Cooling device for cooling a metal strip

A technology of cooling device and metal strip, applied in the direction of workpiece cooling device, metal rolling, metal rolling, etc., can solve the problems of low efficiency of cooling device, small cooling area, uneconomical, etc., and achieve good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be described in detail below in the form of an embodiment with reference to the above-mentioned drawings.

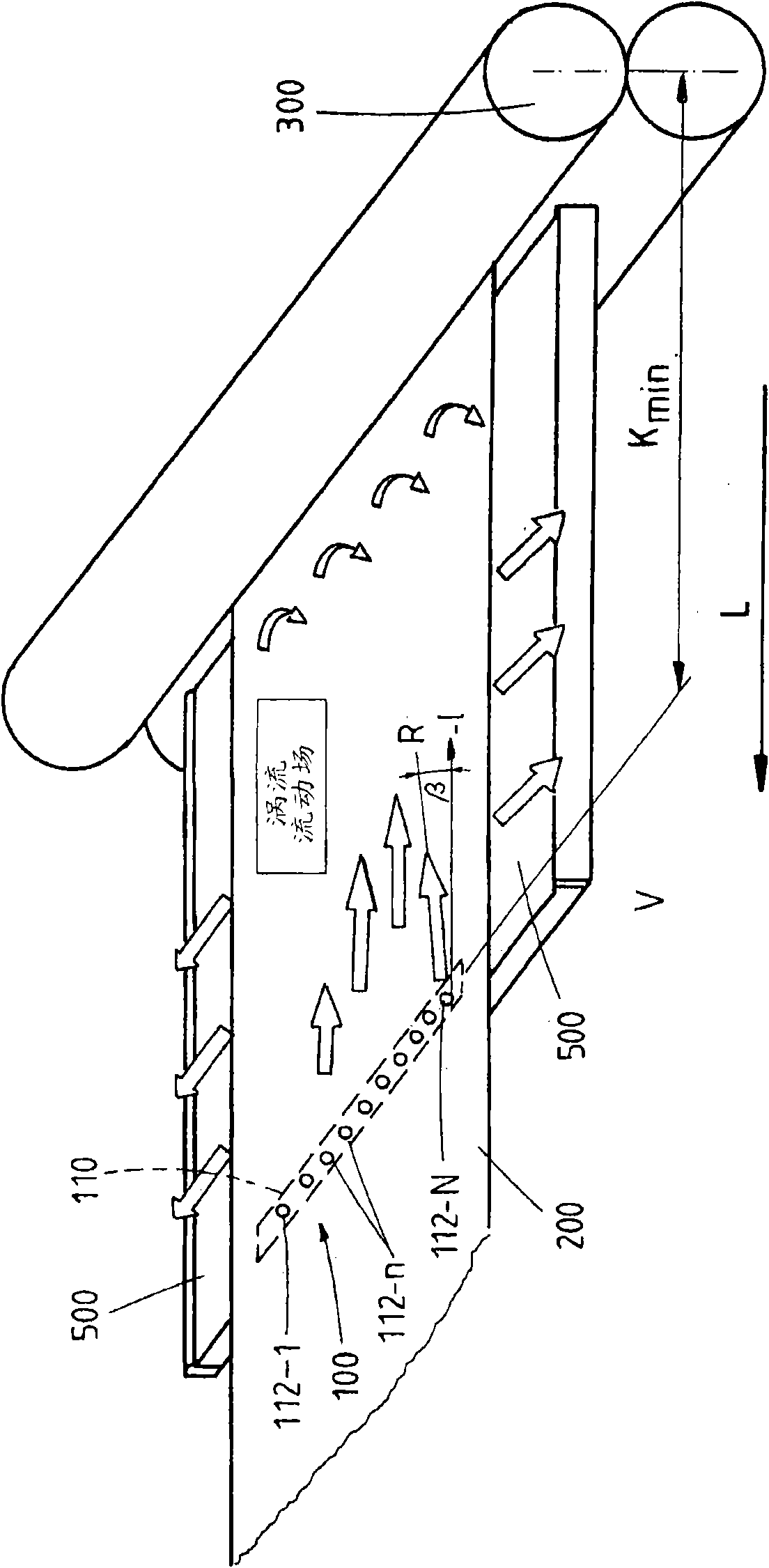

[0025] figure 1 The discharge end of a cold rolling stand 300 with a metal strip 200 running to the left is shown. A panel 500 is arranged under the metal strip in the form of a ledge. At the distance K from the cold rolling stand min A nozzle beam 110 with a plurality of nozzles 112 is arranged in the guide table crossing the running direction of the metal strip.

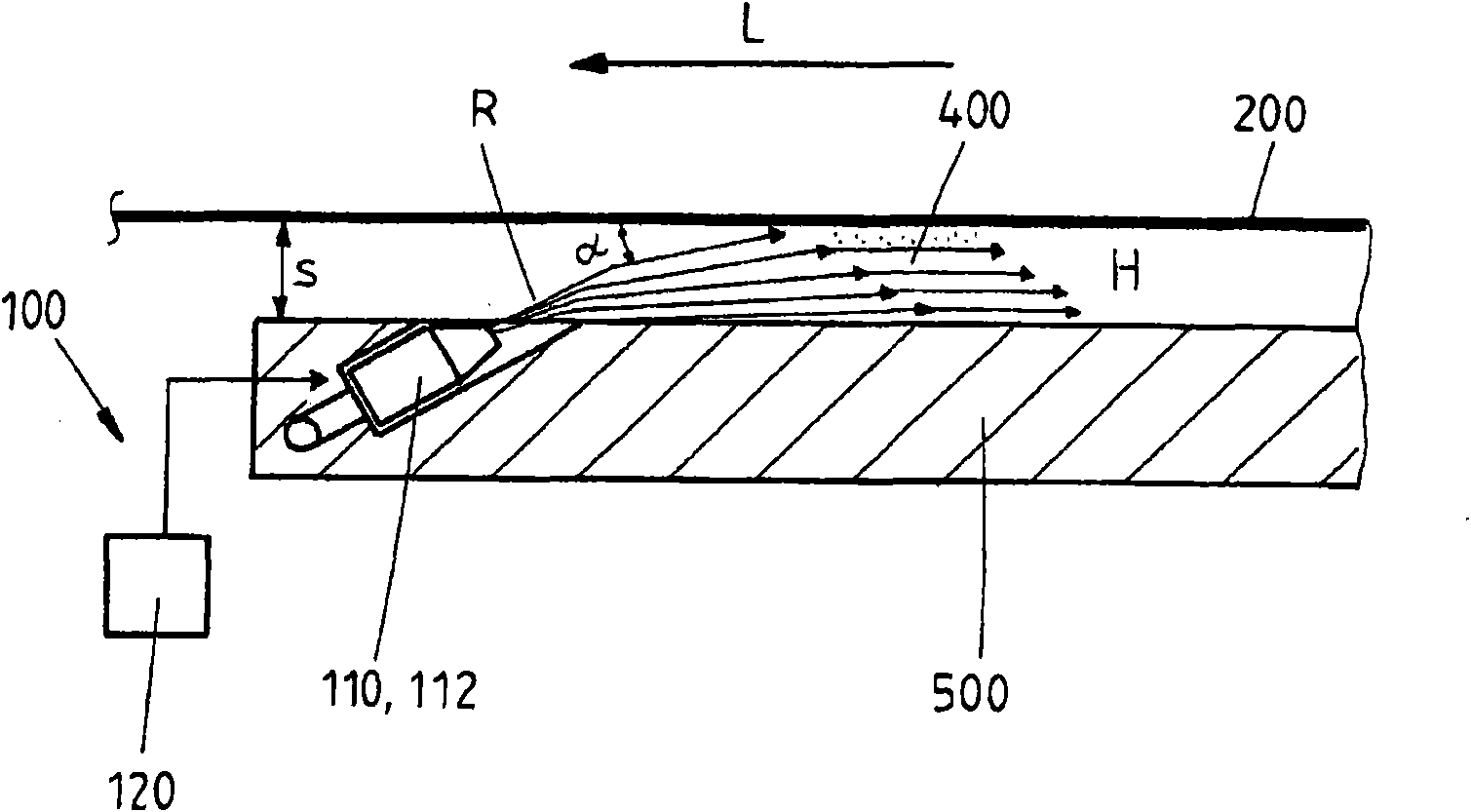

[0026] figure 2The arrangement of the nozzles 112 or the nozzle bar 110 in the guide table 500 is shown. In particular, it can be clearly seen that the nozzles are arranged in the guide table in such a way that it sprays the cooling medium 400 at a sharp spray angle α opposite to the running direction L of the metal strip onto the back side of the metal strip. By contact with the metal strip 200 running in the opposite direction L, shear forces act on the participating particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com