Temperature-sensing valve with flow compensation function and anesthetic vaporizer comprising same

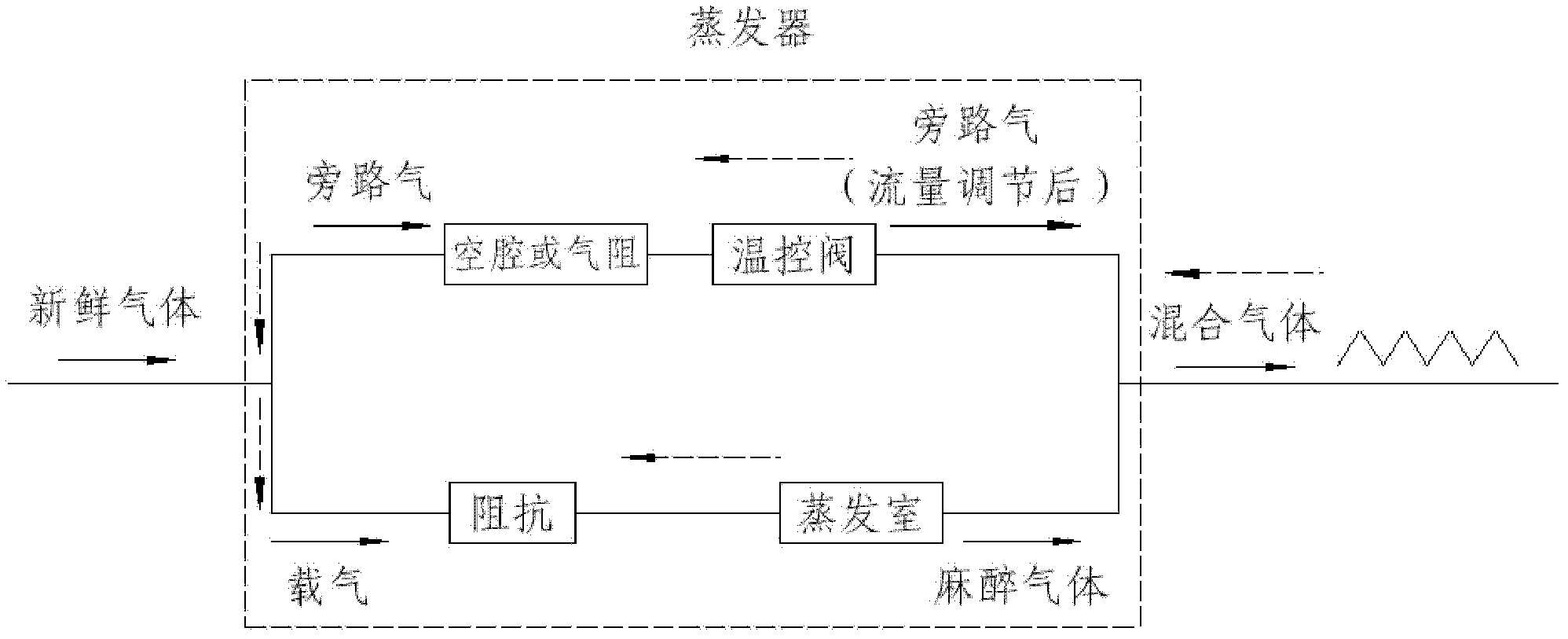

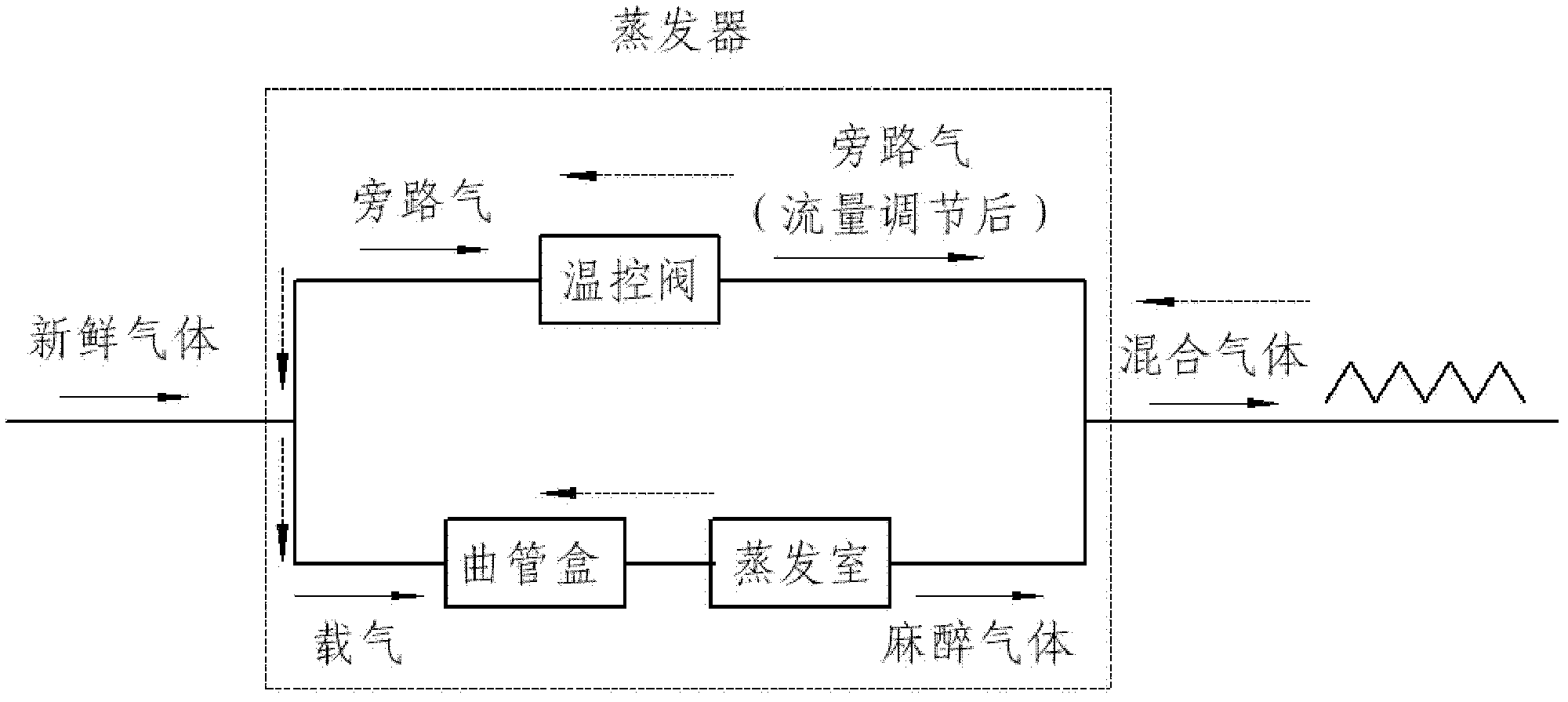

An anesthesia evaporator and flow compensation technology, applied in the field of anesthesia machines, can solve the problems of high processing cost, complex structure, inconvenient disassembly and assembly, and achieve the effect of simple structure, convenient disassembly and assembly, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

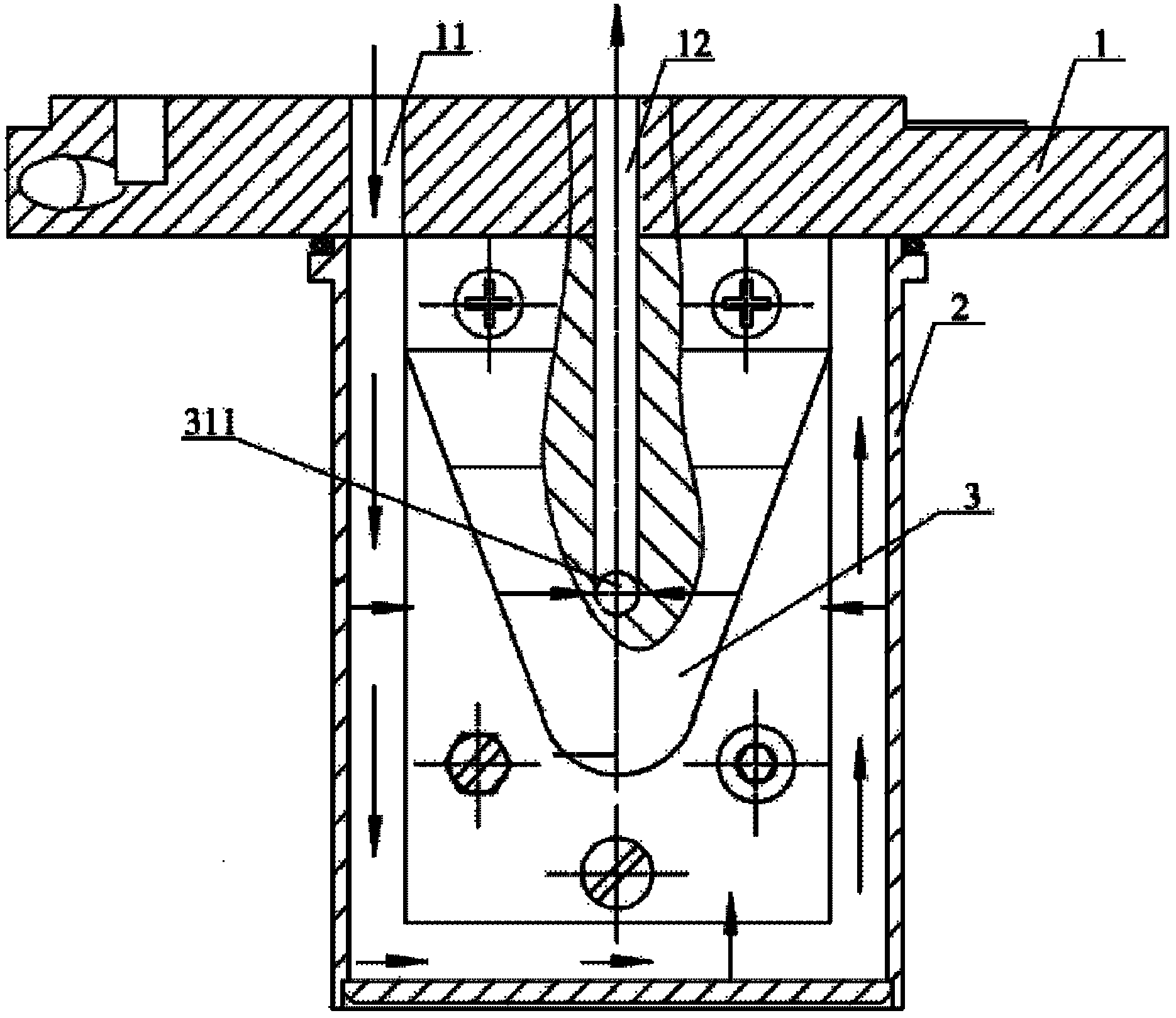

[0031] Such as Figure 5 As shown, in this embodiment, the temperature control valve with flow compensation function of the present invention includes a seat block 31 and a movable plate 32, which form an air flow gap for air flow through each other, and the seat block 31 has gas inside. The cavity 311, the gas cavity 311 communicates with the airflow gap.

[0032] On the front of the seat block 31, a groove for mounting the movable plate 32 is opened, and the movable plate 32 is embedded in the groove. The joint surface of the movable plate 32 and the seat block 31 forms an airflow gap.

[0033] One end of the seat block 31 and the movable plate 32 is fastened by the screw 4, and the other end is compressed by the spring sheet 33. On the outside of the spring sheet 33, an upper backing plate 34 and a lower backing plate are respectively provided corresponding to the movable plate 32 and the seat block 31 35. A spring pressure plate 36 is arranged outside the lower backing plate 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com