High-voltage direct-current polar PLC capacitor

A capacitor and high-voltage technology, which is applied in the field of high-voltage DC polar line PLC capacitors and filter capacitors, can solve the problems of difficult to meet the mechanical strength requirements of capacitor porcelain sleeves, high cost of special porcelain sleeves, and difficult to solve stability, and achieve mechanical Reduced strength requirements, reduced costs, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

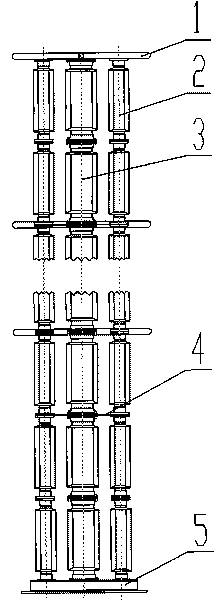

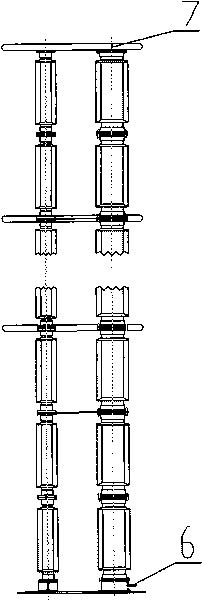

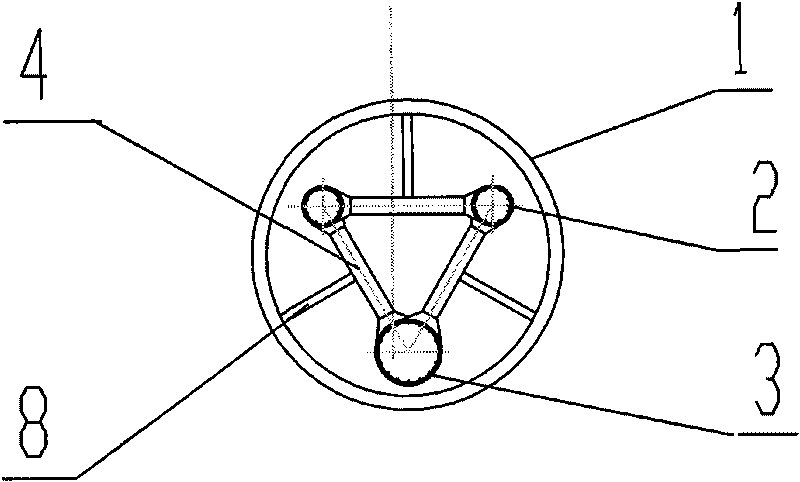

[0023] The implementation of this high voltage DC pole line PLC capacitor is as follows Figure 1 to Figure 4 As shown, it includes vertically stacked capacitor units 3, and the core 3-1 formed by connecting the capacitor elements is located in the porcelain casing 3-3 and immersed in the insulating impregnating agent to form the capacitor unit 3, and the capacitor unit 3 is equipped with a voltage equalizer Component distributed voltage equalizing resistors 3-2; 11-layer capacitor units 3 are stacked vertically to form capacitor columns, the upper end leads to high-voltage terminal 7, the lower end leads to low-voltage terminal 6, and two 11-layer post insulators 2 are vertically stacked Insulator post, the diameter of the post insulator used is 0.5 times the diameter of the capacitor unit. The height of each layer of the three columns is the same, and the total height is also the same. The bottom ends of the three columns are fixed on the base frame 5 made of channel steel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com