Anesthetic vaporizer with flow and pressure fluctuation compensation function

An anesthesia vaporizer and fluctuation compensation technology, applied in the field of anesthesia machines, can solve the problems of high processing cost, complex structure, inconvenient disassembly and assembly, etc., and achieve the effects of simple structure, convenient disassembly and assembly, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

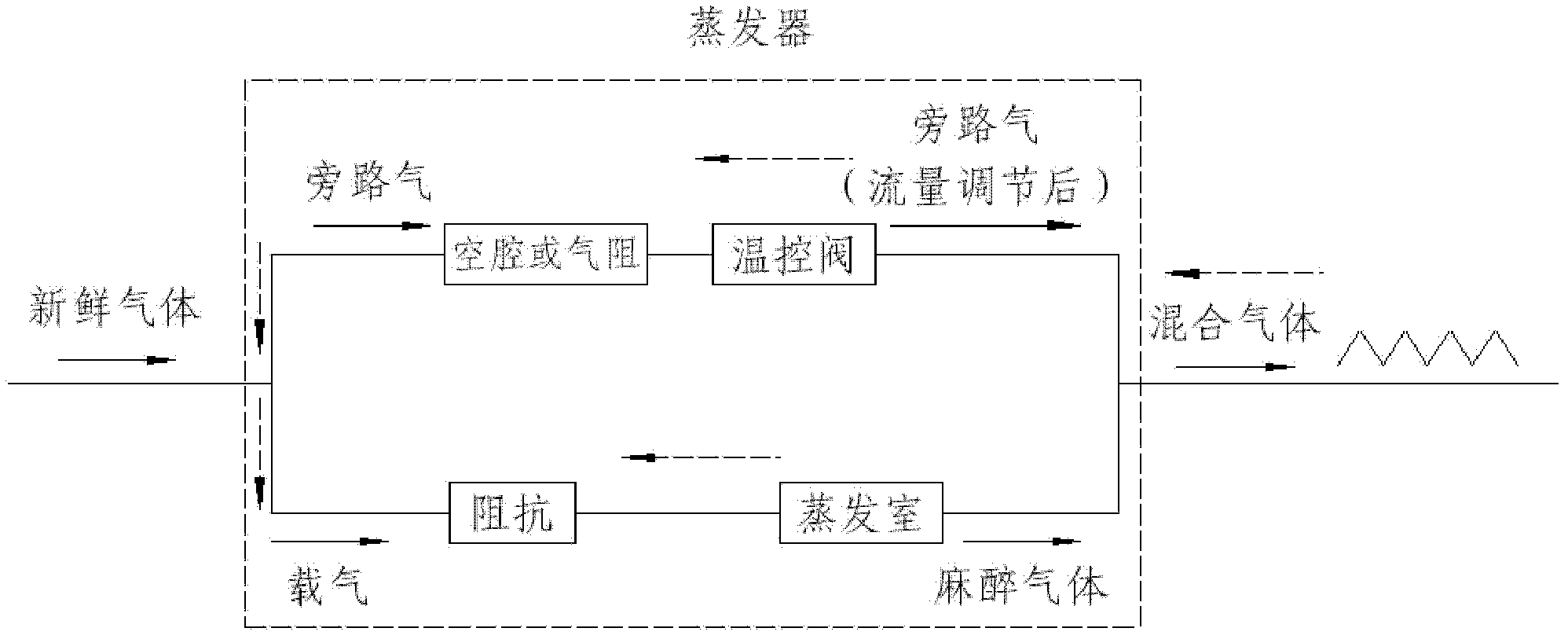

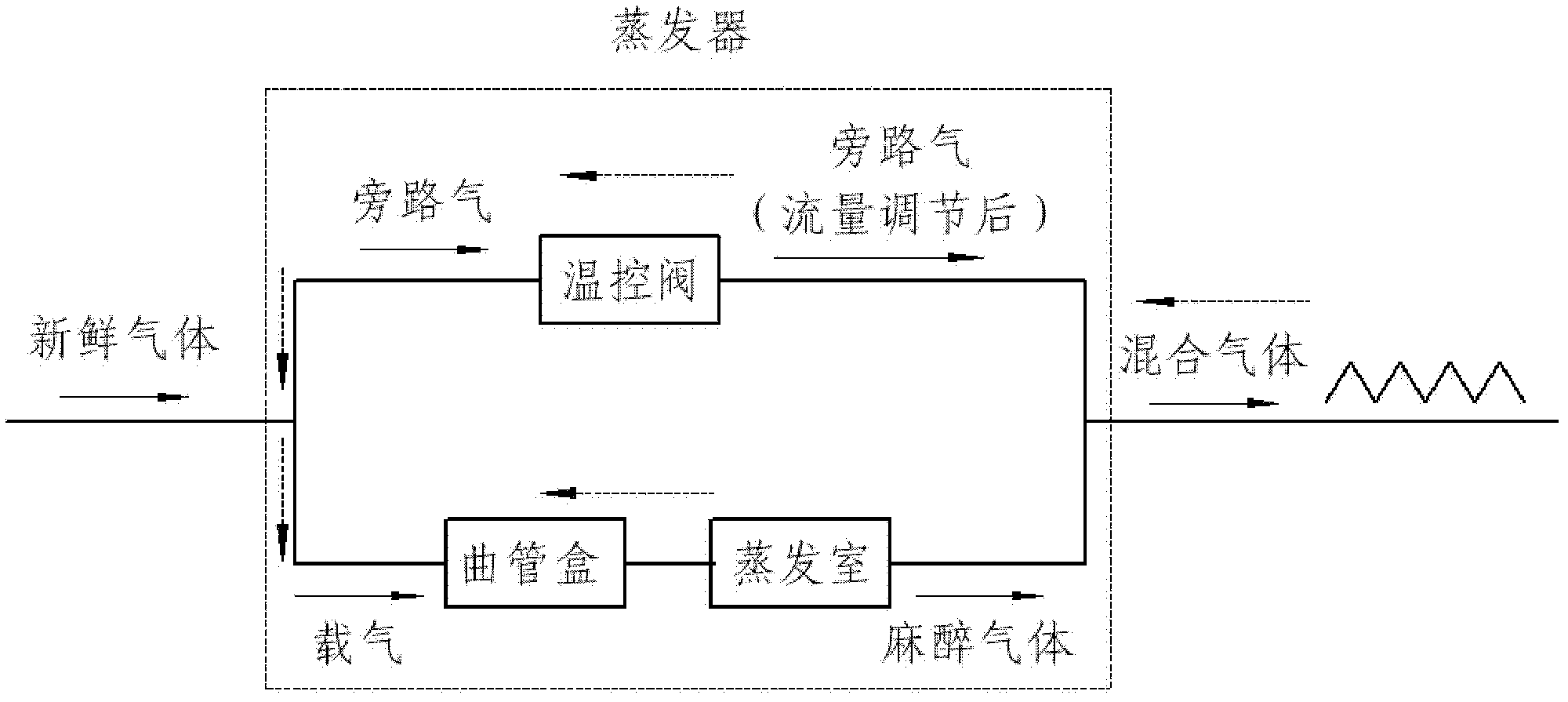

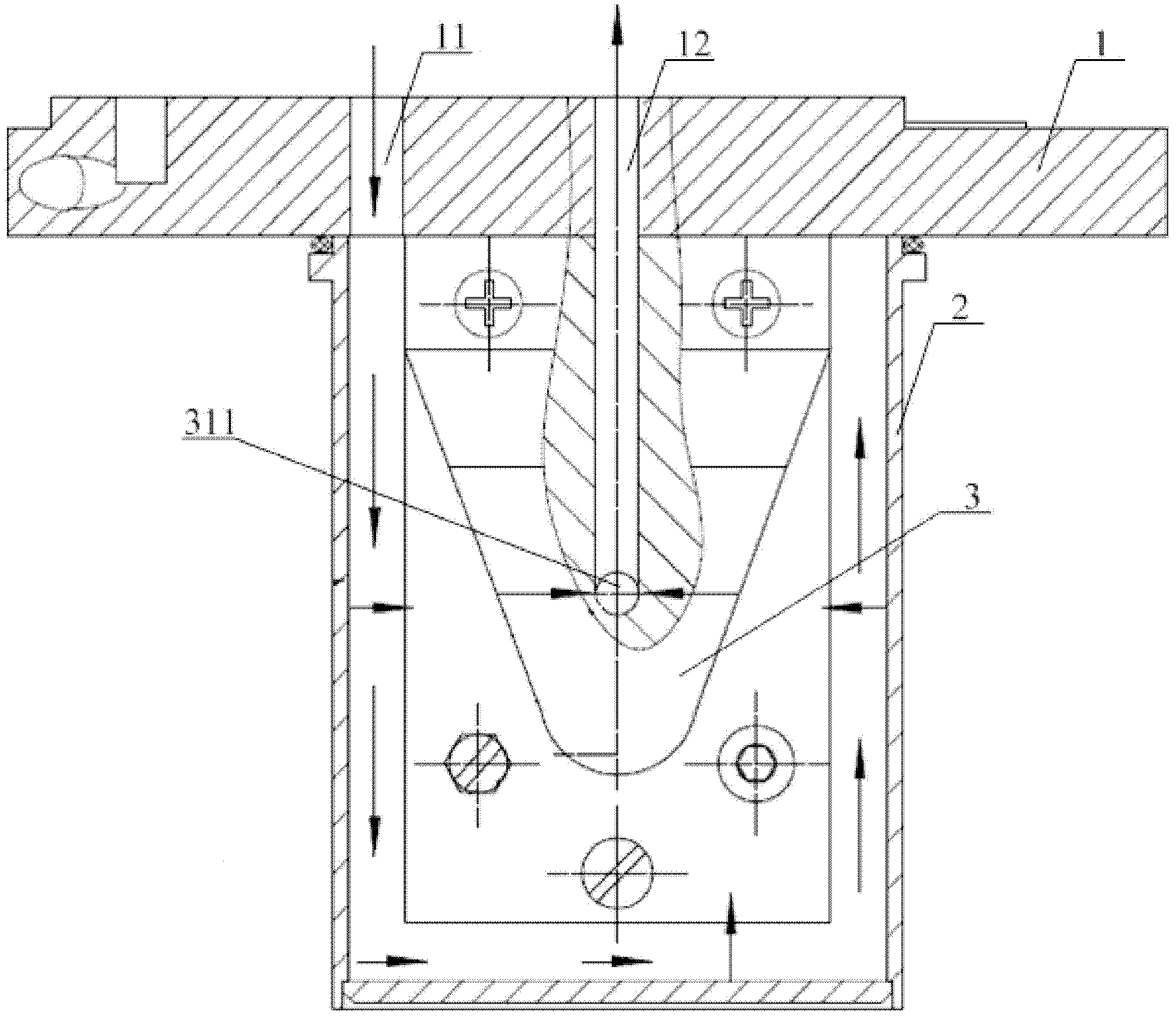

[0037] Such as figure 2 As shown, in this embodiment, the anesthesia vaporizer with flow and pressure fluctuation compensation function described in the present invention includes a fresh gas inlet, a mixed gas outlet, a bypass gas path, a carrier gas path, and the bypass gas The gas path and the carrier gas path are connected in parallel between the fresh gas inlet and the mixed gas outlet, a temperature control valve 3 is set on the bypass gas path, an anesthetic evaporation chamber is set on the carrier gas path, and a curved tube is also set on the carrier gas path Box 6, curved tube box 6 has a tortuous cavity 9 inside, the tortuous cavity inlet 91 communicates with the fresh gas inlet and the temperature control valve inlet respectively, the tortuous cavity outlet 92 communicates with the evaporation chamber inlet, and the temperature control valve 3 has a gas supply The airflow gap flowing to its interior, when the flow rate at the fresh gas inlet increases, the airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com