Multivariate flame monitor-based on-line judgment method for fuel type

A technology of fuel type and identification method, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as large errors, improve combustion efficiency, enhance safety and economy, and avoid unstable flame combustion in the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to clearly understand the technical solution of the present invention, the specific implementation manners of the present invention are now further described.

[0019] Specific implementation method:

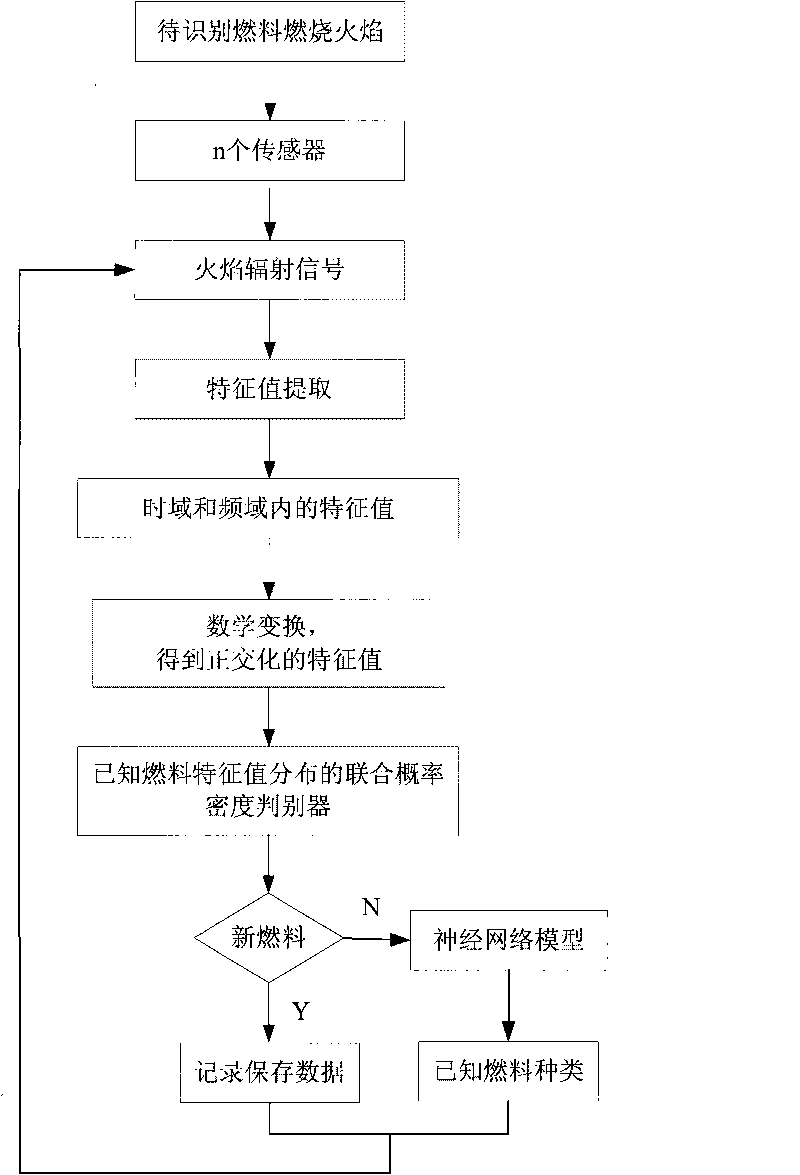

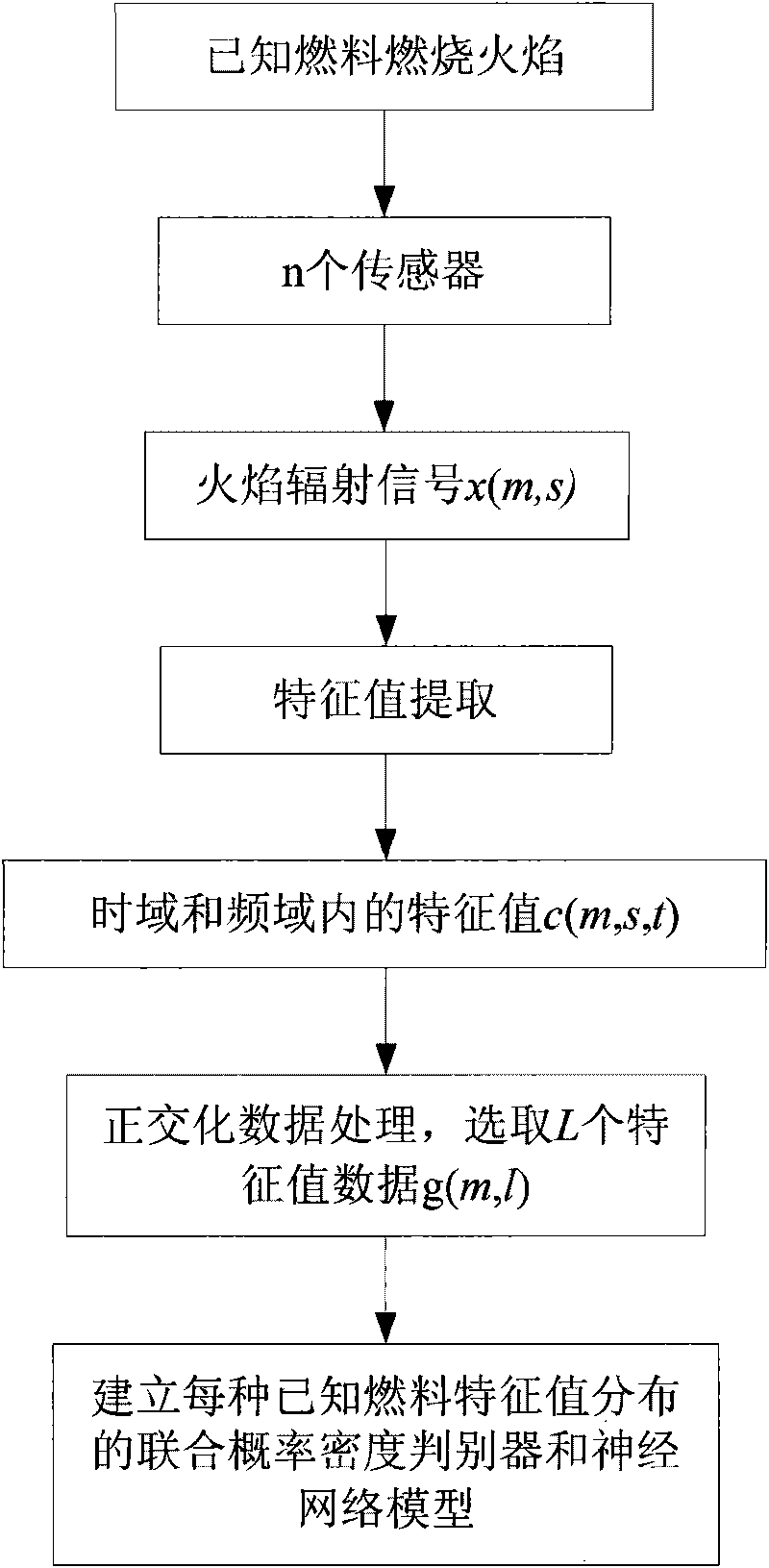

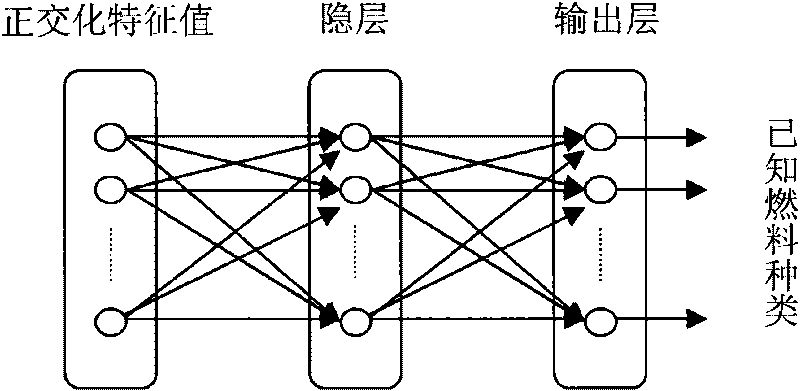

[0020] Such as figure 1 As shown, n (≥ 3) photoelectric sensors are used to obtain a radiation signal of a known fuel combustion flame in the radiation band, and M groups are collected to form a signal sample set {x(m, s)|m=1, 2 , . . . , M; s=1, 2, . . . , n}. Among them, M should be selected so that the signals in the collected sample set {x(m, s)} can cover various conditions of fuel combustion. For example, M=500 may be selected, that is, 500 sets of signals are collected for each fuel. Extract the eigenvalues of the flame in the time domain and frequency domain {c(m, s, t)|m=1, 2,..., M; s=1, 2,..., n; t=1, 2 ,...,T} (such as flicker frequency, mean, root mean square, variance, number of zero crossings, skew rate, kur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com