Dead halt alarm device for CMP equipment

An alarm device and equipment technology, applied in the direction of grinding devices, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as waste chips, affecting normal operation of equipment and production safety, so as to ensure operation safety and perfect automatic alarm function , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

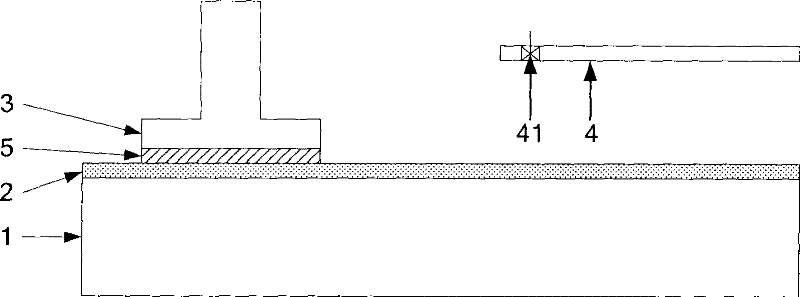

Embodiment Construction

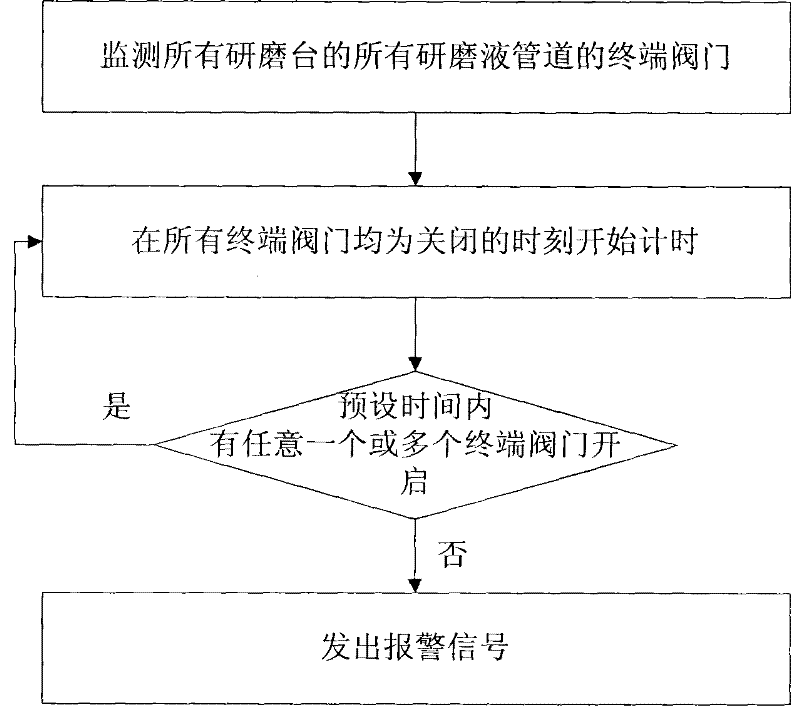

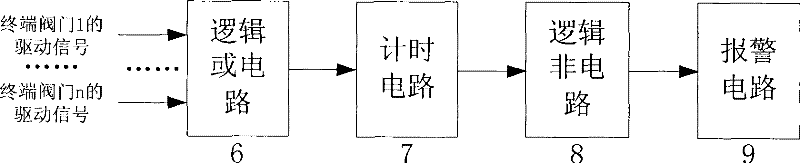

[0018] see figure 2 , the crash alarm method of the CMP equipment of the present invention is to monitor the terminal valves of all grinding liquid pipelines of all grinding tables of the CMP equipment, start timing when all terminal valves are closed, and continue until all terminal valves are closed. At the preset time, an alarm signal will be issued. When all the terminal valves are closed for less than the preset time, it means that one or more terminal valves are open within the preset time, then restart the timing monitoring from the next time when all the terminal valves are closed .

[0019] When the CMP equipment is in a normal state, each grinding table has at least one grinding liquid pipeline to discharge grinding liquid or pure water regularly. If all the grinding liquid pipelines stop discharging the grinding liquid and pure water within a preset time, it can be determined that the CMP equipment is abnormal, so an alarm signal is sent. The staff can manually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com