsSolid materialEngineeringAnaesthetic vaporizer

A filling device for an anesthetic evaporator has filling of an anesthetic evaporator is possible. To accomplish the object, an additional vent hole (36), which is opened immediately after the filling in order for excess anesthetic volume to be able to flow out of the filling device into the anesthetic tank (15) of the anesthetic evaporator (2), is provided within the filling device above a fluid channel (14), via which both the gas and liquid exchange takes place during the filling.

Owner:DRAGERWERK AG

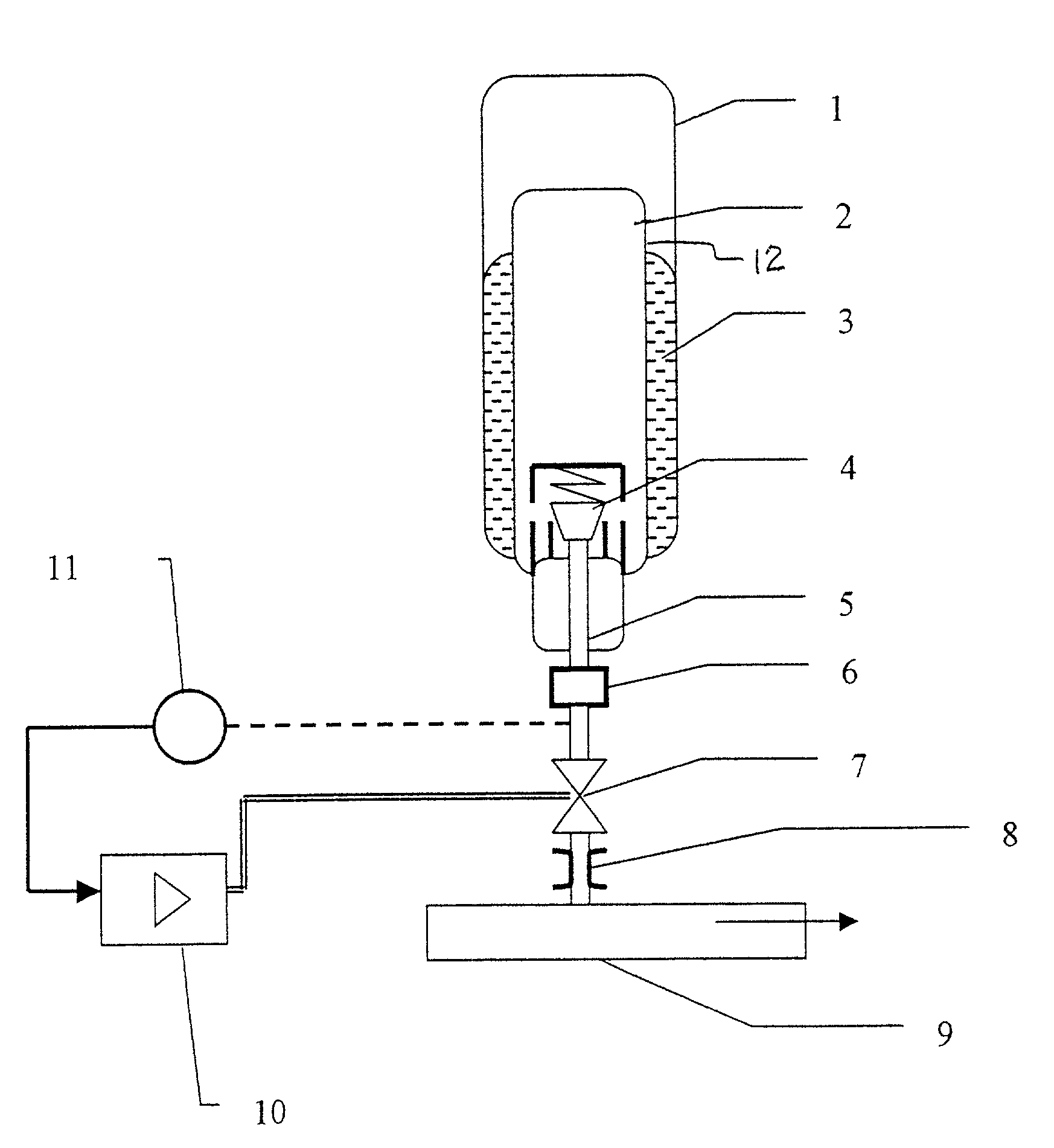

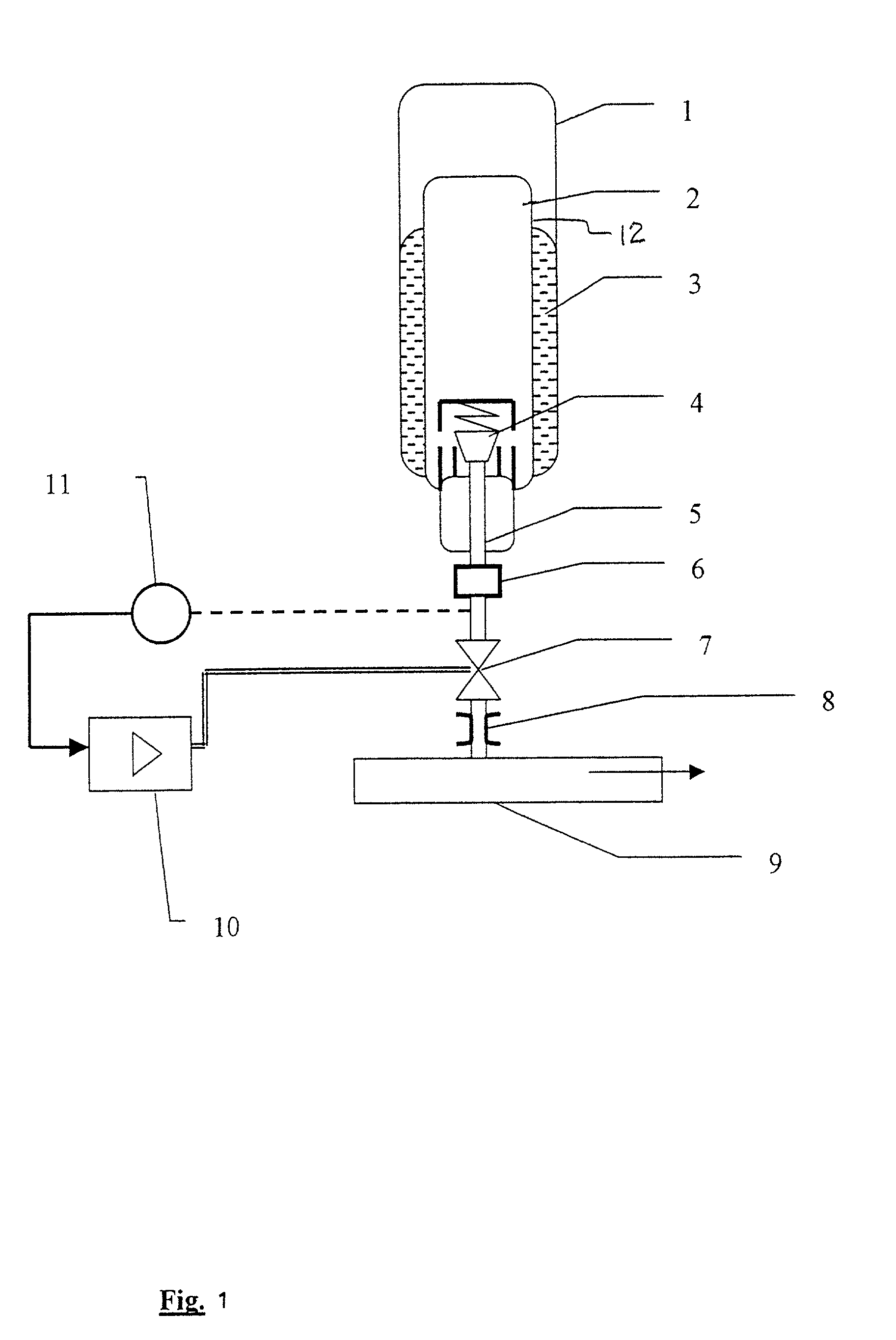

Anesthetic metering system

InactiveUS7066913B2Overcomes drawbackRefilling can be possibleRespiratorsMedical devicesWall materialVALVE PORT

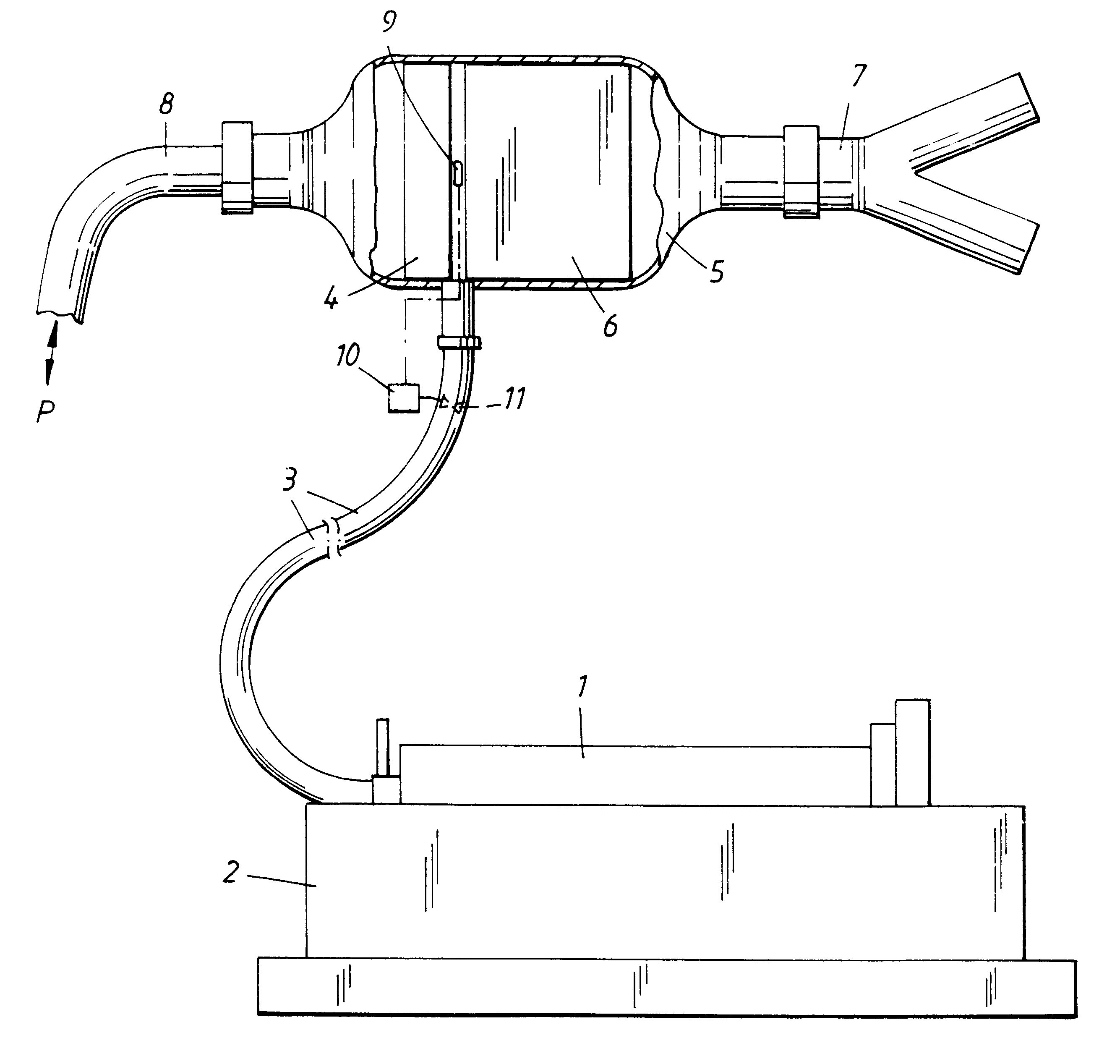

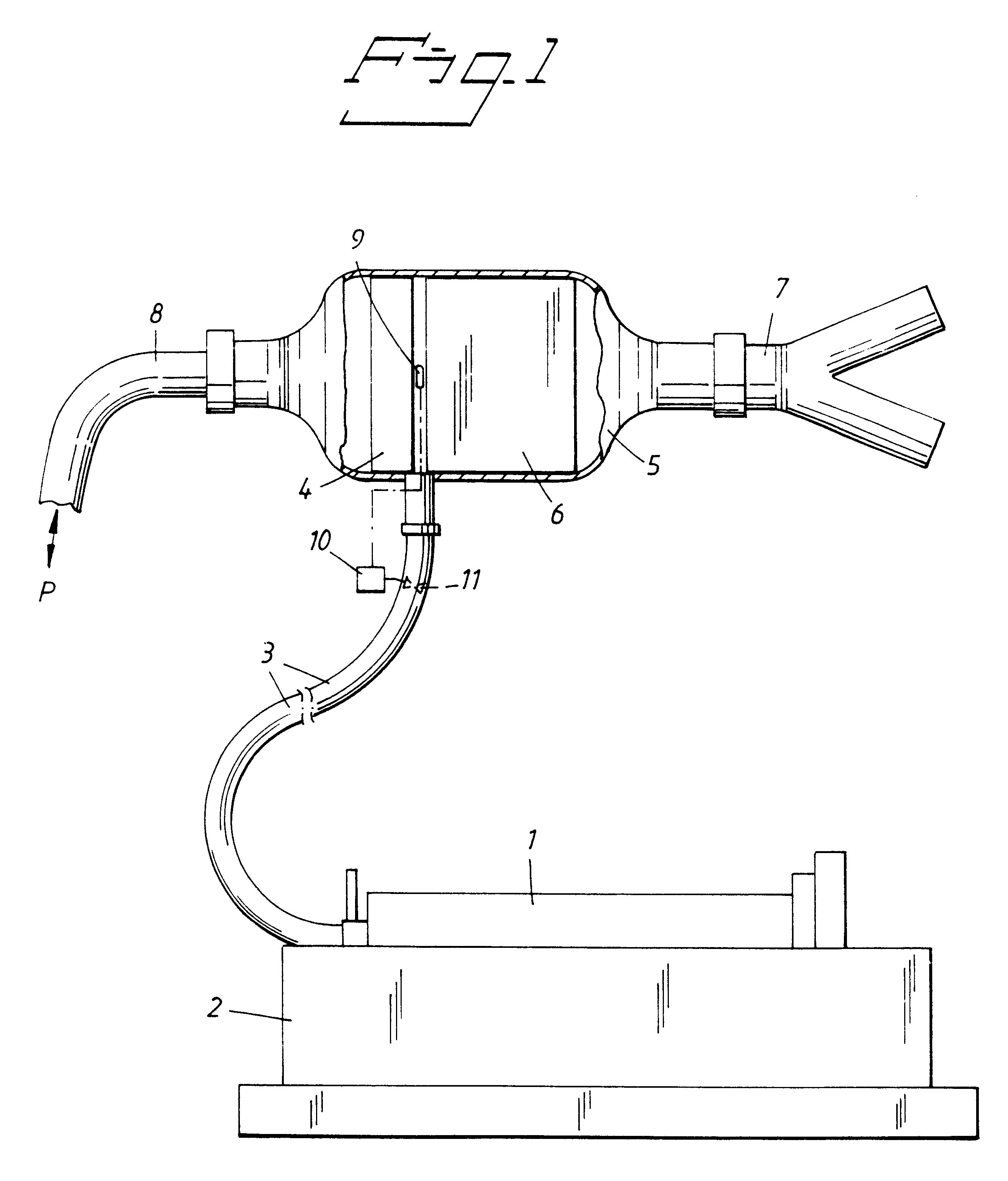

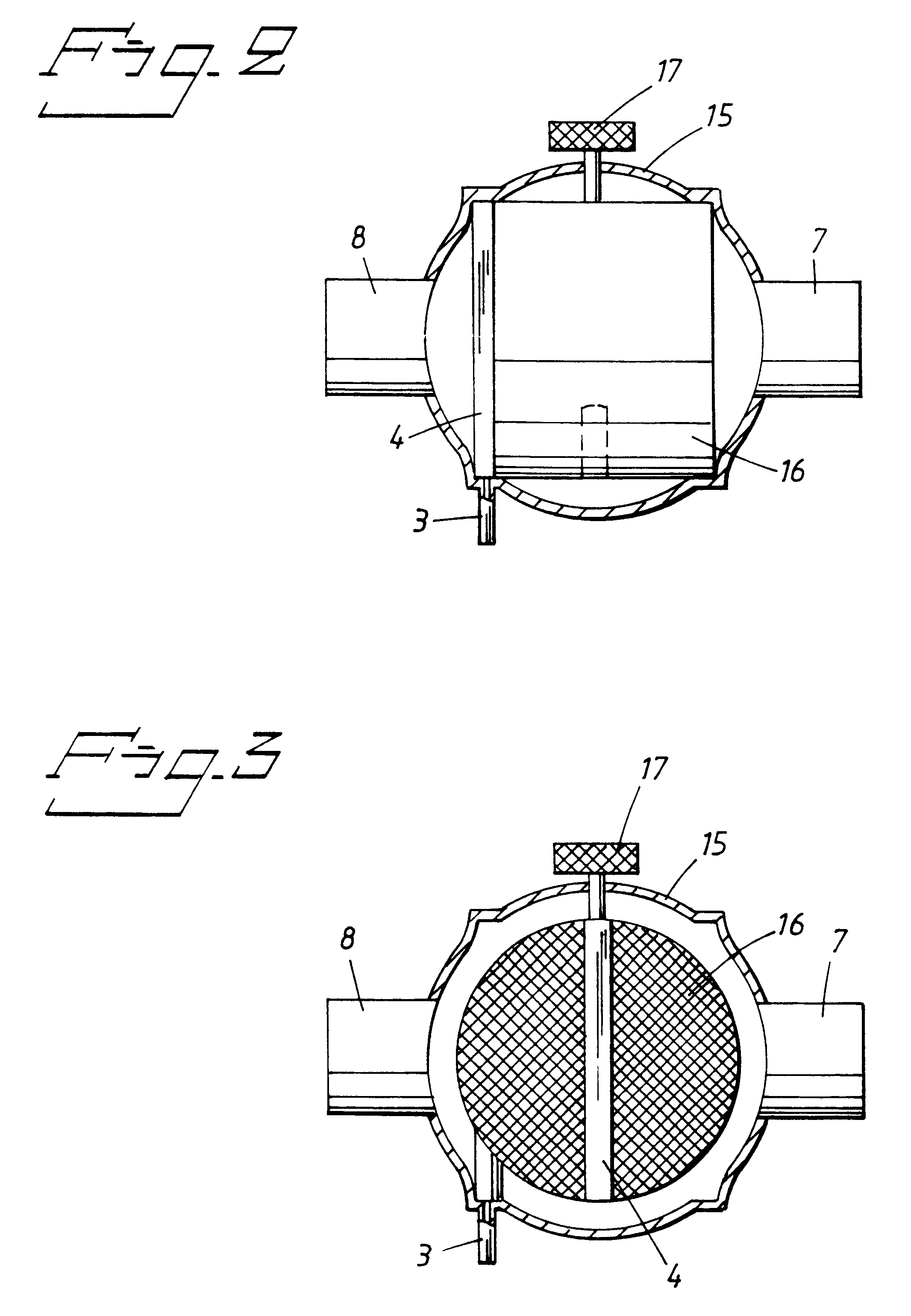

An anesthetic metering system includes an anesthetic reservoir (1) having an anesthetic reserve (2), which is limited by a flexible material wall and to which pressure is admitted by means of a propellant (3) acting thereon via the wall material. The anesthetic reservoir (1) has a first valve (4), which is in flow connection with the liquid anesthetic reserve (2) and can be inserted into a mounting element (6) of an anesthesia apparatus. The metered release of anesthetic to the anesthesia apparatus takes place via a volumetric nozzle (8). The present invention provides an anesthetic metering device which avoids, on the one hand, the drawbacks of the anesthetic evaporators used previously, which are to be refilled with anesthetics at the workplace, and makes possible the refilling of the anesthetic reservoir (1) at the anesthetic manufacturer, on the other hand.

Owner:DRAGERWERK AG

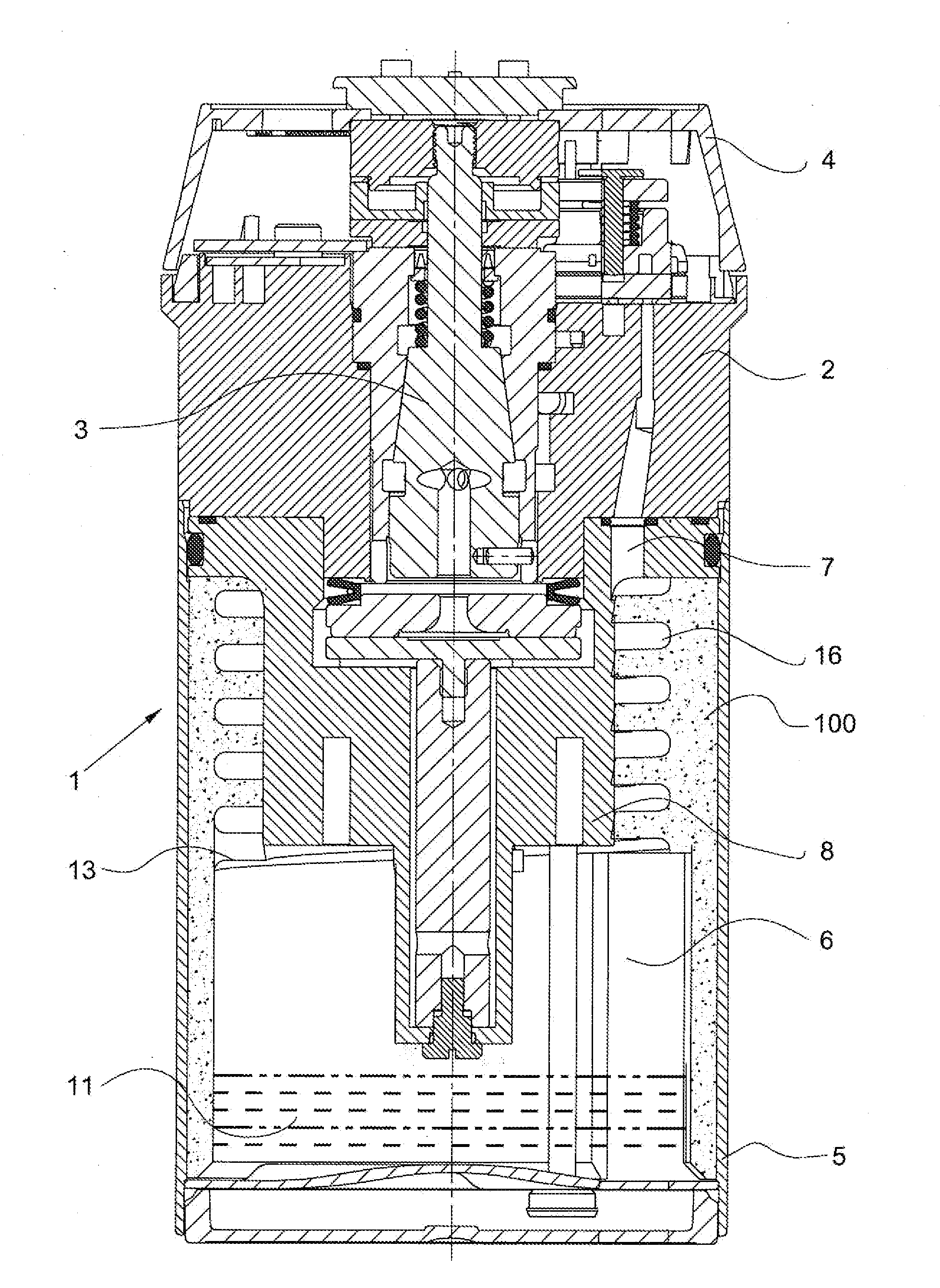

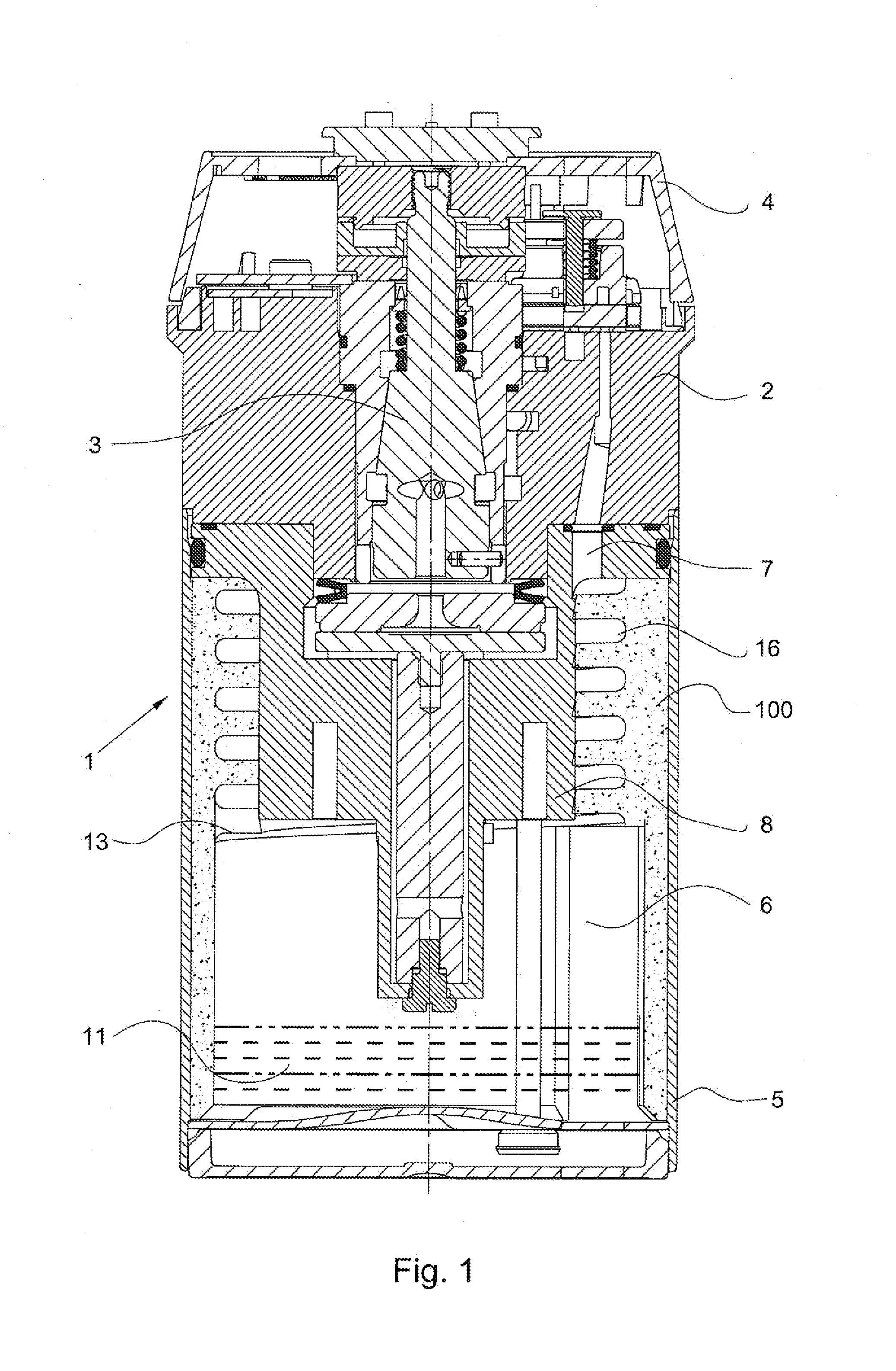

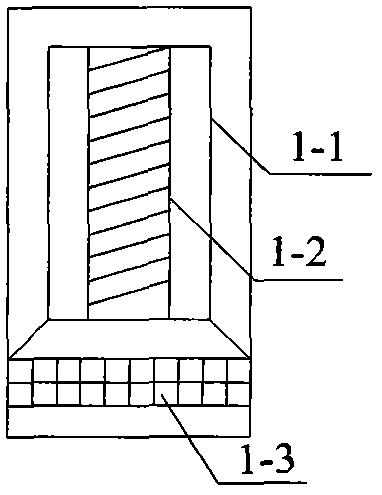

Wick for an anesthetic evaporator

InactiveUS20100051028A1Improve space utilizationThermal couplingRespiratorsInhalatorsEngineeringAnaesthetic vaporizer

A wick for an anesthetic evaporator is provided as a dimensionally stable wick body (14) transporting anesthetic by means of capillary force is provided. The wick body comprises a hollow cylinder as well as webs by which a gas-carrying cavity is formed.

Owner:DRAGERWERK AG

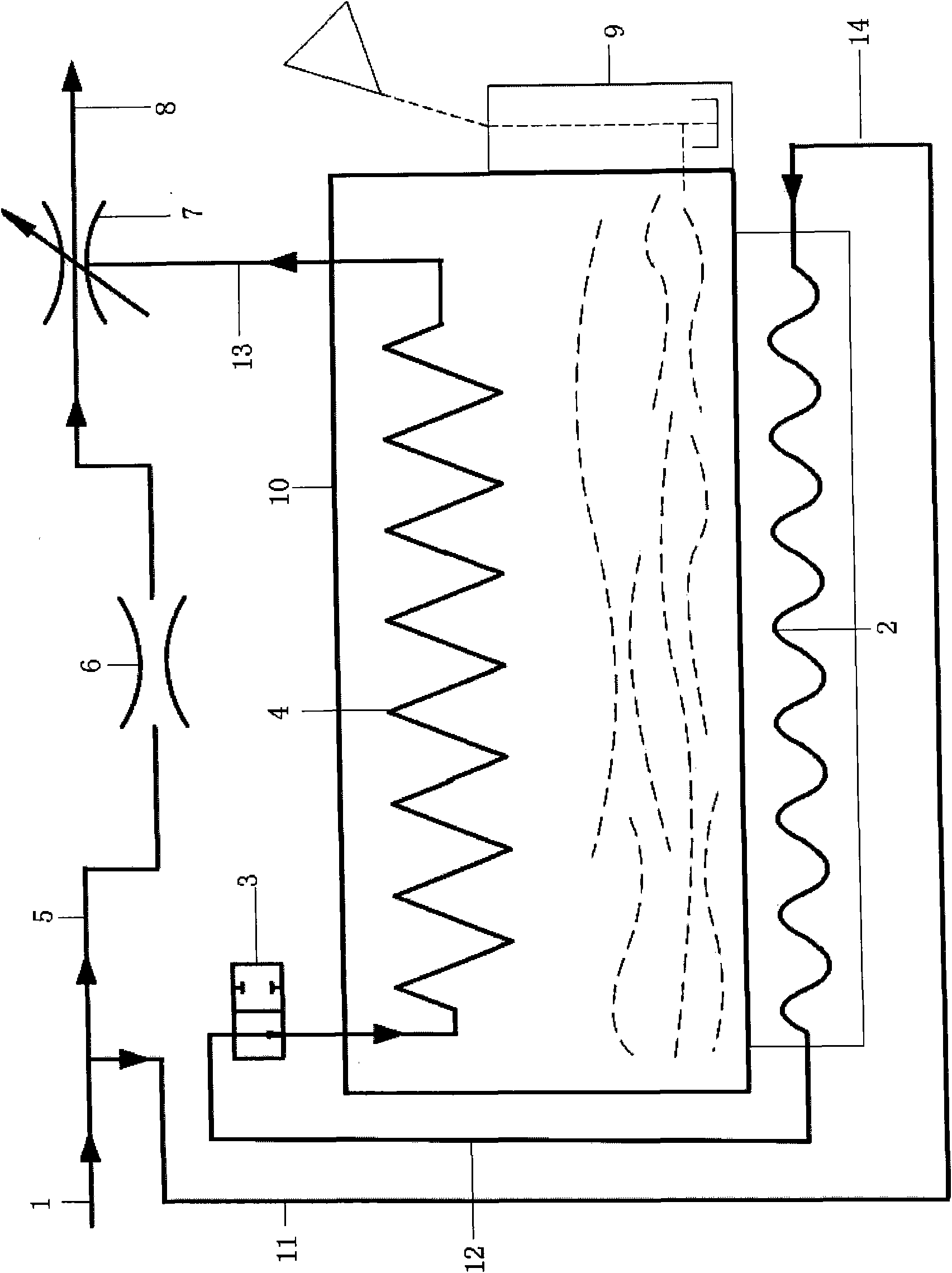

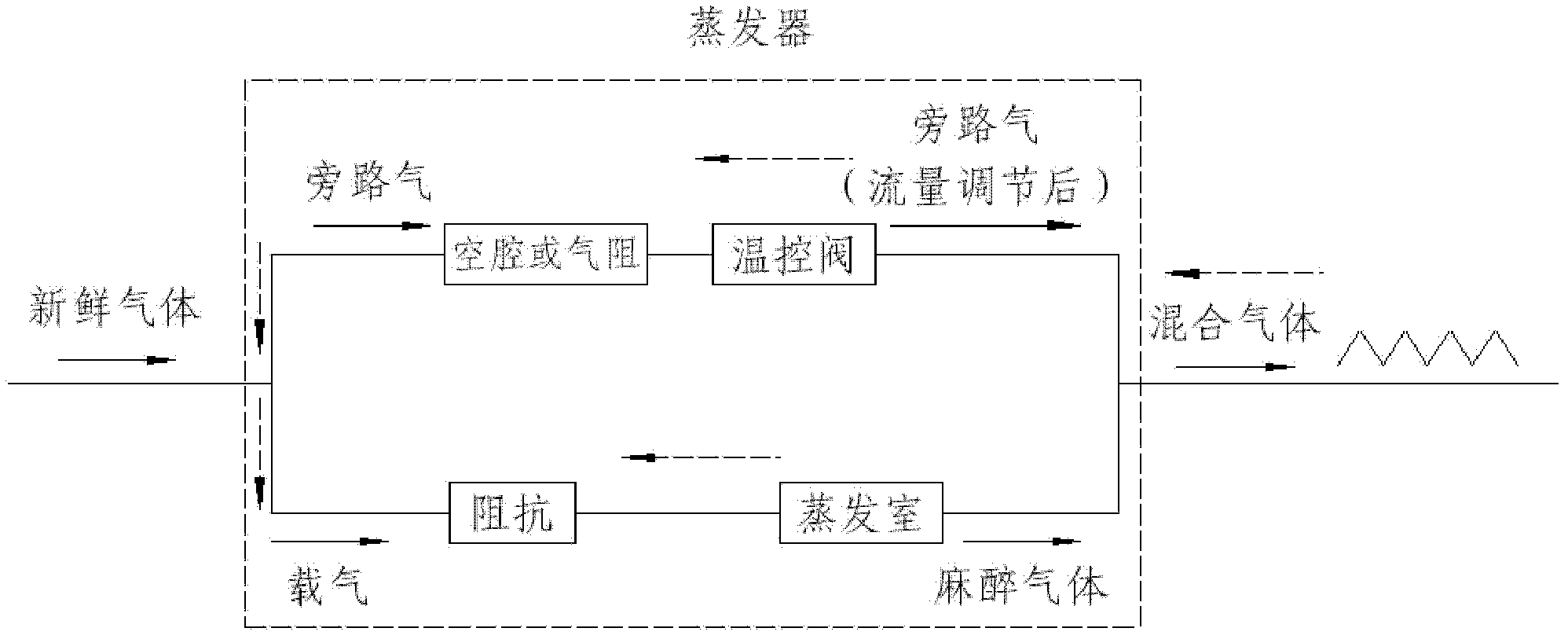

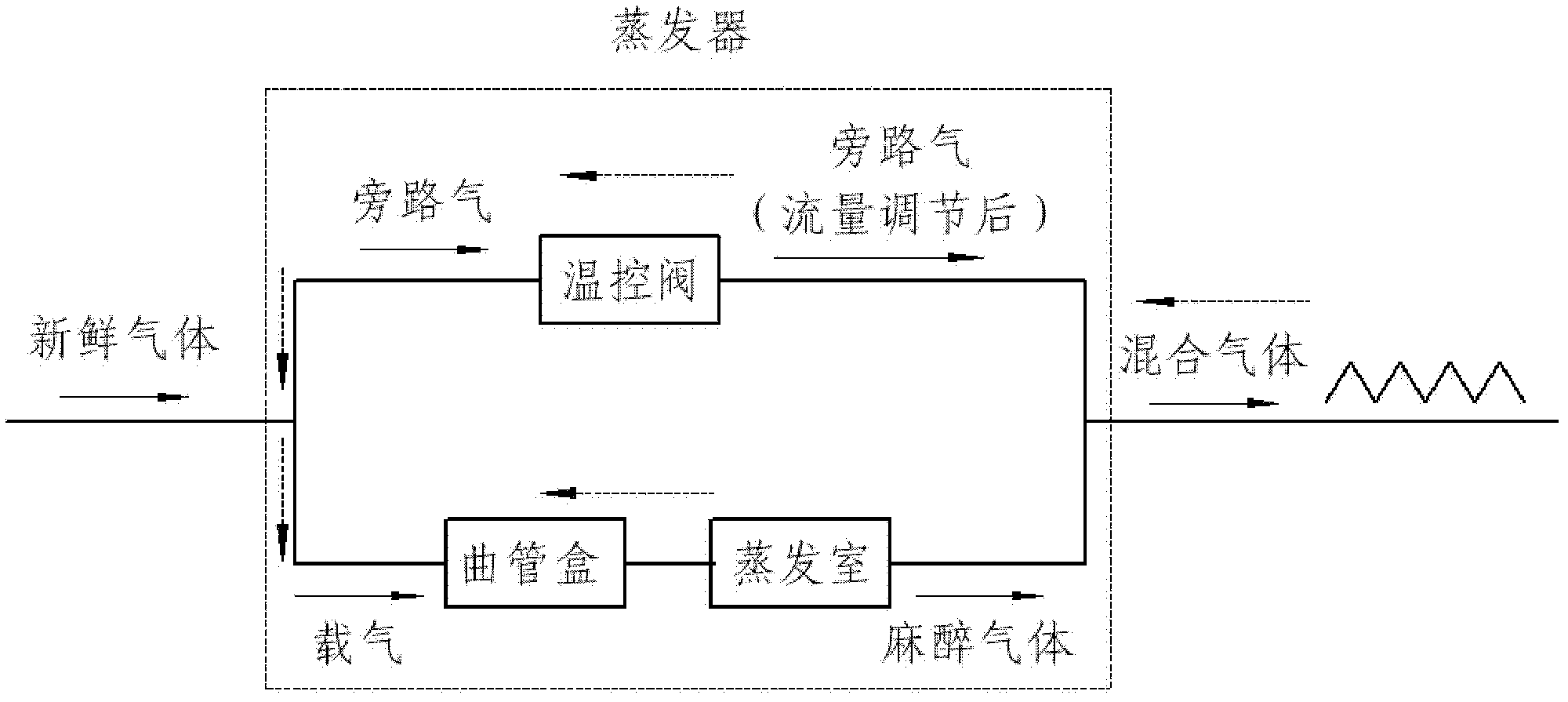

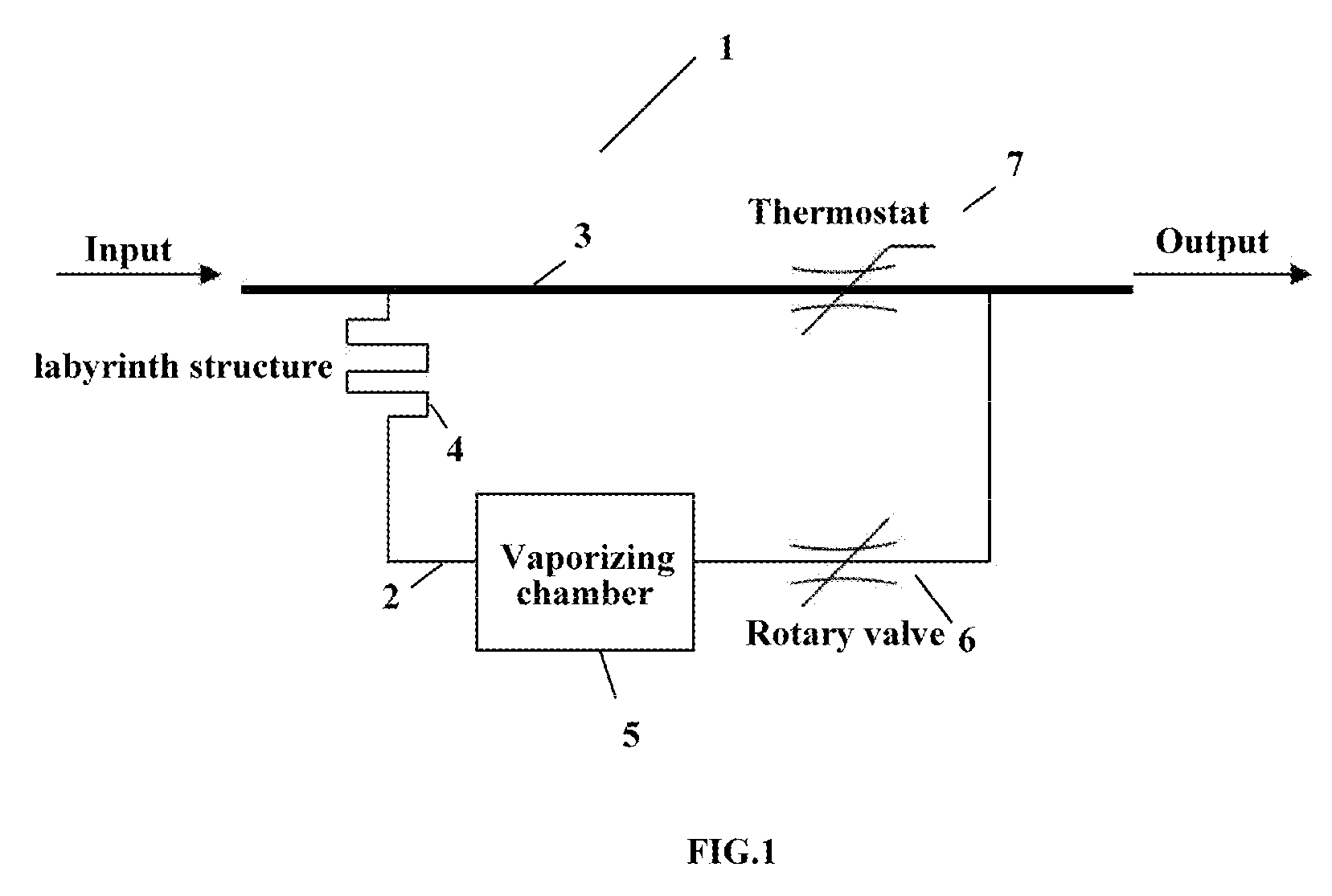

Anesthetic vaporizer with flow and pressure fluctuation compensation function

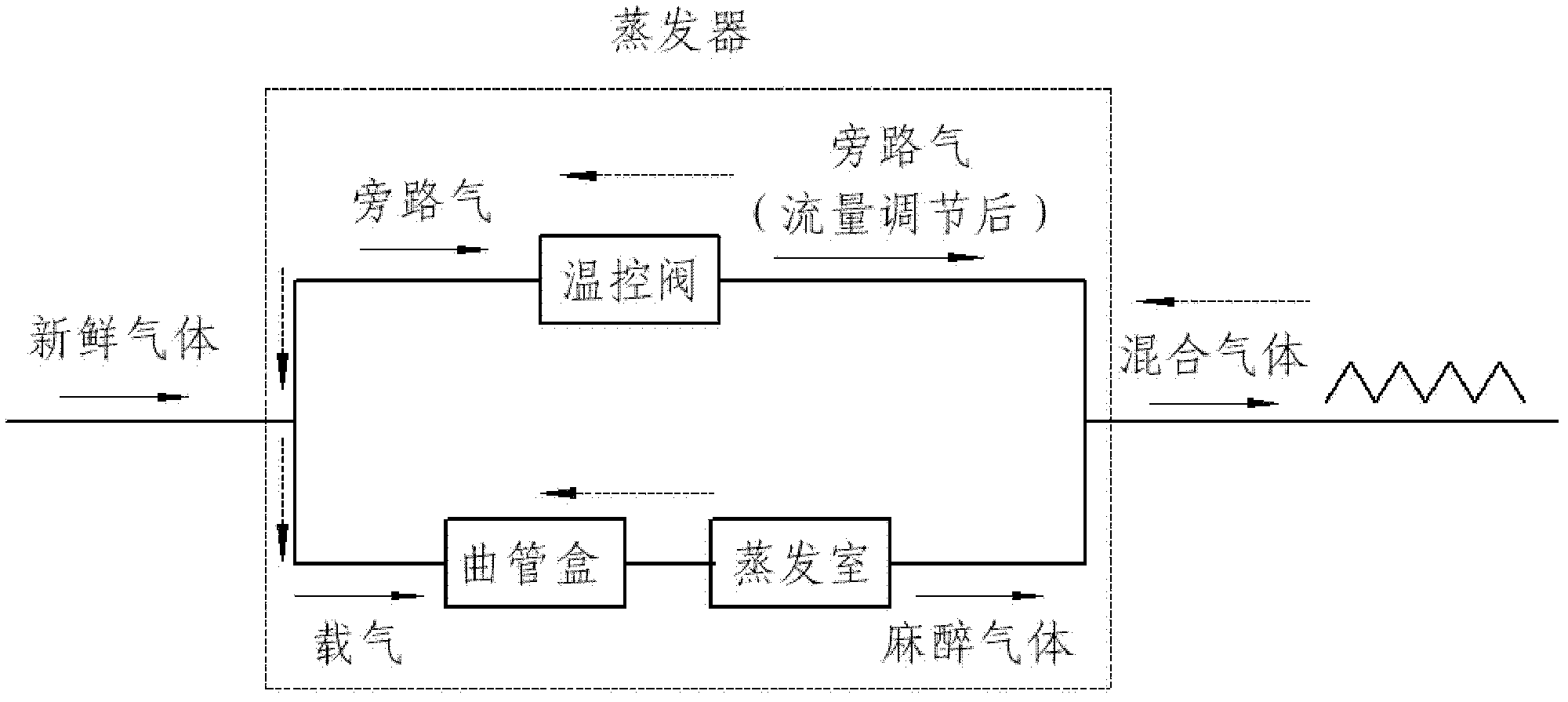

The invention discloses an anesthetic vaporizer with the flow and pressure fluctuation compensation function. The anesthetic vaporizer comprises a fresh gas inlet, a mixed gas outlet, a bypass gas circuit and a carrier gas circuit; a temperature control valve is arranged on the bypass gas circuit; an anesthetic vaporization chamber is arranged on the carrier gas circuit; a curved tube box is also arranged on the carrier gas circuit; a tortuous cavity is formed inside the curved tube box; an inlet of the tortuous cavity is respectively communicated with the fresh gas inlet and an inlet of the temperature control valve; an outlet of the tortuous cavity is communicated with an inlet of the vaporization chamber; an airflow gap for allowing gas to flow into is arranged on the temperature control valve; when flow at the fresh gas inlet increases, the airflow gap becomes small to enable the flow of the fresh gas flowing into the temperature control valve to decrease; and when flow at the fresh gas inlet decreases, the air flow gap becomes large to enable the flow of the fresh gas flowing into the temperature control valve to decrease. The anesthetic vaporizer has the advantages of simple structure, easiness in processing, and convenience in dismantling.

Owner:BEIJING AEONMED

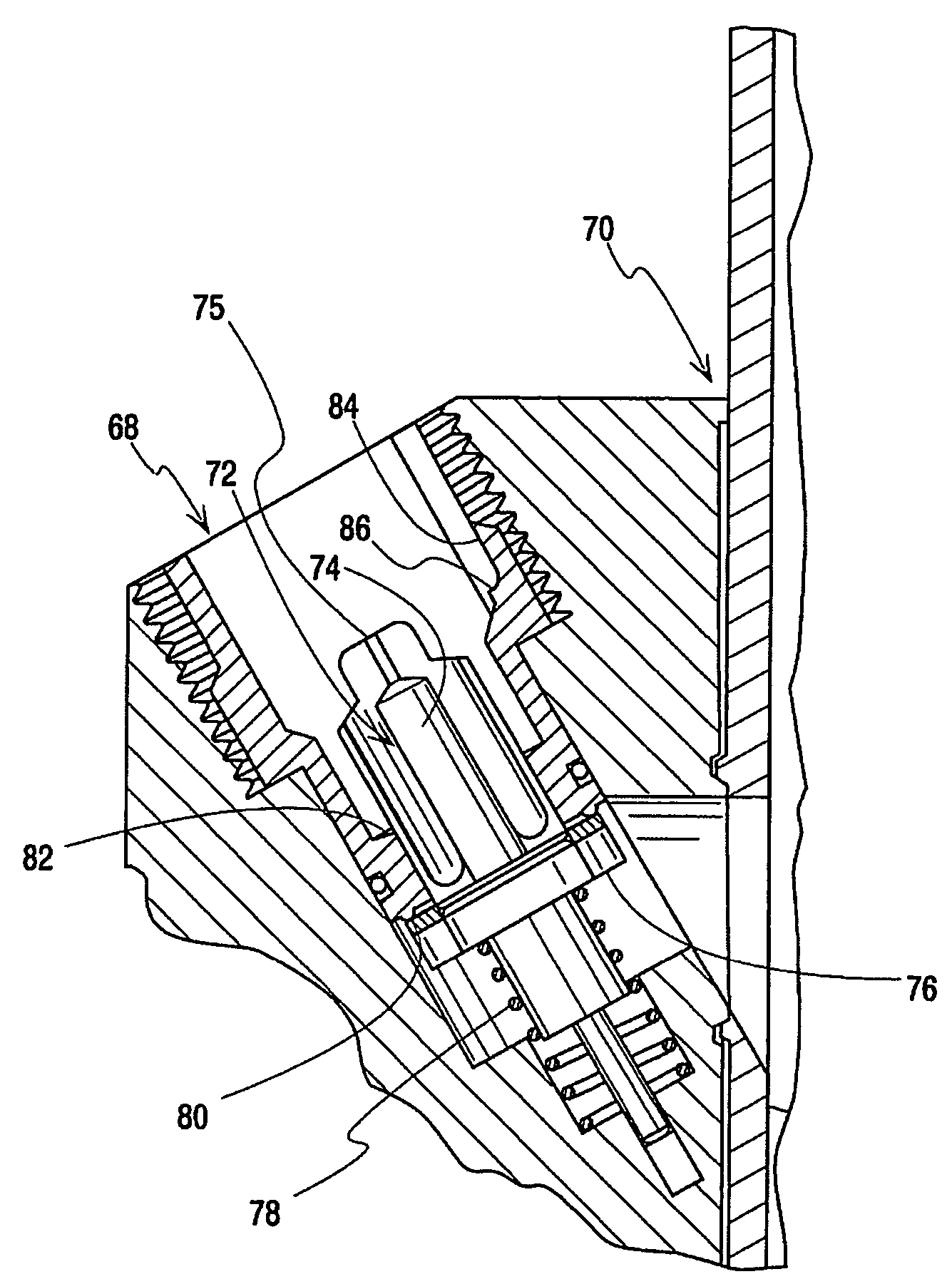

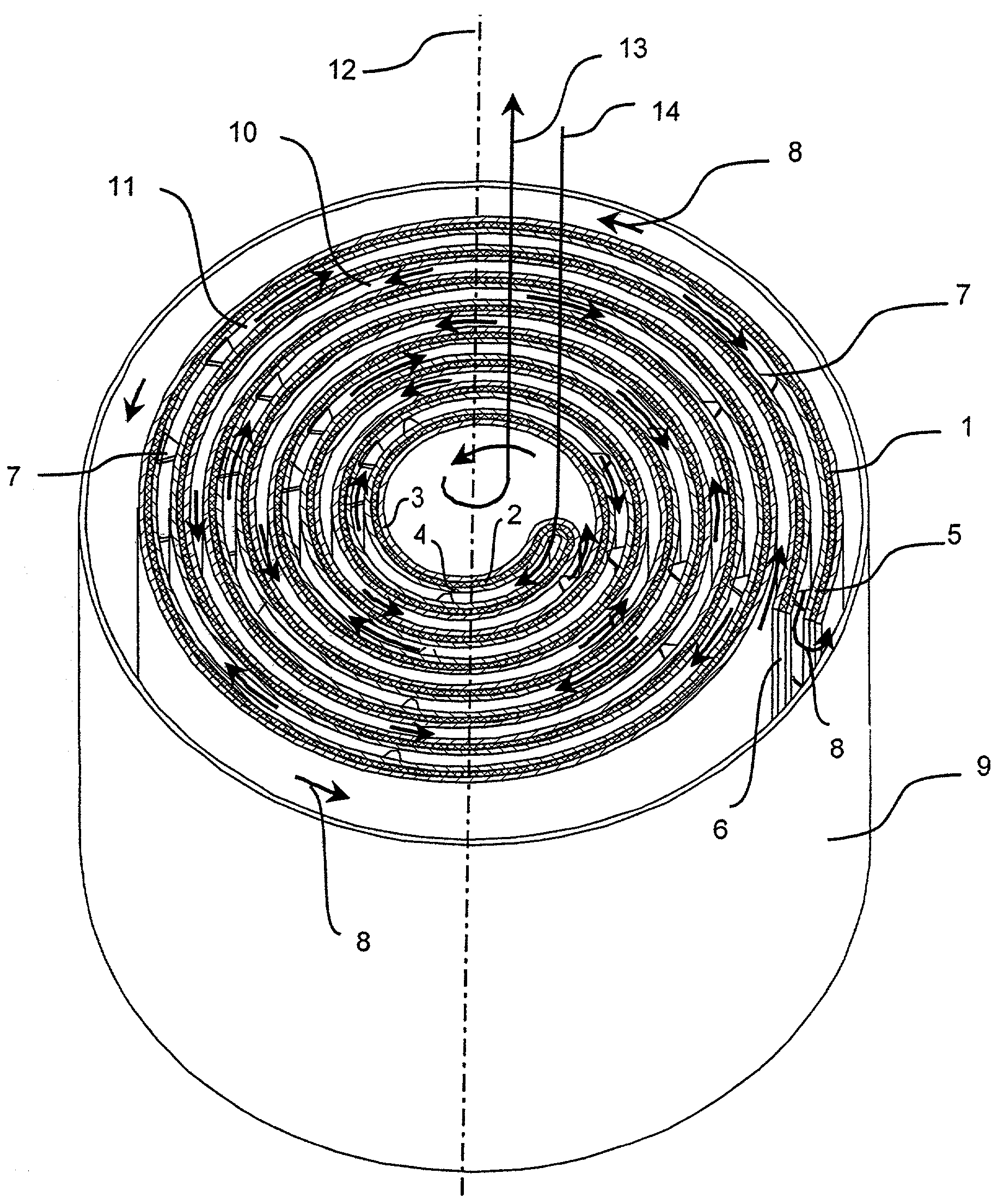

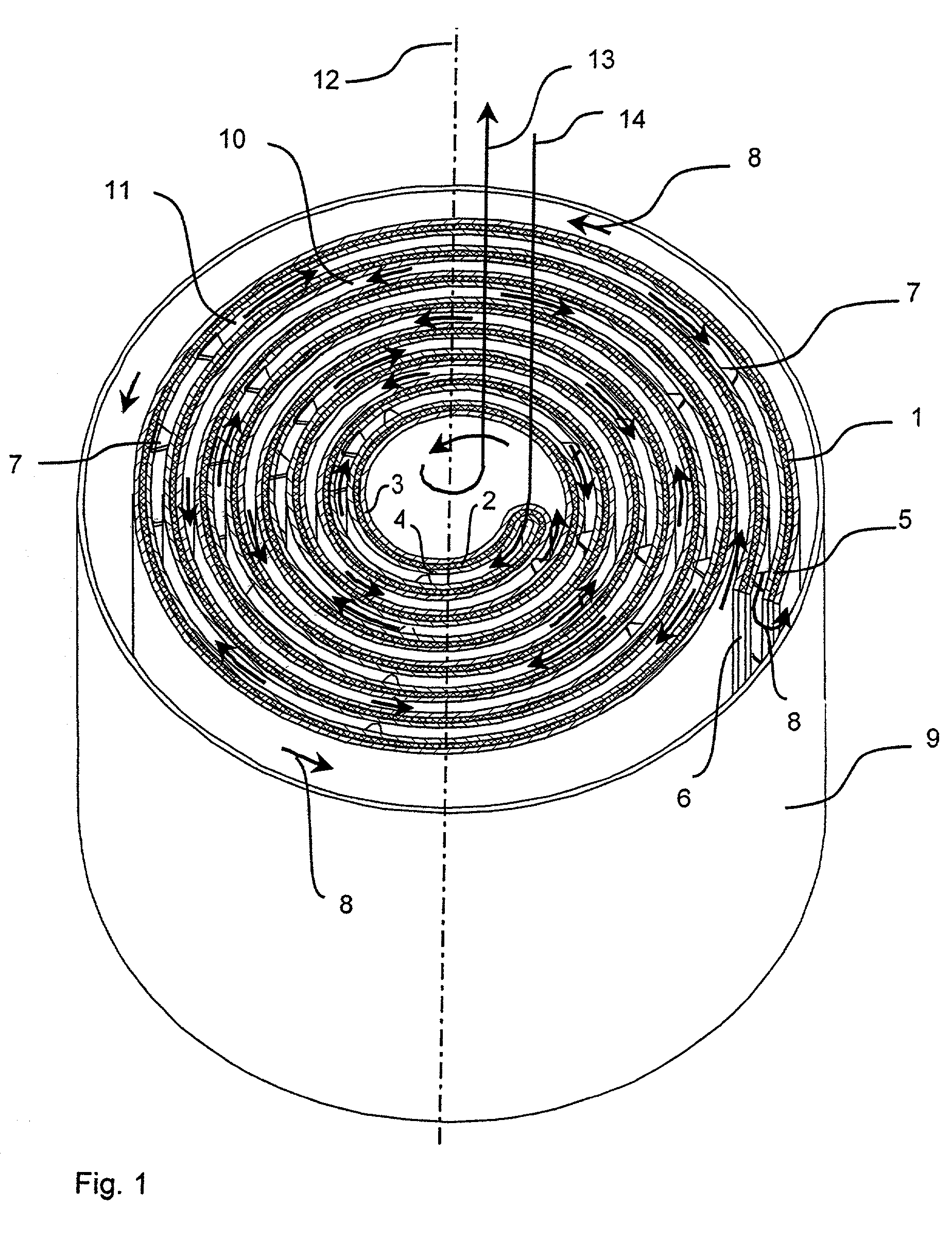

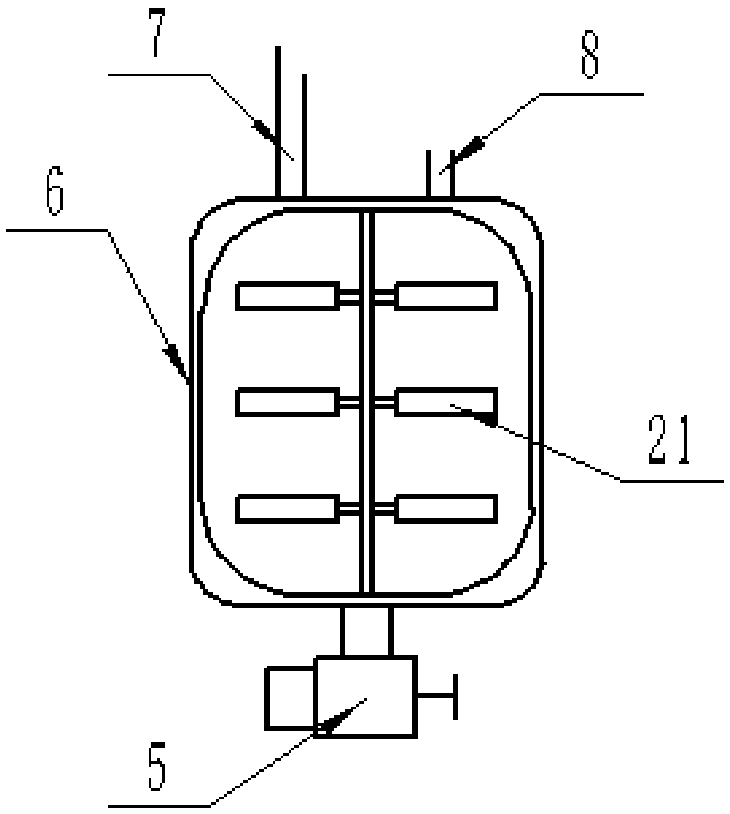

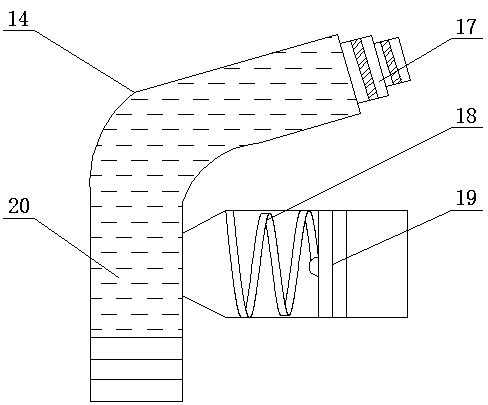

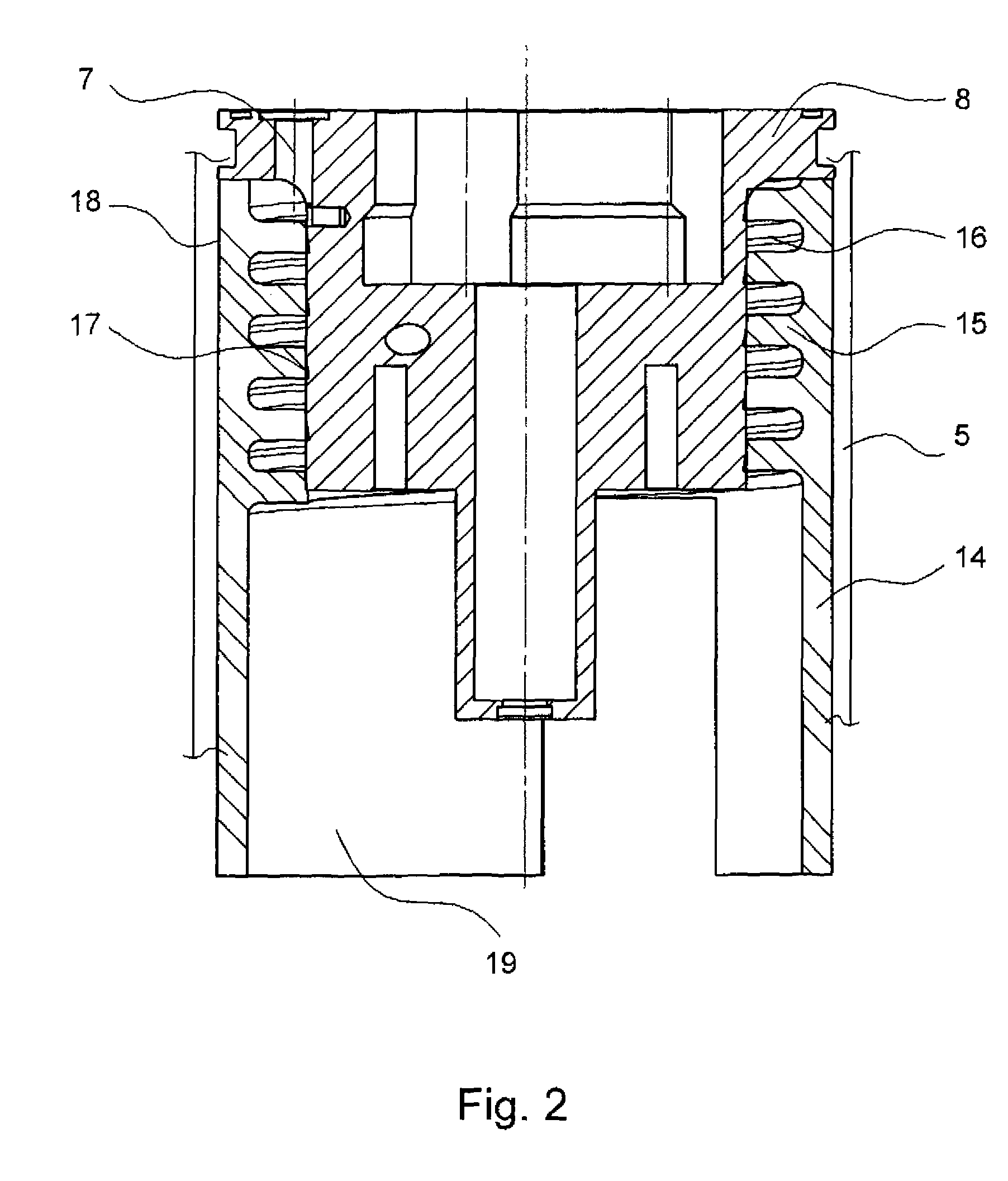

Wick arrangement for an anesthetic evaporator

InactiveUS7275539B2Obstruct passagePassage difficultRespiratorsStationary tubular conduit assembliesAnesthetic AgentPath length

A wick arrangement for an anesthetic evaporator includes a wick with a carrier material (2) that is essentially impermeable to gas provided with wick material (3, 4) on both sides. A great path length is provided for saturating the gas with anesthetic vapor in the smallest possible installation volume by providing flow channels such as helical flow channels (10, 11) extending helically on both sides of the wick. The gas flow is led in counterflow in the flow channels (10, 11) by a housing (9).

Owner:DRAGERWERK AG

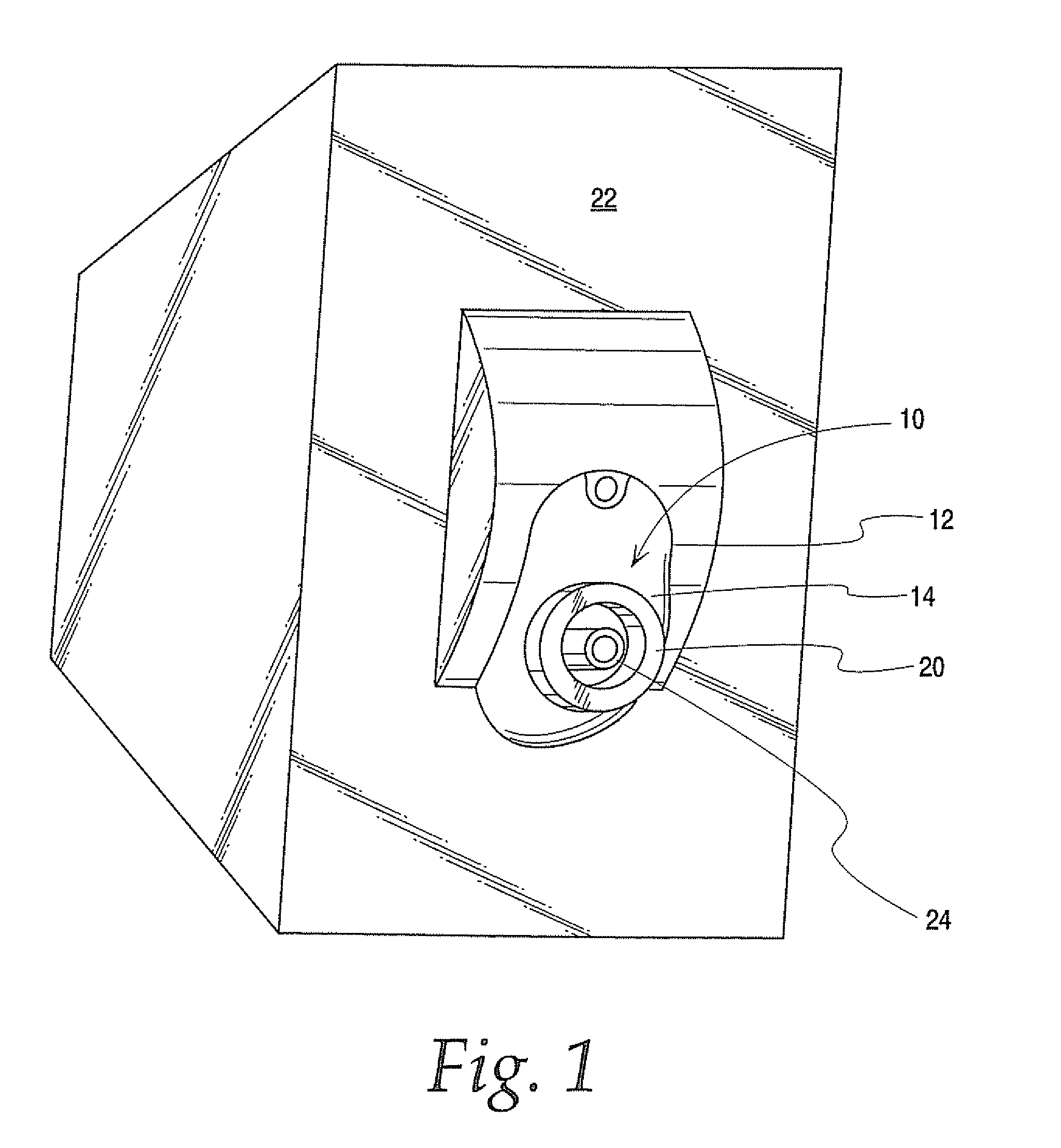

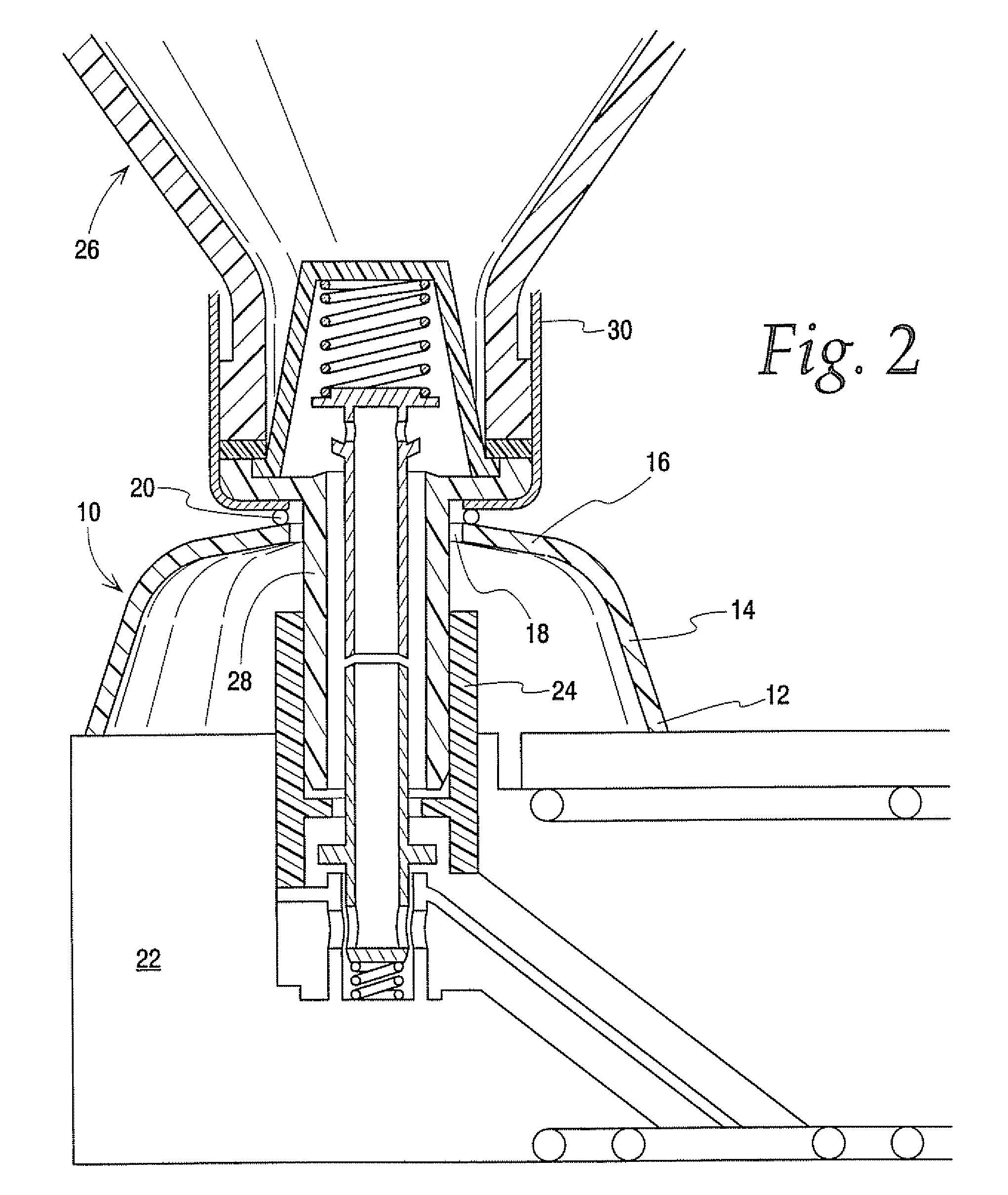

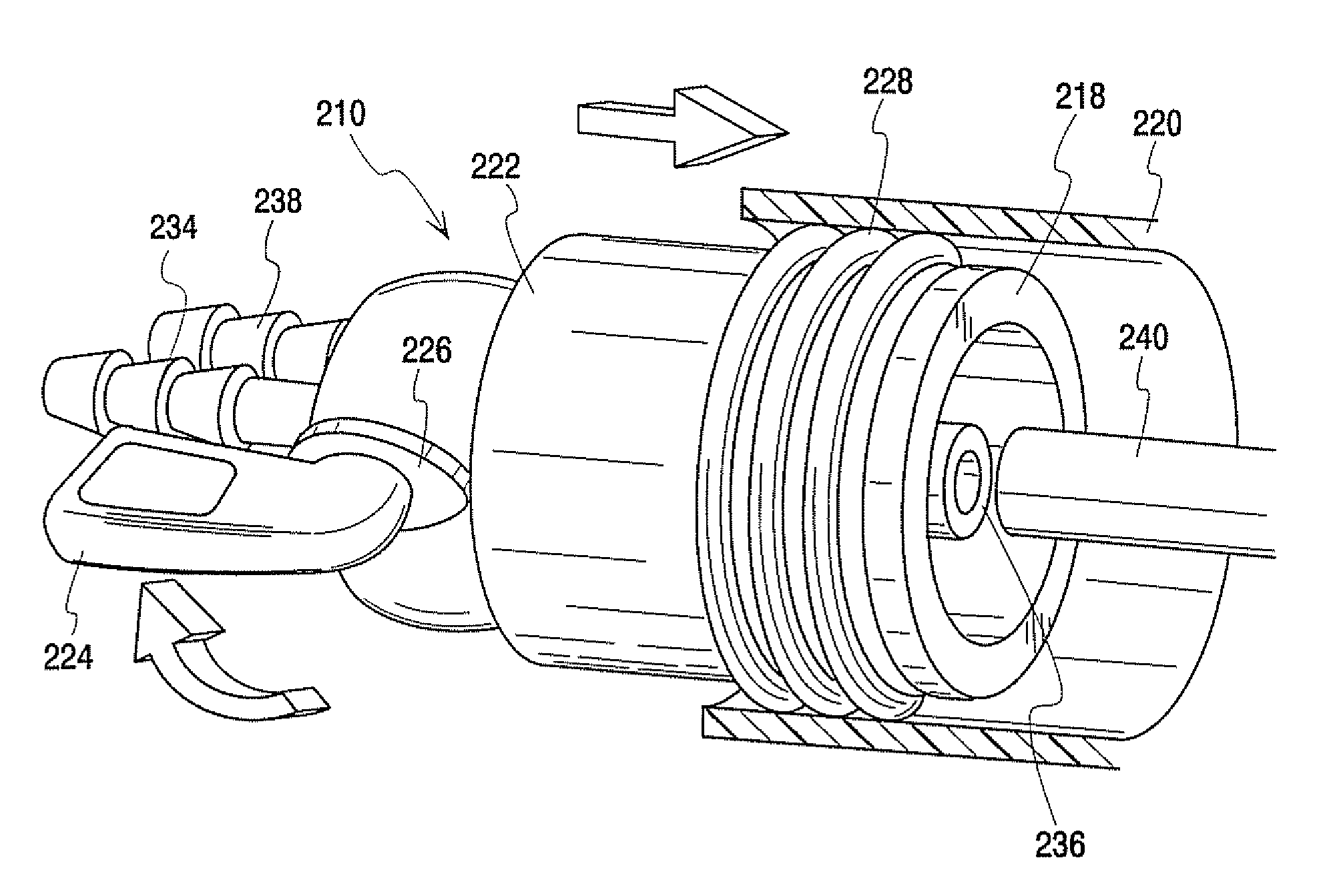

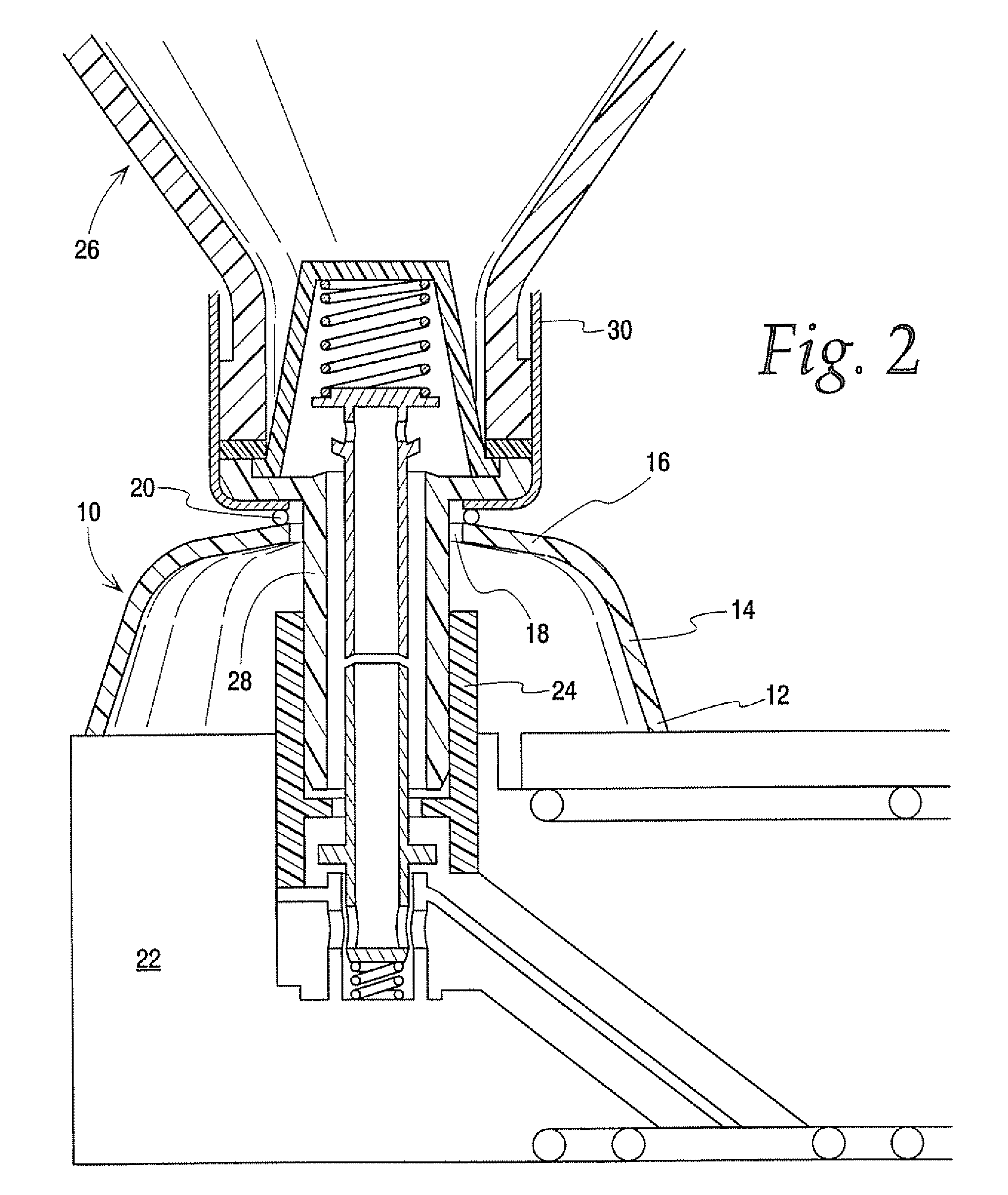

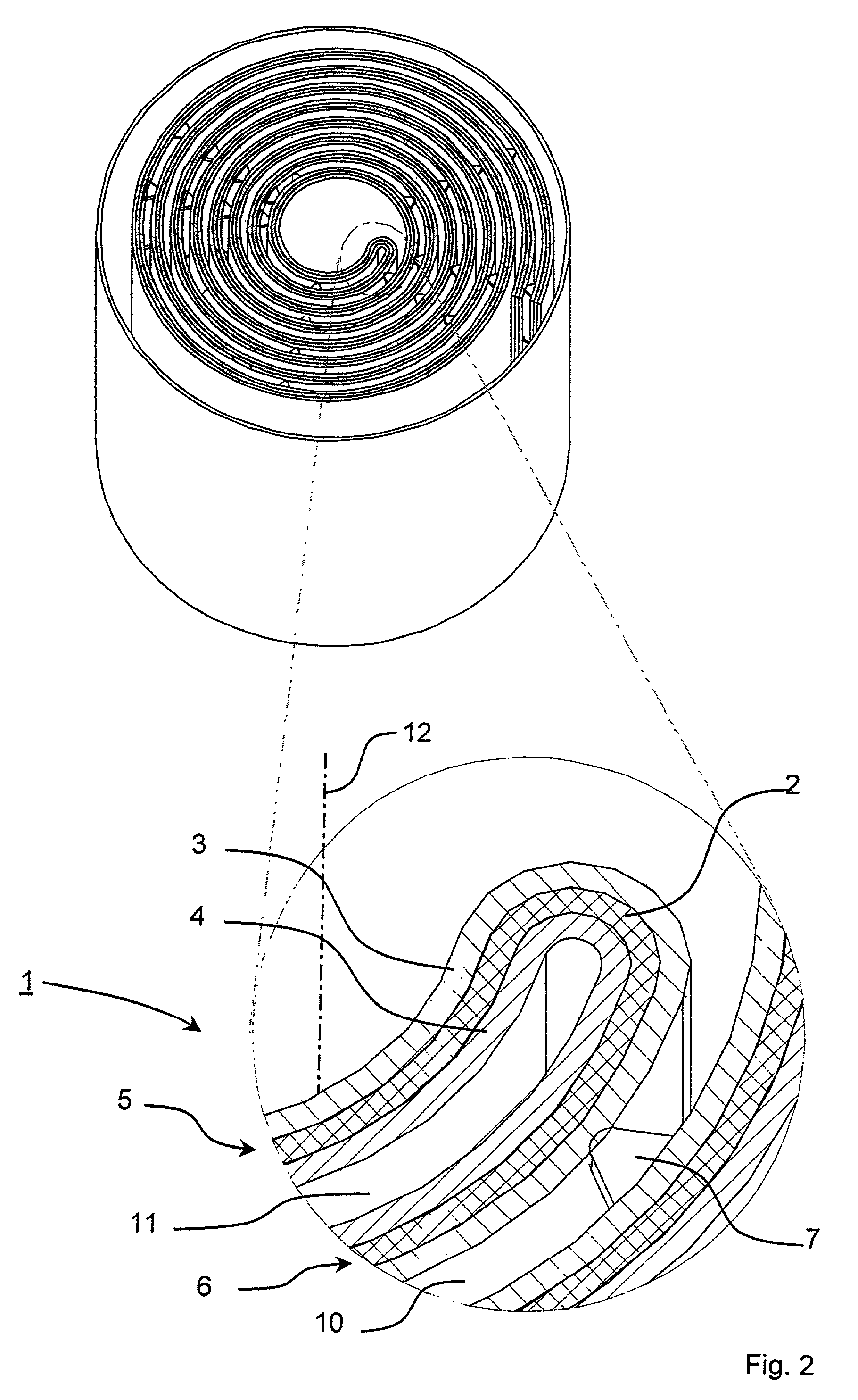

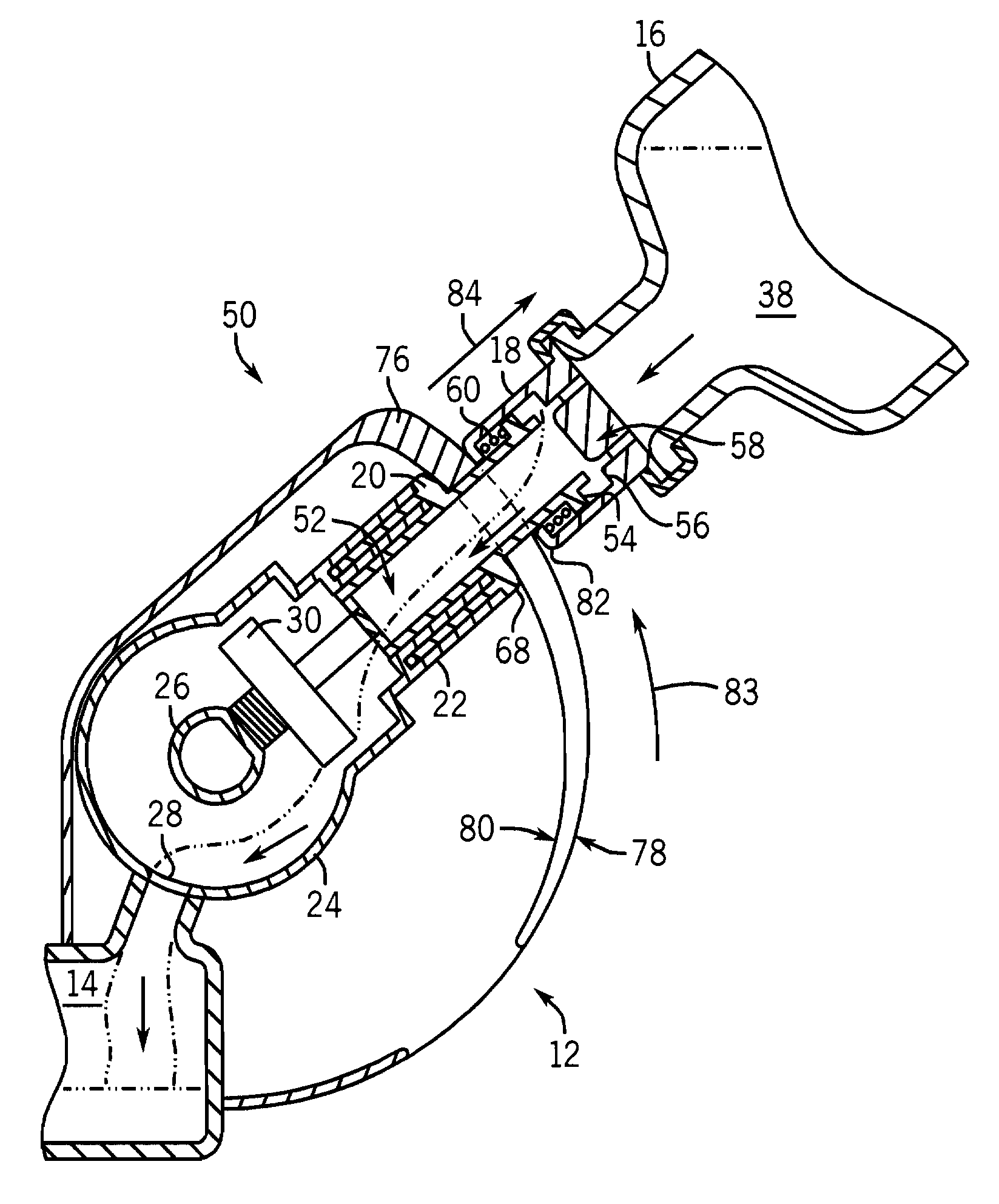

Anesthetic Vaporizer Filling System

A system for the delivery of a liquid anesthetic agent to a sump of an anesthetic vaporizer includes a filler assembly rotatable about a pivot point. The filler assembly further includes a sump valve that controls fluid communication between the filler assembly and the sump. An adapter is coupled with the filler spout and includes a sealing surface that forms a seal against fluid communication between the anesthetic bottle and the adapter. The filler assembly, the filler spout, and the adapter are rotated about the pivot point along the rail. The rotation of the filler assembly, the filler spout, and the adapter about the pivot point opens the sump valve and the seal between the adapter and the anesthetic bottle.

Owner:GENERAL ELECTRIC CO

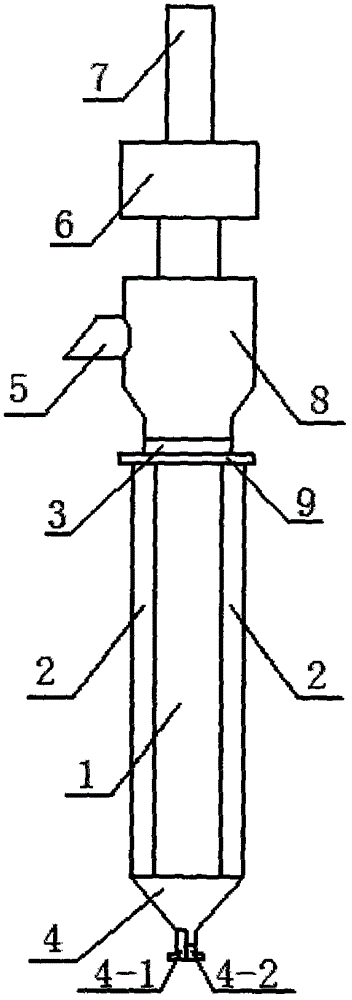

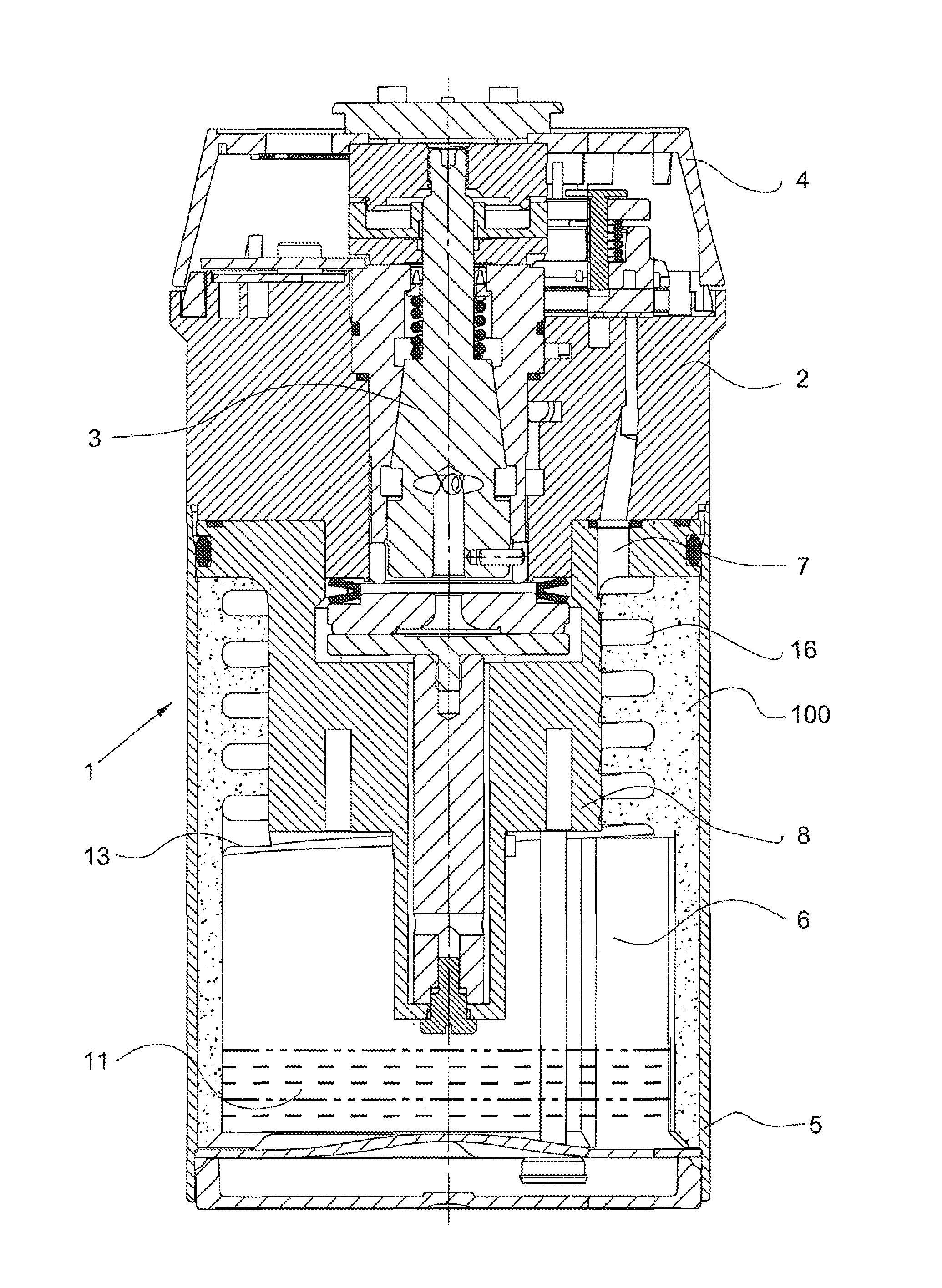

Anesthetic vaporizer

The invention provides an anesthetic vaporizer which comprises a vaporizing cylinder, heating tubes, filter cotton, an end cap, an air inlet, an air pump, an output pipe and a mixing chamber. The heating tubes are arranged on the two sides of the vaporizing cylinder. The upper end of the vaporizing cylinder is connected with the mixing chamber. The filter cotton is arranged at the bottom of the mixing chamber. The end cap is arranged at the lower end of the vaporizing cylinder. The air inlet is formed in the mixing chamber. The output pipe is arranged at the upper end of the mixing chamber and provided with the air pump. The anesthetic vaporizer is simple in structure and convenient to use; the purpose of treating a patient who can not get muscle narcotic injection or a patient who can not get anesthesia on a breathing system can be well achieved. The vaporizer can be detached, assembled and decomposed, all parts can be cleaned and disinfected, the vaporizer is cleaner and safer to use, the work efficiency can be improved, and the labor cost can be reduced.

Owner:钱莹

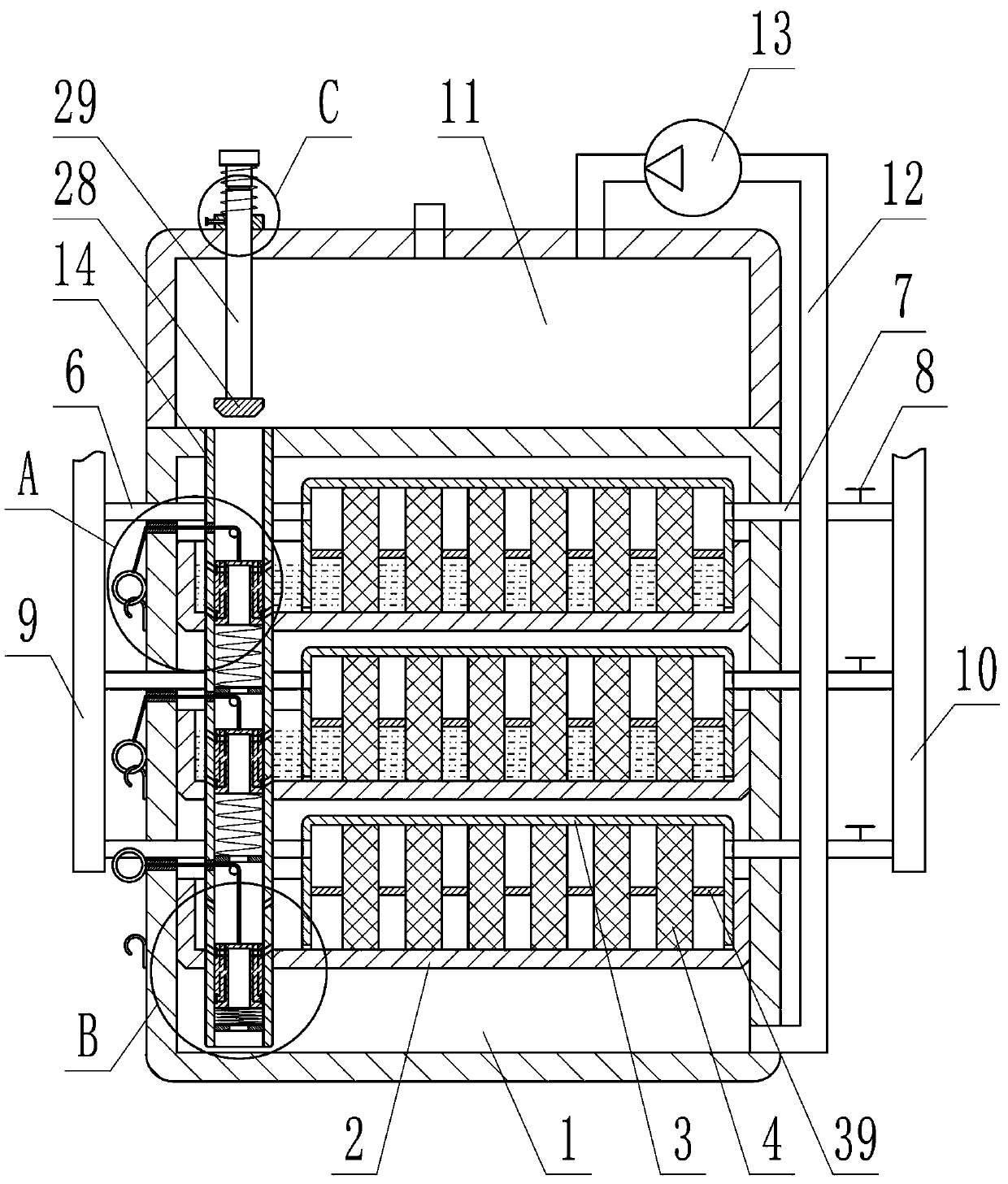

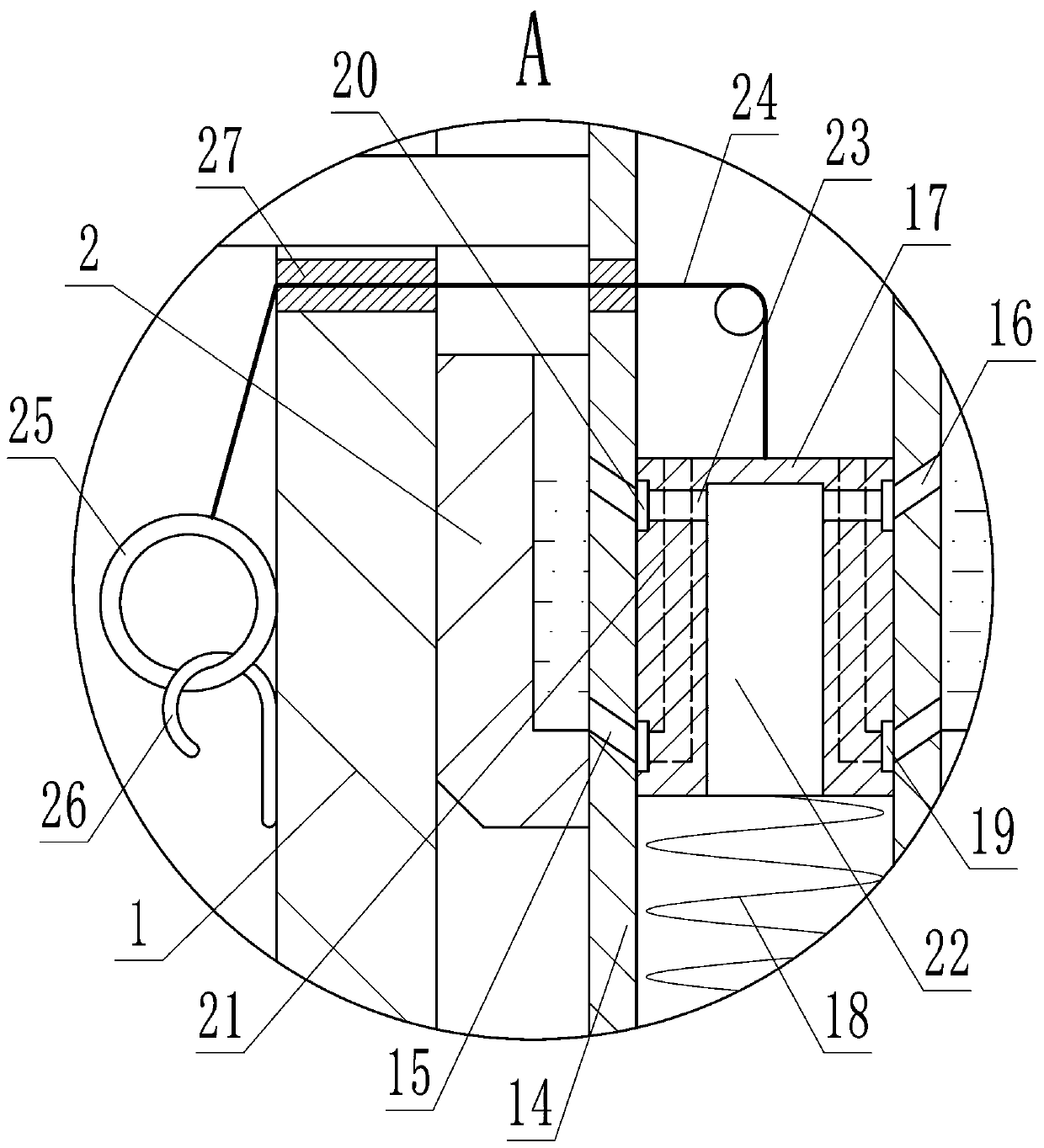

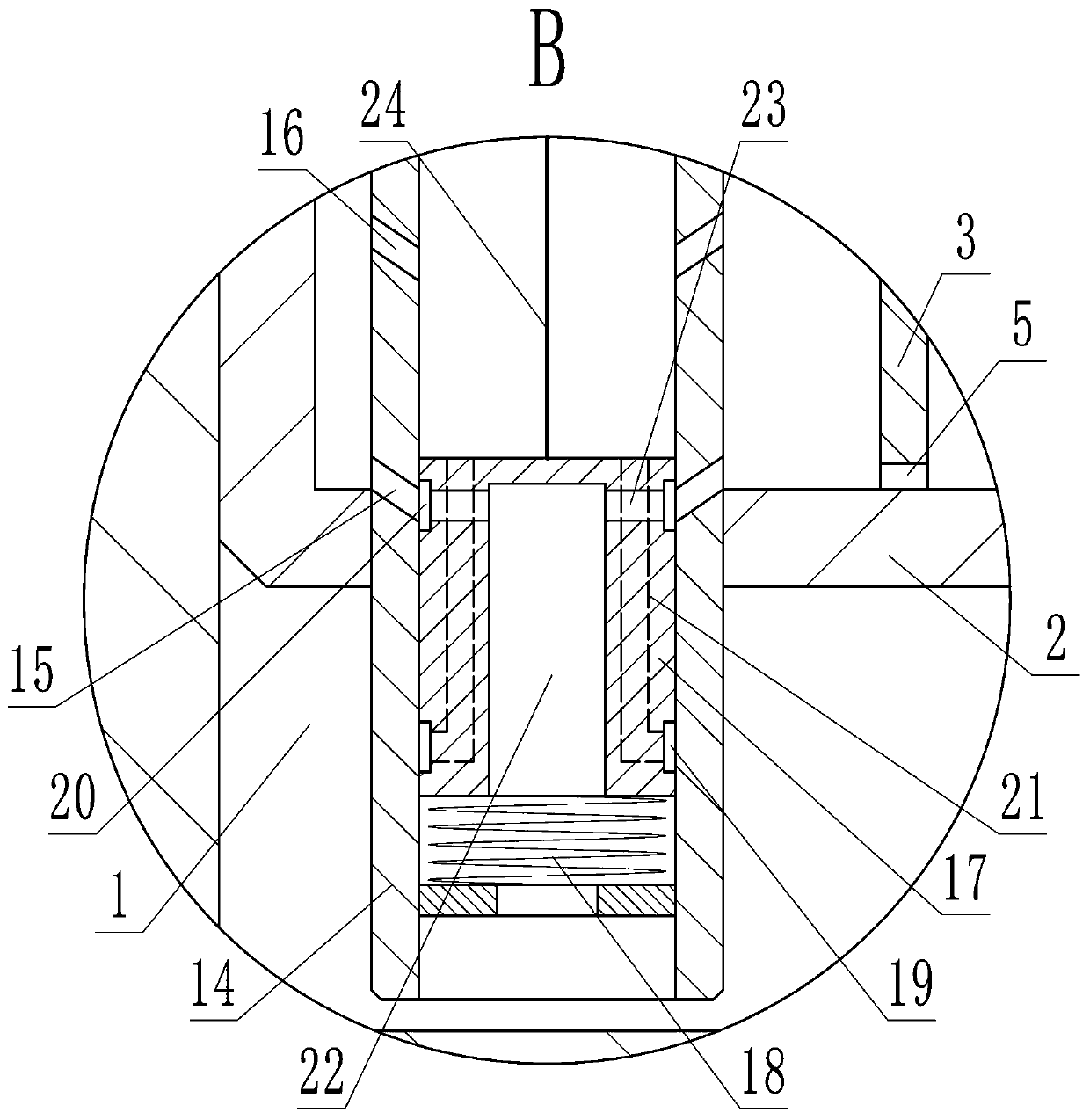

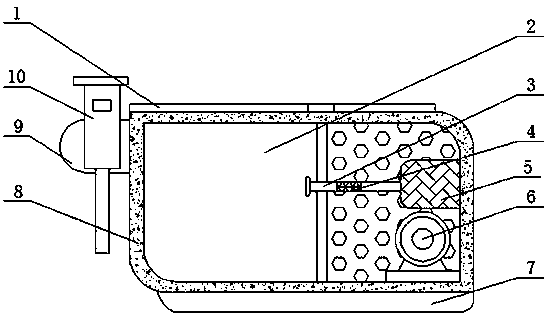

Anesthesia respirator evaporation device

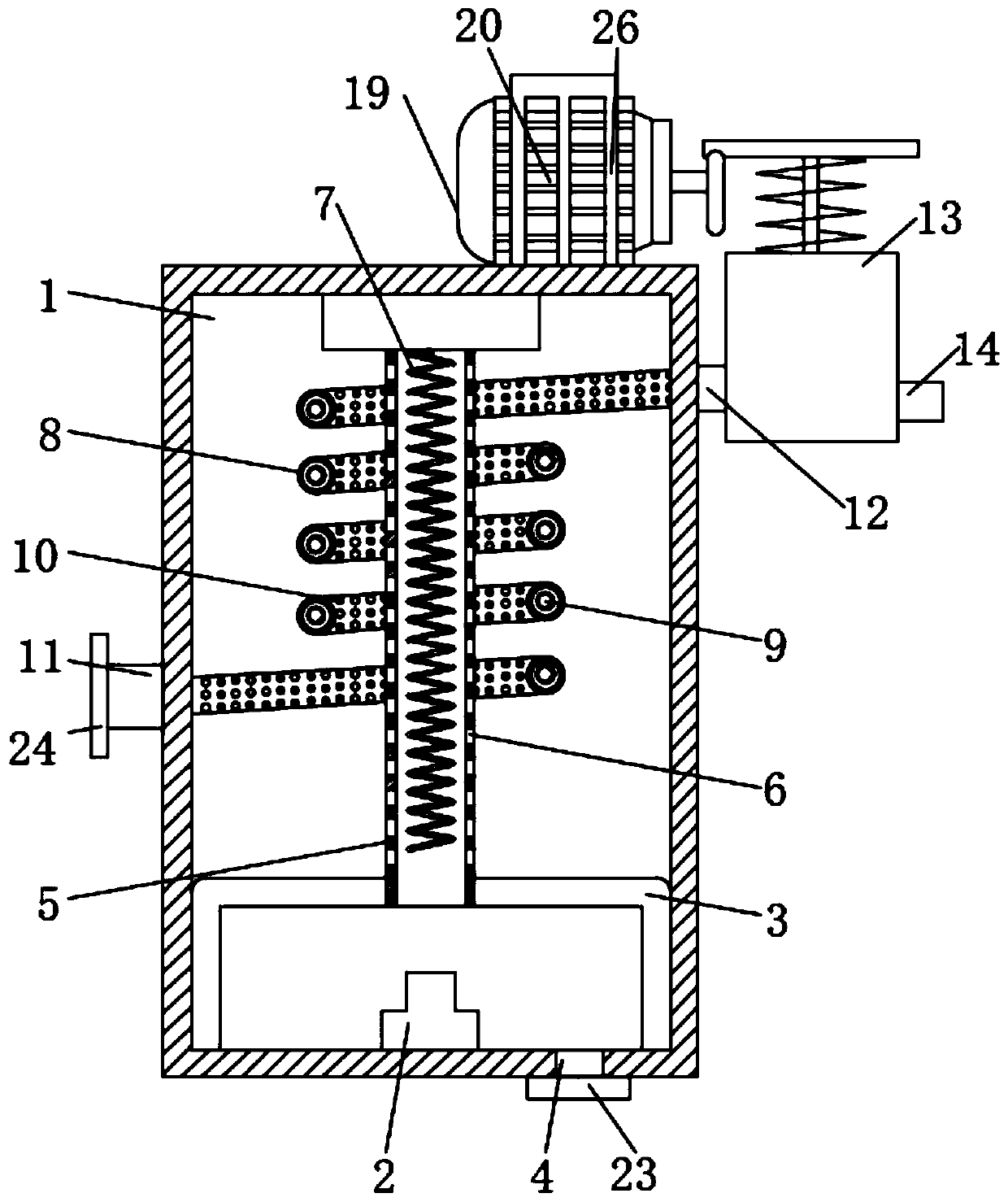

The invention relates to an anesthesia respirator evaporation device. The problems are effectively solved that drawdown of liquid levels of current anesthesia evaporators influences evaporation speed,the evaporation speed and the amount of carried gas cannot be matched and adjusted, and the evaporation speed is low. According to the technical scheme, the anesthesia respirator evaporation device includes an evaporation chamber, multiple layers of evaporating dishes are arranged inside the evaporation chamber, a drug storage cavity is formed above the evaporation chamber, a vertical pipe whichpenetrates through the evaporating dishes in sequence is installed inside the evaporation chamber, the upper end of the vertical pipe is communicated with the bottom of the drug storage cavity, a plurality of plungers which are in one-to-one correspondence to the evaporating dishes and capable of moving up and down are installed inside the vertical pipe, and the plungers move up and down and thencan control whether or not medical liquid is stored inside the corresponding evaporating dishes. The liquid level of the anesthesia respirator evaporation device is constant; according to the amount of the carried gas, the working conditions of the evaporating dishes on each layer can be selectively started and closed, so that the evaporation efficiency of the medical liquid inside the evaporationchamber is matched with the amount of the carried gas; the space utilization rate of the evaporation chamber is high, and the anesthesia respirator evaporation device is compact in structure, small in size and high in evaporation speed.

Owner:刘书勇

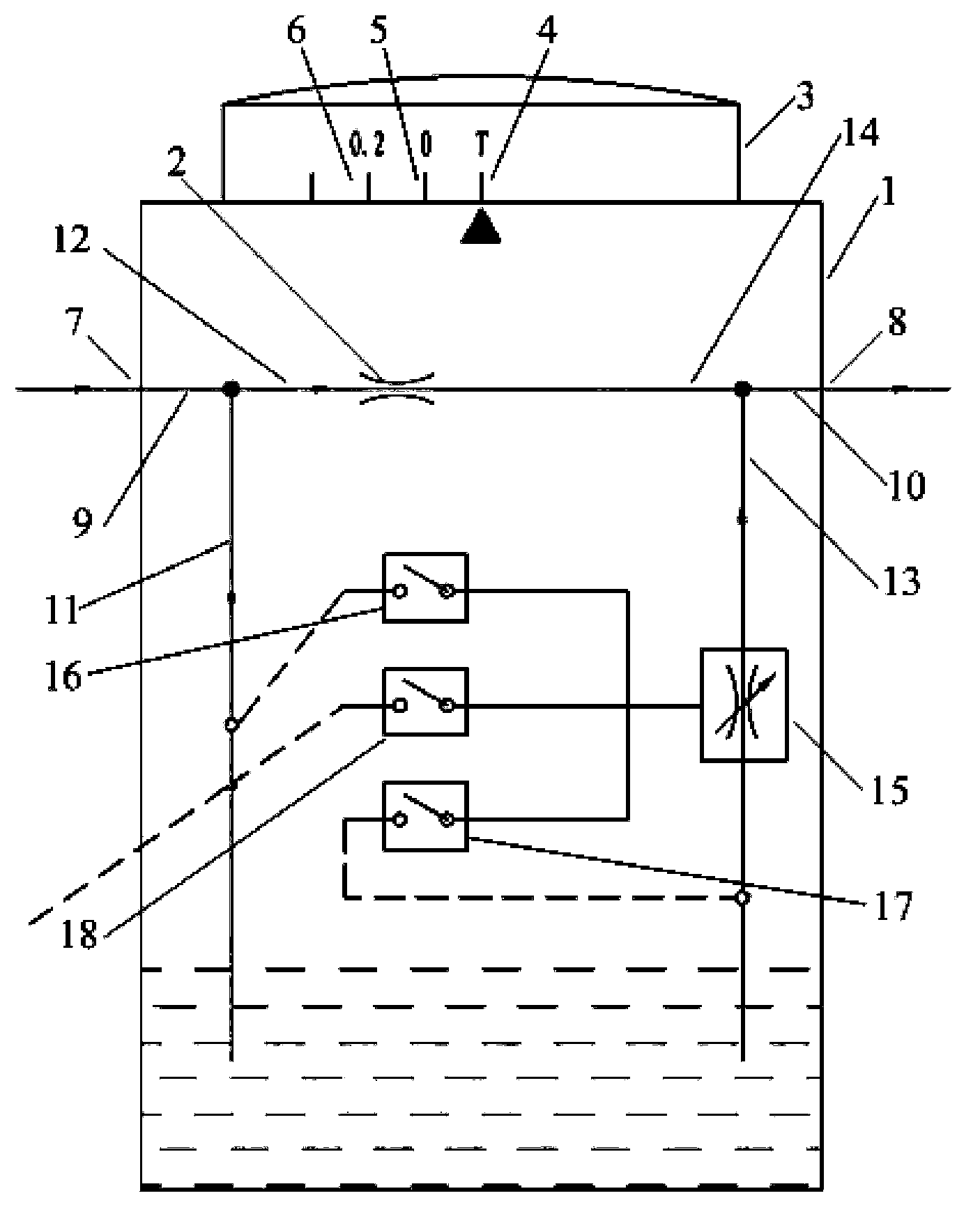

Anesthetic evaporator

The invention discloses an anesthetic evaporator which comprises an evaporation chamber. The anesthetic evaporator is characterized in that the anesthetic evaporator has three stations and comprises a three-station switching device, the three stations include a concentration station, a zero station and a transportation station, and the concentration station is used for regulating the concentration of anesthetic steam outputted by the anesthetic evaporator; the evaporation chamber can be communicated with an external environment via the zero station when the anesthetic evaporator is in a non-working state; the evaporation chamber can form a closed space under the effect of the transportation station; the three-station switching device is used for switching the anesthetic evaporator at the transportation station to the concentration station via the zero station. The anesthetic evaporator has the advantages that a valve plate of a concentration regulating valve rotates relative to a valve seat, so that the three stations can be switched over, and the problem that the internal evaporation pressure of an existing evaporation chamber cannot be effectively relieved when an existing evaporator does not have a transportation station and a zero station can be effectively solved on the premise that the quantity of components is not increased and the cost is saved.

Owner:BEIJING AEONMED

Temperature-sensing valve with flow compensation function and anesthetic vaporizer comprising same

The invention discloses a temperature-sensing valve with the flow compensation function, which comprises a saddle and a movable plate; an airflow gap allowing airflow to pass through is formed between the saddle and the movable plate; an air hole cavity is formed inside the saddle, and is communicated with the airflow gap; when the flow at a fresh air inlet increases, the airflow gap becomes small to cause the flow of fresh air flowing into the temperature-sensing valve to decrease; when the flow at the fresh air inlet decreases, the airflow gap becomes large to cause the flow of the fresh air flowing into the temperature-sensing valve to increase; and the temperature-sensing valve has the advantage of simple structure, and is easy to process and convenient to dismantle. The invention further discloses an anesthetic vaporizer which comprises the temperature-sensing valve, a curved pipe box, the fresh air inlet and a mixed gas outlet; the fresh air inlet is communicated with the inlet of the temperature-sensing valve; an outlet of the temperature-sensing valve is communicated with the mixed gas outlet; and the anesthetic vaporizer can ensure that the concentration of the output gas is not changed along with the variation of flow at the fresh air inlet, that is, the concentration of the output gas keeps consistent with the set valve.

Owner:BEIJING AEONMED

Adapters for use with an anesthetic vaporizer

Adapters are provided for establishing fluid communication between an anesthetic agent container and an anesthetic vaporizer having a fluid port. The adapter may be mountable on the vaporizer to cooperate with the spout of an anesthetic agent container or may be mountable on an anesthetic agent container to cooperate with the fluid port of an anesthetic vaporizer to provide a sealing and / or retaining relationship therebetween.

Owner:BAXTER INT INC +1

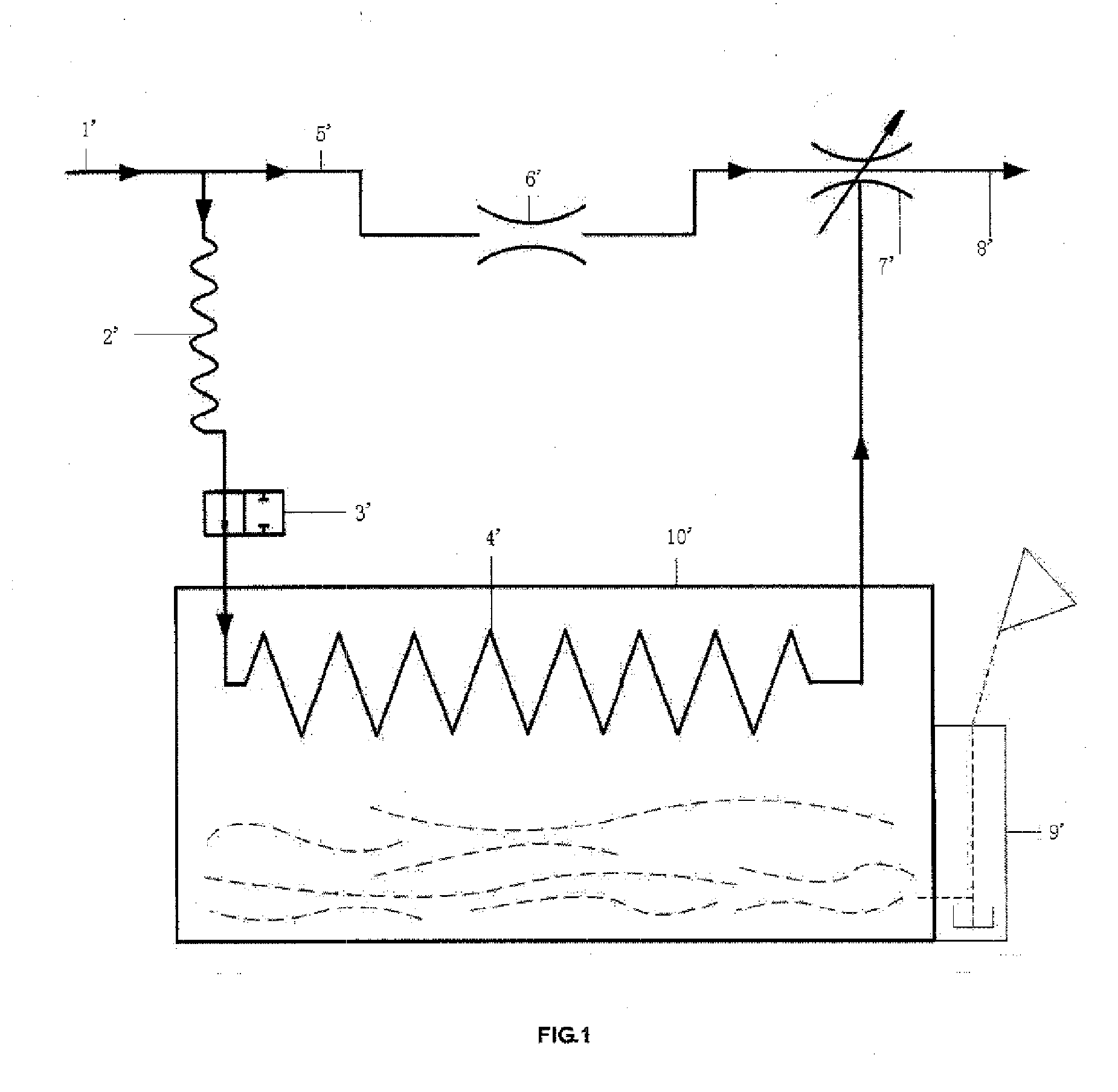

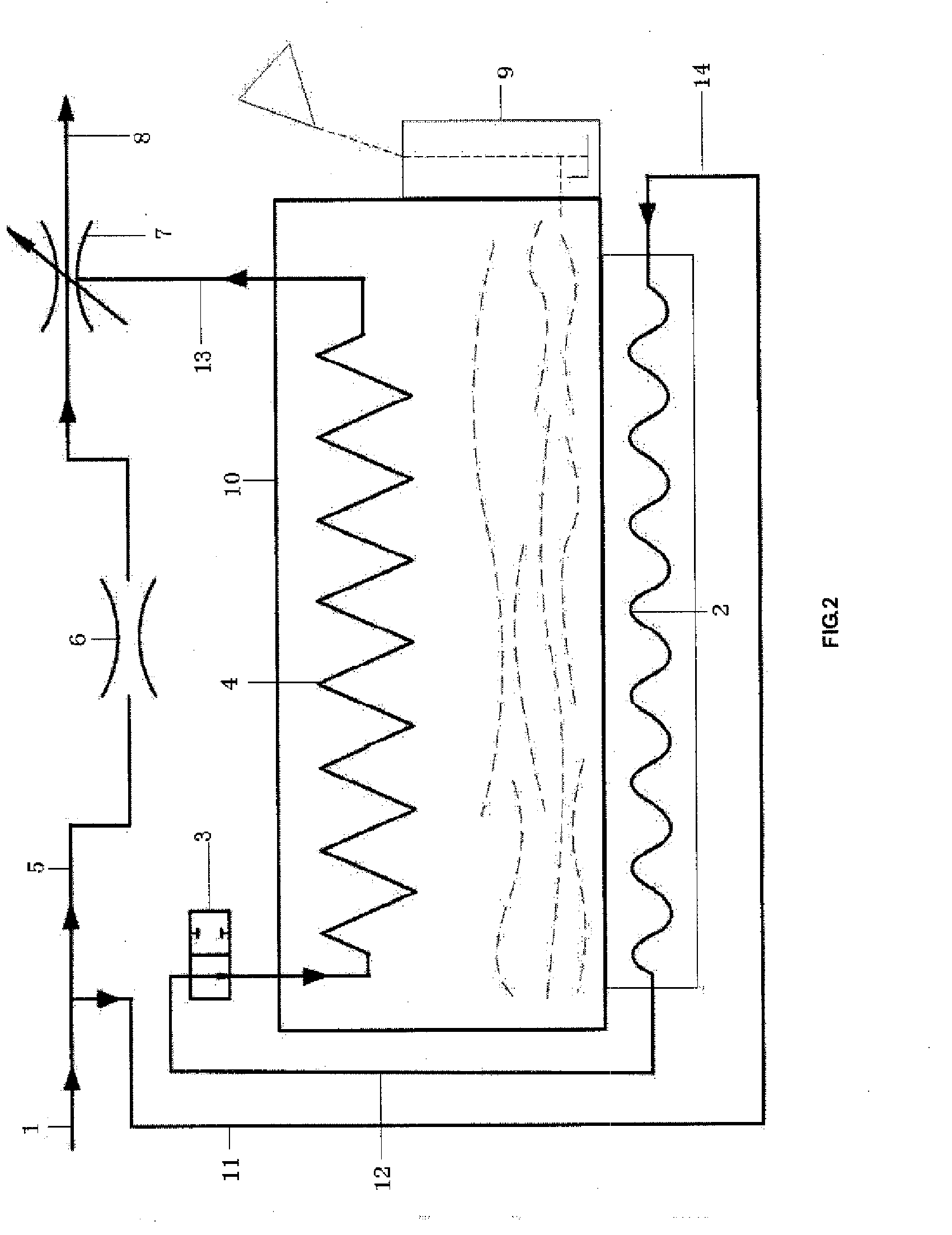

Anesthetic vaporizer

ActiveUS20100242962A1RespiratorsOperating means/releasing devices for valvesElectrical conductorPneumatic circuit

An anesthetic vaporizer is disclosed herein which comprises a fresh gas inlet, a mixed gas outlet, a first gas branch circuit, a second gas branch circuit and a vaporizing chamber. The vaporizing chamber has a reservoir for containing an anesthetic agent. The first gas branch circuit connects the fresh gas inlet and the mixed gas outlet. The second gas branch circuit comprises a first pneumatic circuit, a pressure compensation unit, a second pneumatic circuit, a wick unit and a third pneumatic circuit. The pressure compensation unit has a curved, continuous and sealed vent slot. The wick unit has an immersion portion which is directly contacted with the anesthetic agent in the reservoir. The fresh gas inlet, the first pneumatic circuit, the vent slot, the second pneumatic circuit, the wick unit, the third pneumatic circuit and the mixed gas outlet are sequentially connected with one another. The pressure compensation unit is provided in the reservoir and has a heat conductor which is directly contacted with the anesthetic agent to transfer heat. The vent slot is formed in the heat conductor. The anesthetic vaporizer according to the invention can stabilize the concentration of the anesthetic vapor in the outputted mixed gas.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Medical anaesthetic vaporizer device

PendingCN110893258ARealize reciprocating liftingRespiratorsMedical devicesUltrasonic nebulizersIntramuscular injection

The invention discloses a medical anaesthetic vaporizer device. The device includes a evaporation housing body and an evenly-mixing chamber. The bottom of the inner wall of the evaporation housing body is fixedly connected to an ultrasonic nebulizer. A cover body is fixedly connected to the inner wall near the bottom in the evaporation housing body. A through hole is arranged at the bottom of theevaporation housing body and the evaporation housing body is fixedly connected to a sealing plug in a sealing way through the through hole. A through hole is arranged on the upper surface of the coverbody and the cover body is fixedly connected to a guide tube through the through hole. First guide holes are arranged on the surface of the guide tube and an electric heating rod is eccentrically arranged inside the guide tube. The top of the electric heating rod is fixedly connected to the top of the inner wall of the evaporation housing body. According to the invention, the combination of the structures solves the problems that during practical use, intramuscular injection commonly used in anesthesia treatment is not applicable to patients who show symptoms of induration and infection at injection sites and can not effectively narcotize the respiratory system of patients.

Owner:董桂敏

Medical care anesthesia respiration device

InactiveCN110496283ARealize multi-stage thorough mixingRelieve painRespiratory masksThreaded pipeOxygen

The invention relates to a medical care anesthesia respiration device. The medical care anesthesia respiration device comprises a respiration mask, wherein the respiration mask is connected with a teepipe, the tee pipe is connected with a threaded pipe, the threaded pipe is connected with an anesthesia dosage control valve, the anesthesia dosage control valve is connected with a gas mechanical mixer, the gas mechanical mixer is connected with an oxygen outlet pipe, the oxygen outlet pipe is connected with an respiration machine, the gas mechanical mixer is connected with an anesthesia gas outlet pipe, the anesthesia gas outlet pipe is connected with an anesthesia evaporator, the anesthesia evaporator is connected with an air outlet pipe, the air outlet pipe is connected with the respiration machine, the respiration machine is connected with an air unidirectional inlet pipe, the respiration machine is connected with an oxygen unidirectional inlet pipe, the oxygen unidirectional inlet pipe is connected with an oxygen flow machine, and the oxygen flow machine is connected with an oxygen inlet. According to the medical care anesthesia respiration device disclosed by the invention, through the gas mechanical mixer and the anesthesia evaporator, multistage thorough mixing of anesthesia and oxygen can be realized.

Owner:LIUZHOU HUANSHAN TECH

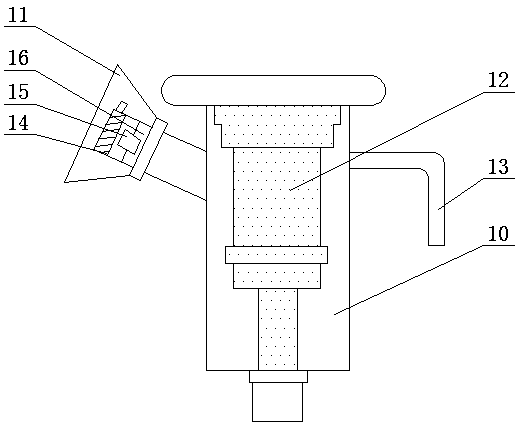

Injection device of anesthetic vaporizer

Owner:BEIJING AEONMED

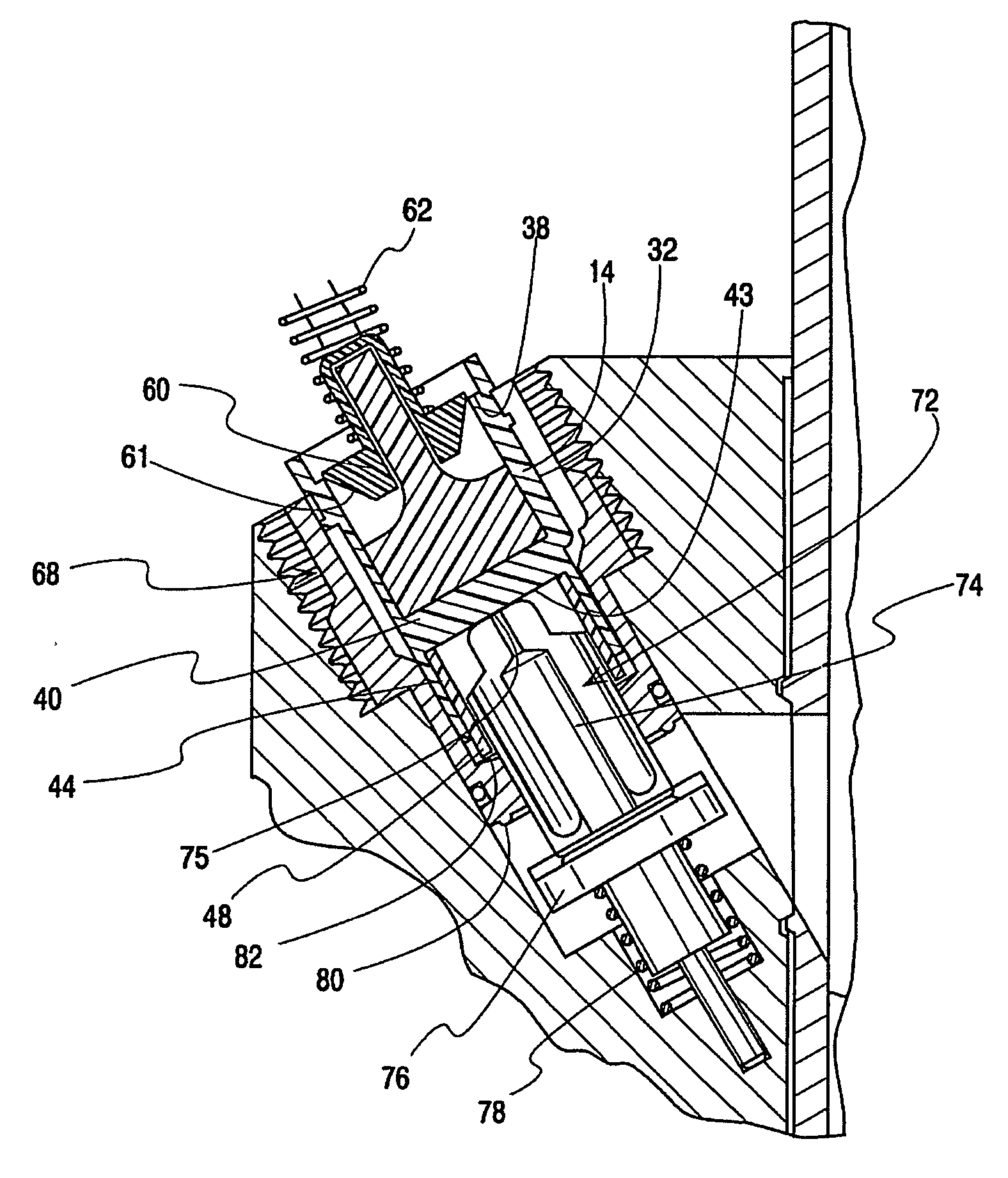

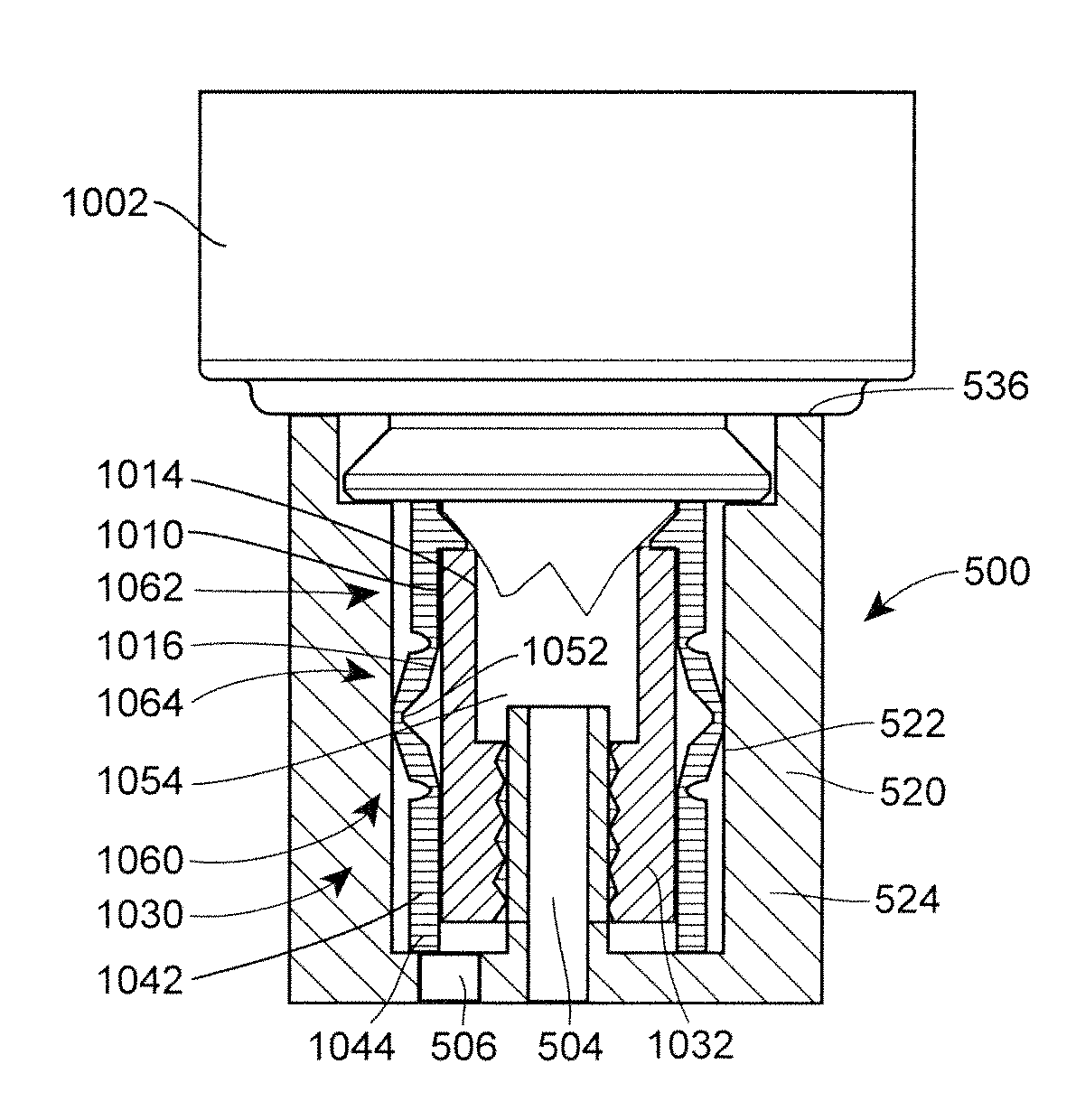

Anesthetic vaporizer and temperature compensation unit

ActiveUS8813744B2Good temperature compensation effectRespiratorsMedical devicesAnesthetic AgentEngineering

An anesthetic vaporizer and a temperature compensation unit are disclosed. The temperature compensation unit, which cooperates with a vaporizing chamber having a bottom wall, includes a first device connected to the bottom wall of the vaporizing chamber for contacting with liquid anesthetic agent in the vaporizing chamber and changing in length according to temperature change of the liquid anesthetic agent, and a second device connected to the vaporizing chamber. A gas flow gap through which a gas flow passes is formed between the first and second devices. The gas flow gap becomes larger as temperature of the liquid anesthetic agent rises and smaller as the temperature of the liquid anesthetic agent drops. Since the first device is connected with the bottom wall of the vaporizing chamber, the first device will directly contact with the liquid anesthetic agent regardless of the liquid level of the anesthetic agent, as long as there is liquid agent in the vaporizing chamber; therefore the efficiency of heat exchange is high and the effect of temperature compensation is good.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

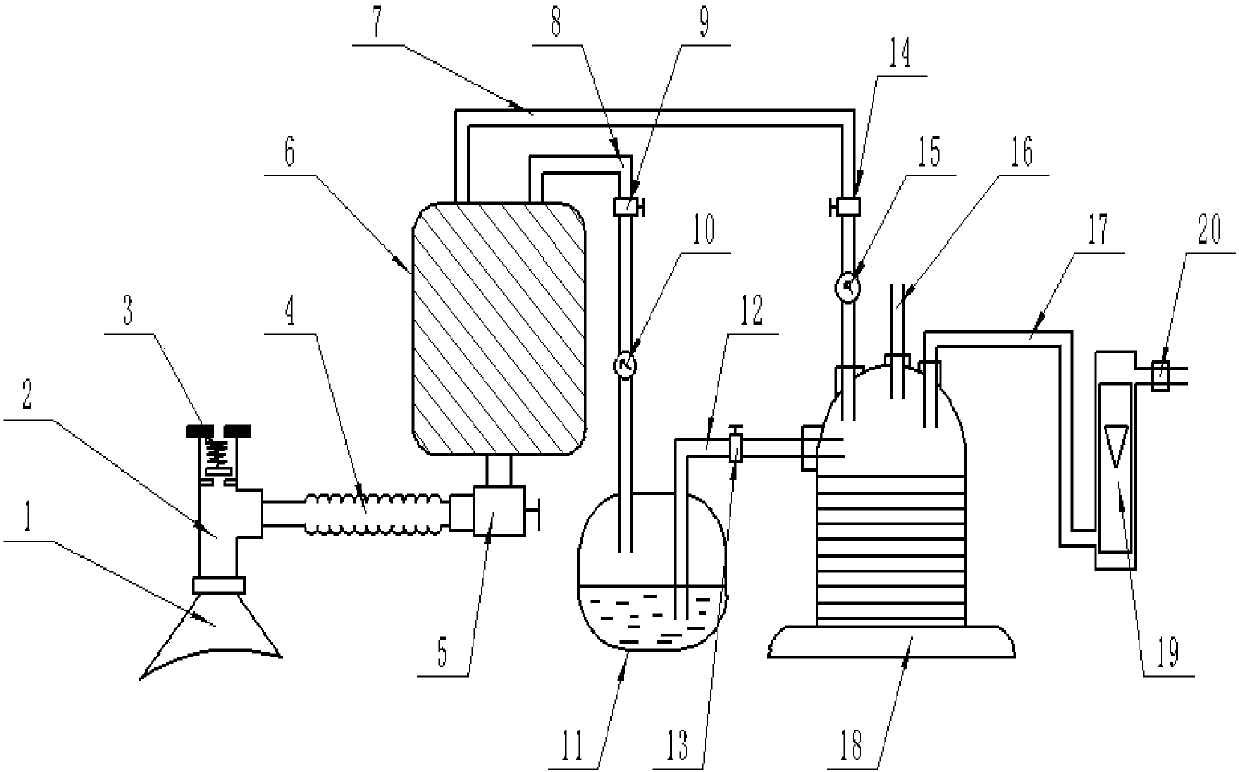

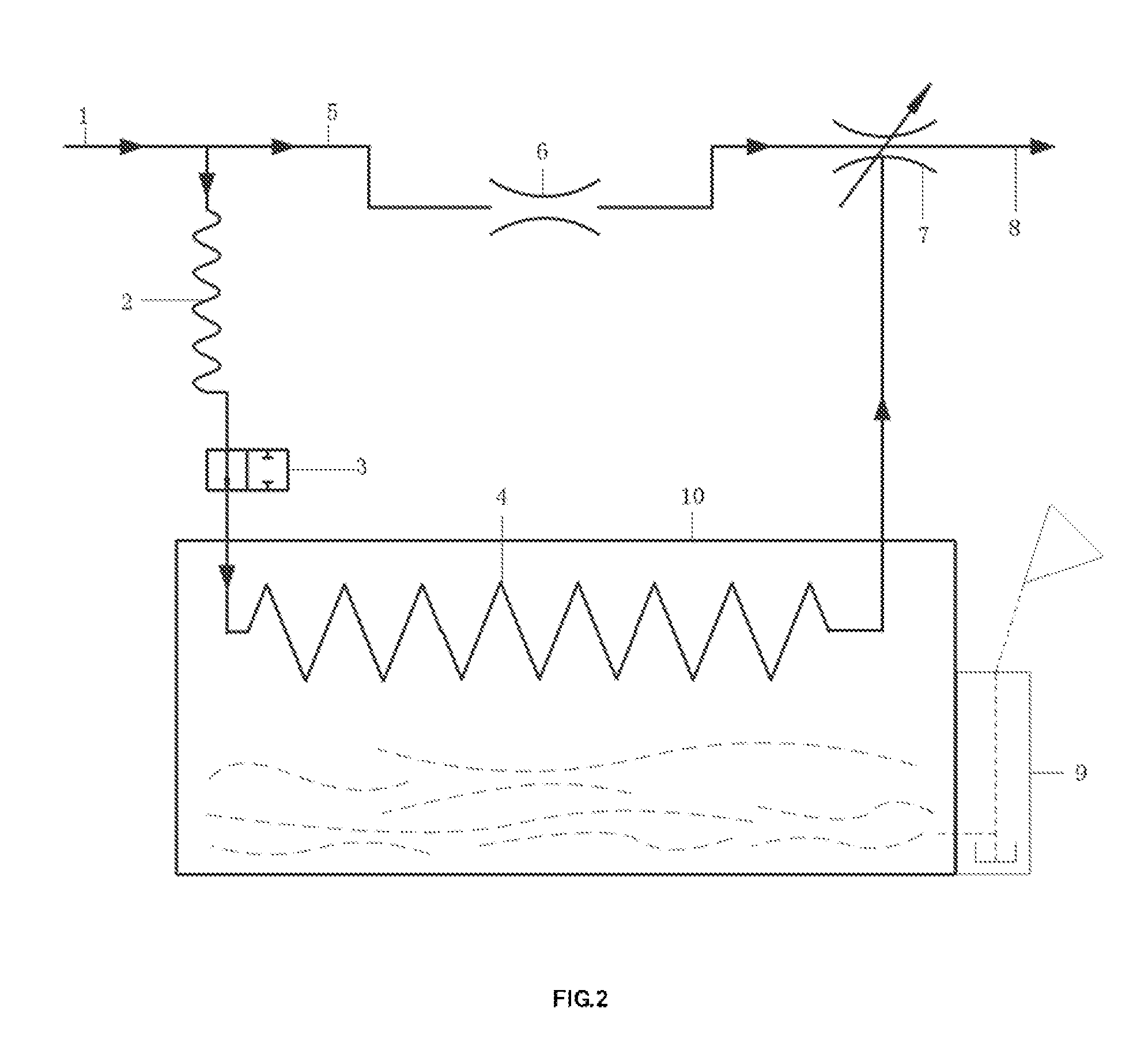

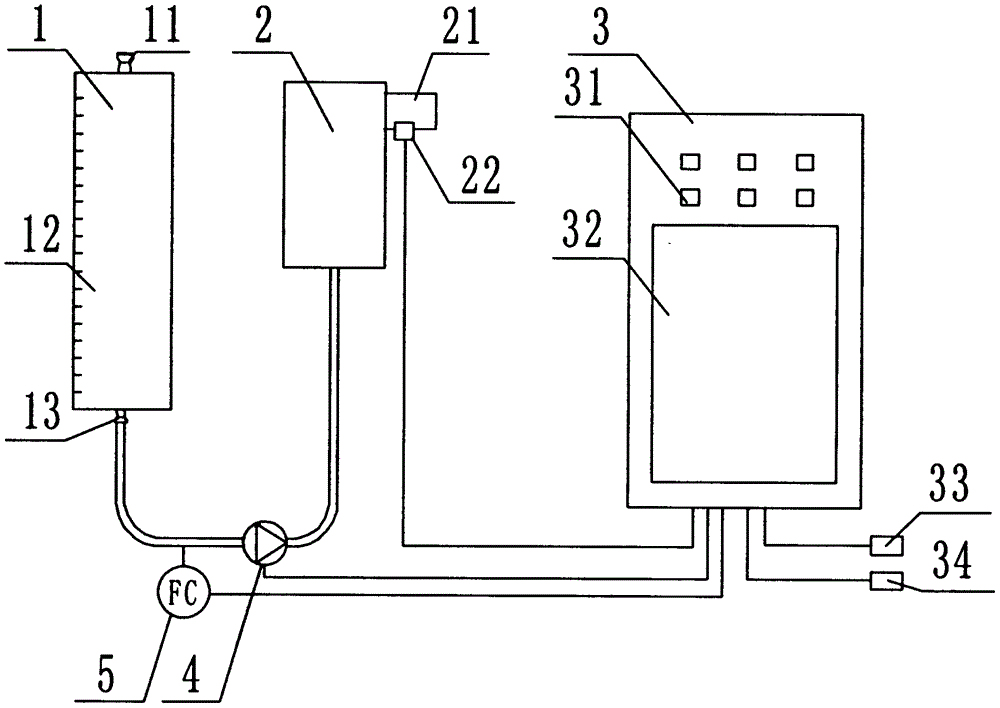

Intelligent anesthetic vaporizer

InactiveCN105963843AAutomatically adjust flowSimple structureRespiratorsBispectral Index MonitorAnesthesia

The invention belongs to the technical field of medical apparatus and instruments, and in particular relates to an intelligent anesthetic vaporizer. The intelligent anesthetic vaporizer comprises an anesthetic tube, an anesthetic vaporizing device, a control cabinet, a booster pump and a flow controller, and is characterized in that the anesthetic tube is connected with the anesthetic vaporizing device through a pipeline, and the booster pump and the flow controller are connected on the pipeline; the lower part of the anesthetic vaporizing device is connected with the booster pump through a pipeline, an anesthetic steam outlet is formed in the upper part of the anesthetic vaporizing device, and an anesthetic steam detector is arranged at the anesthetic steam outlet; and the control cabinet is connected with the booster pump, the flow controller and the anesthetic steam detector through signal lines. According to the intelligent anesthetic vaporizer, the flow of anesthetic solution can be automatically adjusted, the anesthetic steam can be detected, meanwhile, the bispectral index and the cerebral state index can be monitored, in addition, the intelligent anesthetic vaporizer is simple in structure, high in accuracy, easy to operate, and comprehensive in function, and the anesthetic effect is greatly improved.

Owner:杨建勇

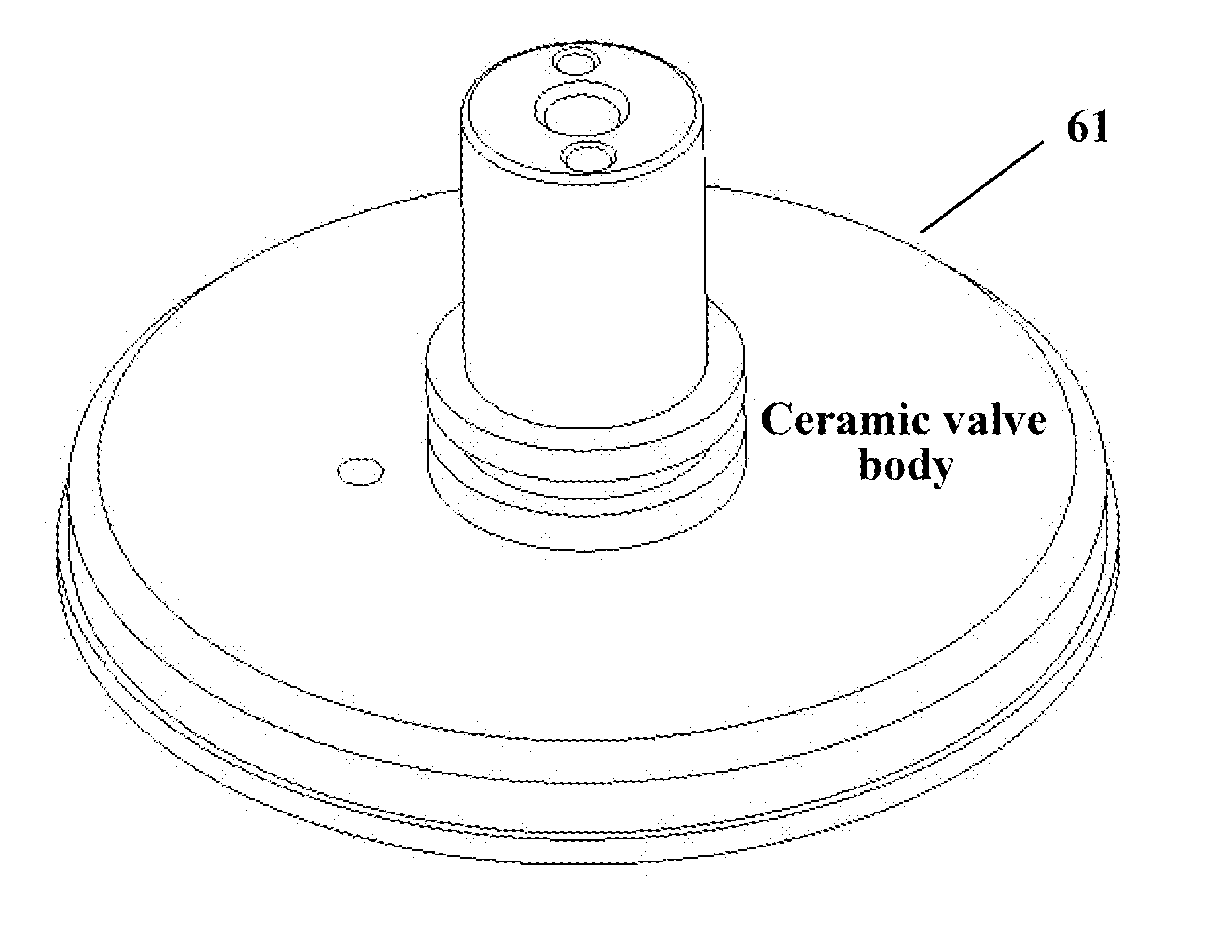

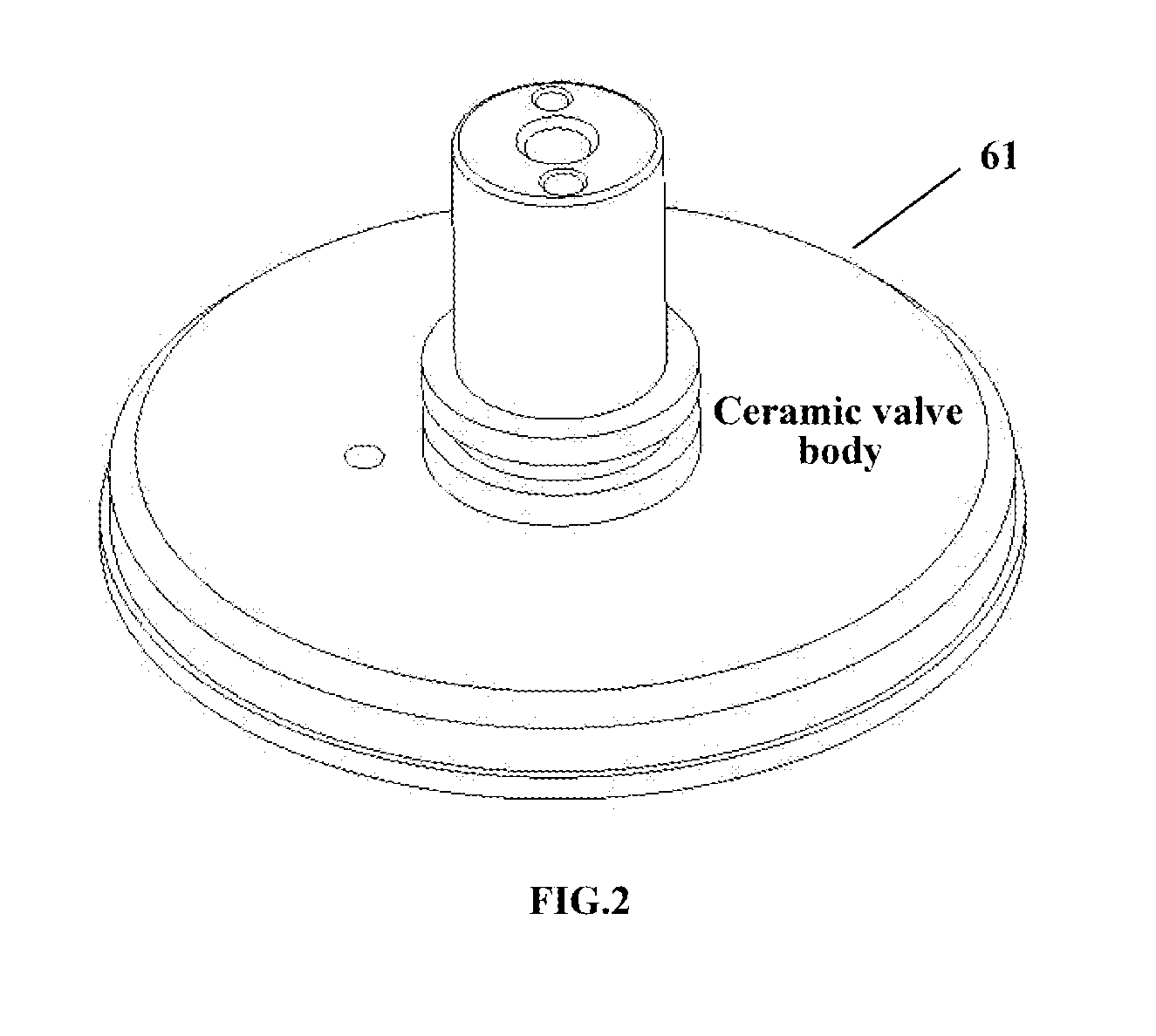

Ceramic rotary valve for an anesthetic vaporizer

Embodiments of the present invention relate to a ceramic rotary valve for an anesthetic vaporizer, the valve body of the rotary valve comprising a ceramic material. Embodiments of the present invention also provide an anesthetic vaporizer comprising the ceramic rotary valve and an anesthesia machine comprising the anesthetic vaporizer. Furthermore, embodiments of the present invention also provide a method of utilizing an anesthetic vaporizer comprising a ceramic rotary valve to control anesthetics concentration output by the anesthetic vaporizer.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Medical anaesthetic vaporizer

InactiveCN108578851ATreatment safetyPeace of mind treatmentMedical atomisersEngineeringAtmospheric pressure

The invention discloses a medical anaesthetic vaporizer comprising a vaporizer body. A handle is arranged at the left end of the vaporizer body. The vaporizer body is fixedly connected with the handle. A medicine cup is arranged on the outer surface of the handle. A sound insulation plate is arranged in an existing medical vaporizer, and generated noise can be insulated through the sound insulation plate so that a patient can be treated securely in a good environment, and the therapeutic efficiency is improved; a piston device is arranged a medicine cup of the existing medical vaporizer, jetting of medicines can be controlled through the piston device, when the patient inhales, sucking force enables a piston in the piston device to move to extrude air in the piston device out, and vacuum is formed in the piston device, so that the atomized medicines are jetted into an oral cavity of the patient through the external atmospheric pressure; and when the patient exhales, the piston does notmove, and the medicines in the piston device are not jetted, so that the medicines are not wasted, and the safe using and saving effects are achieved.

Owner:FUJIAN JINZHUAN INTPROP SERVICES CO LTD

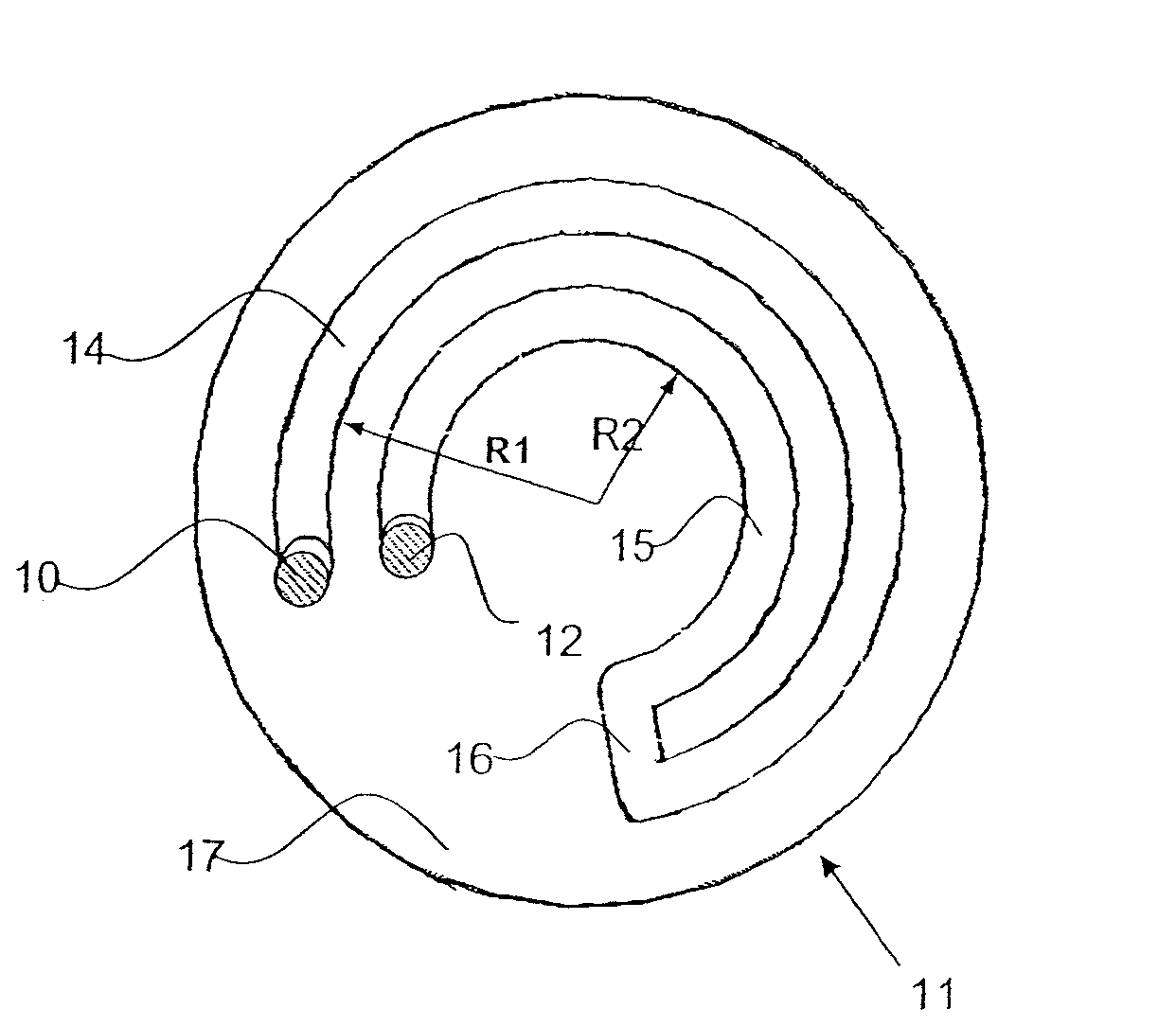

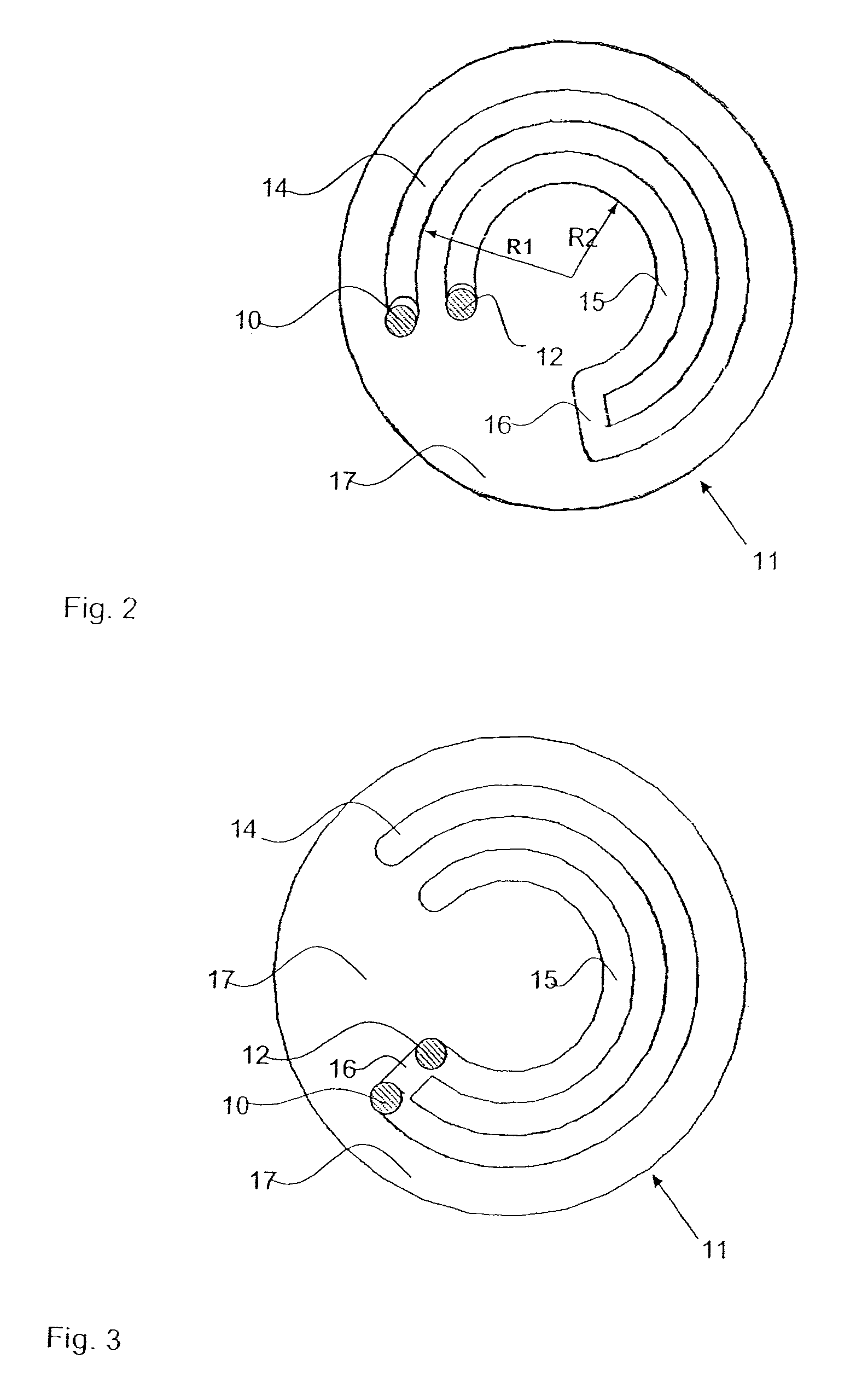

Anesthetic vaporizer

InactiveUS7992843B2Flow mixersLighting and heating apparatusBiomedical engineeringAnesthetic agent vaporizer

A dispensing element of an anesthetic vaporizer is provided that can be manufactured in a simple manner and makes it possible to dispense anesthetic over a broad setting range. The dispensing element (11) includes two, longitudinally extending dispensing channels (14, 15), which are connected to one another in terms of flow by means of a connection channel (16). The gas flows from one of the dispensing channels (14) into the other dispensing channel (15) via the connection channel (16).

Owner:DRAGERWERK AG

Wick for an anesthetic evaporator

InactiveUS8496003B2Improve space utilizationThermal couplingRespiratorsInhalatorsEngineeringAnaesthetic vaporizer

A wick for an anesthetic evaporator is provided as a dimensionally stable wick body (14) transporting anesthetic by means of capillary force is provided. The wick body comprises a hollow cylinder as well as webs by which a gas-carrying cavity is formed.

Owner:DRAGERWERK AG

Anesthetic vaporizer and temperature compensation unit

ActiveUS20100180893A1Good temperature compensation effectRespiratorsMedical devicesEngineeringAnesthetic

An anesthetic vaporizer and a temperature compensation unit are disclosed. The temperature compensation unit, which cooperates with a vaporizing chamber having a bottom wall, includes a first device connected to the bottom wall of the vaporizing chamber for contacting with liquid anesthetic agent in the vaporizing chamber and changing in length according to temperature change of the liquid anesthetic agent, and a second device connected to the vaporizing chamber. A gas flow gap through which a gas flow passes is formed between the first and second devices. The gas flow gap becomes larger as temperature of the liquid anesthetic agent rises and smaller as the temperature of the liquid anesthetic agent drops. Since the first device is connected with the bottom wall of the vaporizing chamber, the first device will directly contact with the liquid anesthetic agent regardless of the liquid level of the anesthetic agent, as long as there is liquid agent in the vaporizing chamber; therefore the efficiency of heat exchange is high and the effect of temperature compensation is good.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

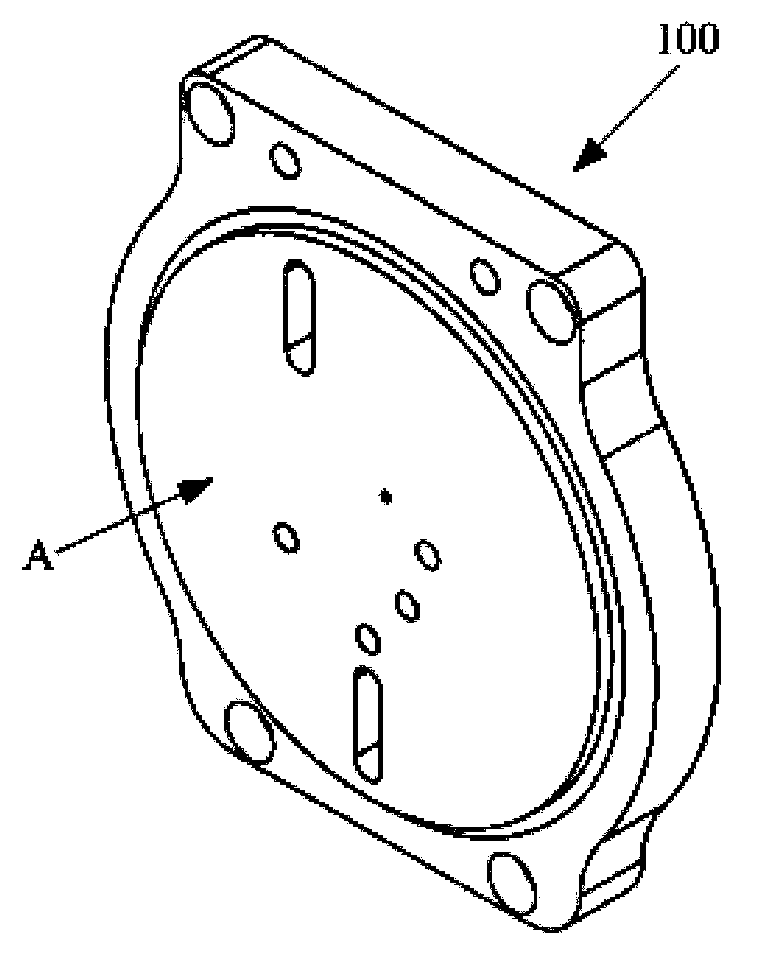

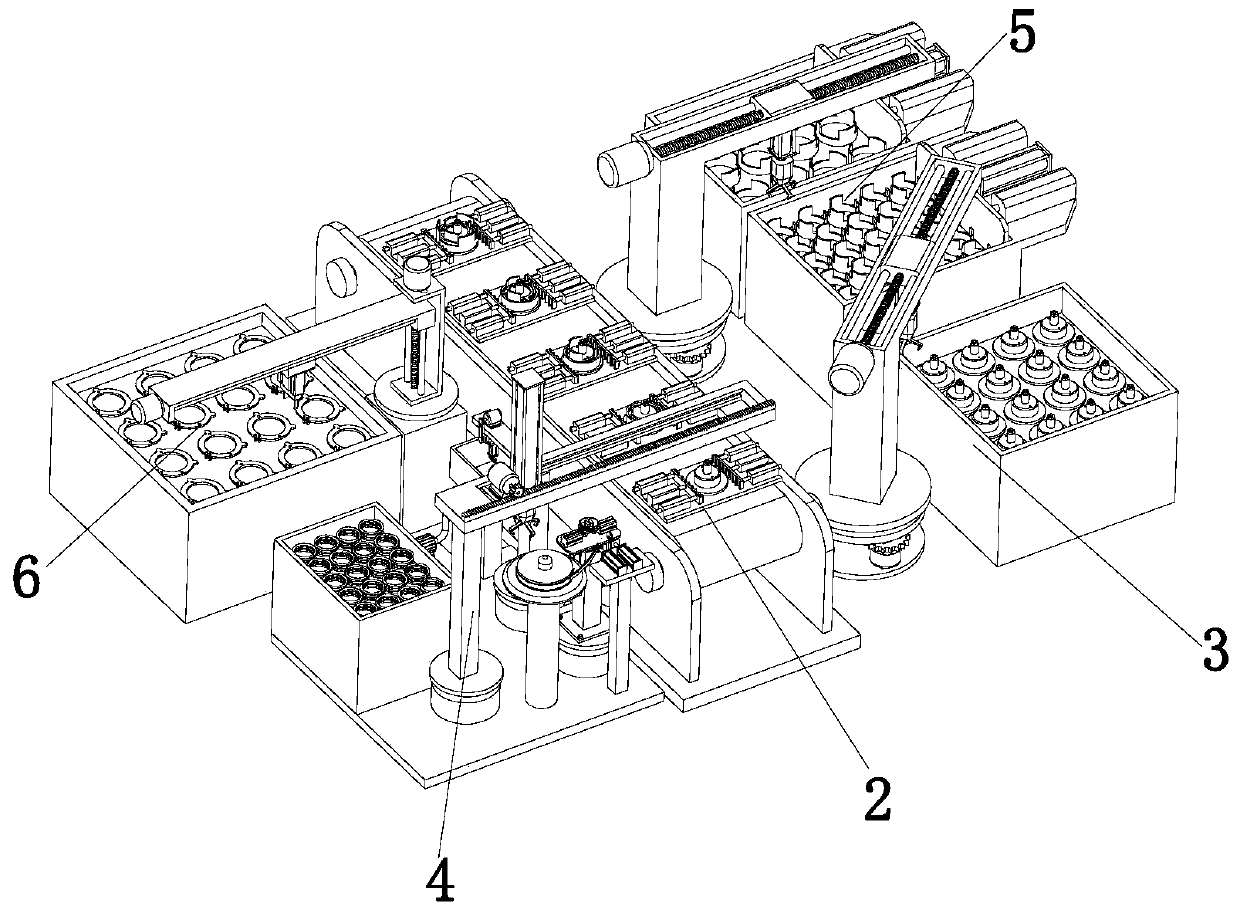

Automatic assembling production line for anaesthetic vaporizer cores

InactiveCN111015160AConvenient clamping and assembly workImprove work efficiencyAssembly machinesMetal working apparatusMedical equipmentSurgery

The invention discloses an automatic assembling production line for anaesthetic vaporizer cores, and belongs to the technical field of medical equipment. The automatic assembling production line for the anaesthetic vaporizer cores comprises a conveying table, a core seat assembling mechanism, a core pipeline assembling and cloth-wrapping mechanism, an inner-outer layer core cotton assembling mechanism and a fixed plate assembling mechanism, wherein the core seat assembling mechanism, the core pipeline assembling and cloth-wrapping mechanism, the inner-outer layer core cotton assembling mechanism and the fixed plate assembling mechanism are sequentially arranged on two sides of the conveying table according to a processing sequence; the core seat assembling mechanism comprises a core seat holding table and a core seat assembling and conveying assembly; the core pipeline assembling and cloth-wrapping mechanism is located on one side opposite to the core seat assembling mechanism; the inner-outer layer core cotton assembling mechanism comprises an inner layer core cotton holding table, an outer layer core cotton holding table and a core cotton assembling and conveying assembly; and the fixed plate assembling mechanism comprises a fixed plate holding table and a fixed plate assembling and conveying assembly. According to the automatic assembling production line for the anaestheticvaporizer cores provided by the invention, through the coordinate work of the various components, the integrated assembling work of the anaesthetic vaporizer cores is accomplished, and the traditionalmanual assembling work is replaced, so that the working efficiency is improved.

Owner:徐玉洁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com