Laser following control method and system in laser processing system

A technology of laser processing and control methods, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing manufacturing costs, reducing the overall efficiency of the laser cutting system, unqualified, etc., and achieve the effect of improving the overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

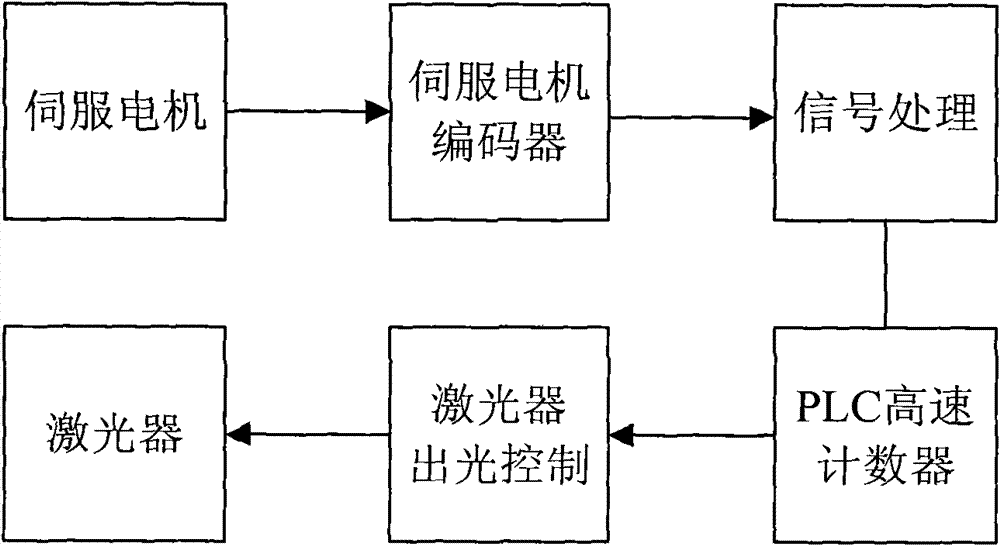

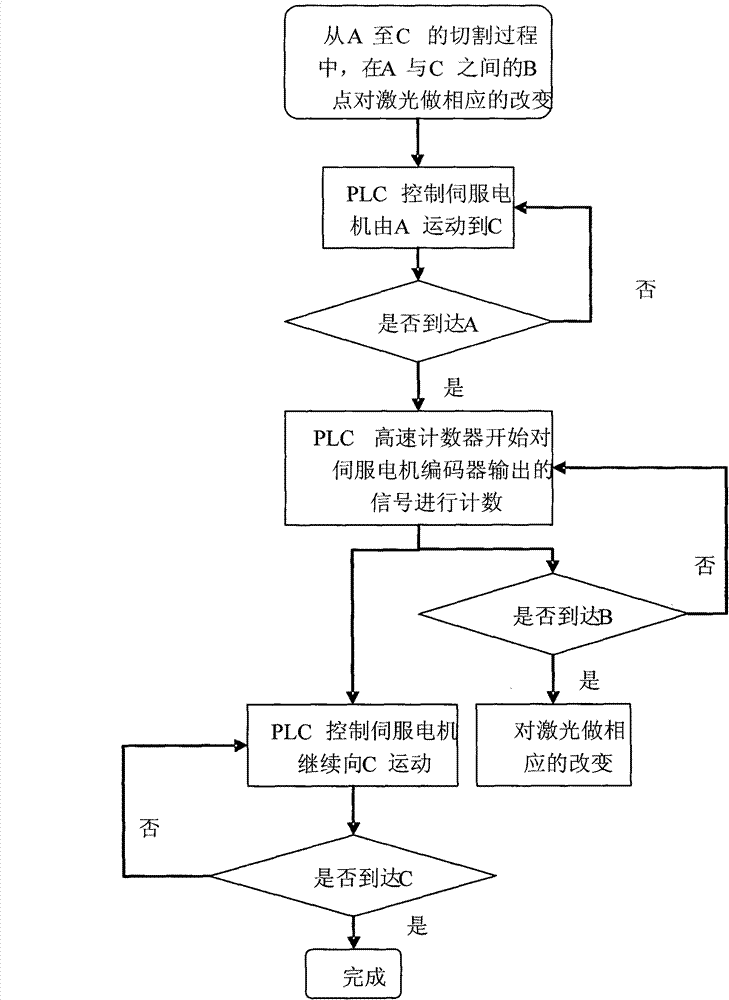

[0014] see figure 1 , the control method of the laser cutting system of the present invention is that a servo motor encoder is arranged on the servo motor, and the output signal of the servo motor encoder is frequency-divided, so that the frequency of the output pulse signal is within the allowable range of the PLC high-speed counter, Then the differential signal output by the servo motor encoder is processed by the external signal conversion circuit to make it meet the input conditions of the PLC. Then, the running distance of the servo motor is counted through the high-speed counter of the PLC, and the "distance" of the trajectory and position of the servo motor relative to the starting point can be known through the value in the counter. When the "distance" is known, the energy, on, off, etc. of the laser can be accurately and timely controlled at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com