Method for testing field ground load calibration of airplane wing and calibration device thereof

A calibration method and technology for aircraft fuselage, which are applied in measurement devices, machine/structural component testing, elasticity testing, etc., can solve the problems of low safety, long test work cycle, low load testing and calibration accuracy, etc. To achieve the effect of ensuring safety, ensuring authenticity, and ensuring security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solutions of the present invention will be further described in more detail in conjunction with the accompanying drawings and specific embodiments.

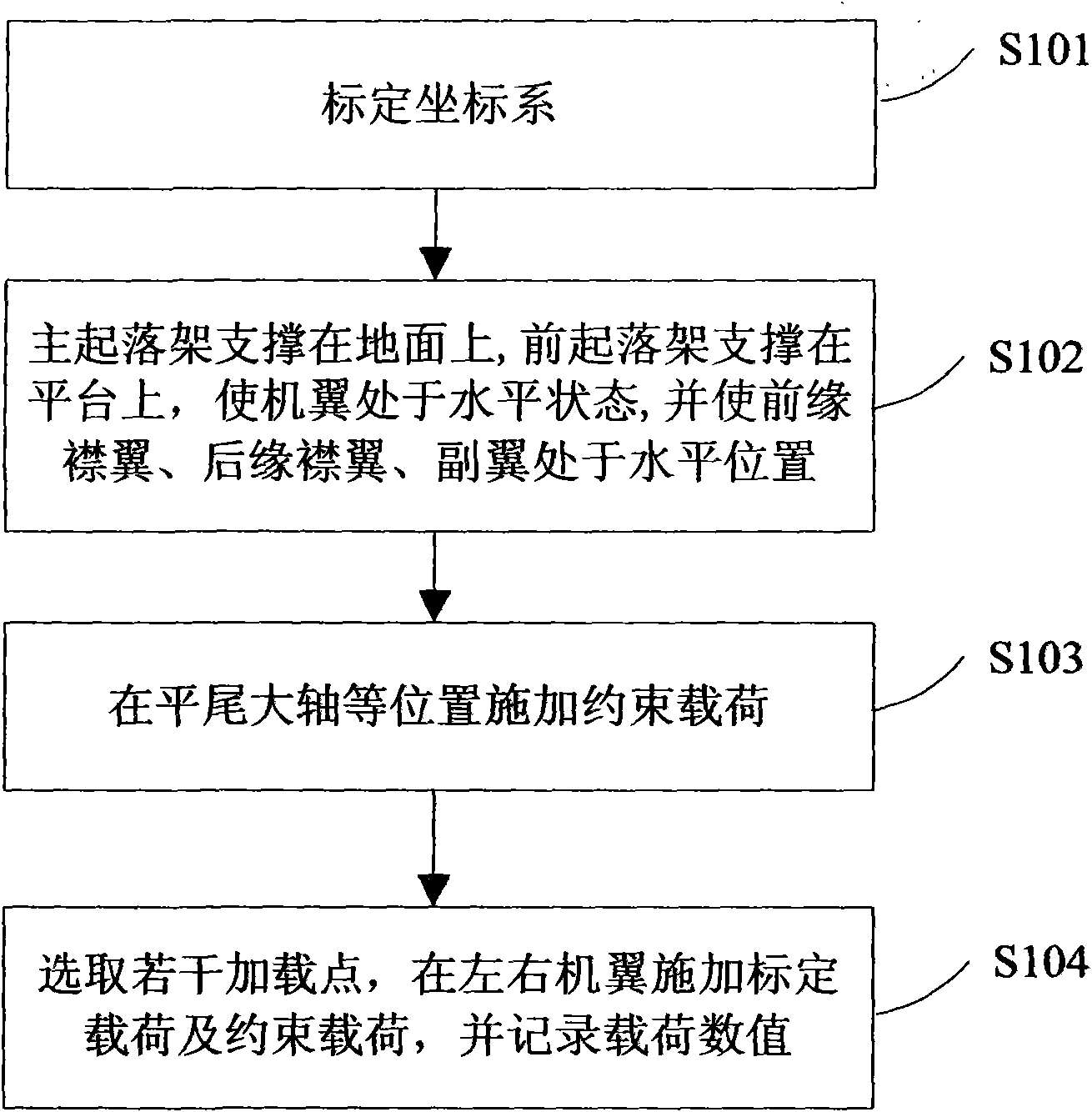

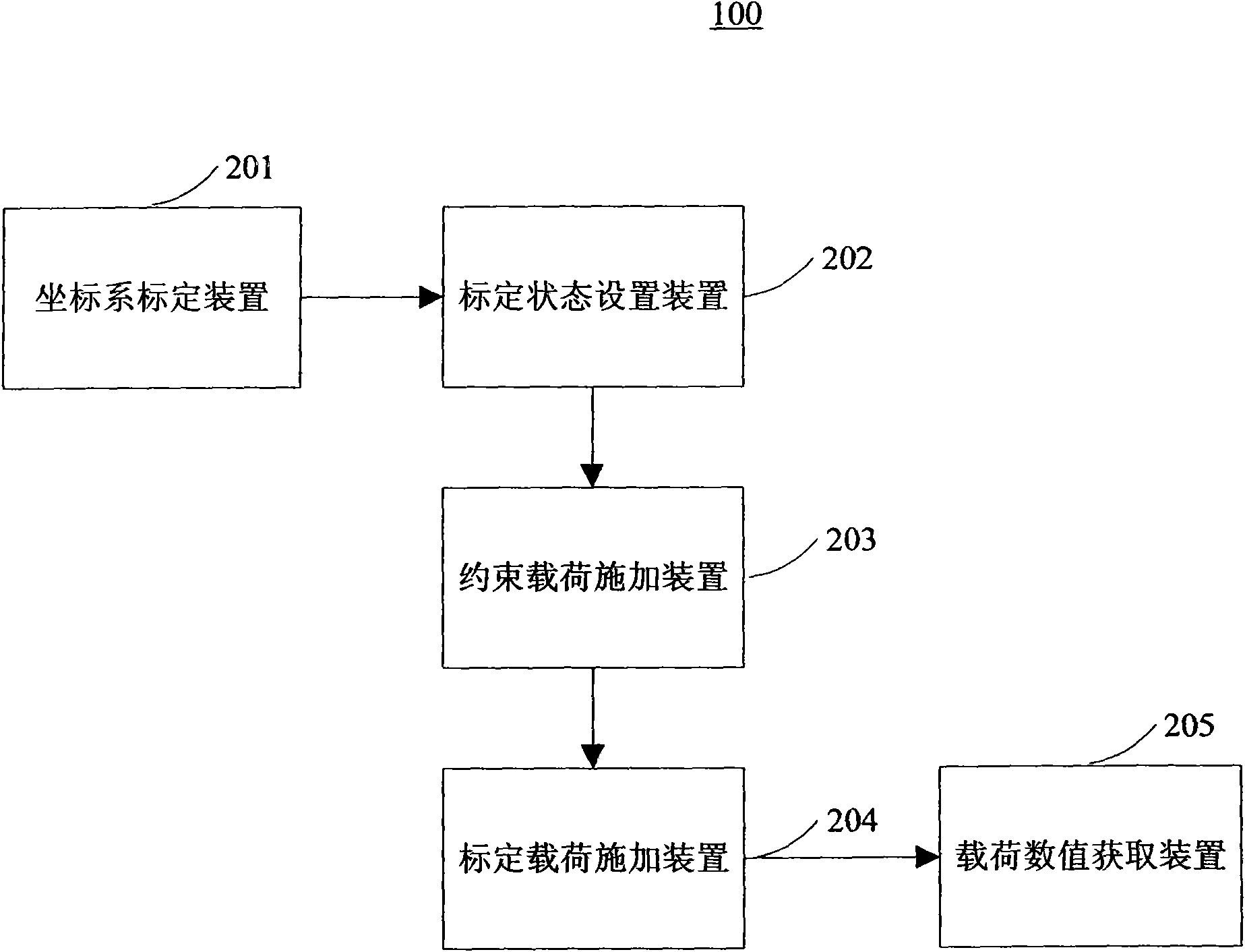

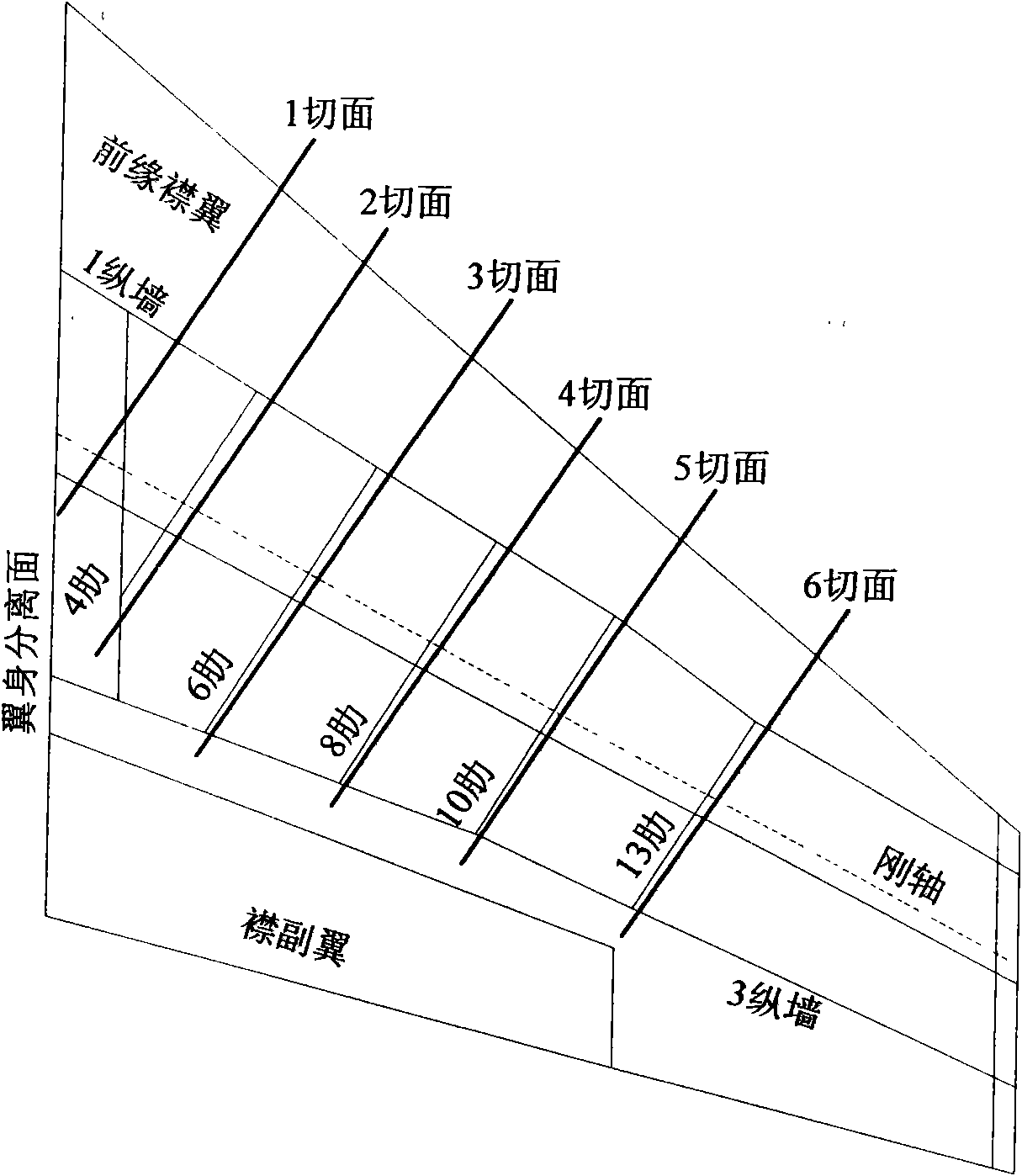

[0053] like figure 1 Shown is the flowchart of the aircraft wing ground load calibration method of the present invention. During the on-site load calibration test of the aircraft wing, the aircraft was kept in a horizontal parking state, combined with figure 1 At this time, the specific implementation steps of aircraft wing ground load calibration include:

[0054] Step S101, calibrate the coordinate system. The origin of the coordinate system is the intersection of the horizontal line of the fuselage structure and the 0-position line. The X-axis coincides with the horizontal line of the fuselage structure. The backward direction is positive, the Y-axis is positive upward in the plane of symmetry of the aircraft, and the Z-axis points to The left wing of the aircraft forms a right-handed system with the X a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com