Method for improving deoxygenating effect of thermal deoxygenator and thermal deoxygenator using same

A technology of thermal deaerator and deaerator, applied in chemical instruments and methods, separation methods, degassed water/sewage treatment, etc. High problems, to avoid the increase of oxygen content and improve the effect of deoxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

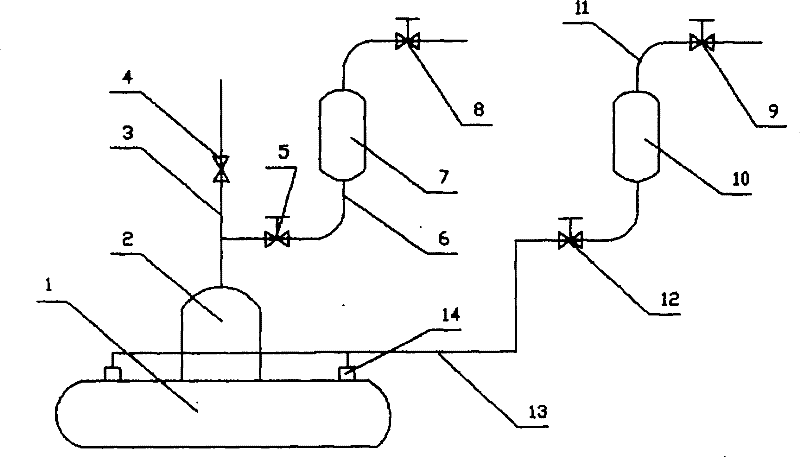

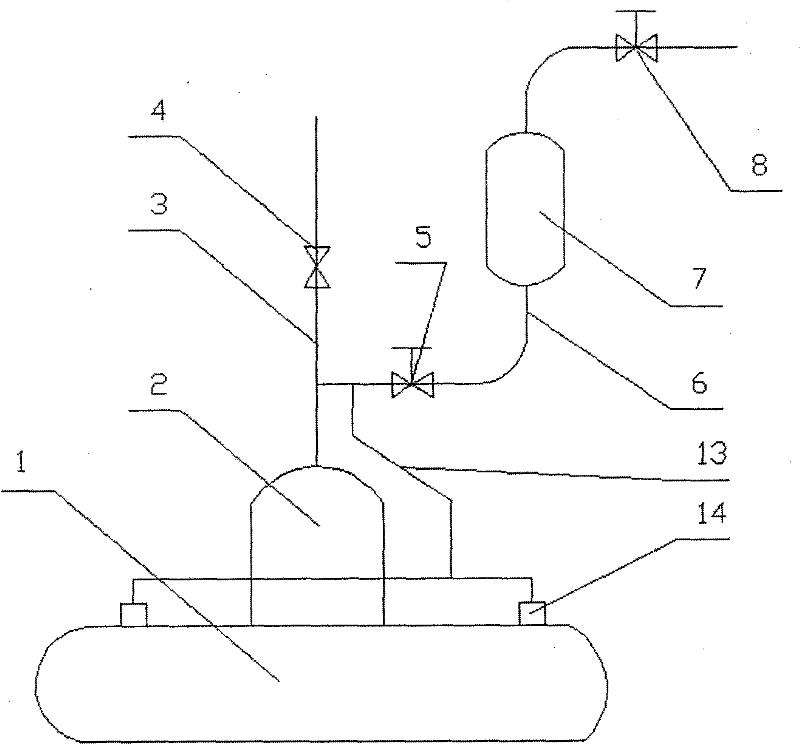

[0010] see figure 1 and figure 2 , the thermal deaerator of the present invention is based on the existing thermal deaerator, and one or more exhaust ports 14 are set at the edge of the top of the water tank 1, and the water tank contains Oxygen gas is discharged, thereby improving the oxygen removal rate.

[0011] The thermal deaerator provided by the present invention includes a thermal deaerator body composed of a degassing tower 2 and a water tank 1. The water tank is installed at the bottom of the degassing tower and communicated with the degassing tower. The degassing tower is provided with a steam inlet One or more water tank exhaust ports 14 are arranged on the peripheral position of the top of the water tank, and the one or more water tank exhaust ports are connected to a water tank exhaust pipe 13 .

[0012] Described water tank exhaust pipe can be connected to the exhaust pipeline that the top of described degassing tower is provided with (as figure 2 shown). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com